Pipe connecting structure

A technology of pipe joints and outer pipes, which is applied in non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as poor air tightness, troublesome docking, and difficult operation, and improve the reliability of docking Good anti-bacterial effect and improved connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

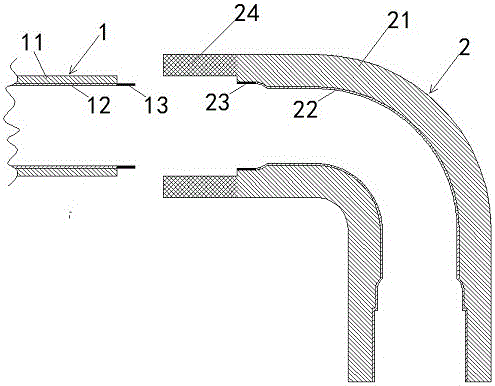

[0025] figure 1 is a schematic cross-sectional structure diagram of a pipe connection structure according to an embodiment of the present invention.

[0026] Such as figure 1 As shown, the pipe connection structure may generally include a pipe connection structure, including a butted pipe connection male 1 and a pipe connection female 2, and the pipe connection male 1 includes a male outer tube 11 and a male Head inner tube 12, the end of the male inner tube 12 has a male joint 13 longer than the male outer tube 11; the pipe joint female 2 includes a female outer tube 21 and a female inner tube 22 , the end of the female outer tube 21 has a female extension 24 longer than the female inner tube 22,

[0027] Wherein, the inner diameter of the female extension part 24 is equal to the outer diameter of the male outer tube 11, and the position where the female inner tube 22 is docked with the male joint part 13 is the female joint part 23, so The inner diameter of the female joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com