Fast valve with controllable damping structure

A damping structure, fast technology, applied in the direction of valve details, valve device, valve operation/release device, etc., can solve the problems of small valve core mass, small impact force of valve body, unable to meet application requirements, etc., and achieve strong damping effect , the effect of cushioning the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

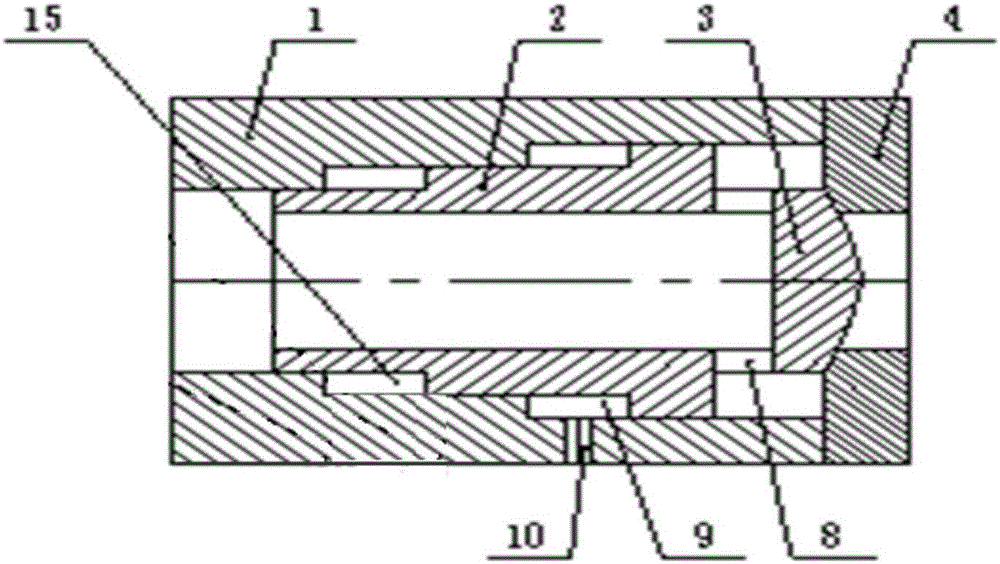

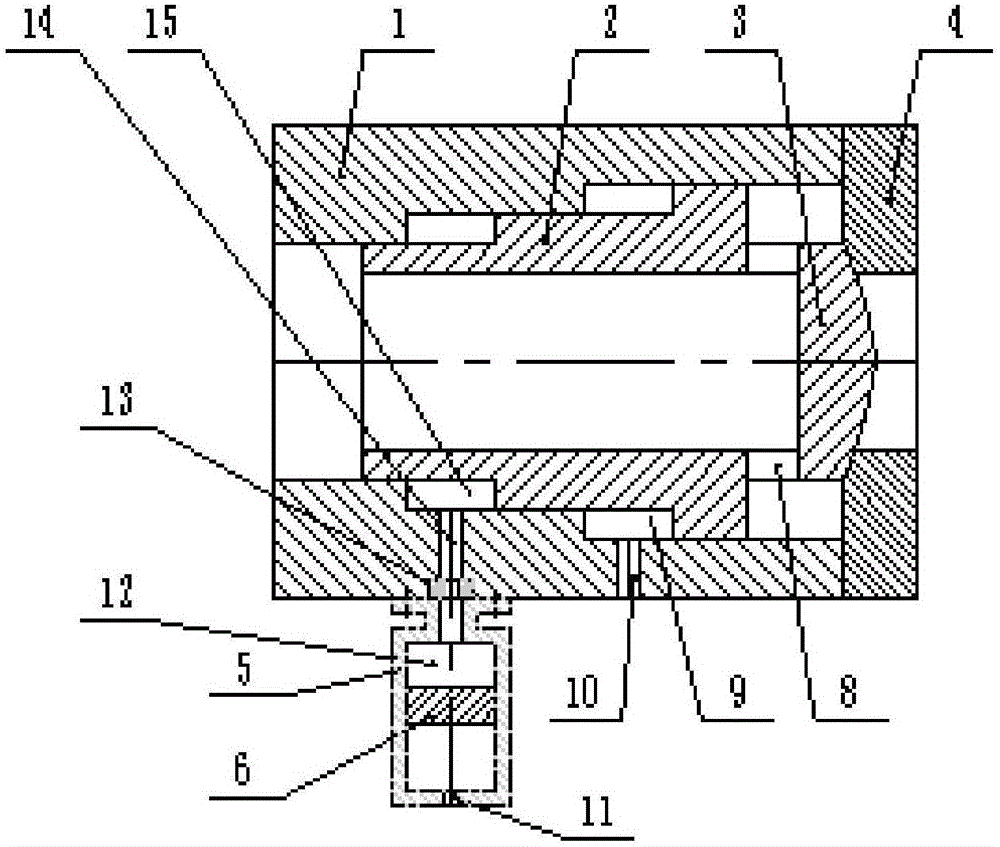

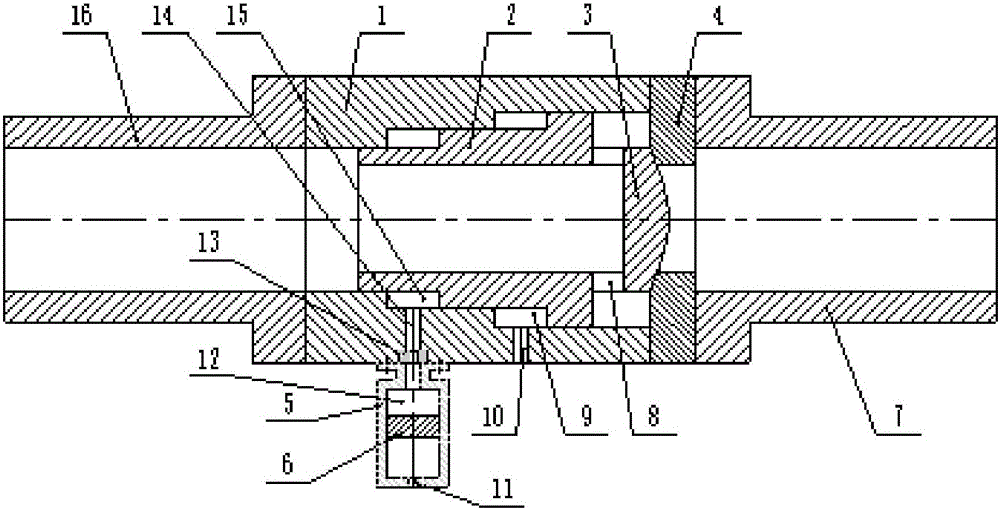

[0017] A fast valve with controllable damping structure, its structure is as follows figure 2 As shown, it includes a tubular valve body 1, a tubular piston 2, a valve core 3 and an end cover 4; the tubular piston 2 is set inside the tubular valve body 1 and can slide left and right; Connected, a radial channel hole 8 is provided between the valve core 3 and the right end surface of the tubular piston 2, a driving air chamber 9 and a damping chamber 15 are respectively provided between the tubular piston 2 and the tubular valve body 1, and the tubular valve body 1 A drive air chamber charging and deflation port 10 communicating with the driving air chamber 9 and a damping liquid through hole 14 communicating with the damping chamber 15 are respectively provided on the top. The fast valve with a controllable damping structure also includes a controllable damping structure, and the controllable damping structure includes a throttling orifice 13, a damping cylinder 5 and a dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com