Male connector and rapid connector assembly adopting same

A technology of male joints and plug-in ends, which is applied in the field of quick joint components, and can solve problems such as easy deflection of the movable valve core and failure to achieve smooth rebound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

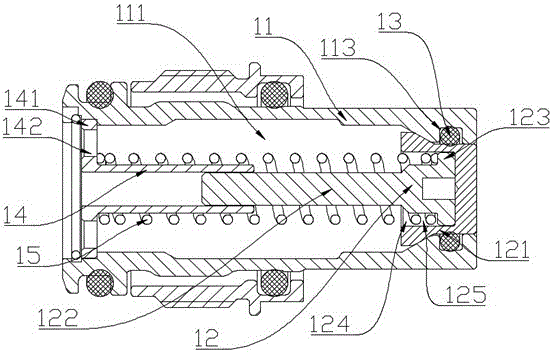

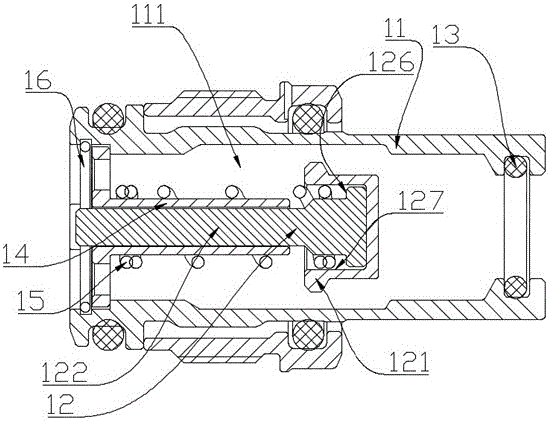

[0023] Specific embodiments of the male joint of the present invention, such as figure 1 , figure 2As shown, the male connector includes a male connector housing 11 whose front end is a plug-in end. The male connector housing 11 has an axial direction along the front-rear direction. The male connector housing 11 is provided with a fluid channel 111 extending along the front-rear direction. The movable valve core 12 and the guide cylinder 14 are elastically assembled in the fluid channel along the axial direction. In this embodiment, the elastic member is a compression spring 15 sleeved on the movable valve core, and the rear end of the guide cylinder 14 on the valve core rod is There is a guide cylinder fixing seat 141 fixedly connected with the male joint housing, and the guide cylinder fixing seat 141 is provided with a mounting seat through hole 142...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com