A three-stage screw rotor and its twin-screw vacuum pump

A three-stage, rotor technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problem of reducing the ultimate vacuum degree and pumping speed of twin-screw vacuum pumps, low cross-sectional line area utilization, and inter-stage leakage and backflow To solve problems such as weak capacity, achieve the effect of compact structure, short axial dimension, and improved strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

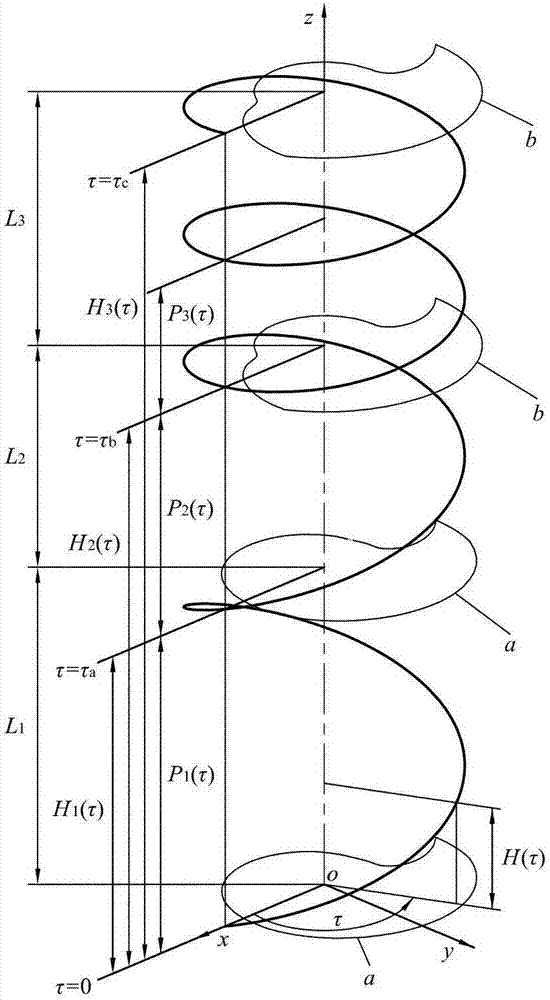

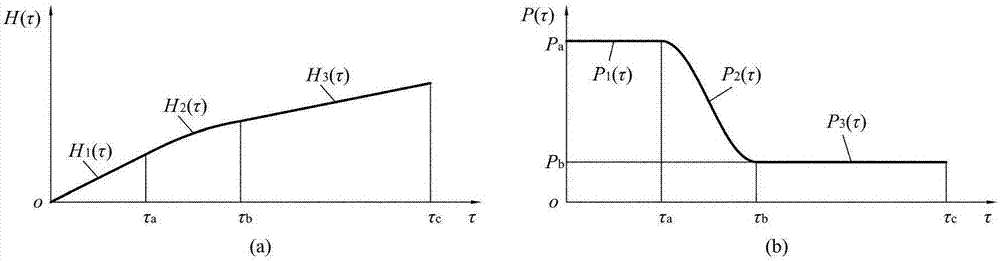

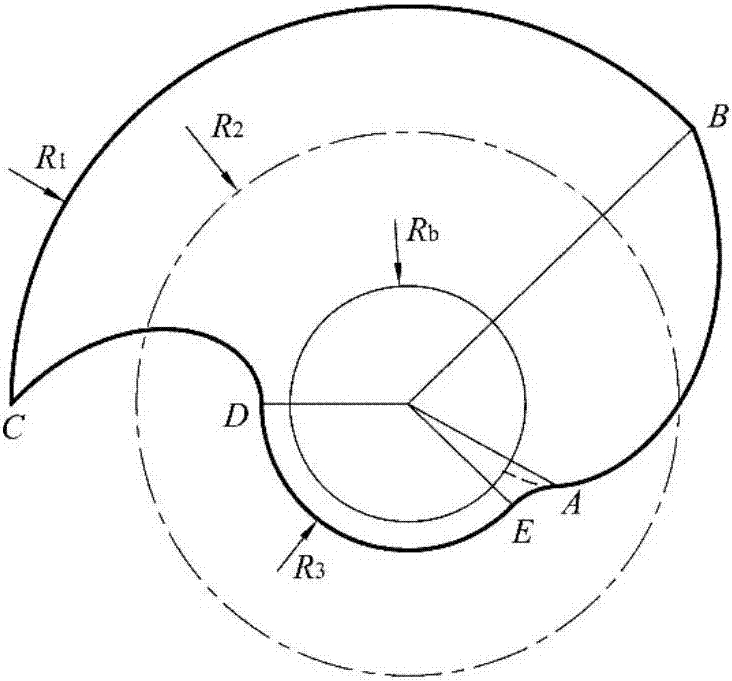

[0038] Such as figure 1 Shown is the cross-sectional profile and axial distance diagram of the three-section screw rotor. The three-section screw rotor consists of the suction section L 1 , Compression section L 2 and exhaust section L 3 Composition, suction section L 1 , Compression section L 2 and exhaust section L 3 The range of the helical expansion angle τ is 0≤τ≤τ a , τ a ≤τ≤τ b and τ b ≤τ≤τ c ;Inspiratory section L 1 and exhaust section L 3 For equal pitch, suction section L 1 and exhaust section L 3 Compression section L is used between 2 Make transition, compression segment L 2 It is a variable pitch; the formulas of the axial distance H(τ) and the pitch P(τ) of the screw rotor are as follows:

[0039]

[0040] Among them, τ is the helix expansion angle, rad; for the whole screw rotor, the value range of the helix expansion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com