Foundation for installation and positioning of automatic meteorological station

An automatic weather station, installation and positioning technology, applied in infrastructure engineering, construction, etc., can solve problems such as difficult construction and difficult implementation, and achieve the effect of convenient connection, convenient assembly, and enhanced integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

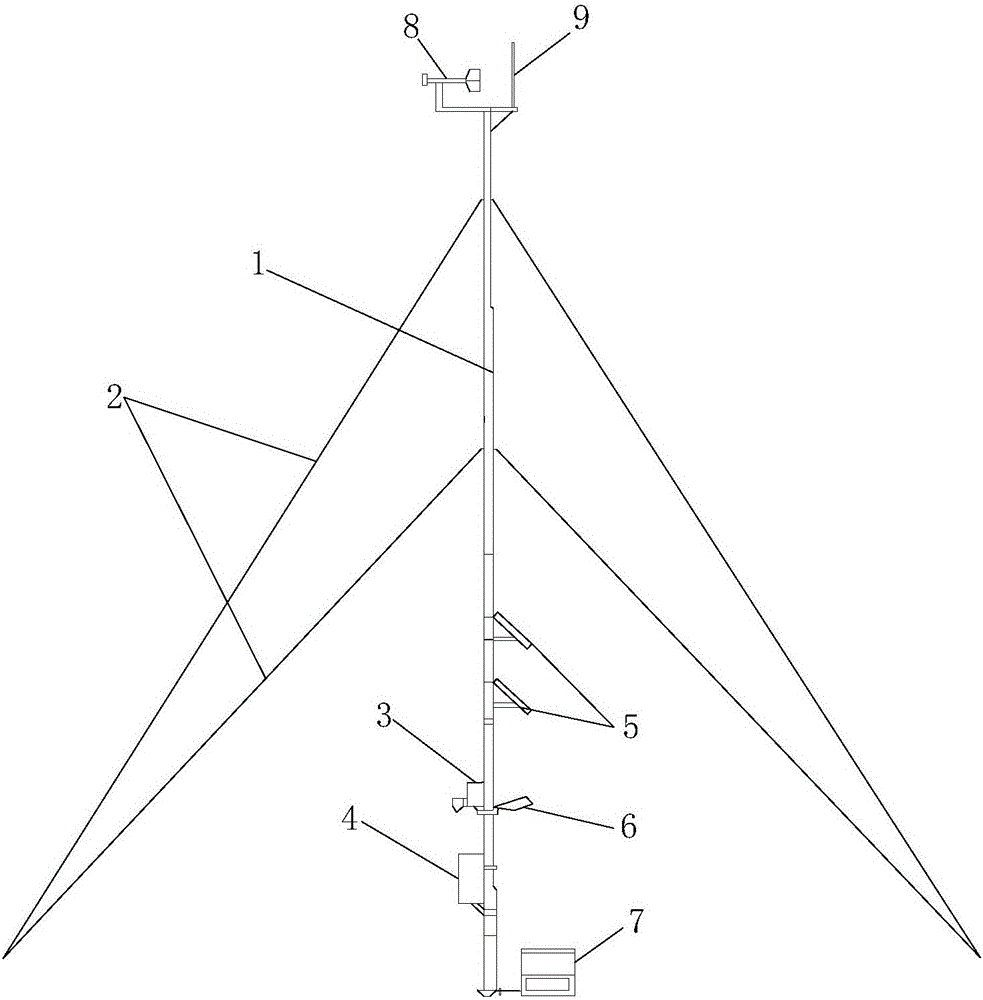

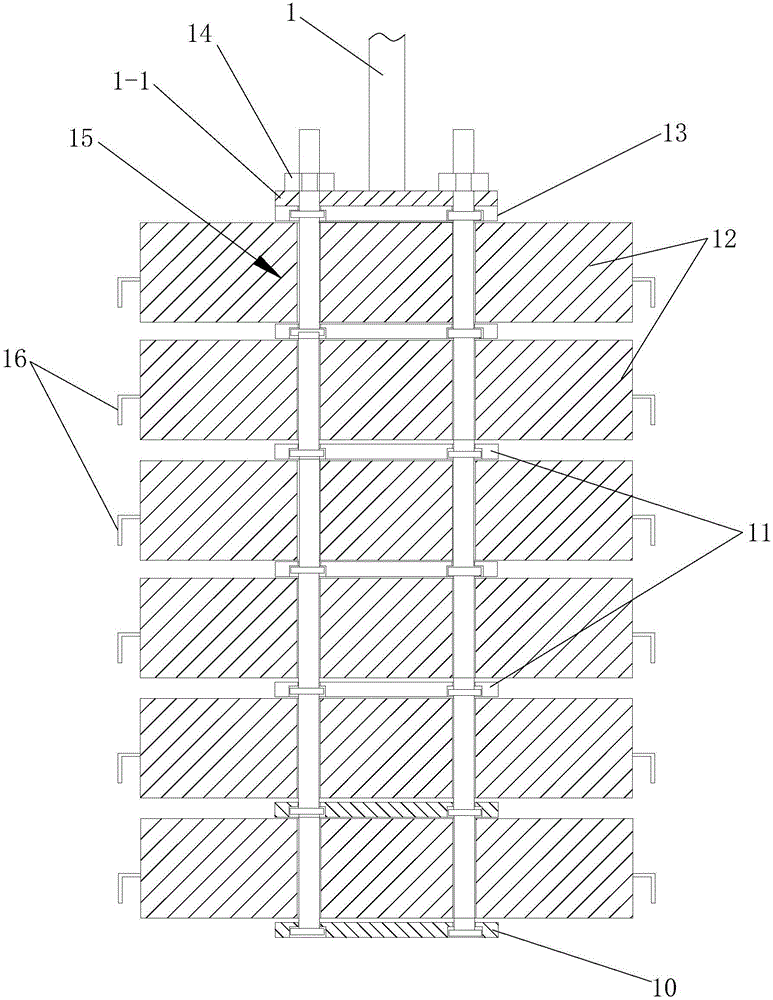

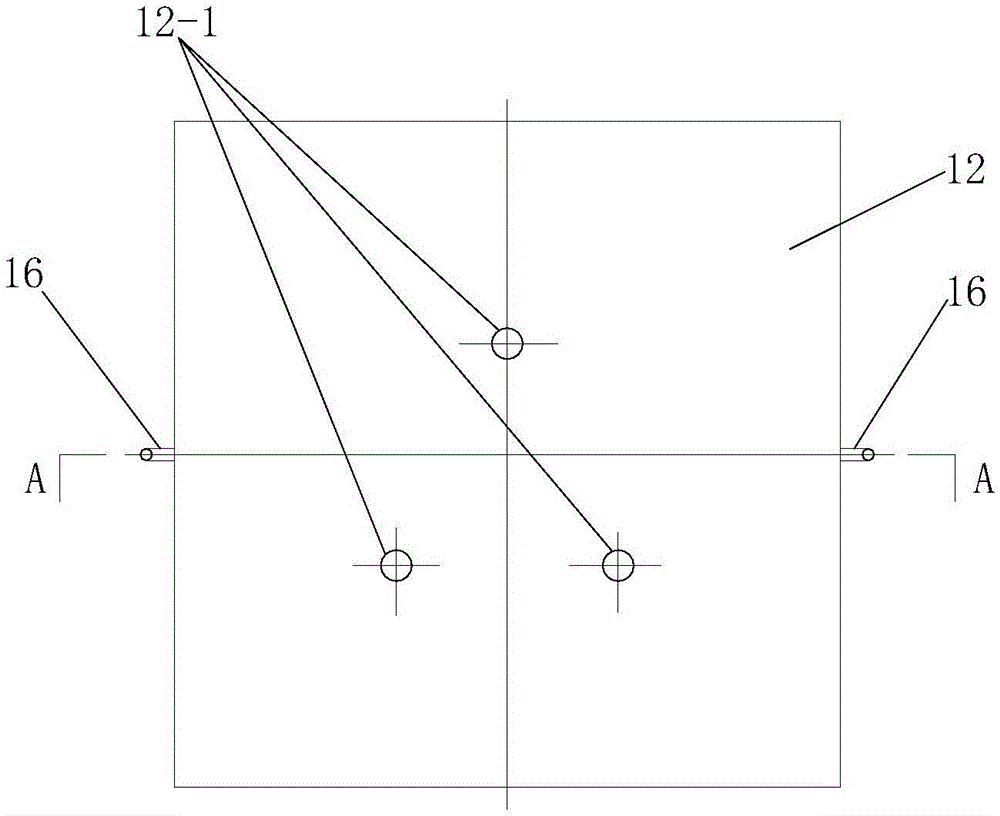

[0045] Such as figure 2 The shown foundation for installing and positioning an automatic weather station includes a prefabricated counterweight set in the foundation pit, the lower end of the prefabricated counterweight is supported on the bottom of the foundation pit, and the upper end of the prefabricated counterweight It is connected with the lower end of the central wind rod 1 of the automatic weather station, the lower end of the guy line 2 of the automatic weather station or the rain gauge of the automatic weather station.

[0046] In this embodiment, the foundation is used for the installation and positioning of the central mast 1 of the automatic weather station. When installing and positioning the central air pole 1, the prefabricated counterweight is placed in the pre-dug foundation pit, and then the lower end of the central air pole 1 is connected with the prefabricated counterweight to achieve The installation and positioning of the central wind pole 1 of the aut...

Embodiment 2

[0060] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the prefabricated counterweight is connected to the lower end of the stay wire 2 of the automatic weather station. That is, the foundation is used for the installation and positioning of the automatic weather station backguy 2. When the backguy 2 is installed and positioned, the prefabricated counterweight is placed in the pre-dug foundation pit, and then the lower end of the backguy 2 is connected to the The prefabricated counterweights are connected to achieve the installation and positioning of the central wind pole 1 of the automatic weather station, thereby avoiding the difficulty of making the foundation temporarily through cement casting on site, which is especially suitable for remote areas, such as Construction in areas such as mountains, wilderness and islands.

[0061] Such as Figure 9 As shown, an eye nut 17 is installed on the screw 15-2 of the co...

Embodiment 3

[0065] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that: the upper end of the prefabricated counterweight is connected to the rain gauge of the automatic weather station. That is, the foundation is used for the installation and positioning of the rain gauge of the automatic weather station. When the rain gauge is installed and positioned, the prefabricated counterweight is placed in the pre-dug foundation pit, and then the lower end of the rain gauge The base plate 19 is connected with the prefabricated counterweight, which achieves the installation and positioning of the base plate 19 of the automatic weather station, thereby avoiding the difficulty of making the foundation temporarily by pouring cement on site, which is especially suitable for remote areas. Construction in areas such as mountains, wilderness and islands.

[0066] In this embodiment, the top plate 13 is closely attached to the base plate 19 at the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com