LED light with built-in pressure compensator

A pressure compensation, LED lamp technology, applied in the loss prevention measures of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc. The adjustment is sensitive and efficient, and the installation process is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

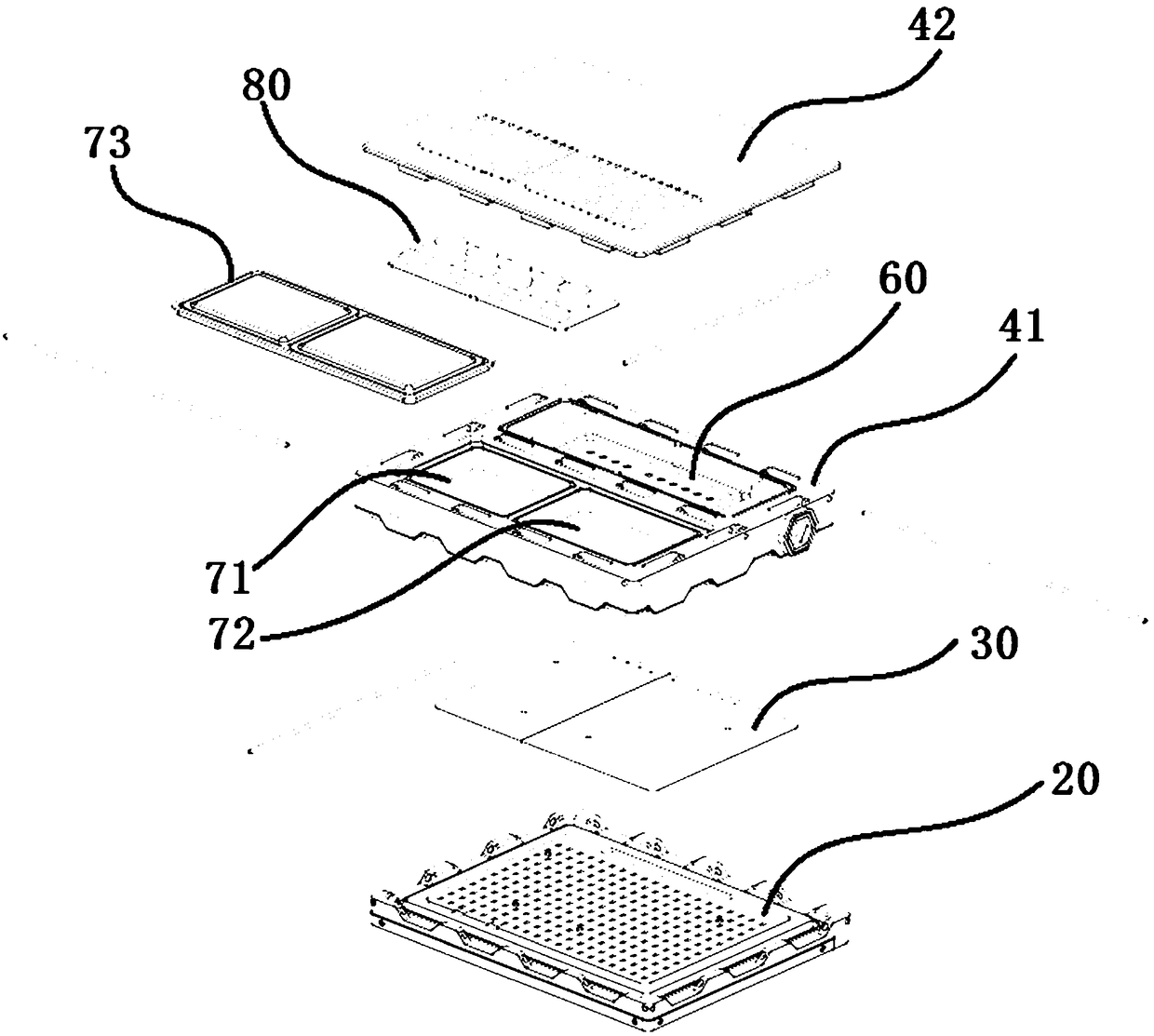

[0018] Example 1: Please refer to the attached figure 1 , which shows an LED lamp with a built-in pressure compensator with a relatively complex structure and more powerful functions, including a grid plate 20, a transparent cover plate 10, a light source assembly 30 and a bottom cover 40, and the transparent cover plate 10 is installed on Above the grid plate 20, the light source assembly 30 is correspondingly arranged under the grid plate 20, and the three constitute the light-emitting component part; the transparent cover plate 10 is used as the light-emitting surface, and is a component that encapsulates internal components and emits light from the LED. The grid plate 20 cooperates with the light source assembly 30 to separate the light-emitting LED chips on the light source assembly 30 to improve light extraction efficiency, and protect the internal chips from being squeezed through the ribs of the grid plate 20 .

[0019] The upper surface of the bottom cover 40 is assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com