Fixing frame for metal sample sheet atmospheric corrosion exposure test

An atmospheric corrosion and exposure test technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of metal sample falling off, sample falling off, complex structure, etc., to improve the success rate, firmly fix, The effect of structural flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the fixing frame for the atmospheric corrosion exposure test of the metal sample provided by the embodiment of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

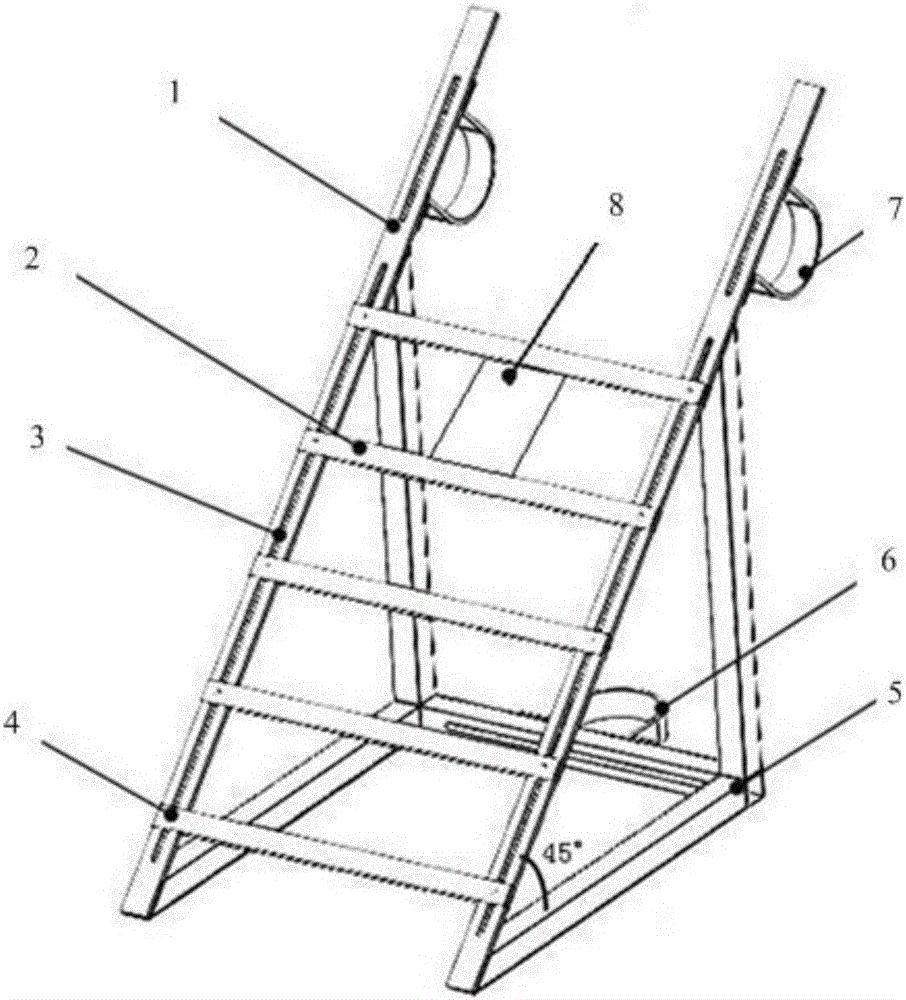

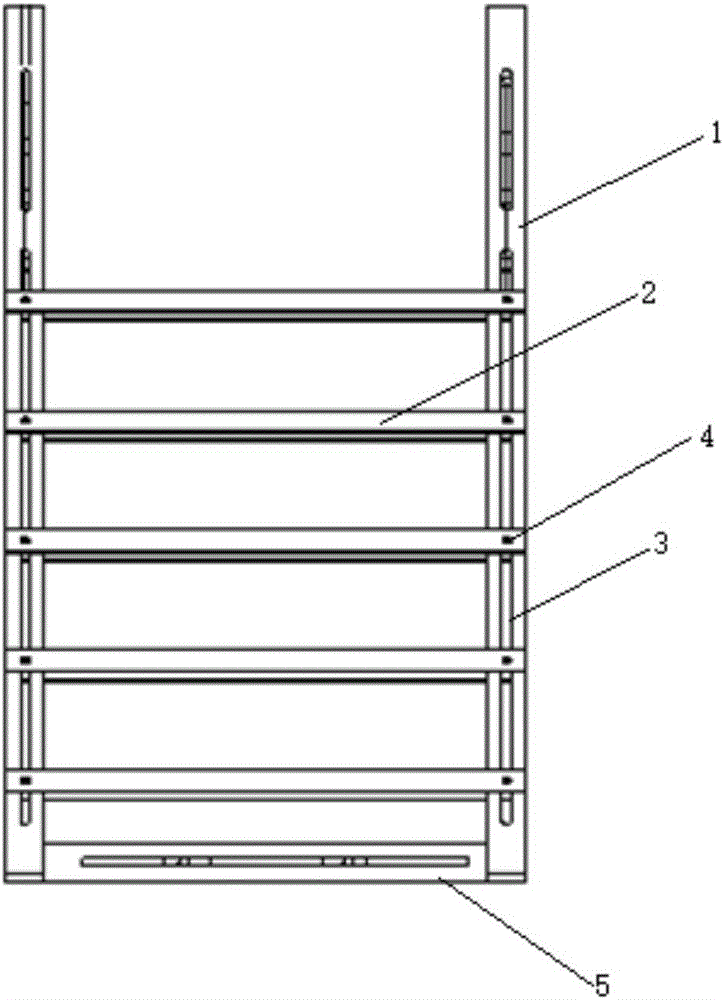

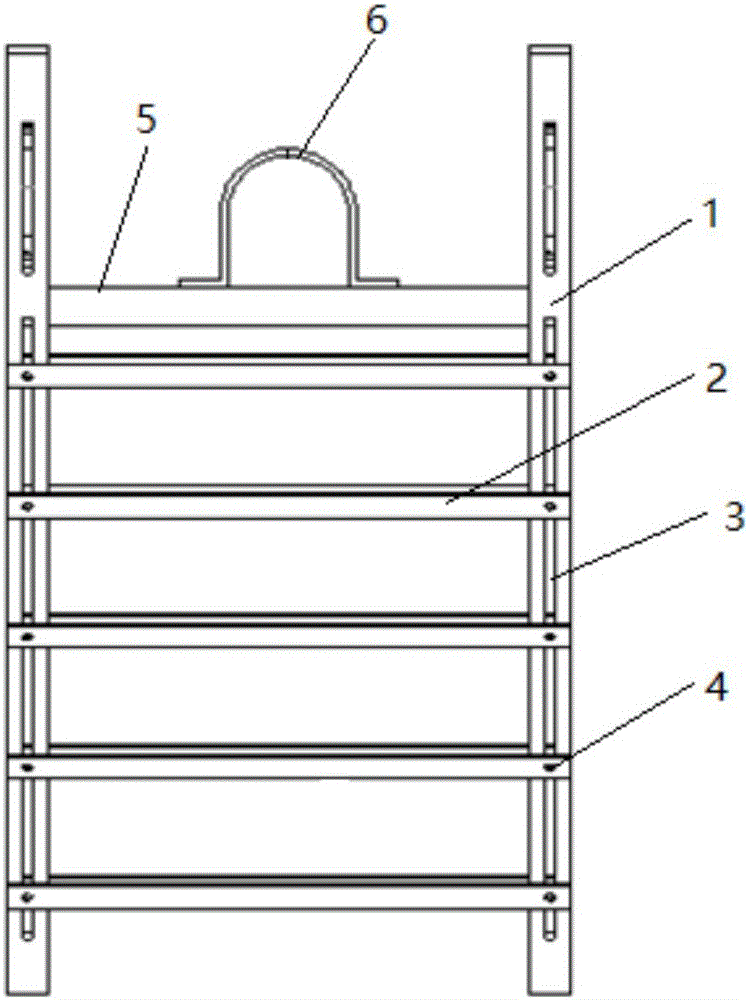

[0022] see figure 1 The metal sample atmospheric corrosion exposure test fixture provided by the embodiment of the present invention includes two vertical beams 1 arranged in parallel, and several cross beams 2 vertically arranged between the two vertical beams 1 and connected to the two vertical beams 1 , the metal sample 8 is fixed between every two adjacent beams 2 .

[0023] The metal sample 8 is made of the metal material used to make power grid transmission line towers. In order to install the fixed frame on the power grid transmission line tower, the embodiment of the present invention is provided with a hook 7 on the vertical beam 1. In actual operation, the angle steel of the power grid transmission line pol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap