Patents

Literature

74results about How to "Meet quantity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

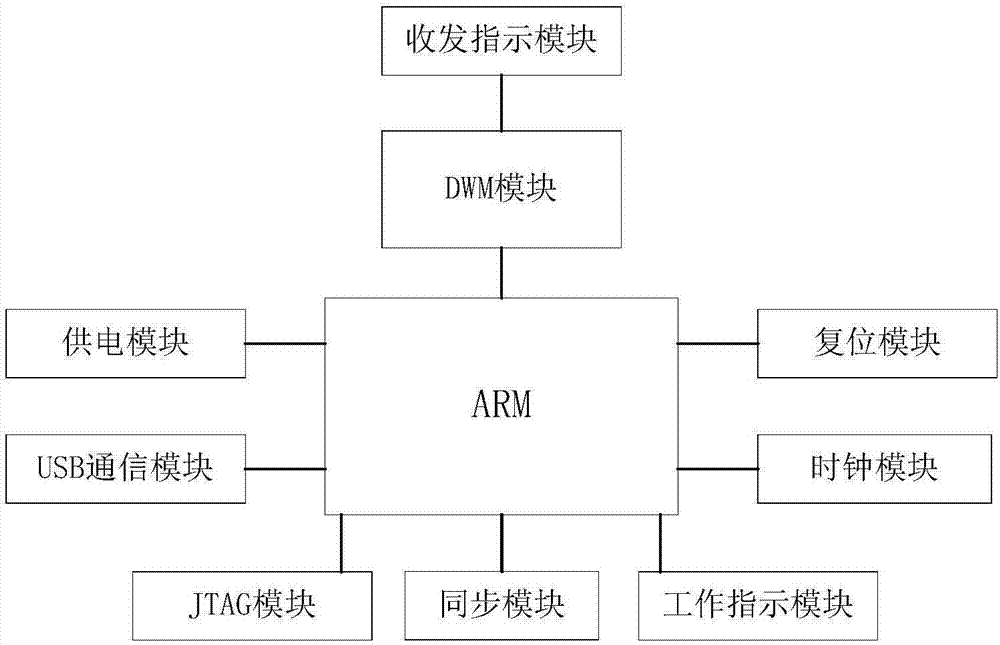

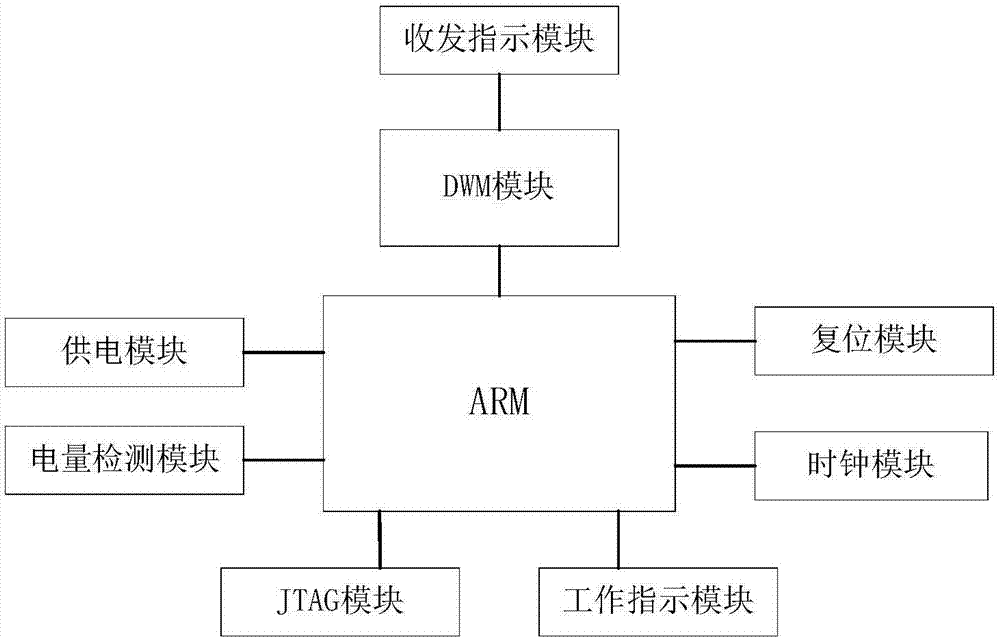

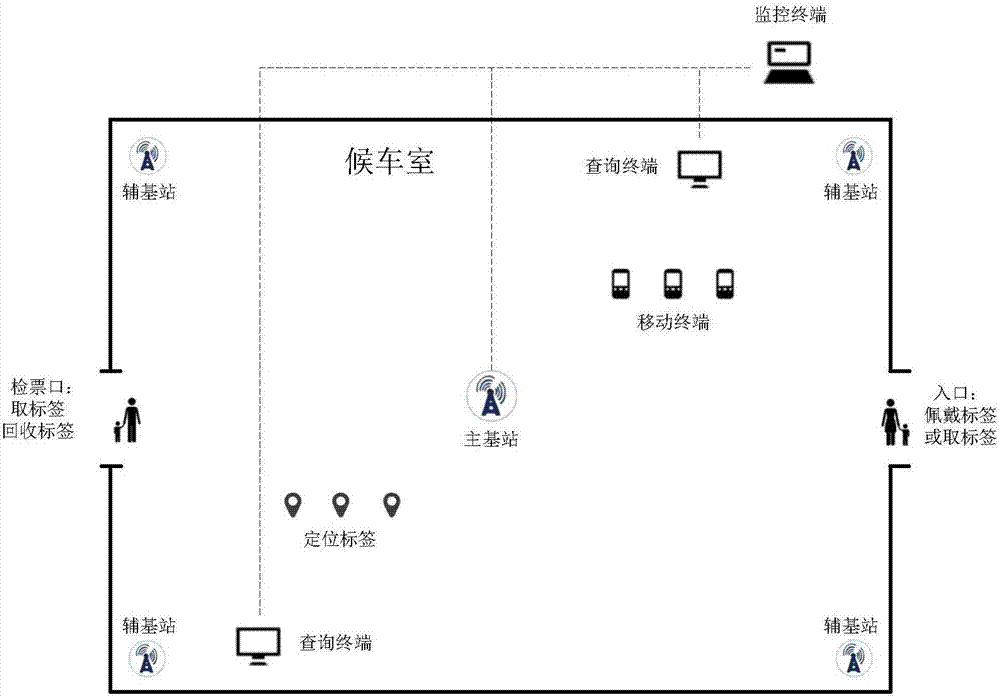

UWB-based positioning device and railway station children positioning method

ActiveCN107255794APrevention of Lost ChildrenHigh positioning accuracyPosition fixationAlarmsEngineeringBase station

The invention relates to the field of indoor positioning and aims at solving existing problems in the prior art. The invention provides a UWB-based positioning device and a railway station children positioning method. Based on the UWB technology, the position positioning is carried out. Based on the UWB positioning system of an extensible base station, the high-precision positioning of children in a large range can be realized. Therefore, children can be effectively prevented from getting lost. The positioning system is mainly used for positioning children in a waiting room. According to the invention, a positioning label sends the positioning information to a base station unit in real time within the detection range of the base station unit. The base station unit establishes a coordinate system based on the mutual positioning of a main base station and an auxiliary base station, measures the real-time distance of the positioning label corresponding to the positioning information sent by the positioning label in communicant with the base station unit, and transmits back the obtained real-time distance information to a monitoring terminal. The monitoring terminal analyzes the positioning position of the corresponding positioning label according to the distance information uploaded by the base station unit. If the positioning position of the positioning label exceeds a threshold value range, an alarm signal is sent out.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

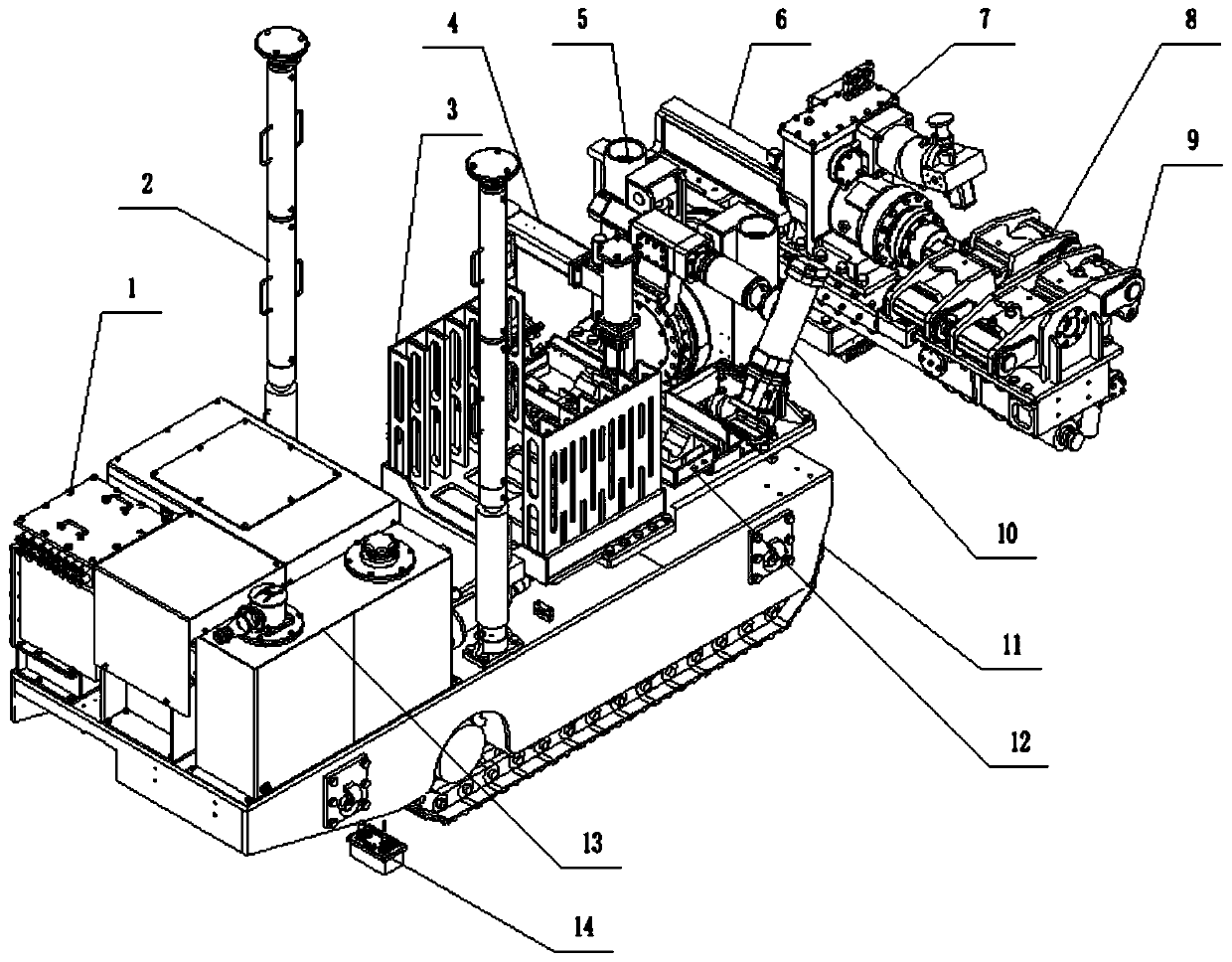

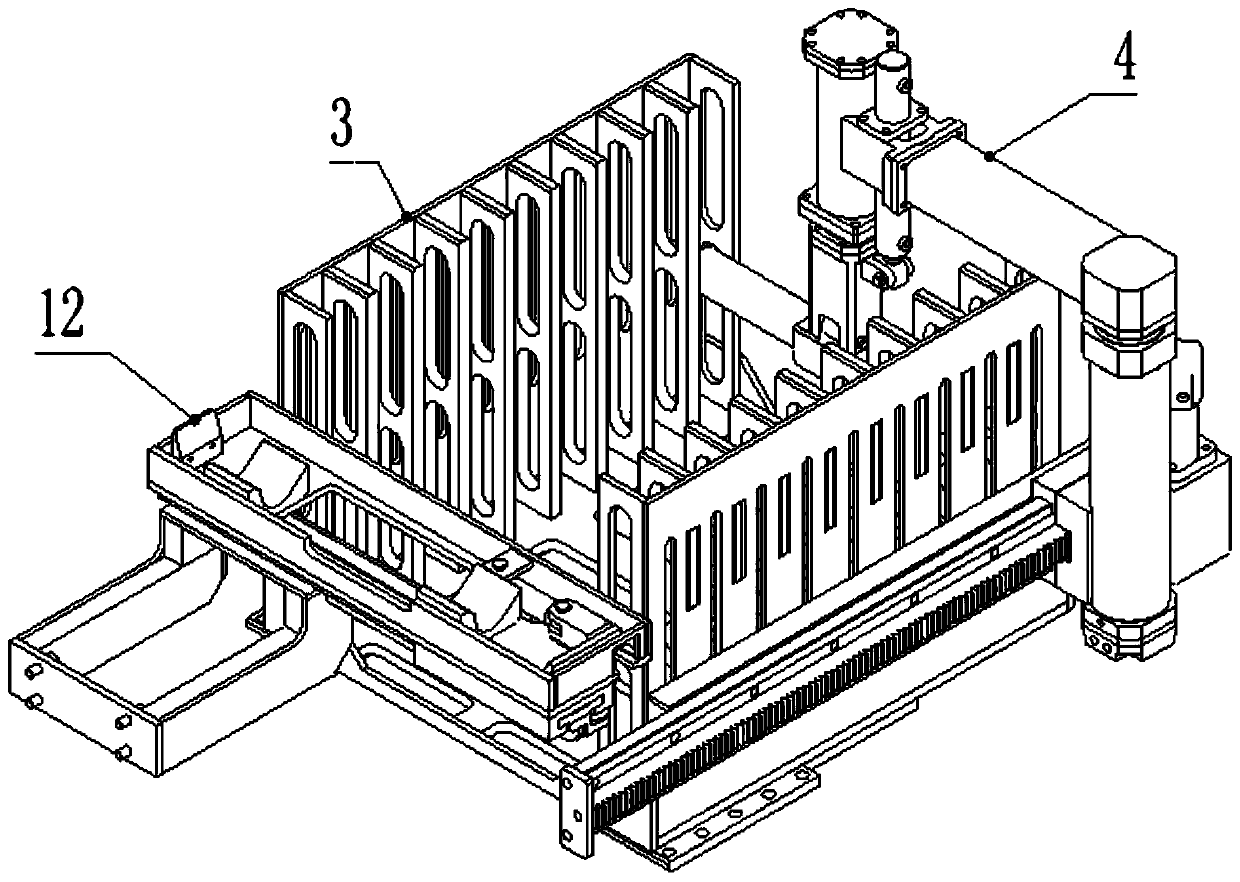

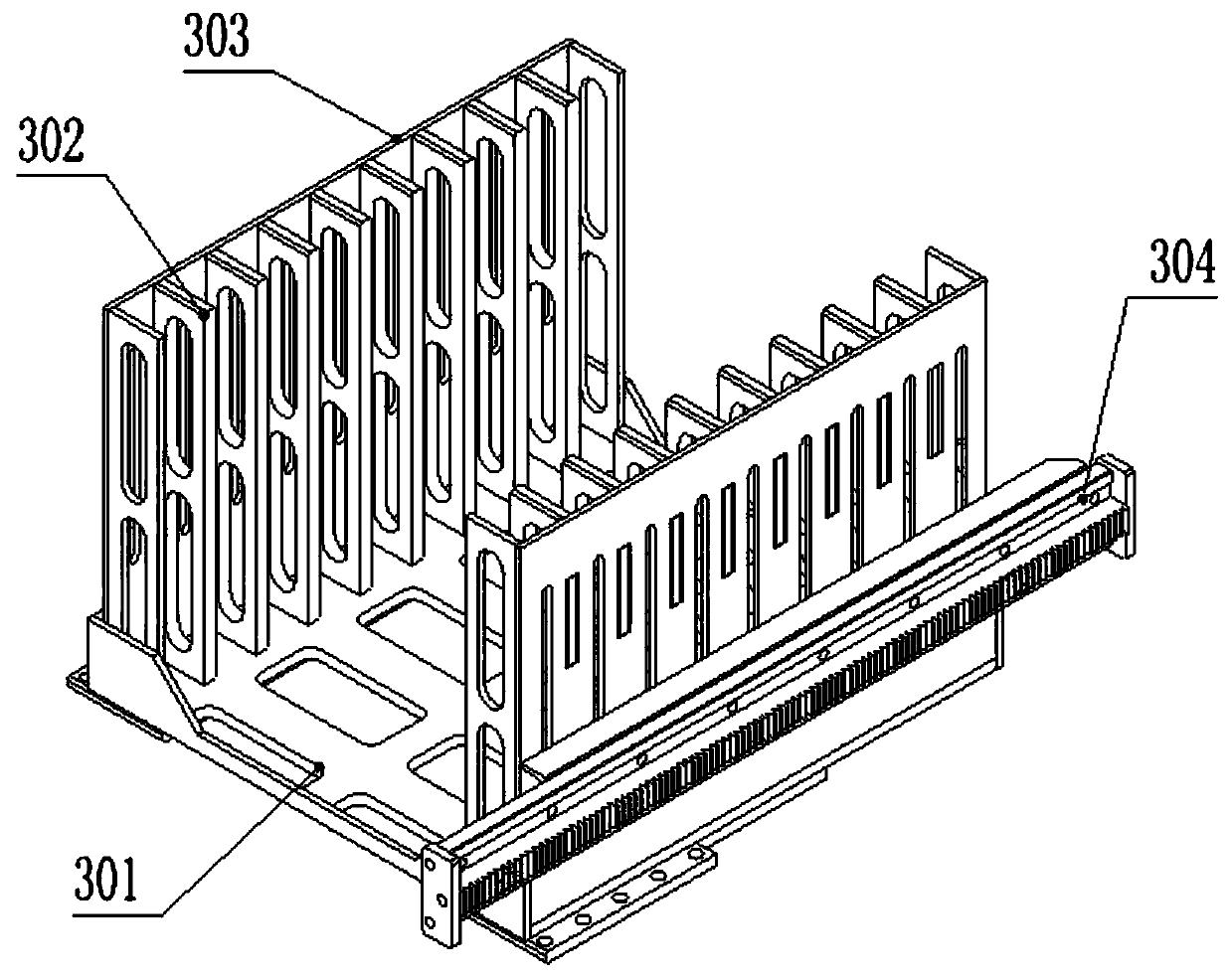

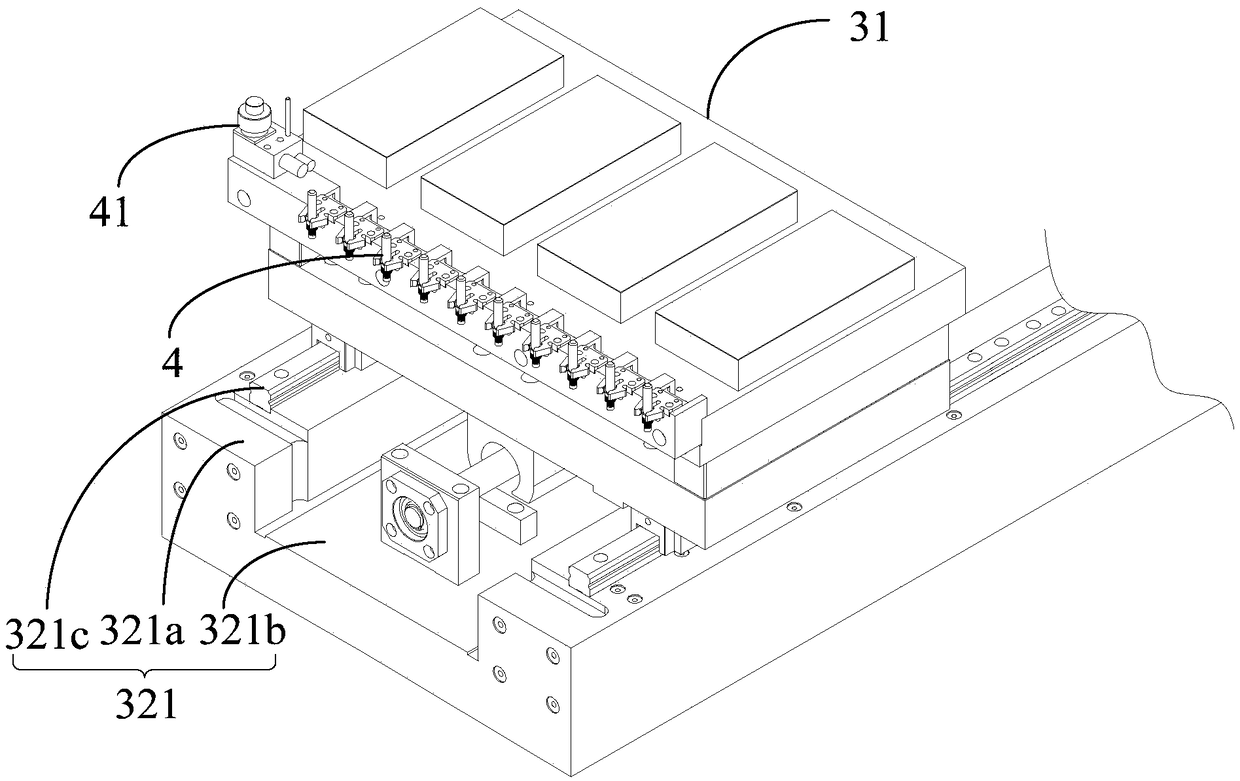

Coal mine drilling rig and control method thereof

ActiveCN110952972ALarge capacityStorage quantity changeDrilling rodsConstructionsAutomatic controlControl system

The invention relates to a coal mine drilling rig and a control method thereof, and belongs to the technical field of coal mine drilling rigs. The coal mine drilling rig includes a drilling rig platform, an automatic installation and disassembly system, a drilling main machine and an automatic control system, wherein the automatic installation and disassembly system and the drilling main machine are arranged on the drilling platform; the automatic installation and disassembly system includes a drill rod box, a rod feed manipulator, a drill rod transfer device and a main manipulator which are arranged in sequence in the conveying direction of drill rods to be installed and clamped; the drill rod box has multiple layers and multiple rows to accommodate the drill rods; and the automatic control system is connected to the automatic installation and disassembly system and the drilling main machine for controlling the drilling main machine to automatically drill. The problem of low drillingefficiency is solved by combining a three-level drill rod transportation method with an arrangement method of arranging the large capacity drill rod box on the drilling rig platform.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

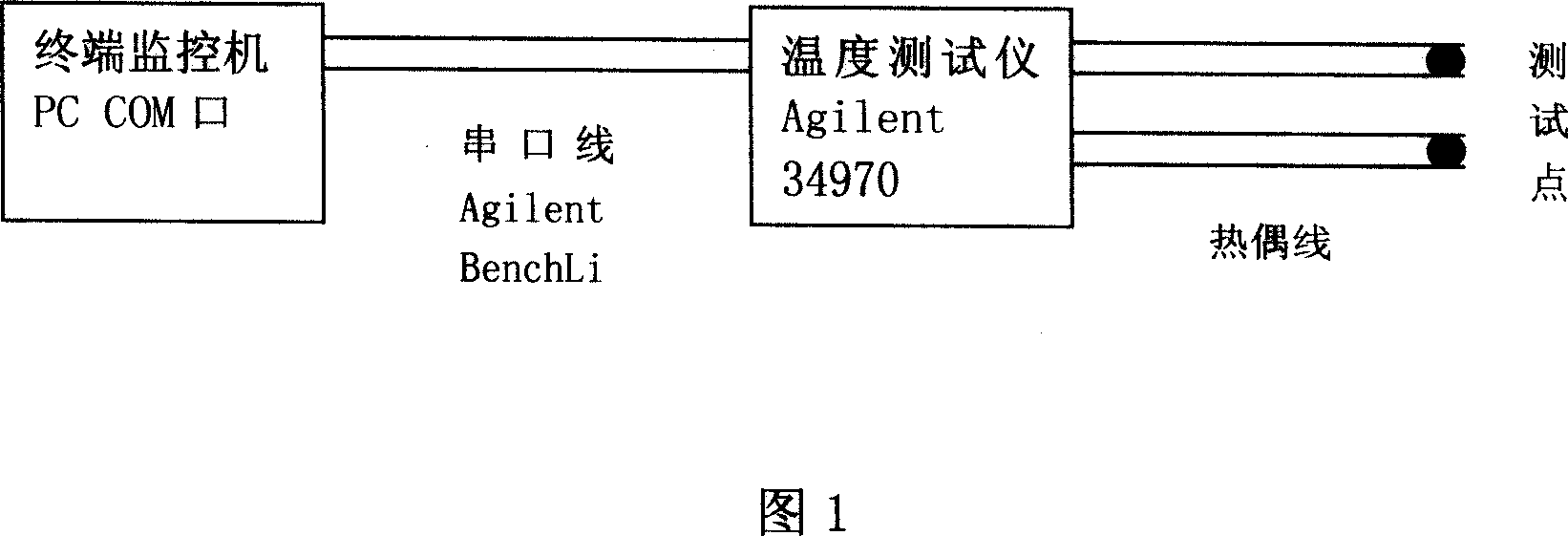

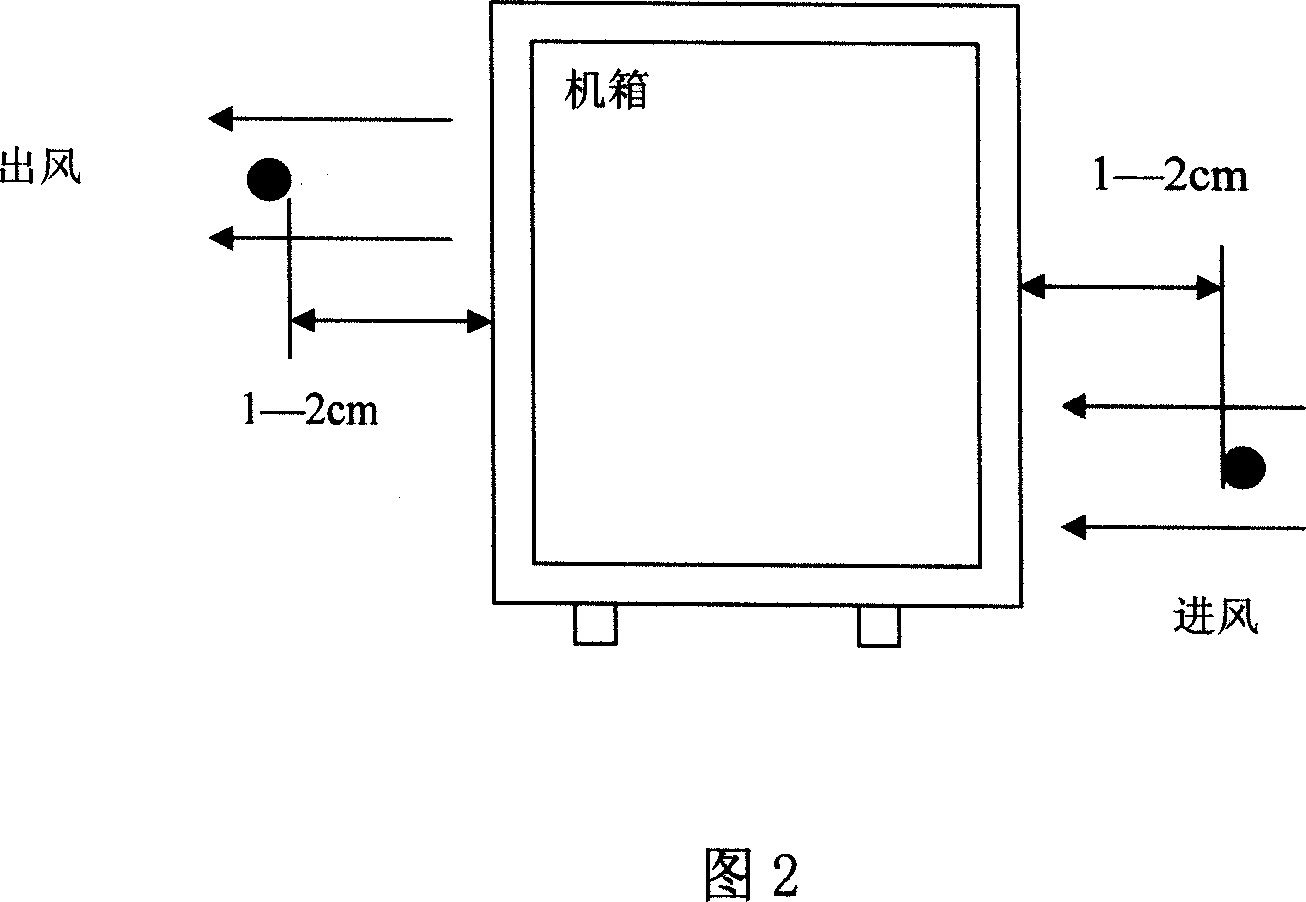

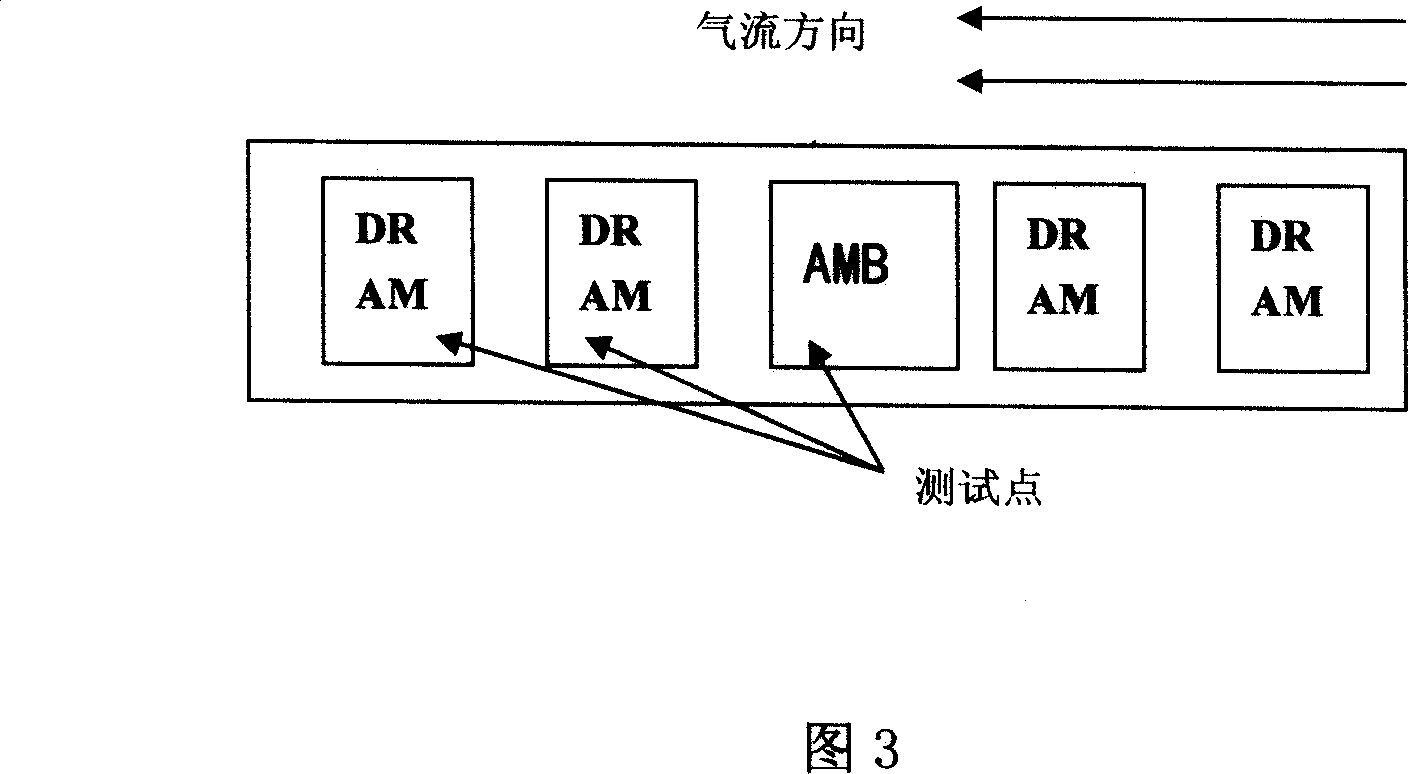

Heat sinking test method

InactiveCN101063642AMeet quantity requirementsImprove test efficiencyThermometers using electric/magnetic elementsDetecting faulty computer hardwareSystem effectsData needs

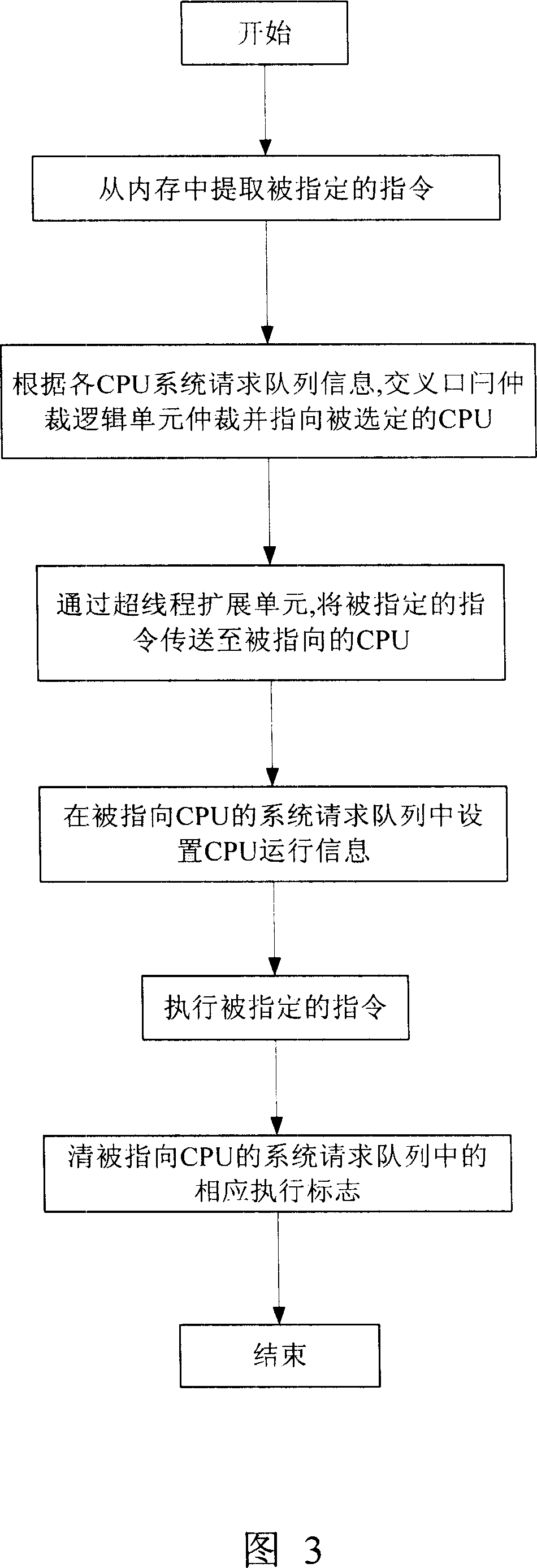

This invention relates to one temperature test field and provides one new dissipation test method, which comprises the following technique keys: it makes the system not only for CPU temperature in testing and integrating the hardware, memory and south and north bridges into test range to totally test system effect; it not only tests part and improves multiple test points hardware to improve test efficiency without human tracing to satisfy the system test point data needs to take place of opaque glue to make the test data more accurate.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

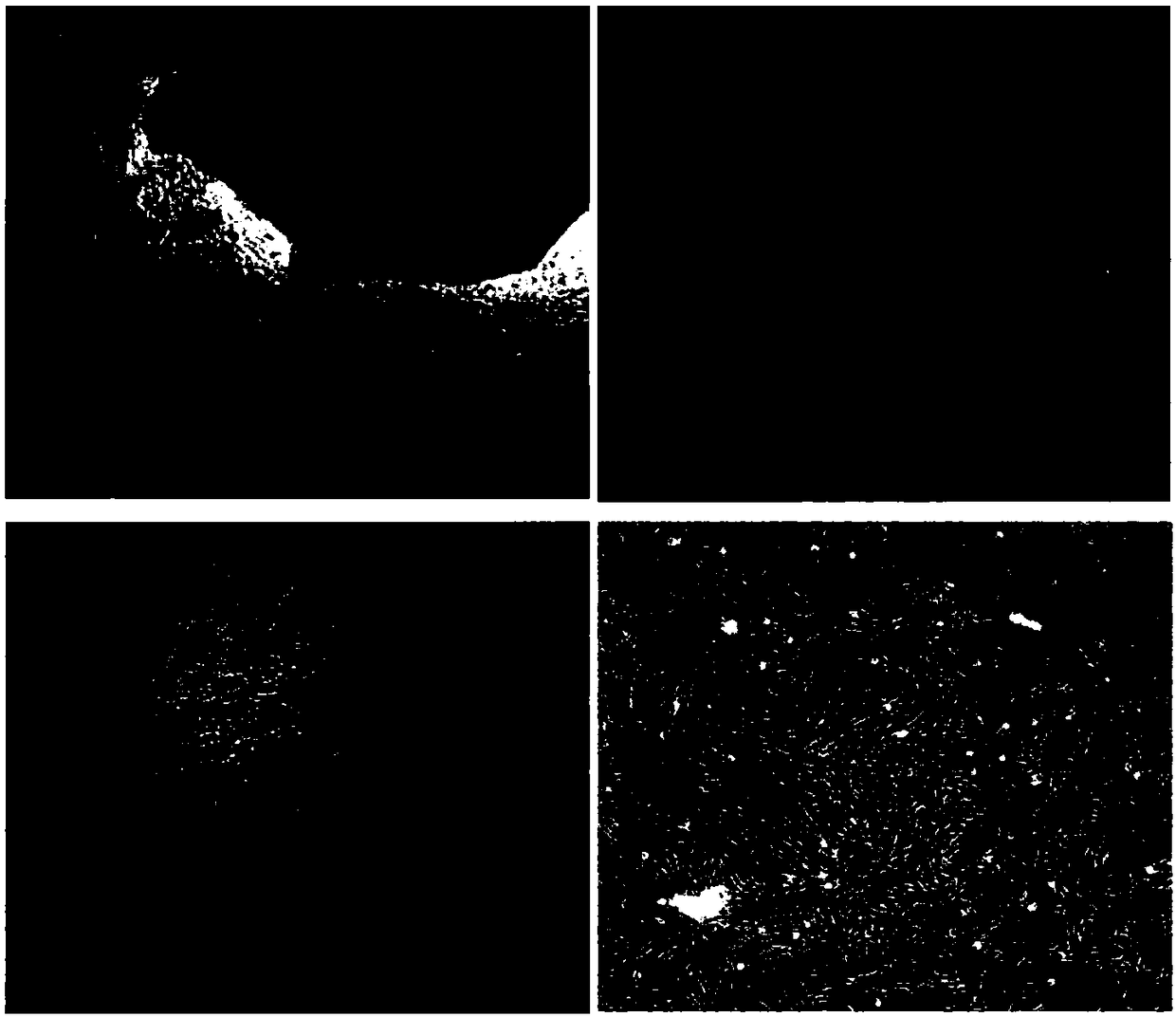

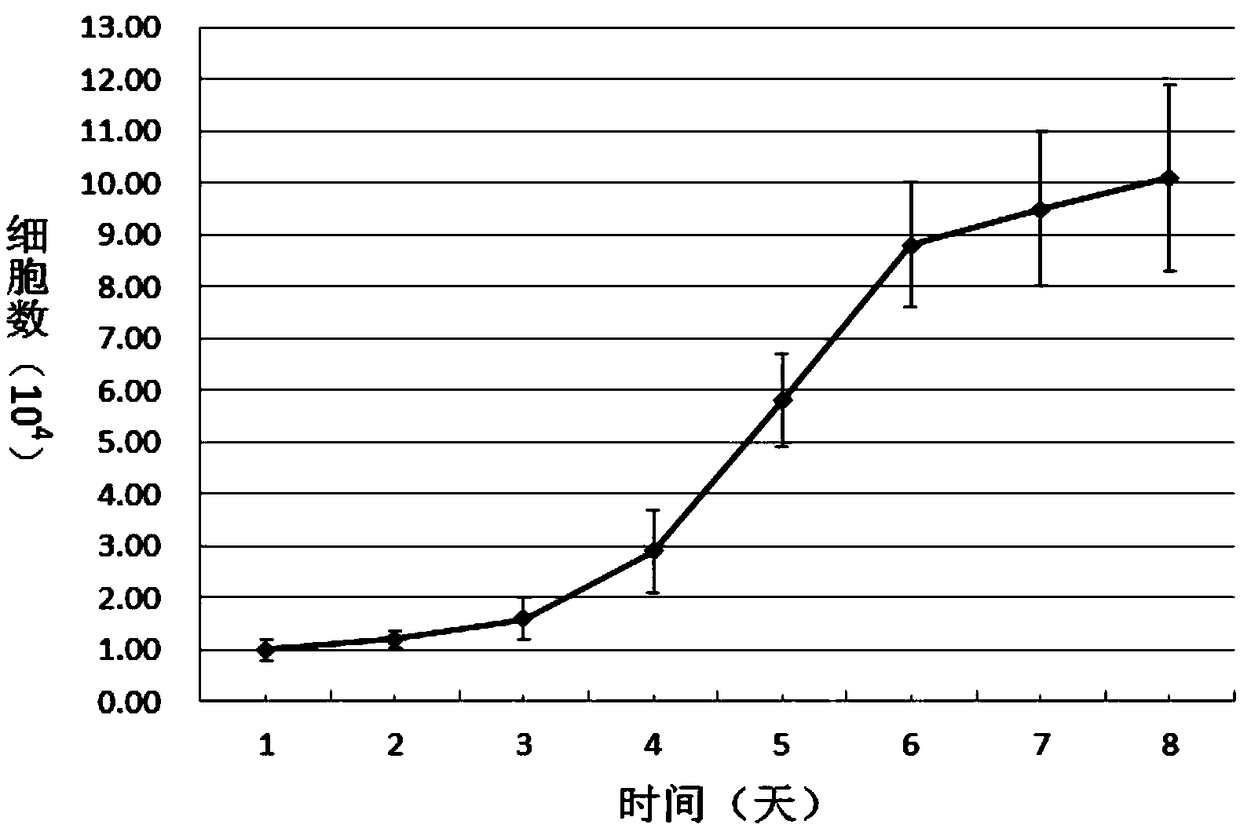

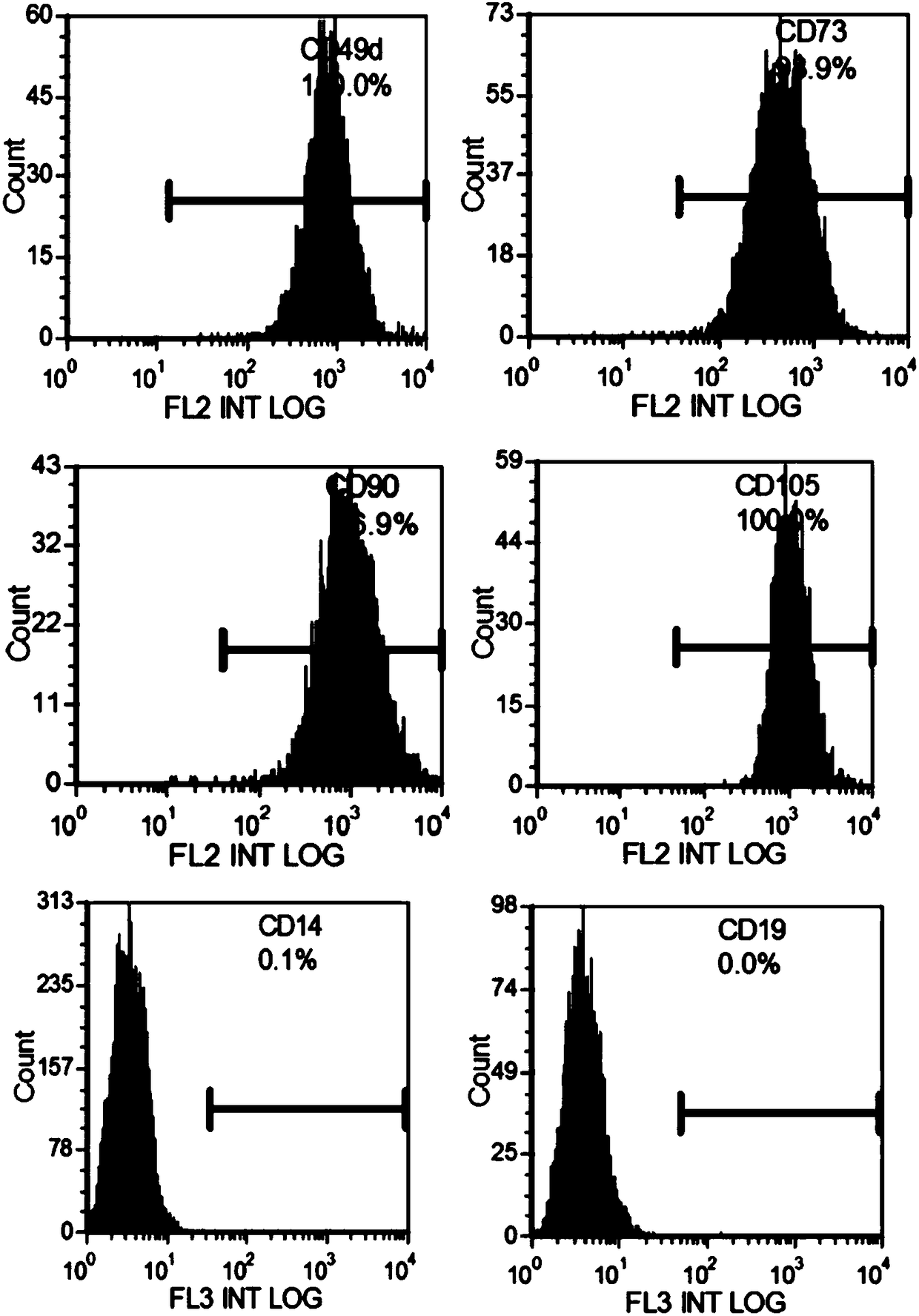

Preparation method for improving yield of umbilical cord derived mesenchymal stem cell primary cells

ActiveCN108220229AImprove utilizationIncrease the number ofCell dissociation methodsSkeletal/connective tissue cellsWharton's jellyPrimary cell

The invention relates to the technical field of cell culture and cell separation and in particular discloses a preparation method for improving the yield of umbilical cord derived mesenchymal stem cell primary cells. On the basis of culturing and separating mesenchymal stem cells on a traditional Wharton's jelly tissue block in a disposable adherence manner, Wharton's jelly tissue blocks are finely collected at different time of a later period of culture and are repeatedly adhered; P0 generation mesenchymal stem cells can be continuously collected at different time. According to the method provided by the invention, the utilization rate of Wharton's jelly is maximized through a property that the mesenchymal stem cells continuously move out from Wharton's jelly tissues to grow; compared with Wharton's jelly tissue block disposable adherence culture, the obtained quantity of the P0 generation mesenchymal stem cells can be increased by two times at least; the culture density of the mesenchymal stem cells, the concentration of serum replacements in a culture medium and the culture time are subsequently controlled; when the cells are sub-cultured to a P3 generation, the obtained cell quantity can completely meet the requirements of cell storage and clinical transplantation.

Owner:北京中科易微生物科技有限公司

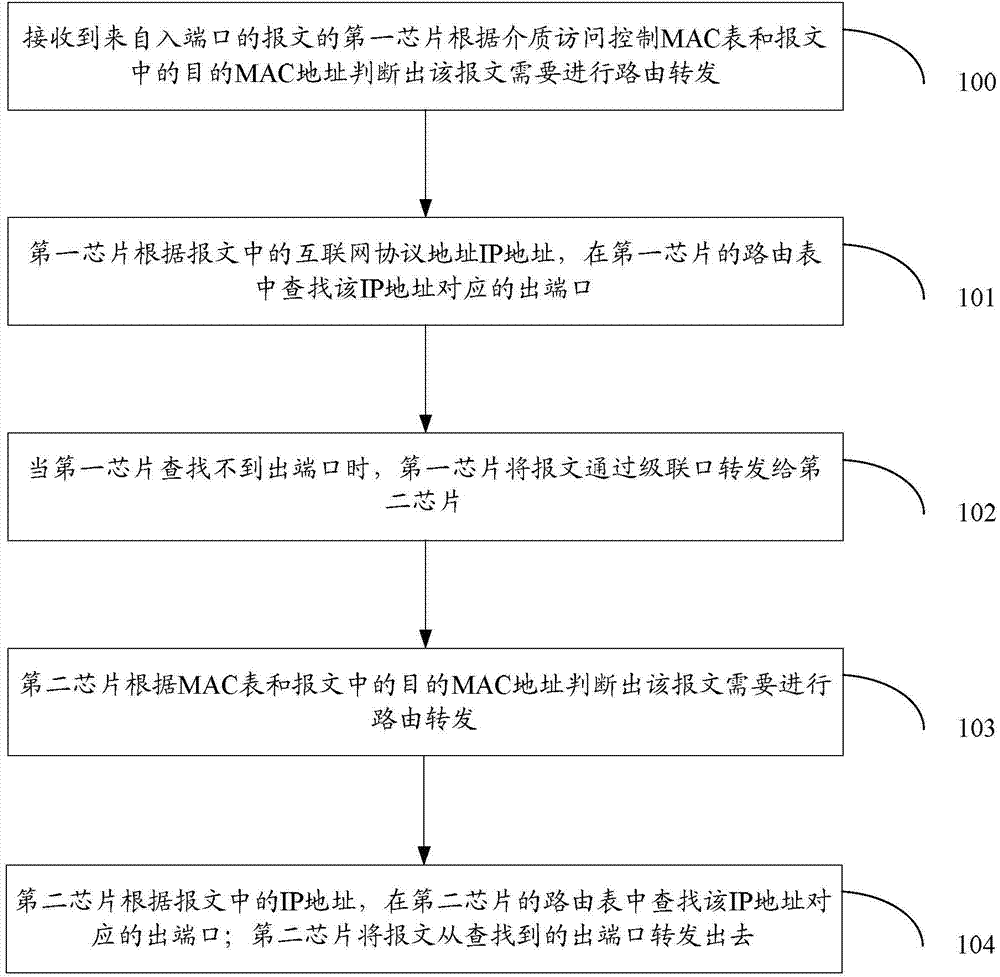

Method of realizing message forwarding and switch

ActiveCN104717138AImprove network adaptabilityMeet quantity requirementsHybrid transportEmbedded systemIp address

Proposed are a method for realizing message forwarding and a switch. The method is applied to a switch. The switch comprises a first chip and a second chip which are cascaded. The method comprises: a first chip which has received a message from an ingress port judging that the message is required to be routed and forwarded according to a media access control (MAC) table and a target MAC address in the message; according to an Internet protocol address (IP address) in the message, the first chip looking for an egress port corresponding to the IP address in a routing table of the first chip; when the first chip does not find the egress port, the first chip forwarding the message to the second chip via a cascading port; according to the MAC table and the target MAC address in the message, the second chip judging that the message is required to be routed and forwarded; according to the IP address in the message, the second chip looking for the egress port corresponding to the IP address in a routing table of the second chip; and the second chip forwarding the message from the found egress port.

Owner:ZTE CORP

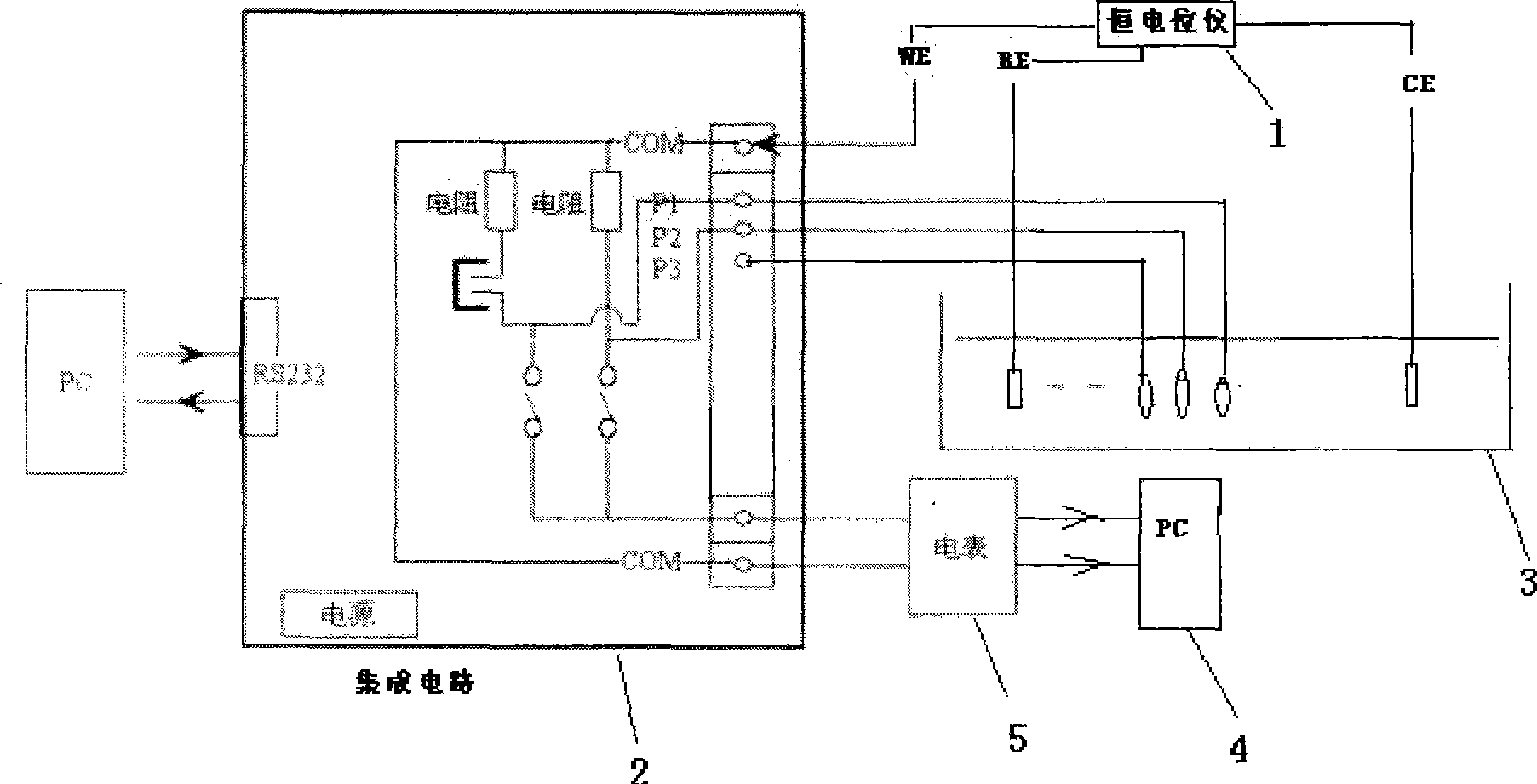

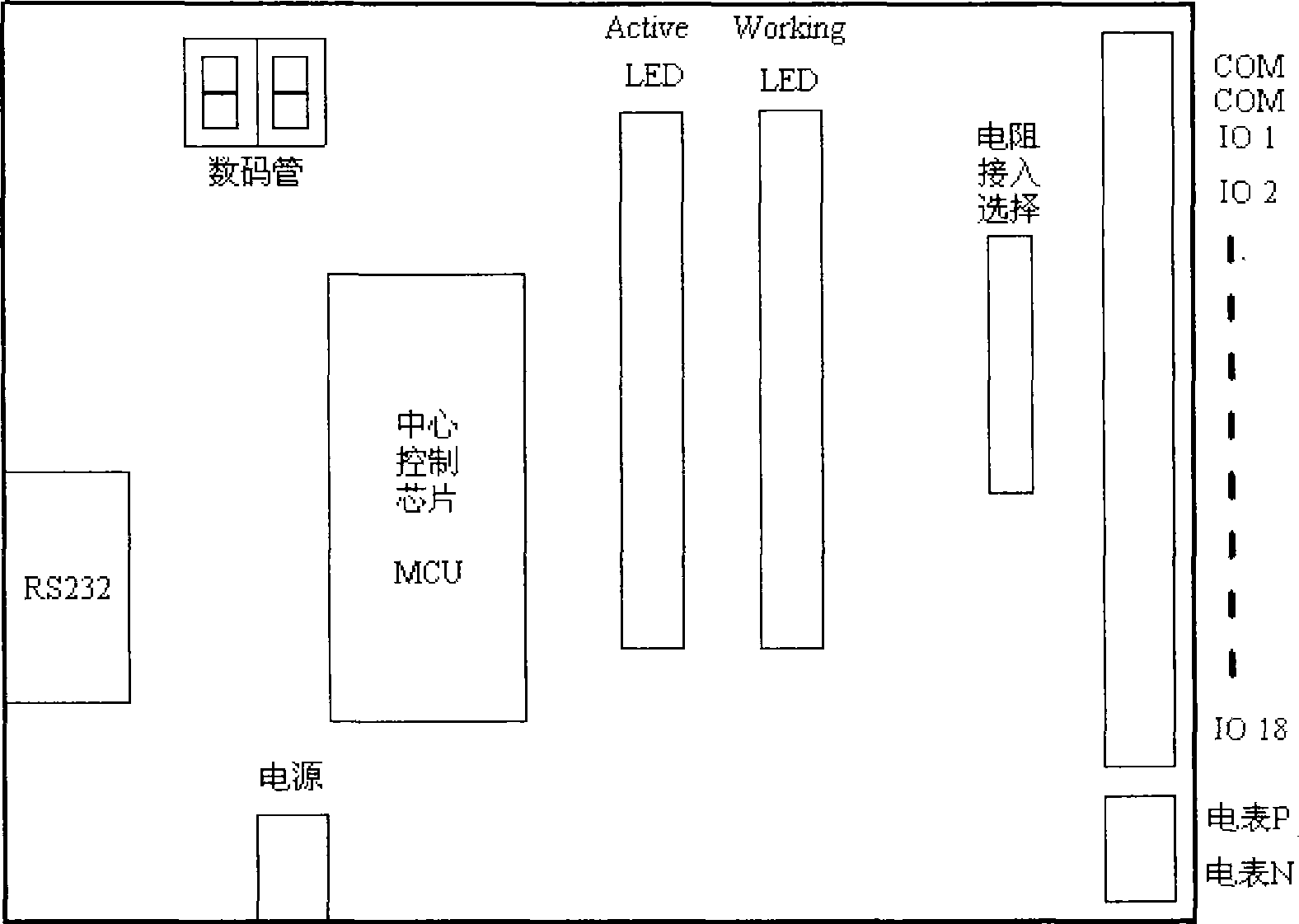

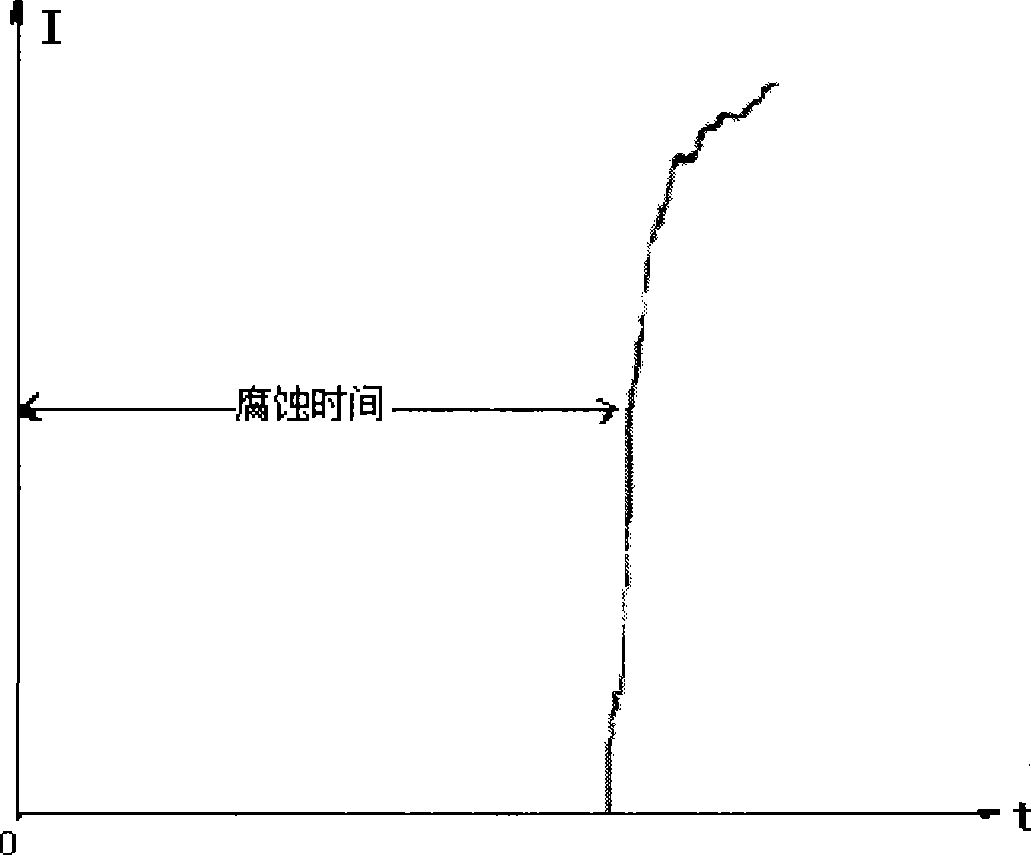

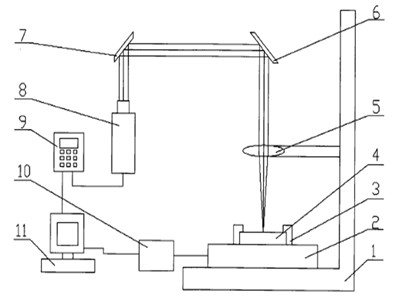

Automatic acquisition multichannel accelerated attack test device for measuring anti corrosion capability against chloride ion

InactiveCN101419153AStable outputMeet quantity requirementsWeather/light/corrosion resistanceMaterial testing goodsEngineeringTest fixture

The invention relates to an automatic acquisition multi-channel accelerated corrosion test device for measuring the capability against the erosion of chloride ions. A common three-electrode potentiostat is utilized to form a set of device system capable of synchronously measuring a plurality of test samples and automatically recording test data through an integrated circuit, a software and an electrolytic bath which are integratedly and independently developed. The device overcomes the defect that the quantity of the test samples for accelerated corrosion tests at home and abroad is limited by channels of the potentiostat, greatly saves test cost, enlarges test scale, and saves test time. The invention has convenient and simple use, and provides the low-cost and high-efficiency test device for evaluating the capabilities of cement-based grout materials and concrete materials against the erosion of the chloride ions.

Owner:TONGJI UNIV

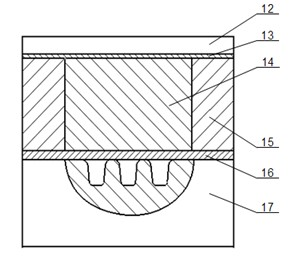

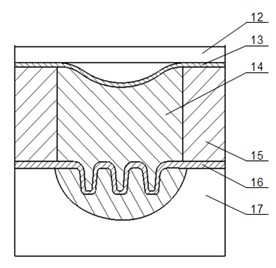

Laser shock high molecular polymer indirect micro-forming method and dedicated device thereof

InactiveCN102513431AQuality improvementAvoid ablative damageLaser beam welding apparatusEtchingPhysical chemistry

The invention discloses a laser shock high molecular polymer indirect micro-forming method and a dedicated device thereof. A laser beam goes through an optical medium in a forming system and is exposed to an absorption coating film, so that a part of the absorption coating film is ablated to generate high-temperature high-pressure plasmas; the plasmas further absorb laser energy and then expand and explode; and the exploding plasmas expand towards the absorption coating film to generate a GPa-level impact pressure on the absorption coating film, resulting in plastic deformation of the absorption coating film. A high molecular polymer deforms towards a target work piece which is arranged at the lower part of the polymer under constraints of the impact pressure of the absorption coating film and the cavity of the high molecular polymer, resulting in plastic deformation of the target work piece. The method prevents ablative degradation or etching of the work piece surface and ensures precision forming of the work piece in the micro-mould.

Owner:JIANGSU UNIV

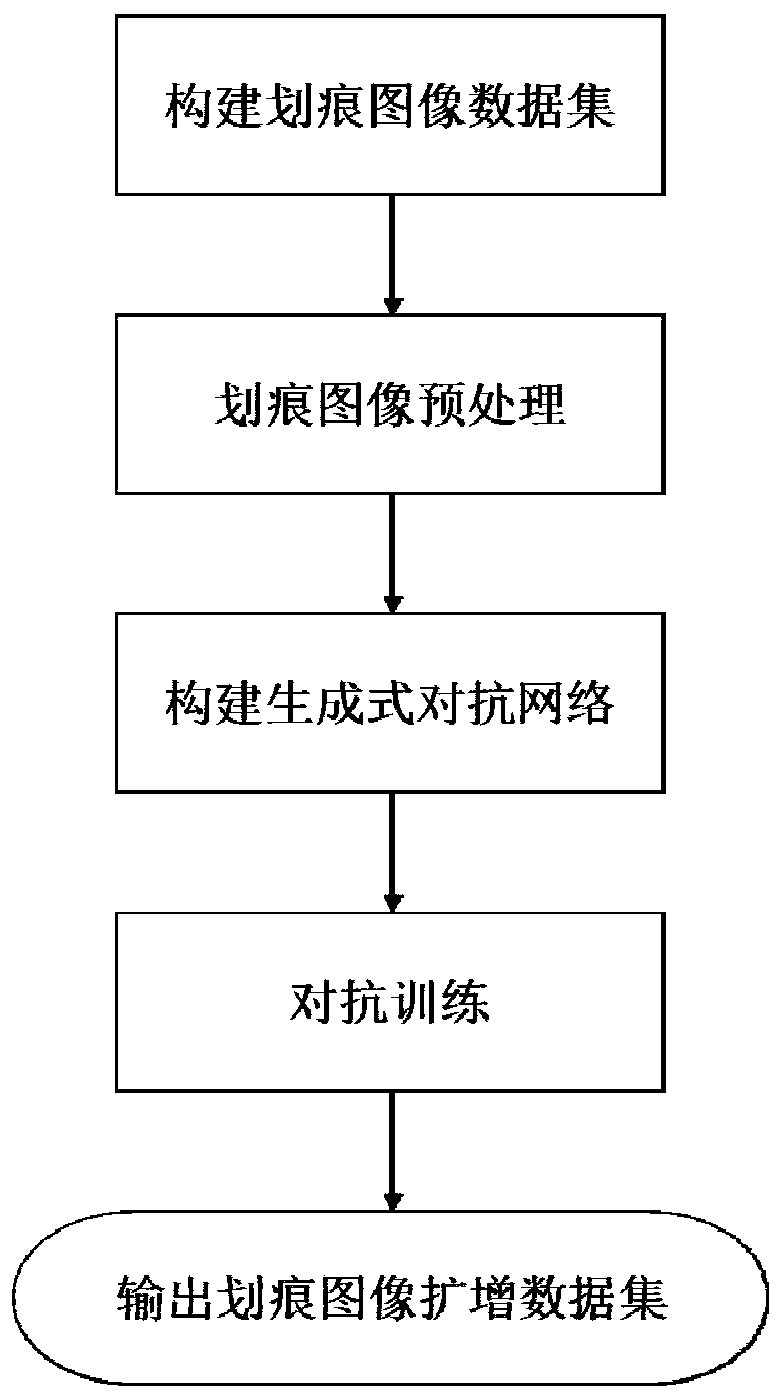

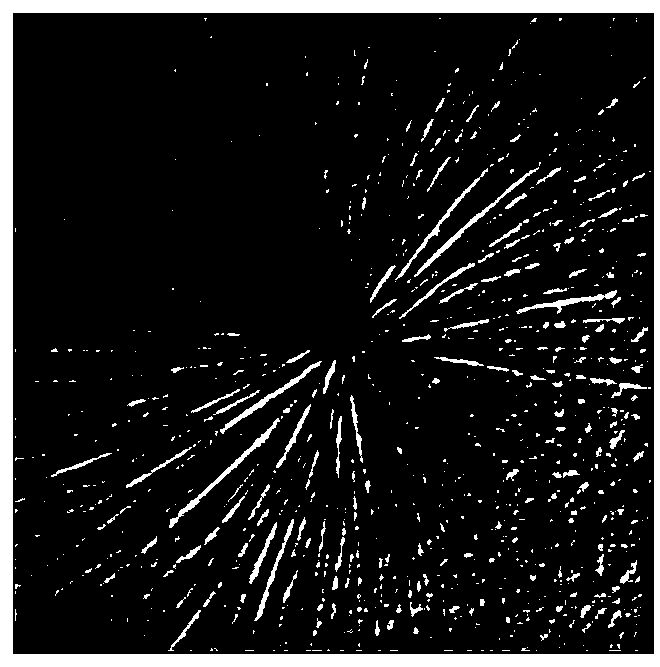

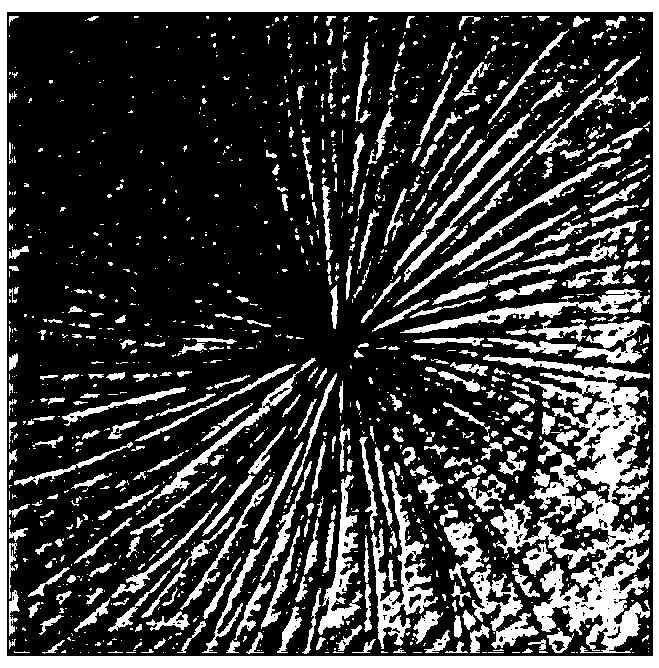

Scratch image data amplification method based on generative adversarial network

InactiveCN110189351ANarrowing down the difference in statistical laws of probability distributionMeet quantity requirementsImage enhancementImage analysisGenerative adversarial networkData set

The invention discloses a scratch image data amplification method based on a generative adversarial network. The scratch image data amplification method comprises the following steps: S1, constructinga scratch image data set; S2, preprocessing the scratch image; S3, constructing a generative adversarial network; S4, performing confrontation training; and S5, outputting a scratch image amplification data set. The main beneficial effects of the method are that a large amount of scratch image data can be generated by utilizing a generation network, effective characteristics of a real scratch image can be learned by using a discrimination network. Through performing the adversarial training on the generation network and the discrimination network, the probability distribution statistical lawdifference between the generated image and the real image can be effectively reduced, so that the requirement of a defect detection system based on deep learning on the number of training samples is met, and the quality requirement of the defect detection system on the training samples is also met.

Owner:ZHEJIANG UNIV CITY COLLEGE

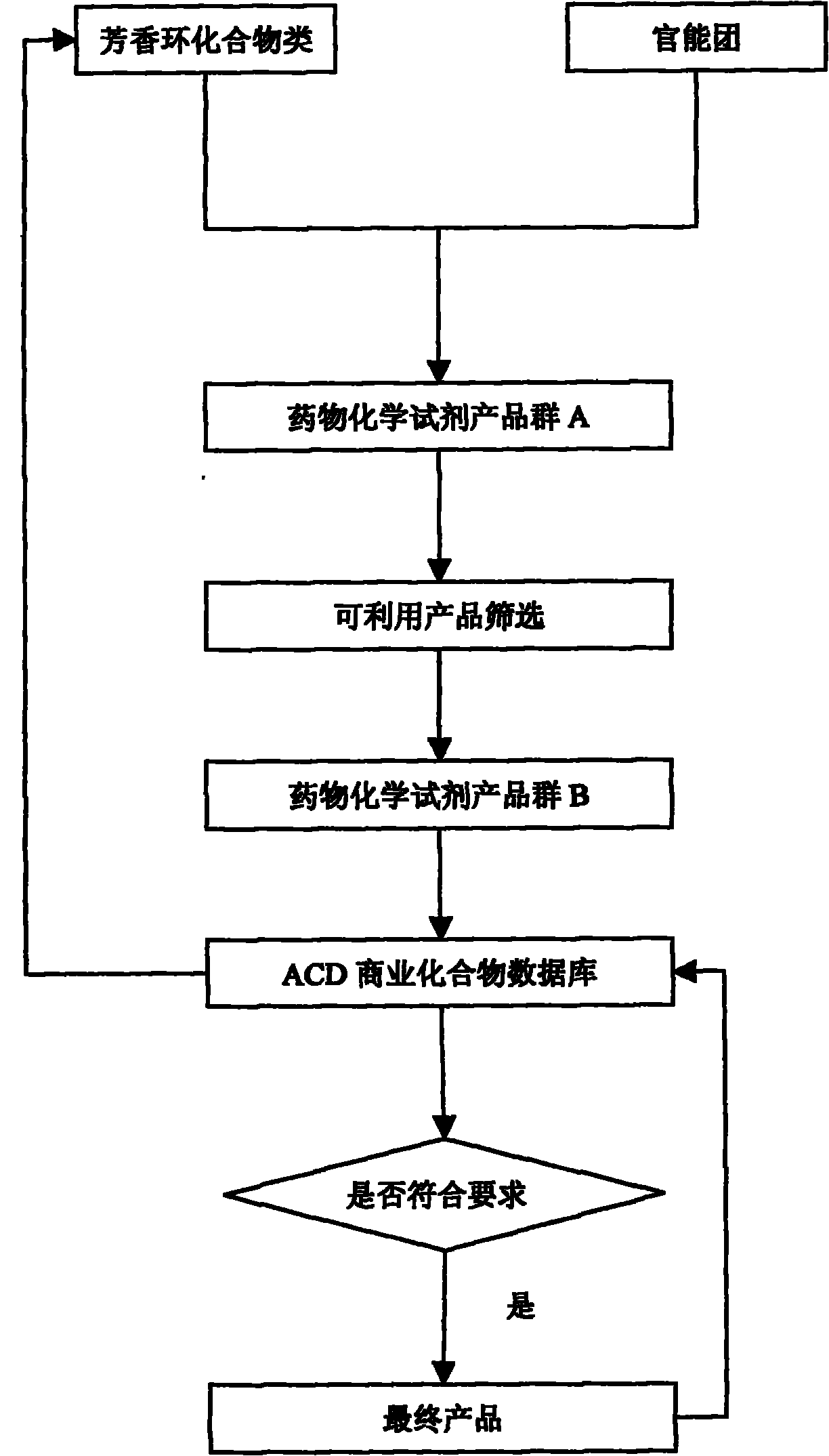

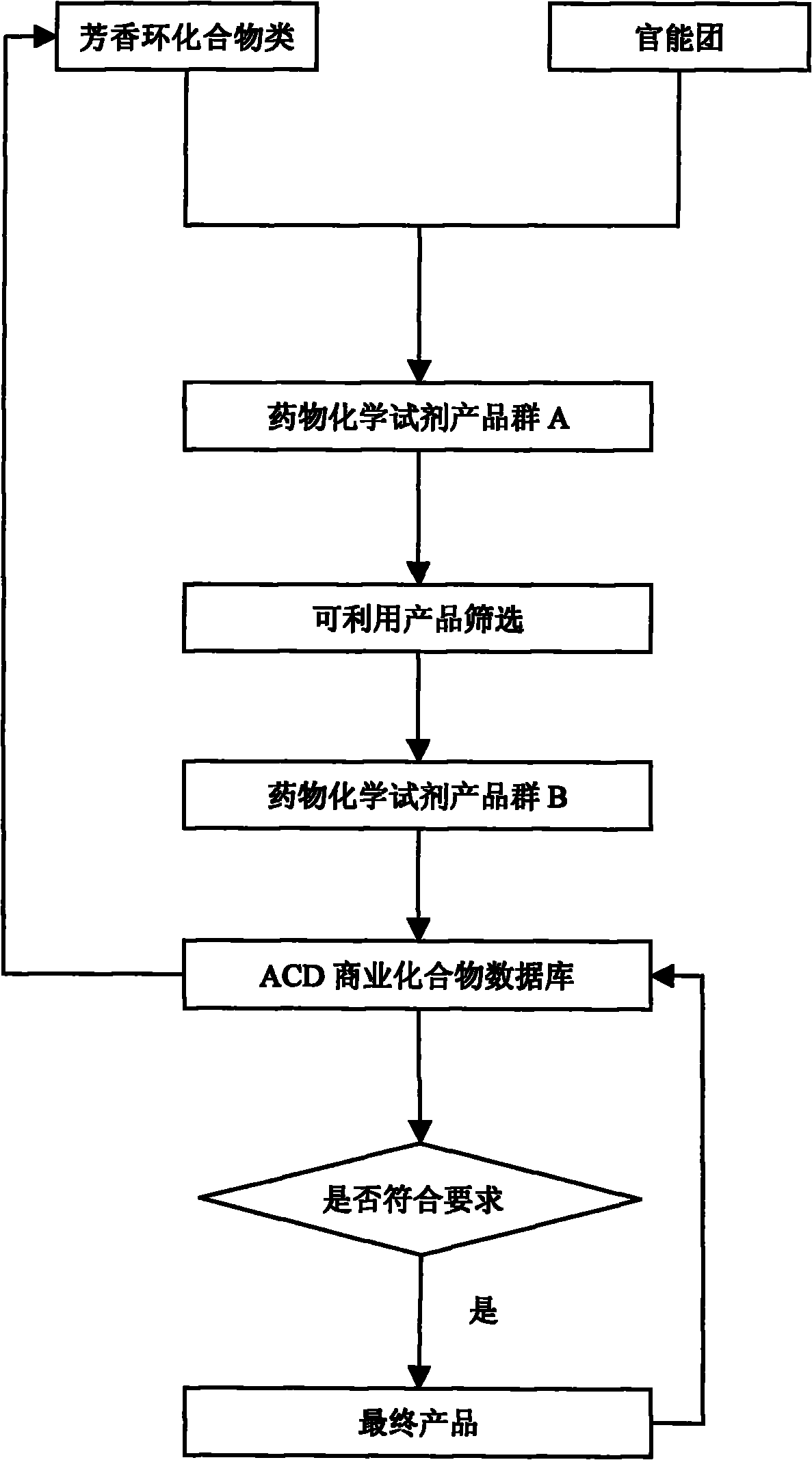

Design and production flow process of medicine development chemical reagent

The invention relates to a design and production flow process of medicine development chemical reagent, which is characterized by comprising the following process steps of: 1. combining heteroaromatic compounds with functional groups for forming a medicine chemical reagent product group A; 2. identifying and sieving the medicine chemical reagent product group A according to raw materials, the production process, the biological activity, the physicochemical properties and the like for forming a medicine chemical reagent product group B; 3. comparing the medicine chemical reagent product group B to an ACD (Automatic Call Distribution) commercial compound database, forming final products when the sieving requirement is met if the ACD commercial compound database does not comprise the medicine chemical reagent product group B, and supplementing the final products into the ACD commercial compound database; and 4. combining the heteroaromatic compounds in the supplemented ACD commercial compound database with the functional group, and repeating the steps for forming the novel medicine chemical reagent. The invention changes the passive action into active action, can effectively supplement the ACD compounds and can relieve the medicine development bottle neck pressure.

Owner:程海燕 +1

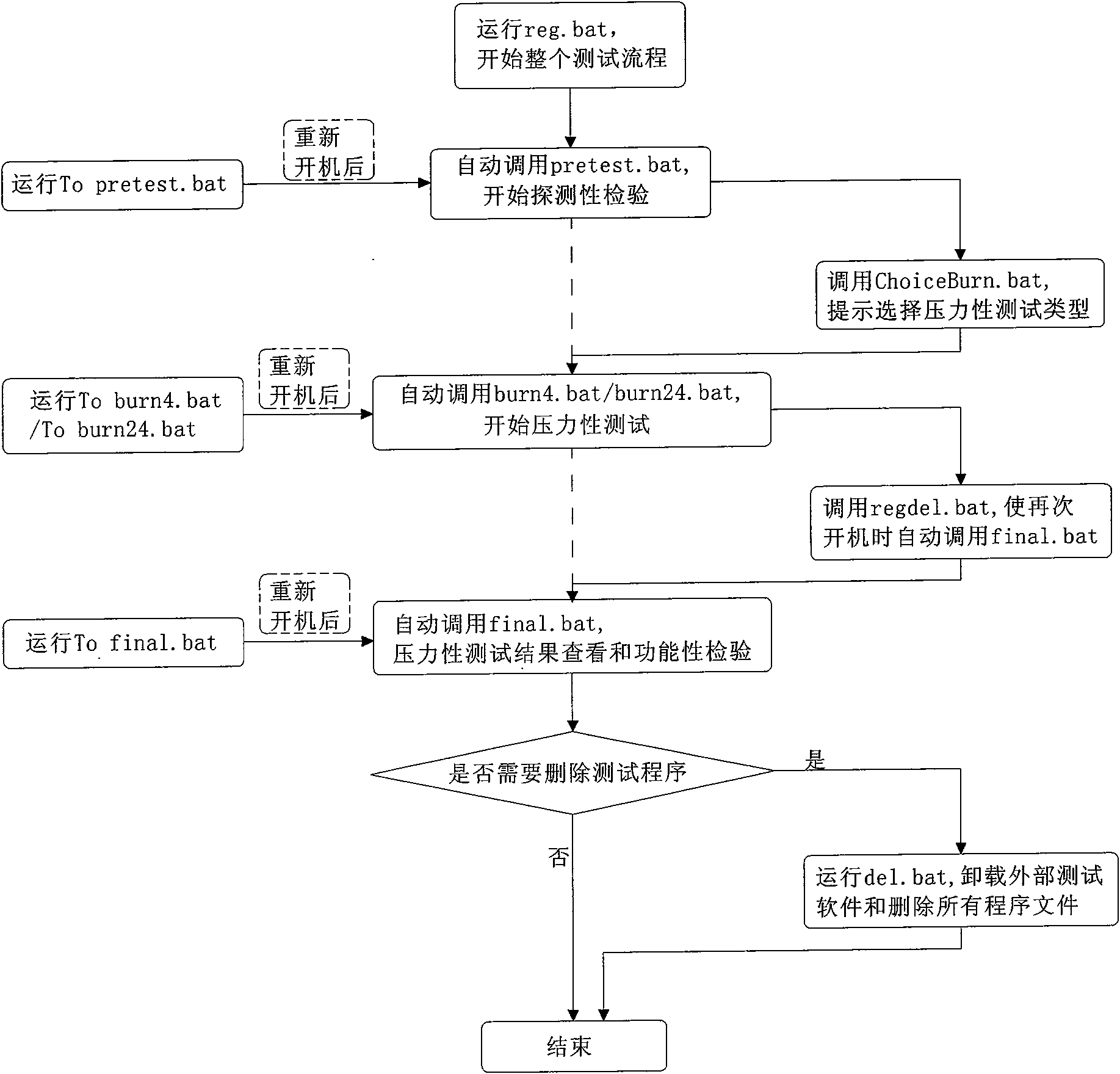

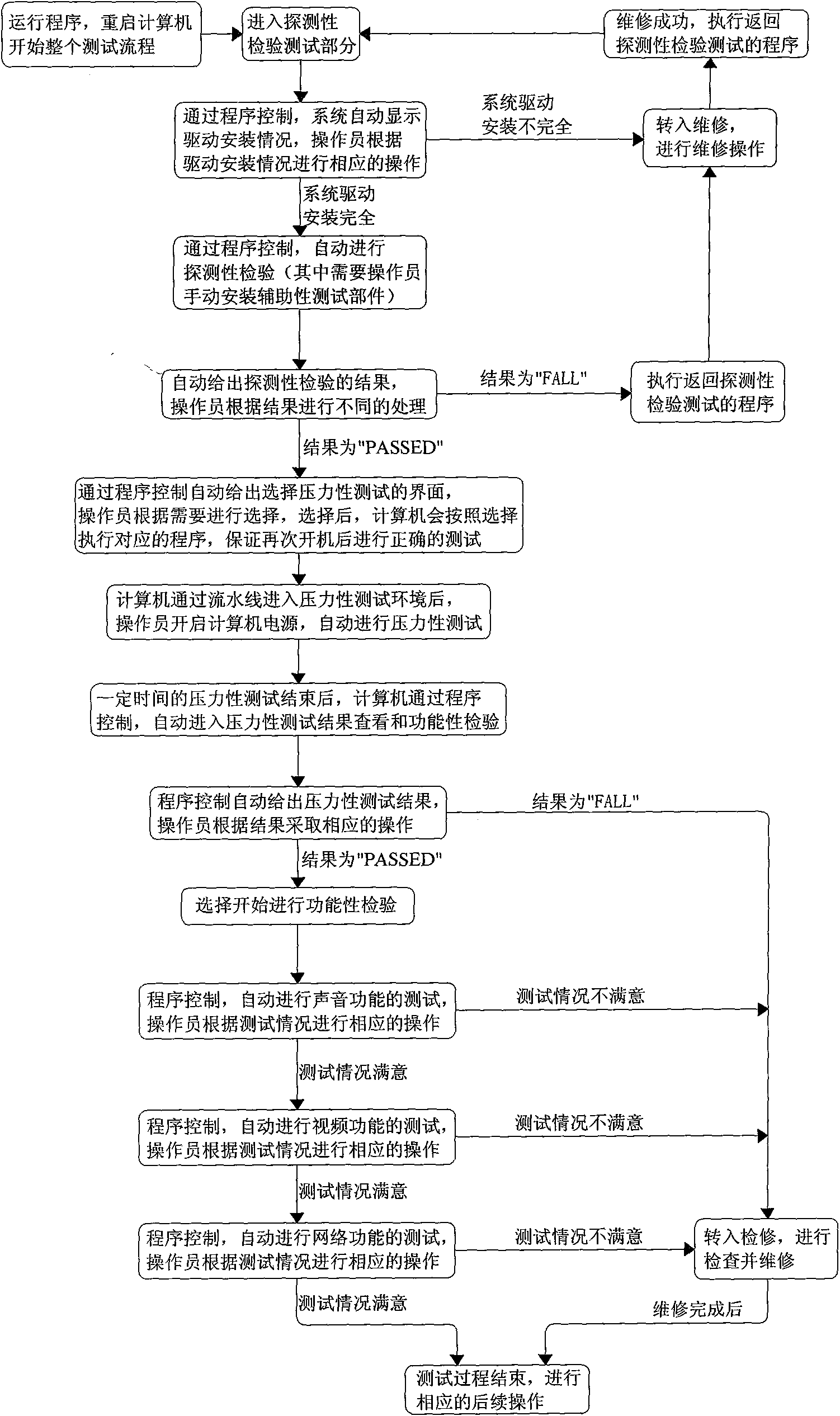

Method for realizing human-machine interactive test automatically performed by computer

InactiveCN101609426AEasy to judgeMeet quality requirementsSoftware testing/debuggingState of artMan machine

The invention discloses a method for realizing a human-machine interactive test automatically carried out by a computer, belonging to the field of computer production tests. A plurality of procedures are designed in the computer, a part of the procedures can transfer other procedures, and the whole human-machine interactive test process is realized by the layer-upon-layer transfer and the operation of the procedures; and the computer can carry out four tests, i.e. detection check, pressure tests, a pressure test result review and function check, according to the programmed procedures and by the manual operation of operators. Compared with the prior art, the method for realizing the human-machine interactive test automatically carried out by the computer realizes the whole process of the man-machine interactive test automatically carried out by the computer through procedure design, can meet the requirement of clients for the quality and the quantity of the computer and also has human operation and judgment, thereby enhancing the applicability of the computer.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

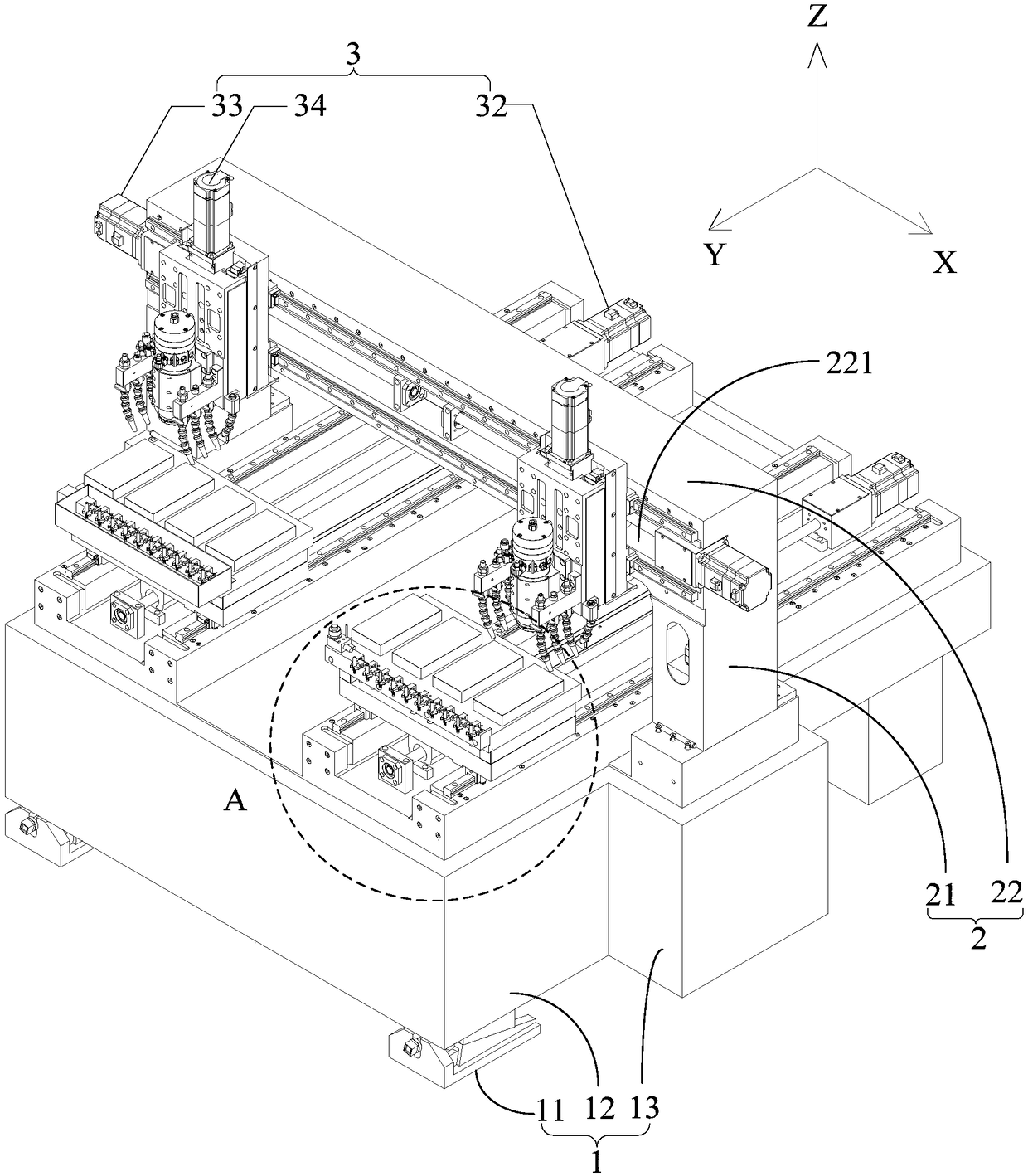

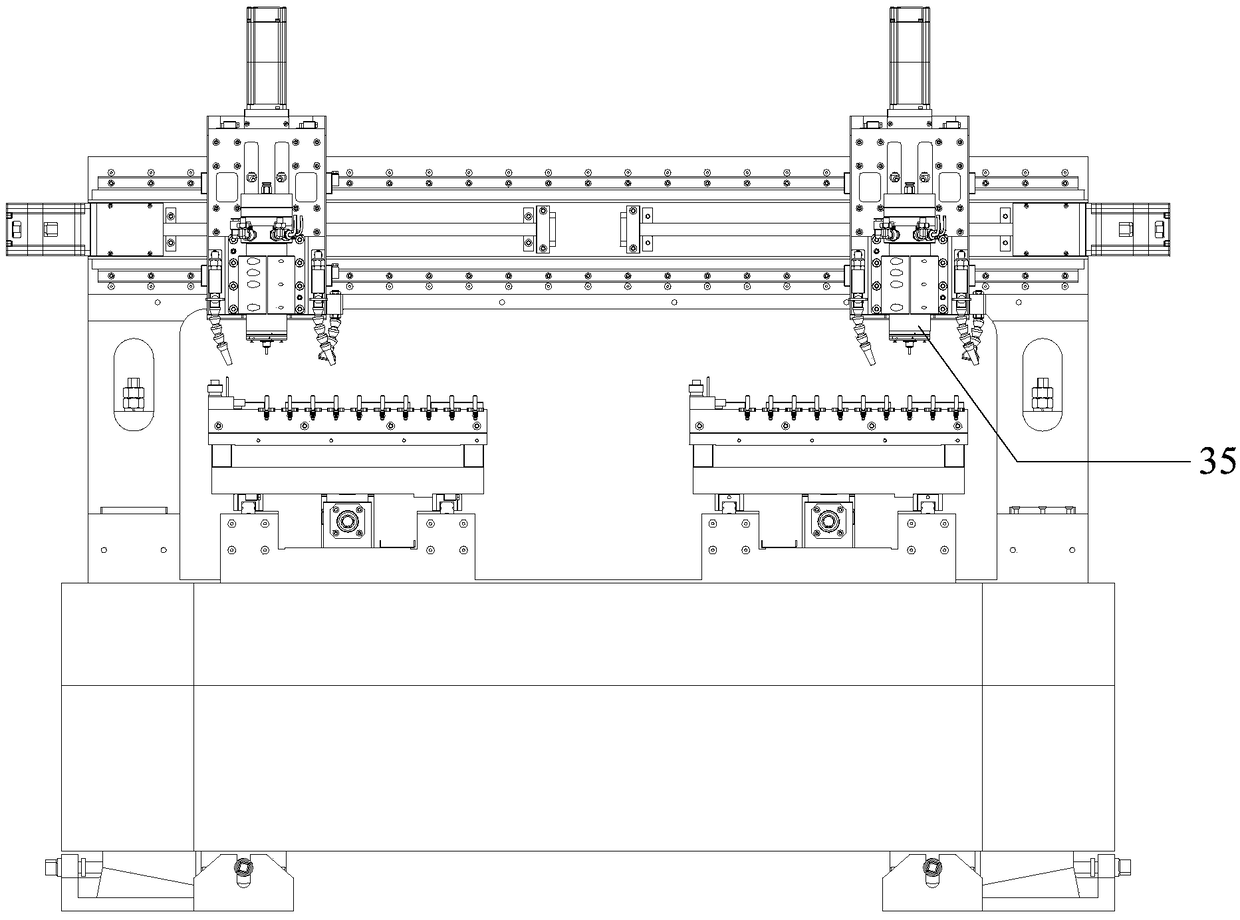

Glass accurate engraving machine

PendingCN108995453AReduce manufacturing costMeet production needsOther artistic work equipmentsModel makingEngineeringPulp and paper industry

The invention discloses a glass accurate engraving machine. The glass accurate engraving machine comprises a base, a gantry type supporting frame stretching across the two sides of the base, at leasttwo sets of glass processing mechanisms arranged on the gantry type supporting frame and processing platforms arranged on a table face of the base and corresponding to the glass processing mechanismsin a one-to-one manner; the at least two sets of glass processing mechanisms are arranged side by side independently in the span direction of the gantry type supporting frame, each glass processing mechanism comprises an X-axis transmission mechanism arranged on the gantry type supporting frame and a Z-axis transmission mechanism arranged on the X-axis transmission mechanism and provided with a processing main shaft; Y-axis transmission mechanisms used for driving the processing platforms to move in the Y-axis direction are arranged between the base and the processing platforms; and the glassaccurate engraving machine further comprises a mechanical arm arranged on the peripheral side of the base and used for conducting feeding and discharging for the at least two processing platforms. Bymeans of the glass accurate engraving machine, the glass product manufacturing cost can be effectively reduced, the production efficiency of the glass accurate engraving machine is further improved, and the market requirements are met.

Owner:SHENZHEN CREATE CENTURY MACHINERY

Method for cultivating medicinal and food two purpose loosestrife

InactiveCN1857053AQuality improvementIncrease productionFertilising methodsHorticulturePest controlSeedling

The cultivating technique for loosestrife as food and medicine material includes selecting seedling of loosestrife, preparing land, planting, applying fertilizer, weeding, watering, pest controlling and harvesting. The present invention has raised loosestrife yield and quality.

Owner:梁忠仁

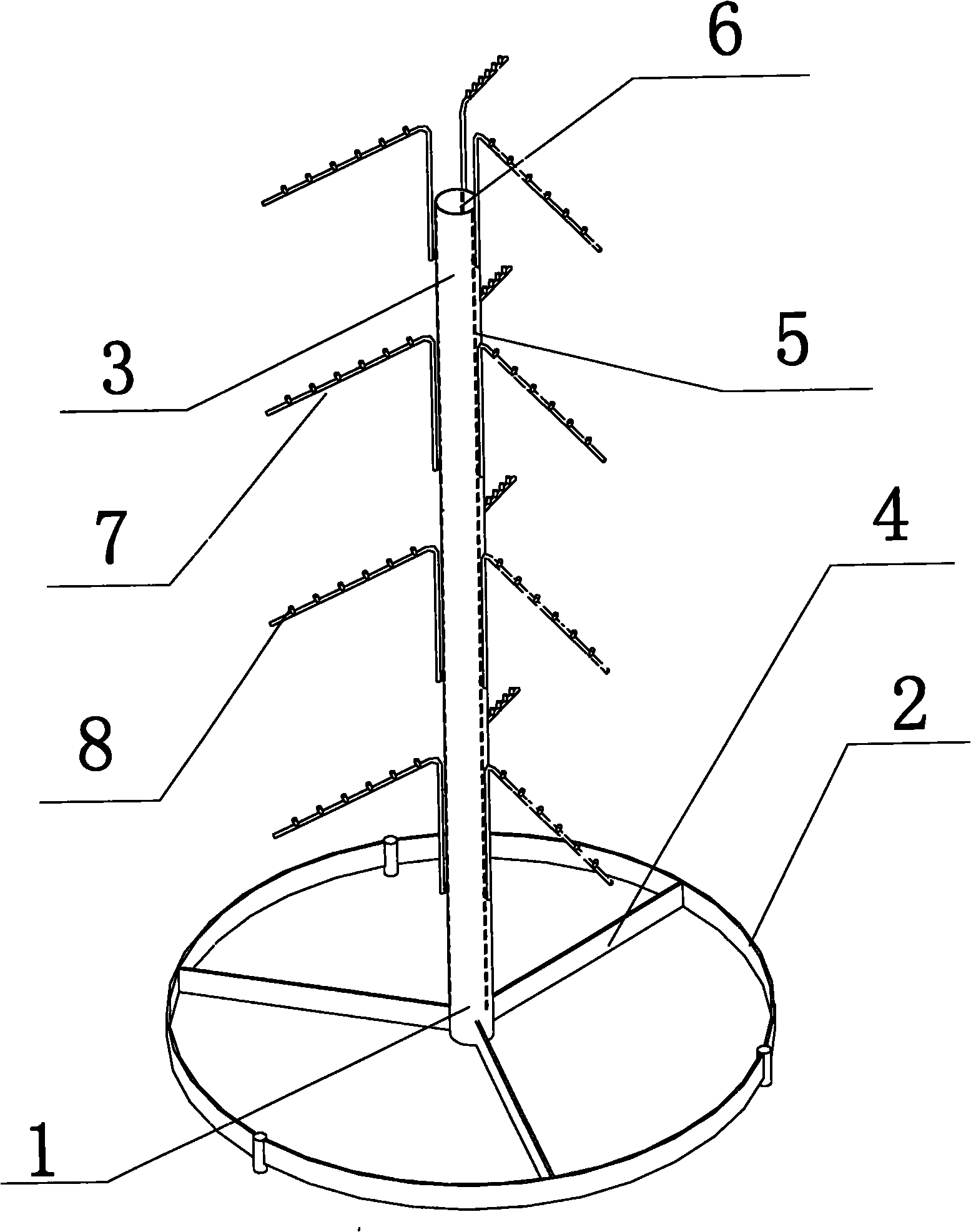

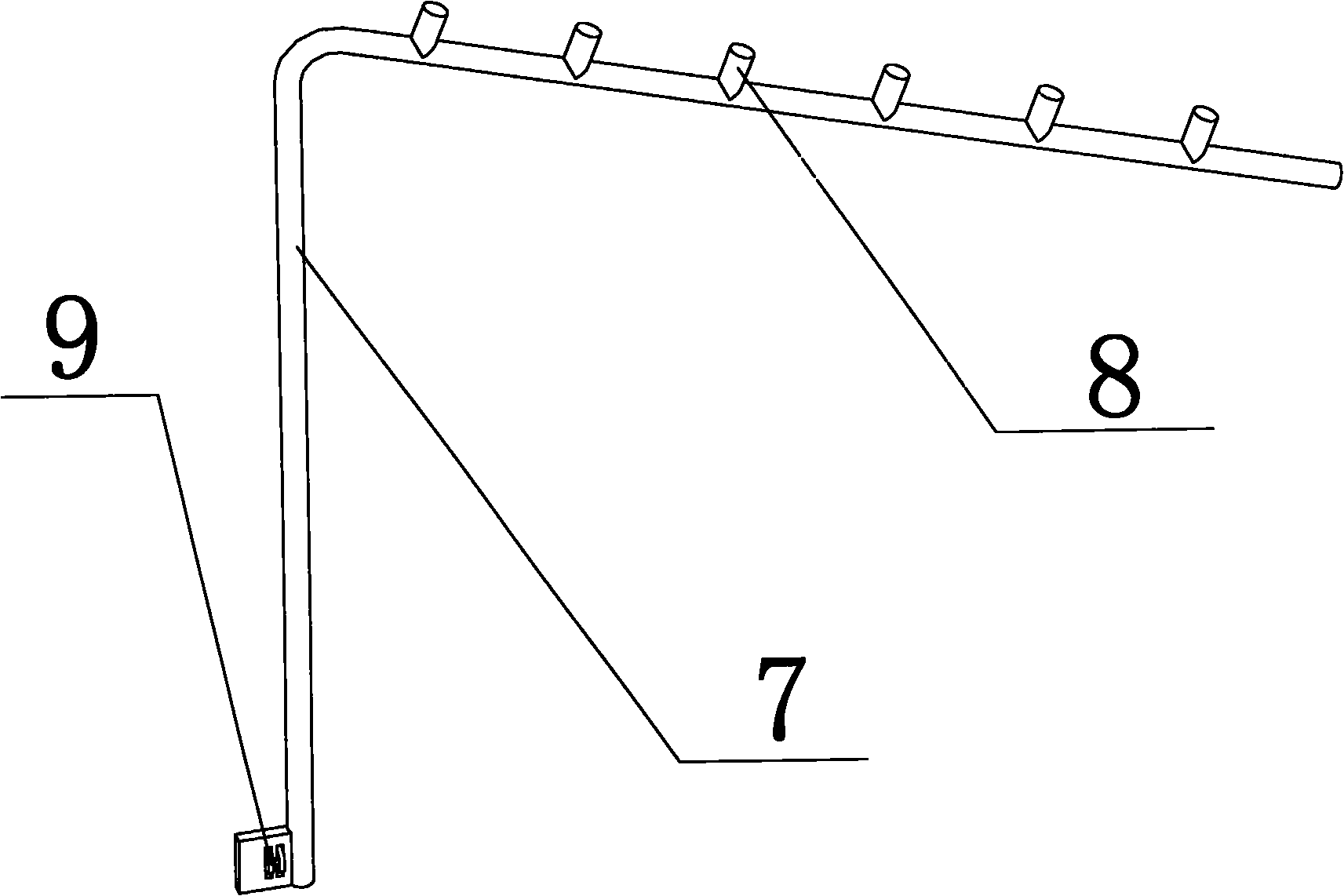

Coat-hat showing stand

InactiveCN101940418AIncrease or decrease the quantityMeet quantity requirementsShow shelvesShow hangersMechanical engineeringEngineering

The invention discloses a coat-hat showing stand. The coat-hat showing stand comprises a bracket; and the bracket comprises a base plate and an upright pipe vertically arranged, wherein the upright pipe is arranged in the middle of the base plate, the lower end of the upright pipe is fixed on the base plate by a plurality of discs, the peripheral surface of the upright pipe is uniformly provided with three hole groups vertically arranged, each hole group is formed by arranging a plurality of holes in a row, and a hanging rack can be inserted in each hole. The coat-hat showing stand has the advantages of meeting the quantity requirement on articles to be hung by increasing or decreasing the hanging racks, along with manual assembly, convenient disassembly and placement and saved space.

Owner:KUSN XINGYUE ZHAOYUAN METAL PRODS

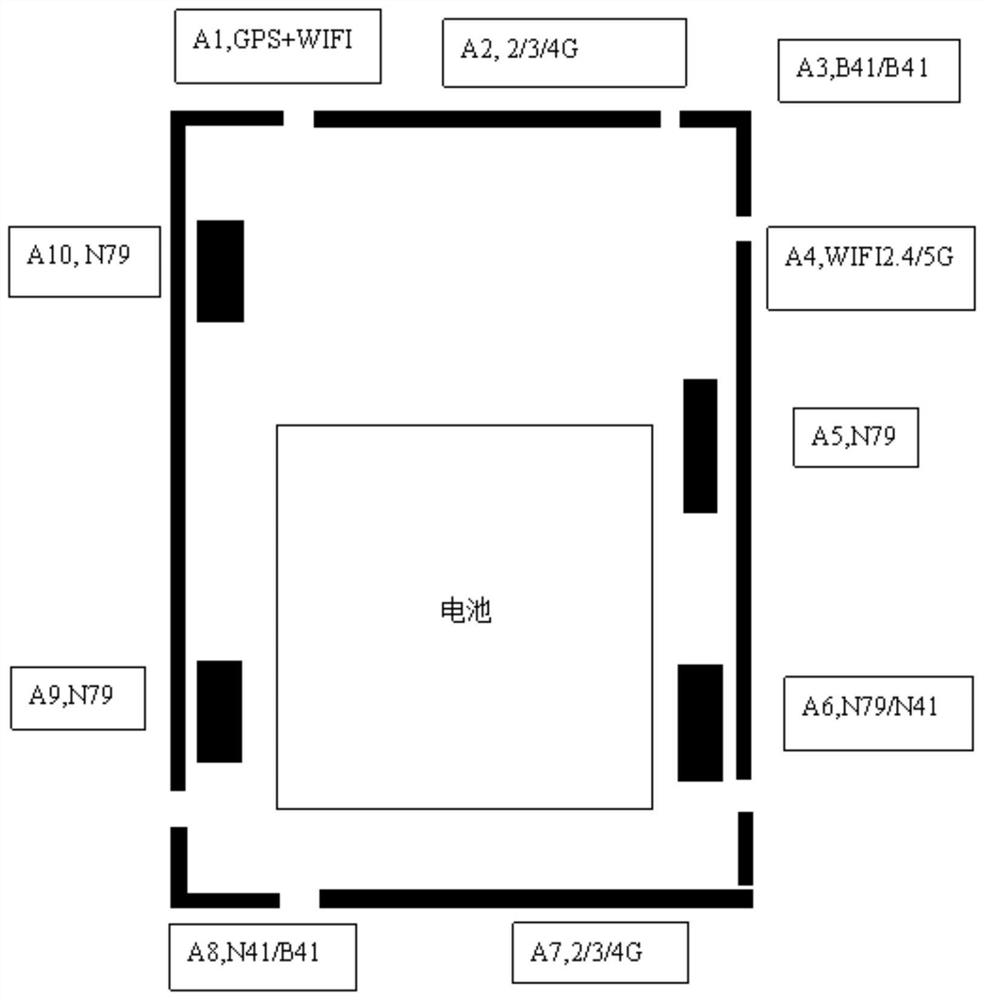

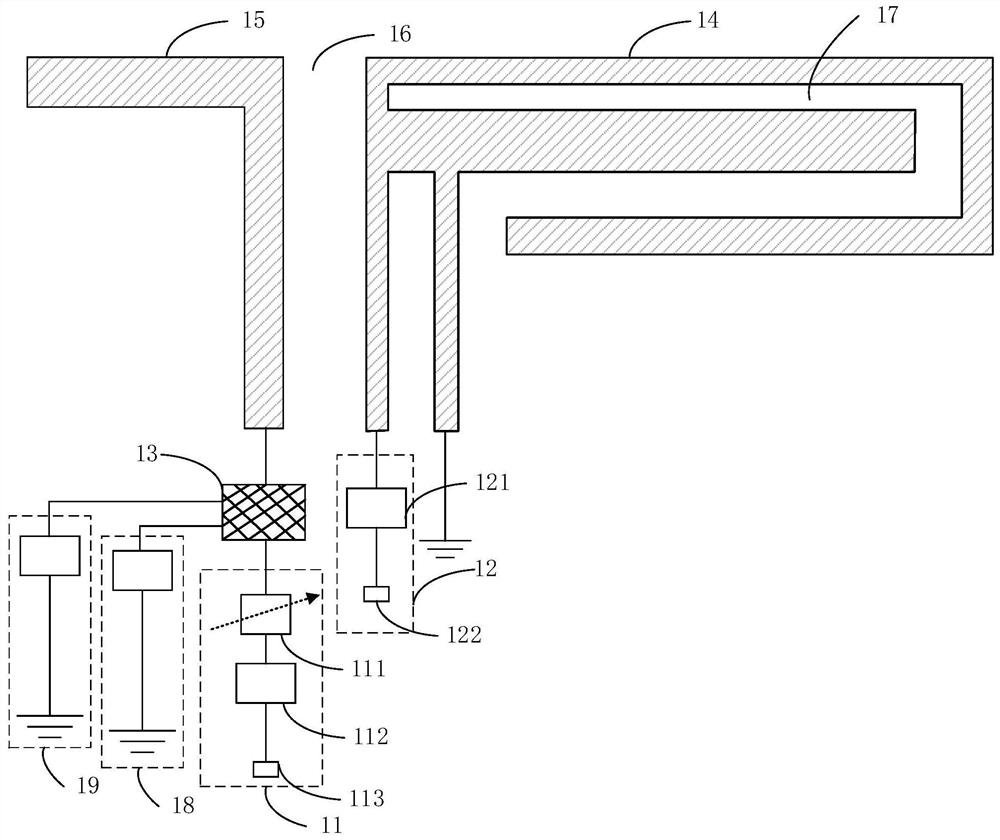

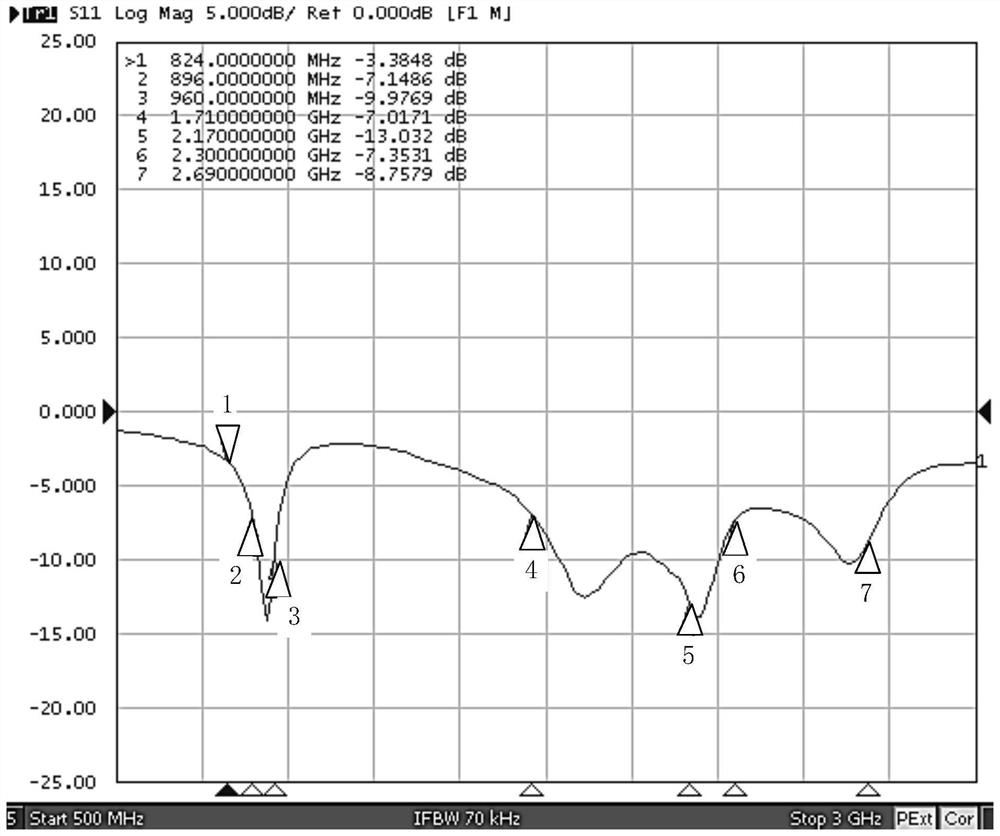

Antenna multiplexing system and terminal

PendingCN112838371ARealize multiplexingMeet quantity requirementsSimultaneous aerial operationsSlot antennasMultiplexingAntenna matching

The embodiment of the invention discloses an antenna multiplexing system and a terminal, wherein the antenna multiplexing system comprises an antenna body, a first antenna matching path, a second antenna matching path, a switching module and a control module, the resonant frequencies of the first antenna matching path and the second antenna matching path are different, and the control module is connected with the switching module; the antenna body comprises an antenna radiation branch knot and a coupling parasitic unit; the coupling parasitic unit is connected with the first antenna matching path through the switching module; the antenna radiation branch knot is connected with the second antenna matching path; and the coupling parasitic unit and the antenna radiation branch knot are mutually coupled through a first gap between the coupling parasitic unit and the antenna radiation branch knot to generate resonance. According to the embodiment of the invention, the multiplexing of the antenna can be realized, the requirements of various resonant frequencies on the number of antennas are met on the premise of not sacrificing the efficiency of the antenna, and the bandwidth and efficiency of the antenna are improved on the basis of saving the layout space.

Owner:ZTE CORP

Digital low-level control processor capable of flexibly configuring clock frequency

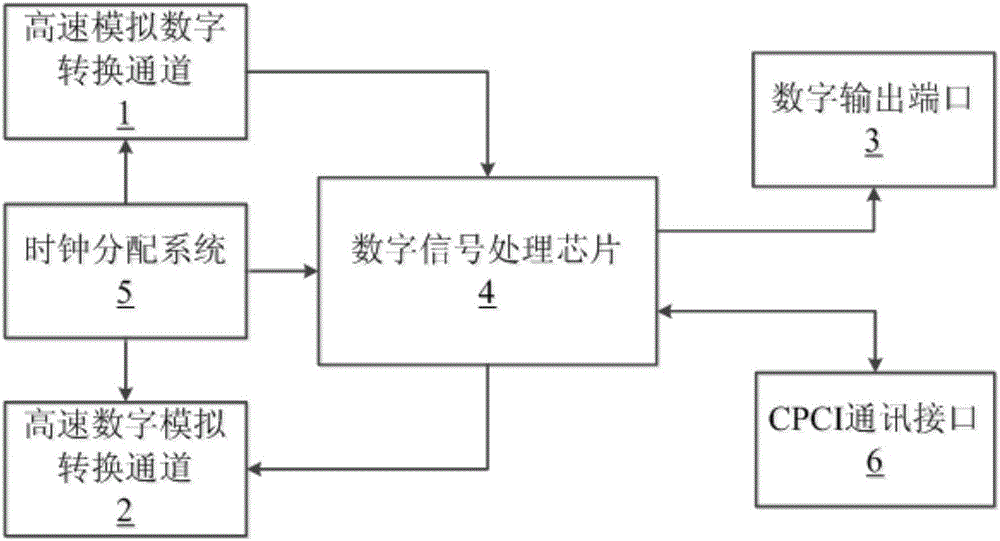

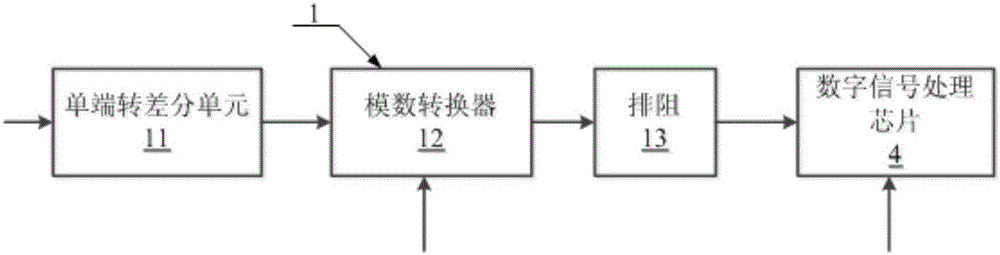

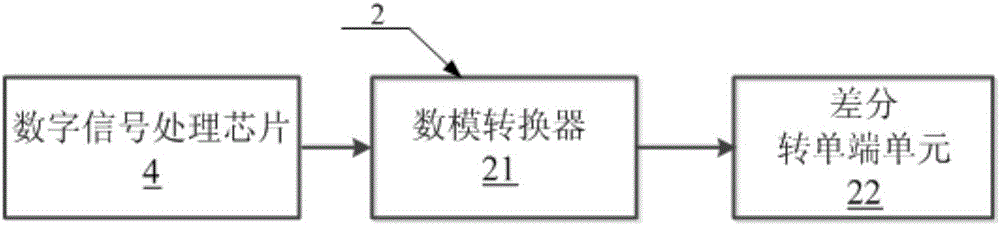

ActiveCN106155973AEasy to installRealize chain protectionPulse automatic controlElectric digital data processingDigital signal processingProcessor register

The invention provides a digital low-level control processor capable of flexibly configuring the clock frequency. The processor comprises a multi-path high-speed analog-digital conversion channel, a multi-path high-speed digital-analog conversion channel, a multi-path digital output port, a digital signal processing chip and a clock distribution system. The clock distribution system is used for providing clock signals for the digital signal processing chip and comprises a clock distribution chip and a CPLD chip. The clock distribution chip is used for sending clock signal to the digital signal processing chip according to input reference signals and configuration parameters of a clock distribution chip register, and the CPLD chip is used for setting configuration parameters and storing the configuration parameters. The digital low-level control processor capable of flexibly configuring the clock frequency integrates the clock distribution unit having a register parameter automatic response function and a multi-path fan-out function, the multi-path high-speed analog-digital conversion channel, a two-path high-speed digital-analog conversion channel and the multi-path digital output port, and has the advantages of being small in size, stable, reliable, economical and convenient to maintain.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

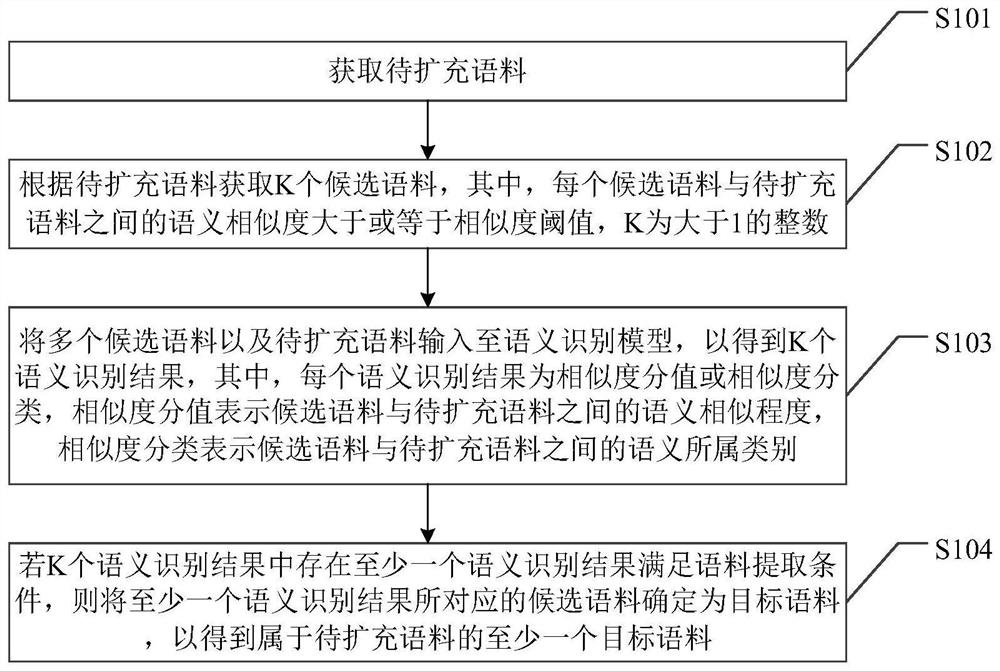

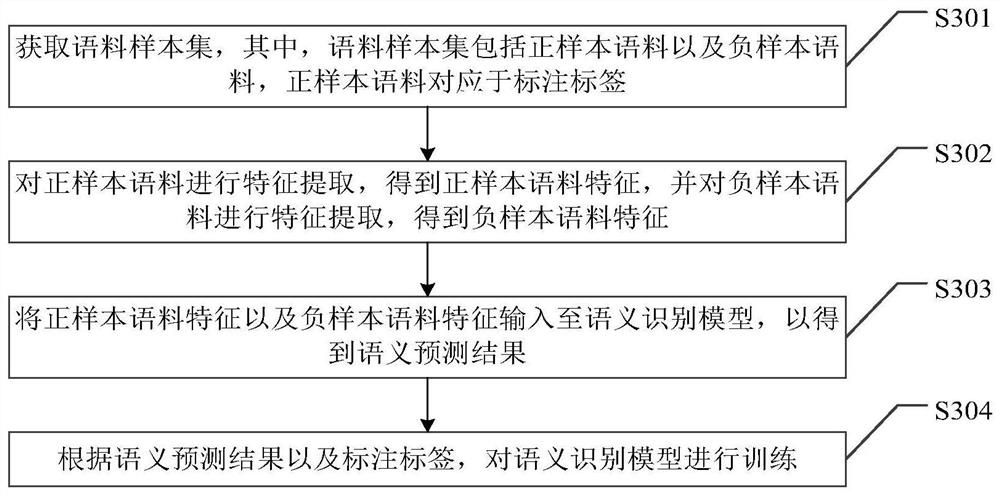

Corpus processing method, related device and equipment

PendingCN113821593AMeet quantity requirementsSemantic analysisText database queryingMedicineDegree of similarity

The embodiment of the invention discloses a corpus processing method, a related device and equipment, which are used for sufficiently expanding corpora to be expanded so as to meet the requirement of model training for the number of the corpora. The method of the embodiment of the invention comprises the steps that: corpora to be expanded are obtained, K candidate corpora are obtained according to the corpora to be expanded, and the K candidate corpora and the corpora to be expanded are input into a semantic recognition model so as to obtain K semantic recognition results, wherein each semantic recognition result is a similarity score or a similarity classification, the similarity score represents the semantic similarity degree between the candidate corpus and the corpus to be expanded, and the similarity classification represents the semantic category between the candidate corpus and the corpus to be expanded; and if at least one semantic recognition result in the K semantic recognition results meets the corpus extraction condition, the candidate corpus corresponding to the at least one semantic recognition result is determined as the target corpus to obtain at least one target corpus belonging to the corpus to be expanded.

Owner:TENCENT TECH (SHENZHEN) CO LTD

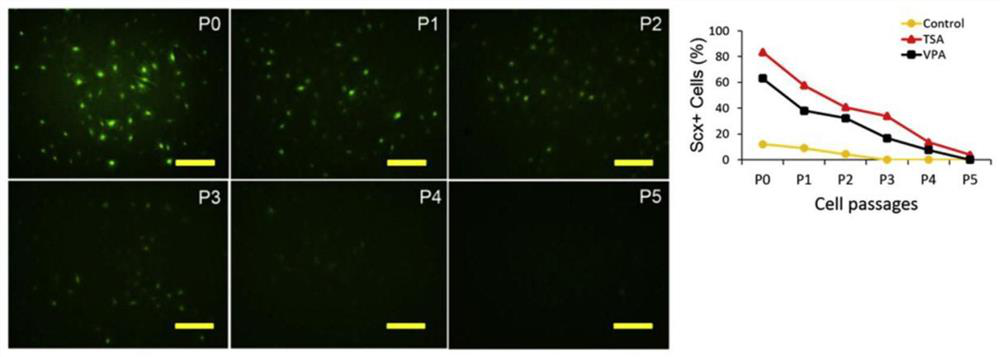

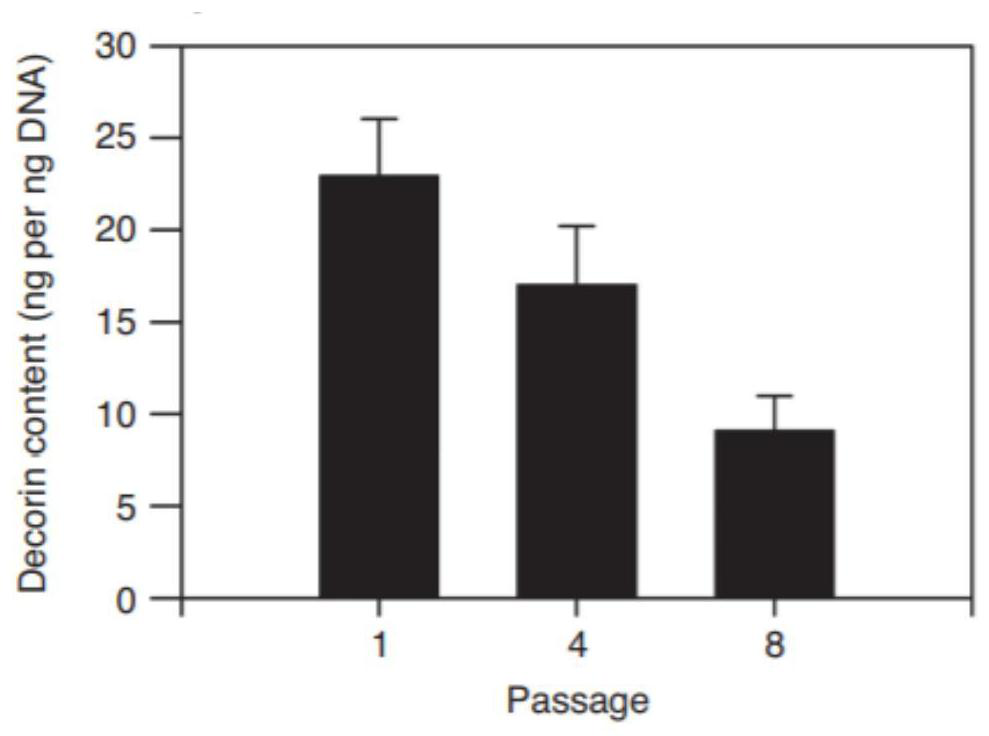

Bioactive substance composition, serum-free culture medium containing composition and application of serum-free culture medium

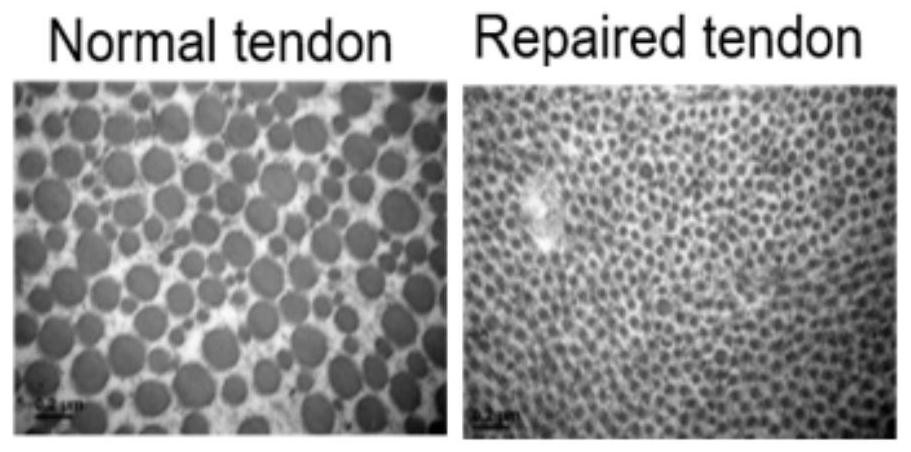

PendingCN113692282AHigh activityAchieve primary culturePeptide/protein ingredientsCulture processOrgan damageMotor system

The invention provides a bioactive substance composition, a serum-free culture medium containing the composition and application of the serum-free culture medium. The bioactive substance composition is used for a serum-free culture medium and / or a composition and preparation thereof; the serum-free culture medium and / or composition can be used for primary culture and subculture of cells and / or tissues. The cells are selected from any one or more of tendon and / or ligament source cells, chondrocytes, meniscus stem cells, mesenchymal stem cells, skeletal stem cells and muscle stem cells. The tissue is a source tissue of a motor system. The bioactive substance composition and / or the serum-free culture medium and / or the composition can be used for preparing a medicine for treating tissue and / or organ injury; the tissue or organ injury is selected from movement system tissue or organ injury.

Owner:ZHEJIANG UNIV

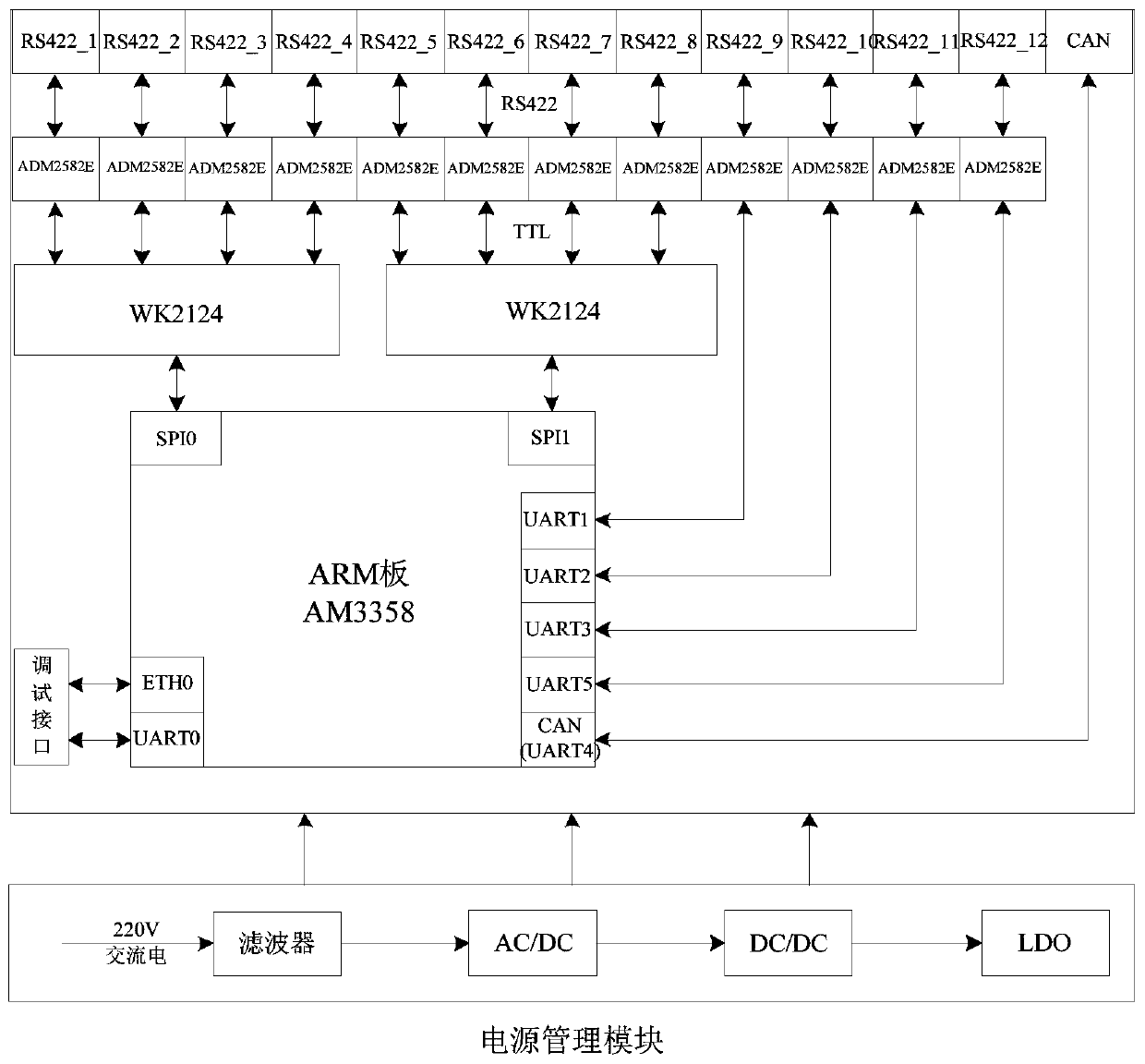

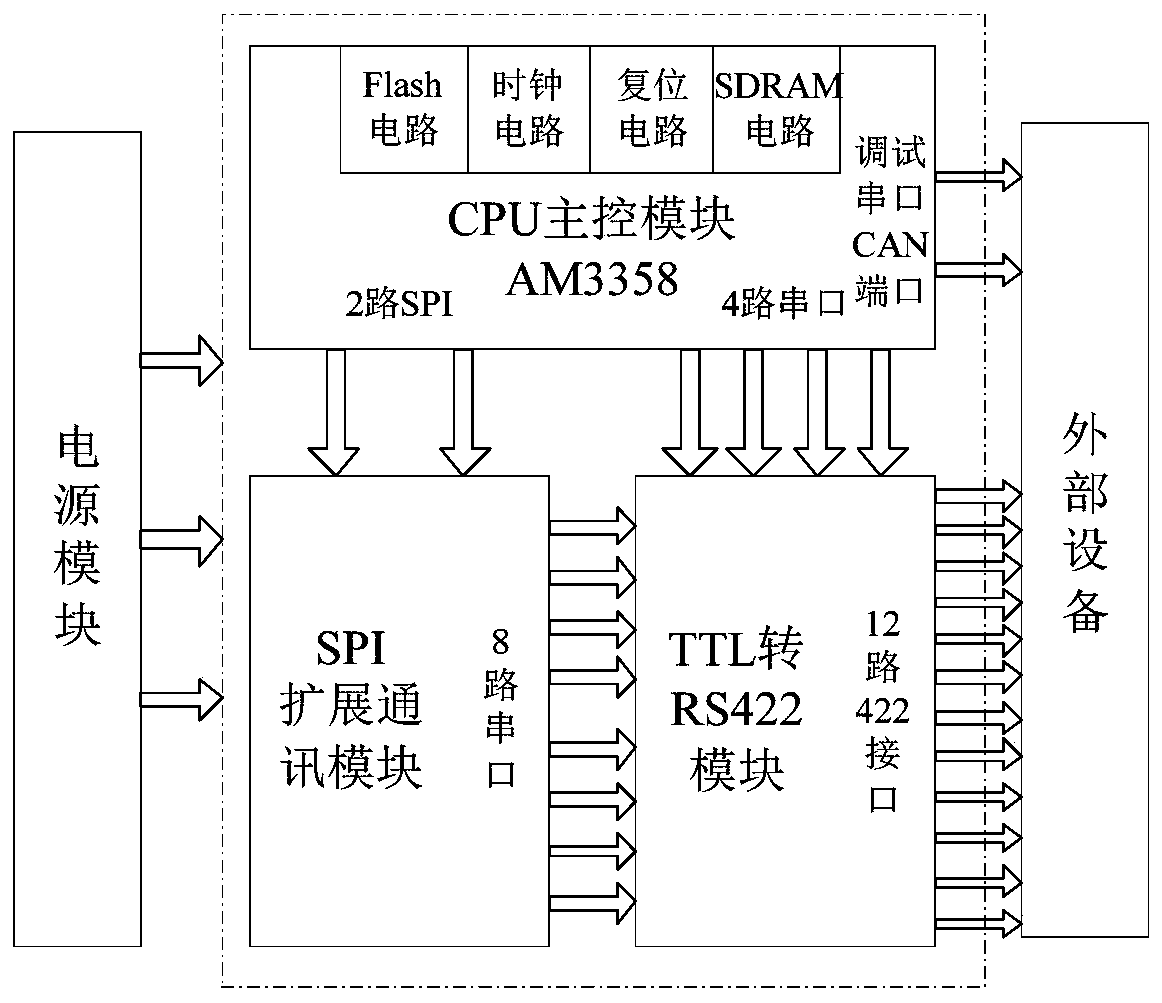

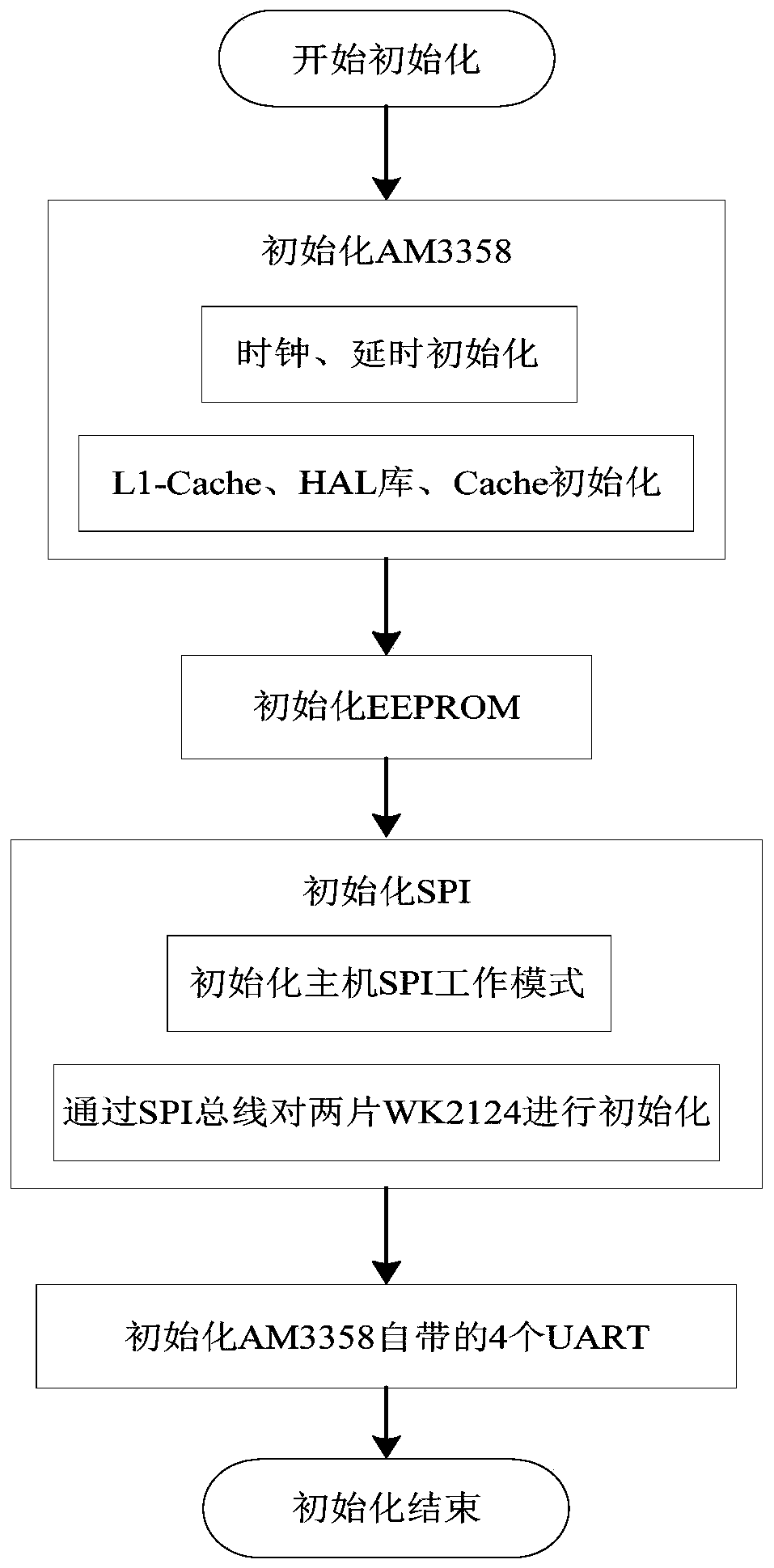

Information real-time interaction terminal based on embedded system

PendingCN110196830ARich communication interfaceLow costArchitecture with single central processing unitElectric digital data processingEmbedded systemPeripheral

The invention discloses an information real-time interaction terminal based on an embedded system. The information real-time interaction terminal comprises a CPU main control module, an SPI expansioncommunication module, a level conversion module and a power management module. The CPU master control module comprises a core processor AM3358, a reset circuit, a clock circuit, a download circuit, aFLASH circuit and an SDRAM circuit. The AM3358 is provided with six configurable serial ports and two high-speed SPI interfaces, the CPU main control module is connected with the SPI expansion communication module through a high-speed SPI interface, and the SPI expansion communication module converts an SPI signal into a serial port signal and transmits the serial port signal to the level conversion module; the CPU main control module can configure a serial port to be connected with the level conversion module and convert a received TTL level into an RS422 level to communicate with the external equipment, and the power supply management module supplies power to the system. According to the present invention, the problem that the communication serial ports are insufficient is effectively solved, and meanwhile the input and output states of the serial ports can be freely configured.

Owner:HARBIN ENG UNIV

Large-scale native chicken breeding method

Owner:昭通市昭阳区隐山居养殖有限公司

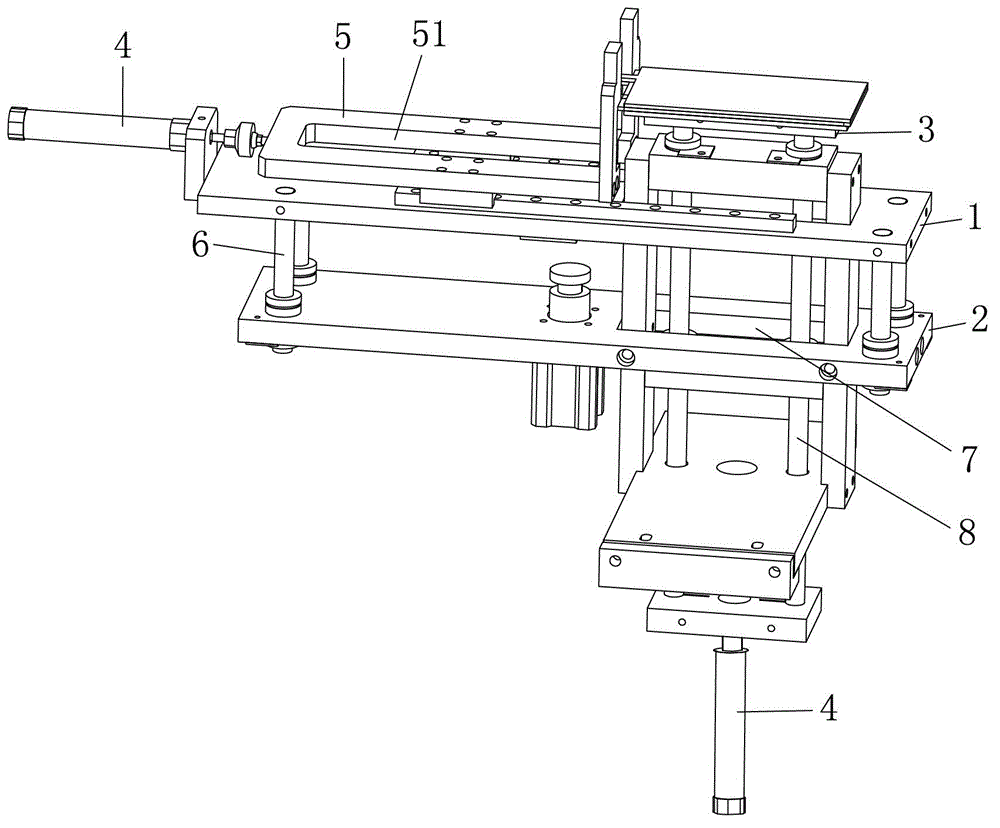

Pole plate assembling device of automatic piece coating machine

InactiveCN102867995AMeet quantity requirementsFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a pole plate assembling device of an automatic piece coating machine. The pole plate assembling device is arranged at a discharge port of the piece coating machine and comprises a retainer bracket, a retainer cylinder and a retainer plate, wherein the retainer cylinder drives the retainer plate to lift and descend through a transmission column; and the retainer plate is opposite to the discharge port of the piece coating machine. When a pole plate group falls down from the discharge port of the piece coating machine, the retainer plate supports the pole plate group, the retainer cylinder drives the retainer plate to descend by the height of one pole plate group through the transmission column, the space of one pole plate group is made to support the subsequent pole plate group, the descending height or lifting height of the retainer plate can be regulated by the retainer cylinder, and requirements on the quantity of pole plates in a pole group are met.

Owner:浙江长兴奥利尔科技股份有限公司

Continuous casting billet conveying device and method

PendingCN113522993AGuaranteed production effectGuaranteed outputWork heating devicesMetal rolling arrangementsHeat controlHeating furnace

The invention discloses a continuous casting billet conveying device and method, and belongs to the technical field of metallurgy. The continuous casting billet conveying device comprises a continuous casting machine tail end roller way, a straight roller way and a shared roller way, the straight roller way and the shared roller way are connected with the outlet end of the continuous casting machine tail end roller way, a first allocating device is arranged between the straight roller way and the shared roller way and used for allocating continuous casting billets, the outlet end of the shared roller way is connected with a first heating furnace, the straight roller way is connected with a rolling line, and the first heating furnace is connected with the rolling line through a first inlet roller way. By means of the device, when multi-strand continuous casting is conducted on double-rolling-line or single-rolling-line production, continuous casting straight rolling billets, uniform-temperature billets and cold billets can flexibly enter rolling lines for production, the requirements of different rolling lines for the temperature and number of different continuous casting billets are met, a production plan is reasonably arranged, and the production efficiency is improved; and heating control over the continuous casting billets can be arranged according to the actual conditions needed by the continuous casting billets and the rolling line, so that energy conservation and emission reduction of the working procedures are achieved, and meanwhile the normal production working procedures and yield of the rolling line under various conditions are guaranteed.

Owner:NANJING JINGHUANRE METALLURGICAL ENG CO LTD

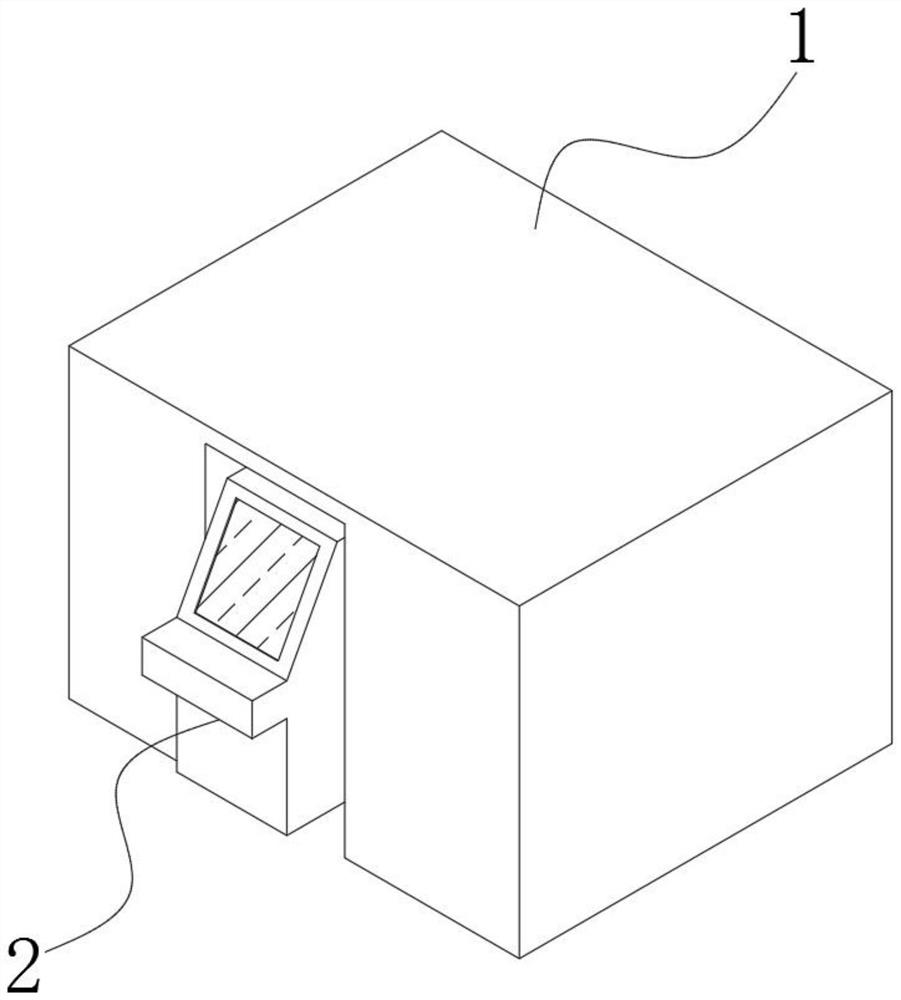

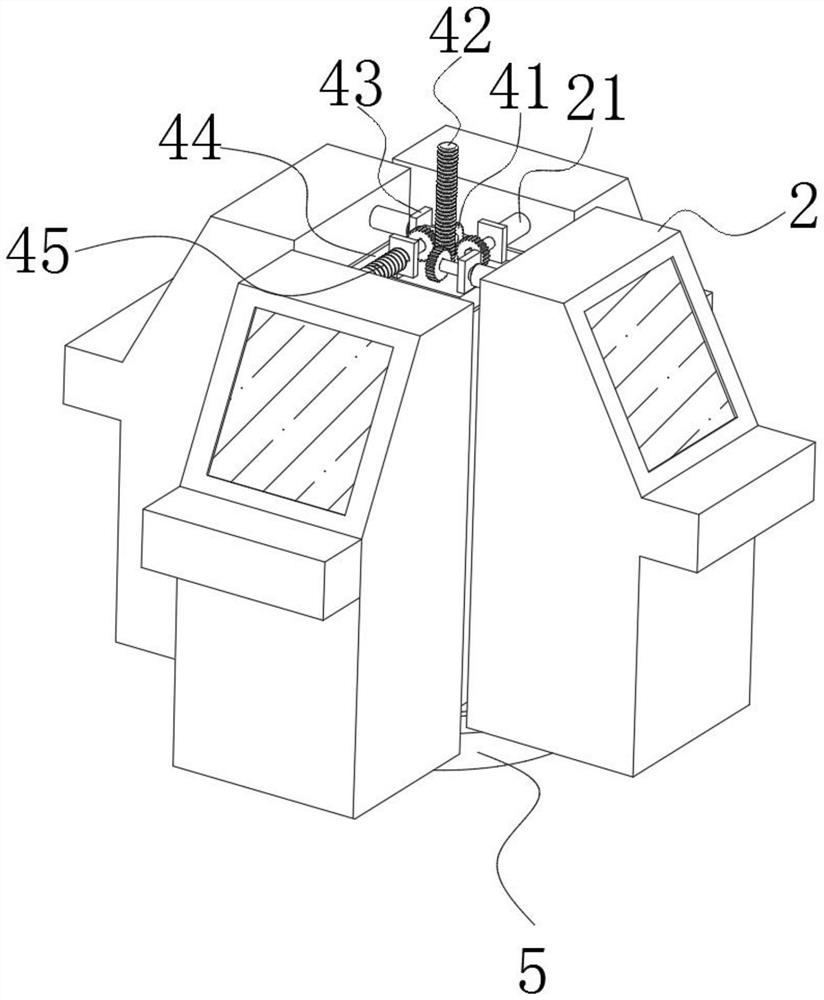

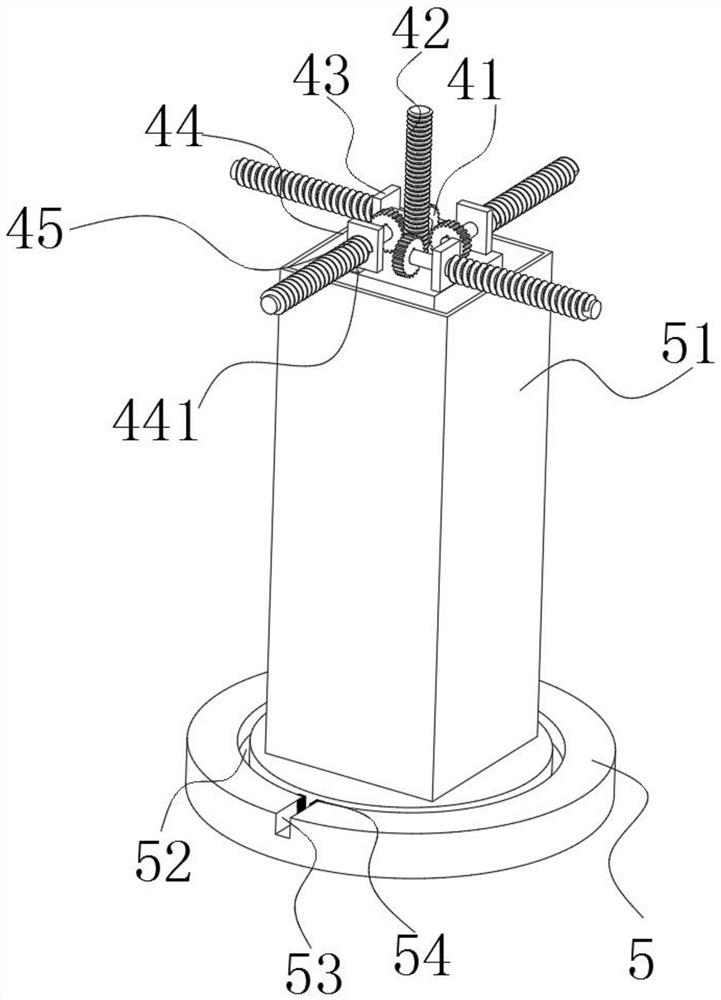

Intervening changeable virtual simulation teaching system

InactiveCN112002166AGuaranteed variabilityMeet quantity requirementsCosmonautic condition simulationsSimulatorsElectric machineryEngineering

The invention discloses an intervening changeable virtual simulation teaching system and relates to the technical field of teaching equipment production. The system specifically comprises a wall body,an operation table, a base and a teaching system, wherein a shell is fixedly mounted at a middle shaft of the top of the base, a mounting table is fixedly mounted at an edge of one side of the bottomsurface of the shell, a motor is fixedly mounted at the top of the mounting table, a bevel gear b is fixedly mounted at an output end of the motor, a rotating mechanism is fixedly mounted at the topof the bevel gear b, a rotating table and a driving motor are fixedly mounted at the top of the rotating mechanism, the rotating table keeps rotating in the vertical direction, and a moving mechanismis fixedly mounted at the middle axis of the bottom surface of the shell. According to the intervening changeable virtual simulation teaching system, the occupied space is fully utilized, it is guaranteed that the area in teaching can fully meet the requirement for the number of students, teachers can conduct unified control, a problem that due to the fact that the number of students is large, theteaching quality is low is solved, and operability and predictability of the teachers are very high.

Owner:NANJING XUANSHI QIYUAN SOFTWARE TECH CO LTD

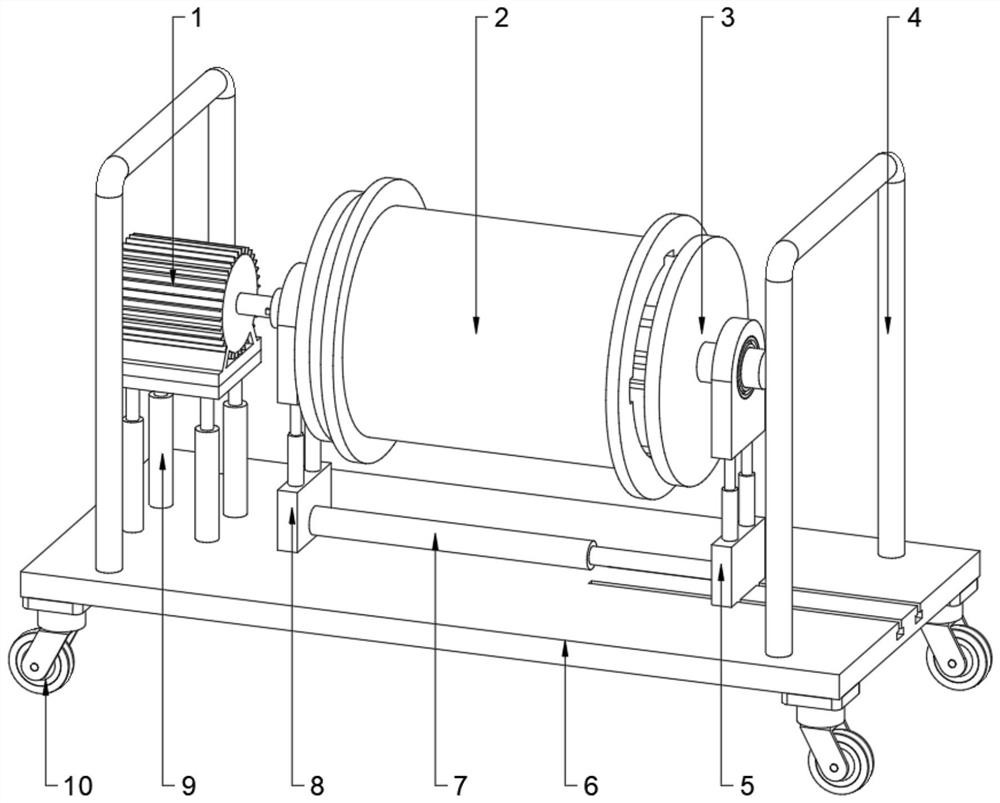

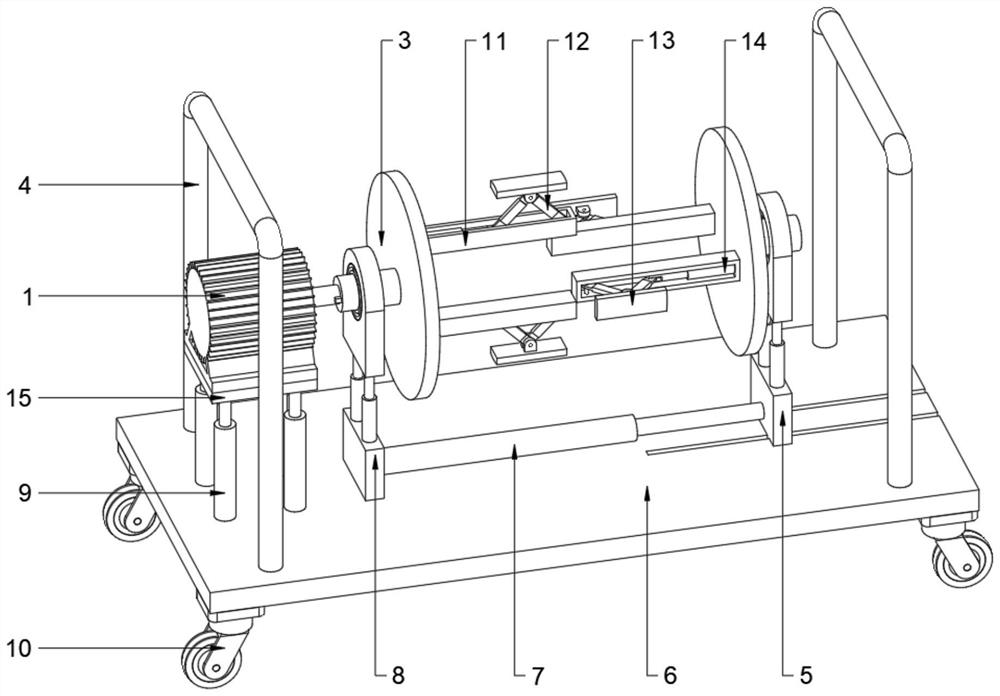

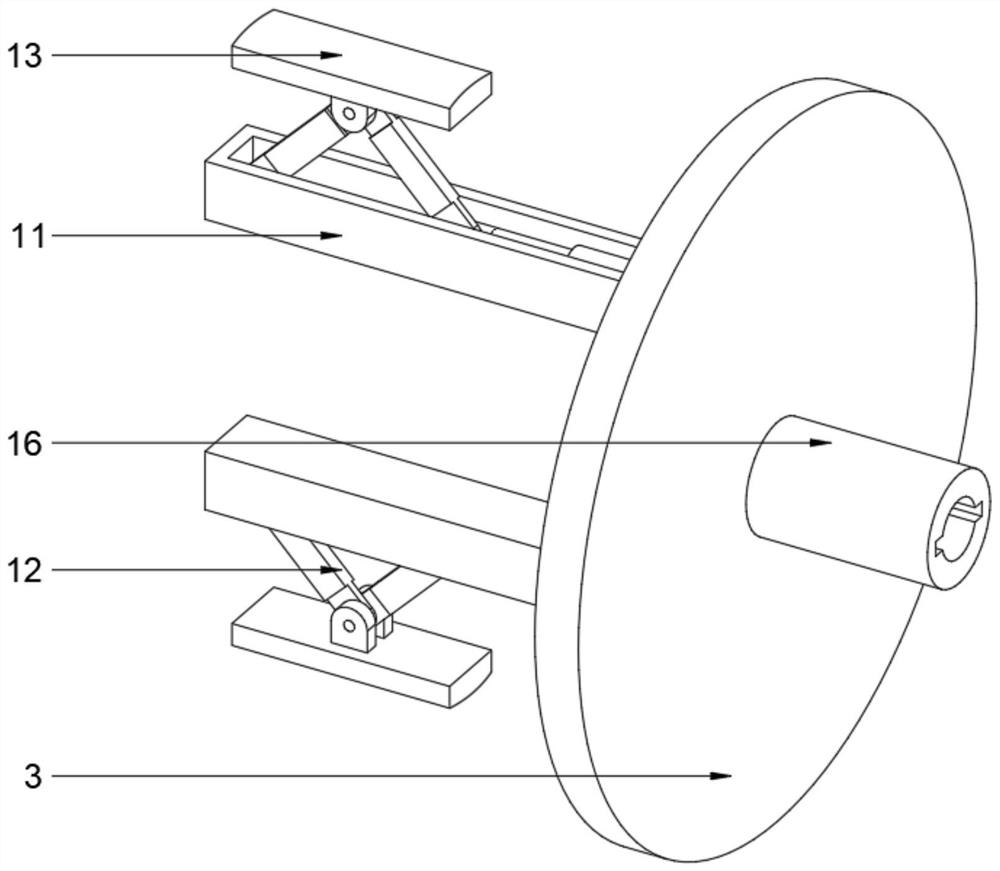

Power cable winding device

InactiveCN112239107AQuick snap-onFacilitate circumferential fixationFilament handlingPower cableEngineering

The invention discloses a power cable winding device which comprises a rack and a winding assembly arranged on the rack, and the rack is composed of a supporting plate and a rack bottom plate; the winding assembly comprises a supporting device rotationally installed on the supporting plate and a winding shaft sleeve arranged on the periphery of the supporting device in a sleeving mode, the supporting device comprises a supporting rotary disc, a supporting stop rod and a supporting stop block, and the supporting rotary disc is in linkage with the driving device and is fixedly connected with thesupporting stop rod; a rectangular groove is formed in the supporting stop rod, and a pushing device rotationally connected with the supporting stop block is installed in the rectangular groove; andthe pushing device comprises a supporting push rod and two groups of supporting connecting rods. According to the power cable winding device, the supporting stop rod and the supporting stop block arematched with the supporting push rod and the supporting connecting rods, a fixed supporting plate and a movable supporting plate are matched with telescopic rod, rapid clamping and dismounting of winding shaft sleeves with different diameters and lengths can be achieved, the flexibility is high, and the application range is wide.

Owner:马灿芳

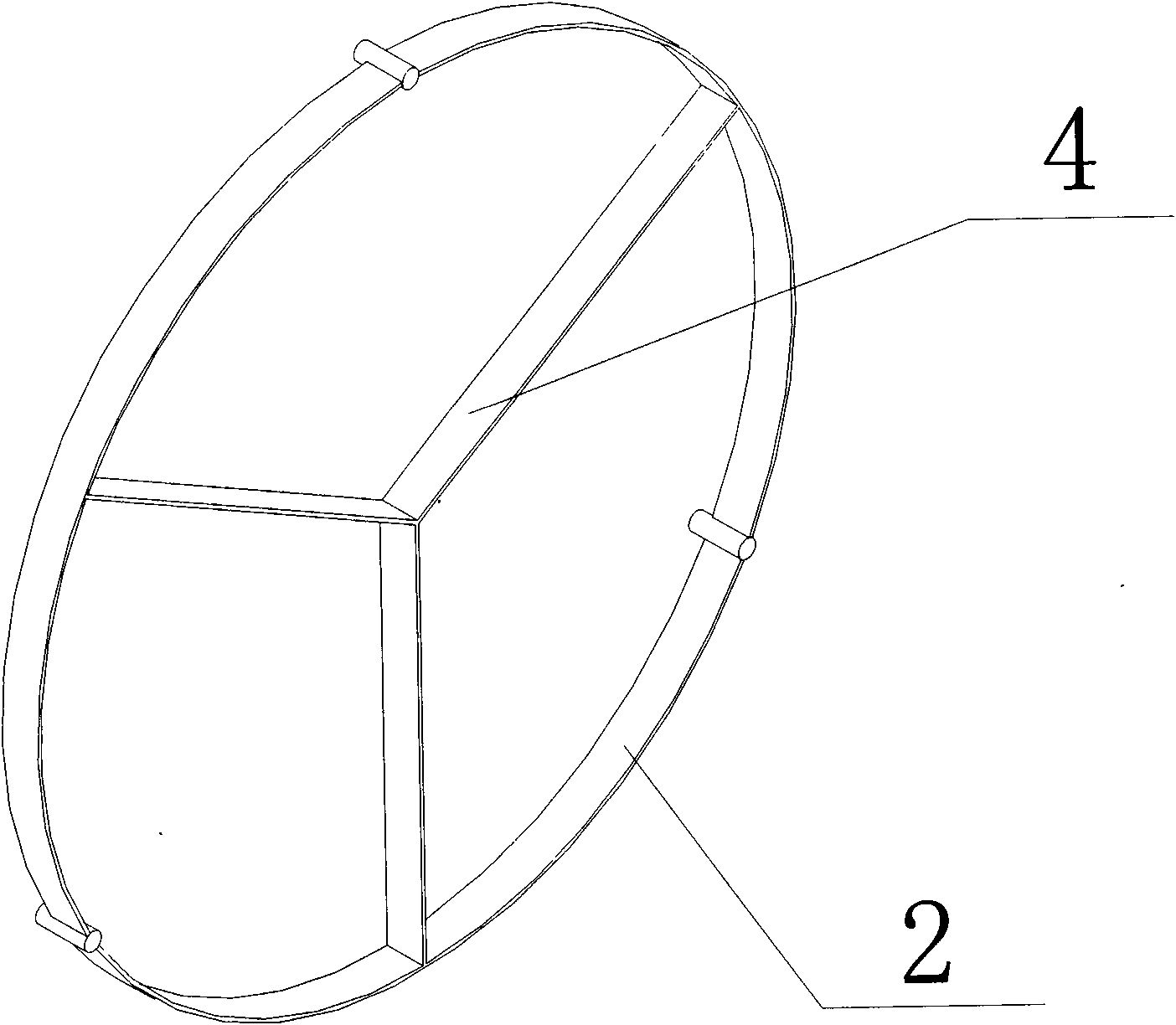

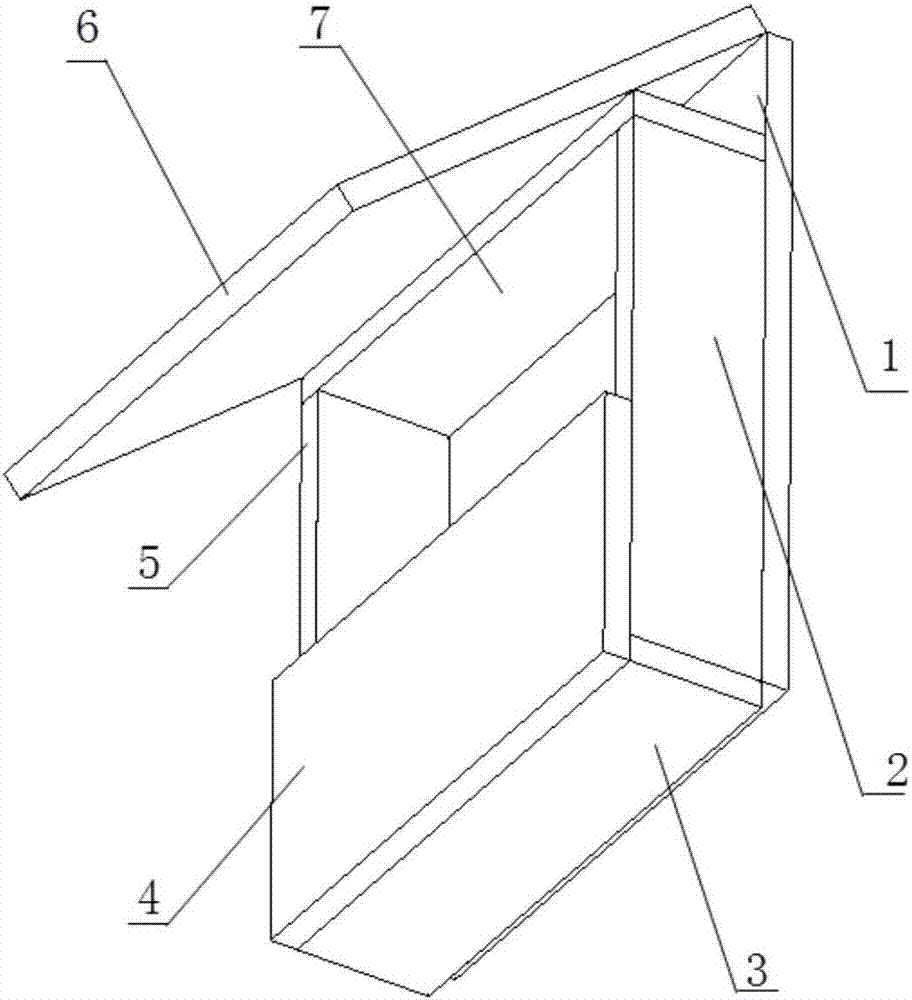

Artificial nest and full-automatic artificial nest manufacturing machine

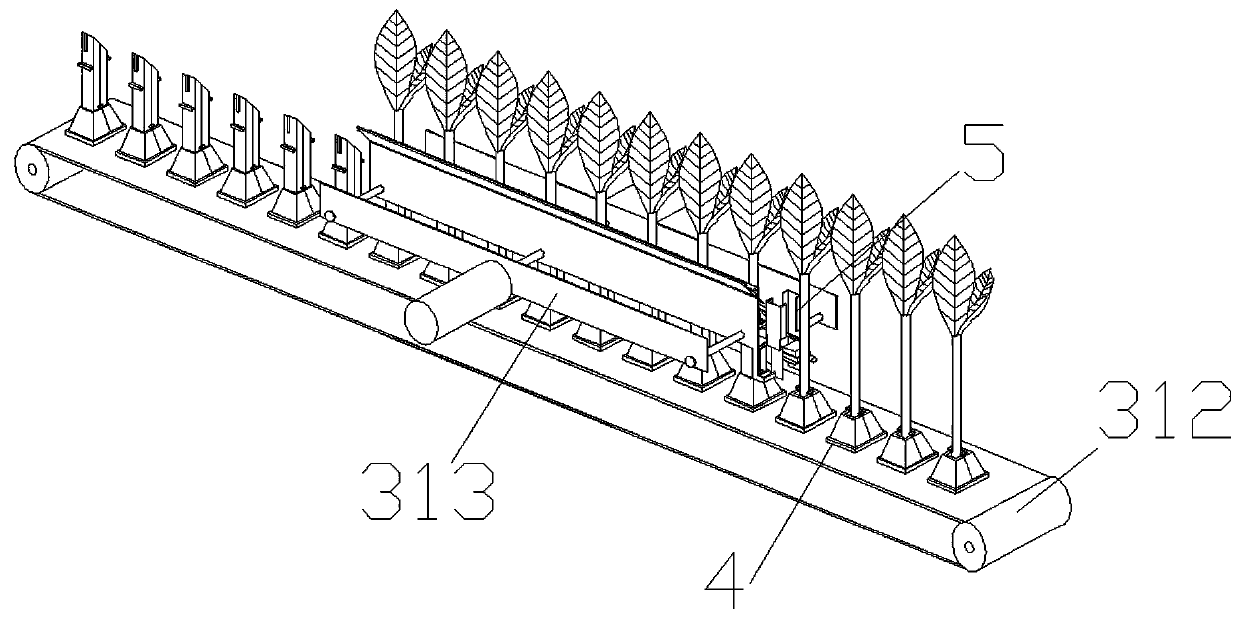

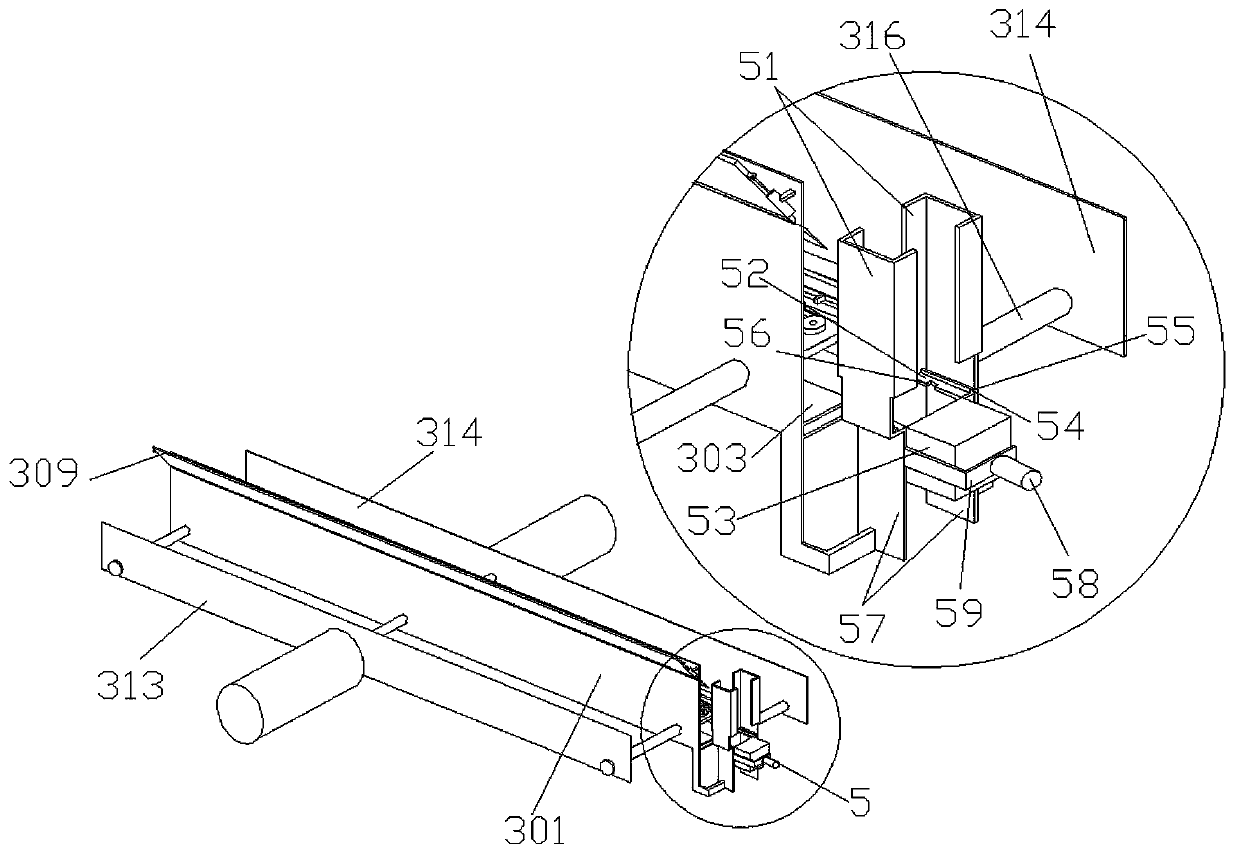

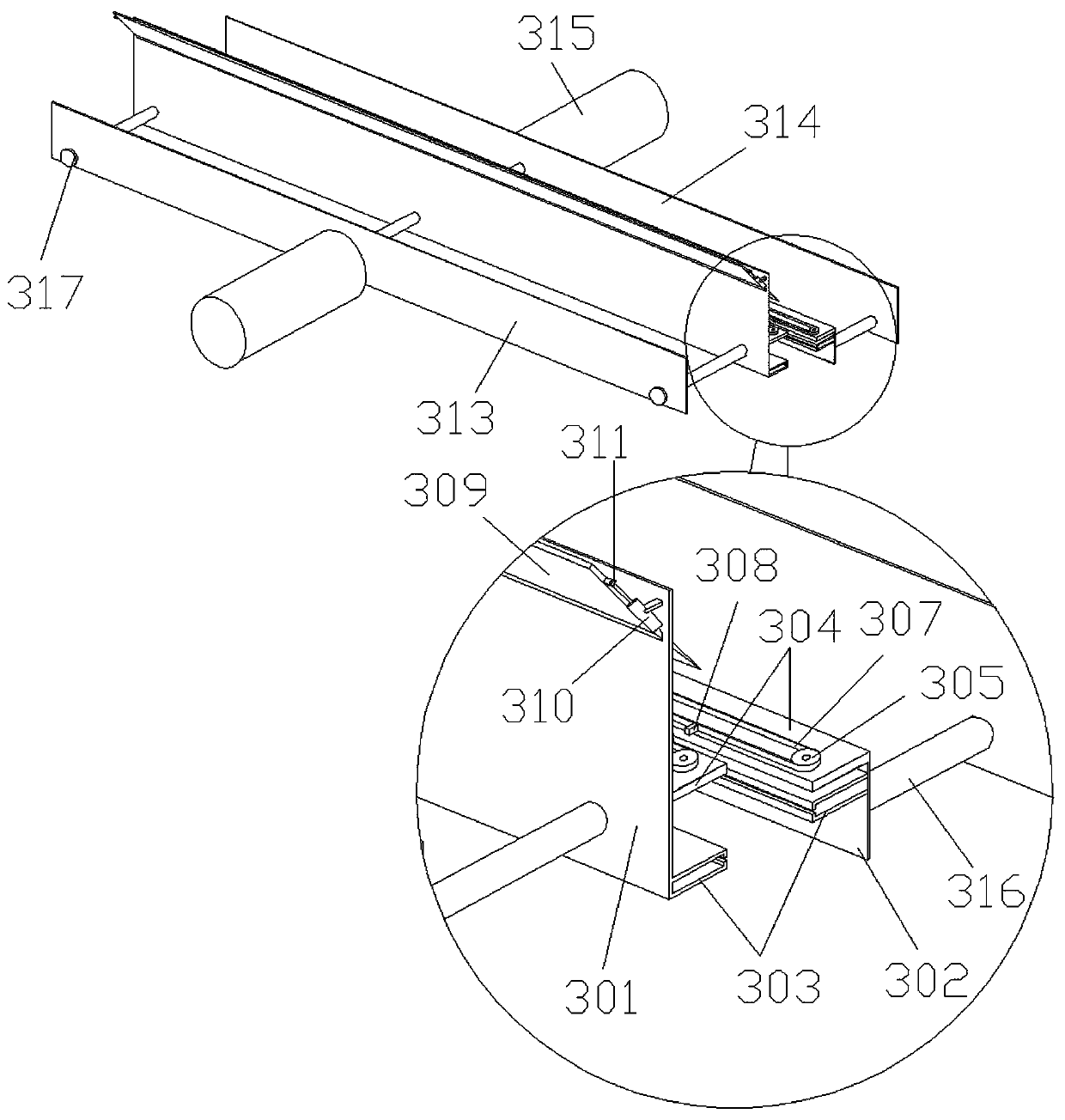

InactiveCN107087557AReasonable structureRealize fully automatic productionBird housingsEavesEngineering

The invention provides an artificial nest. A nest cell body is composed of a back plate, a frame which is installed on the front surface of the back plate and composed of four rectangular plates, a baffle plate in the front of the frame and an eave plate on the top of the back plate. The plates are the same in thickness, and one edges of the plates are the same in width. The invention further provides a full-automatic artificial nest manufacturing machine which comprises a transmission cutting unit and a mold assembling unit. According to the artificial nest and the full-automatic artificial nest manufacturing machine, one complete plate can be used for completing artificial nest manufacturing from cutting to assembling and connecting of the artificial nest in a full-automatic mode, the modeling of the manufactured artificial nest is suitable for various birds to live in, the effects of sheltering from wind and rain and keeping the temperature are achieved, low-cost mass production can be achieved, and particularly the requirements for the artificial nest number and quality of a bird attracting project can be met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

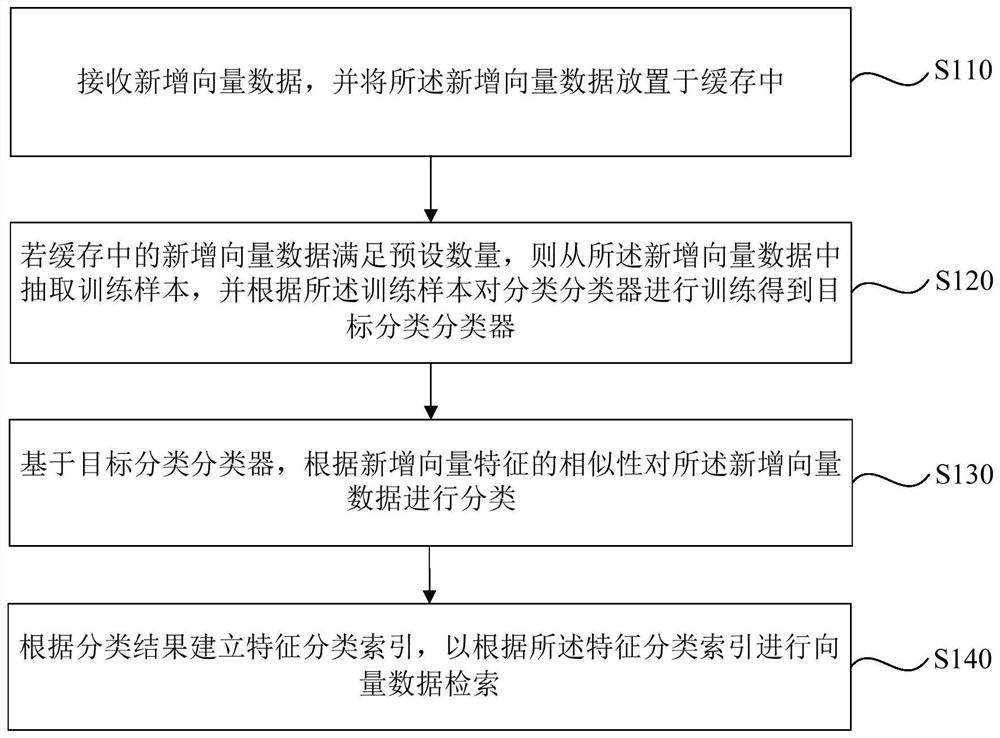

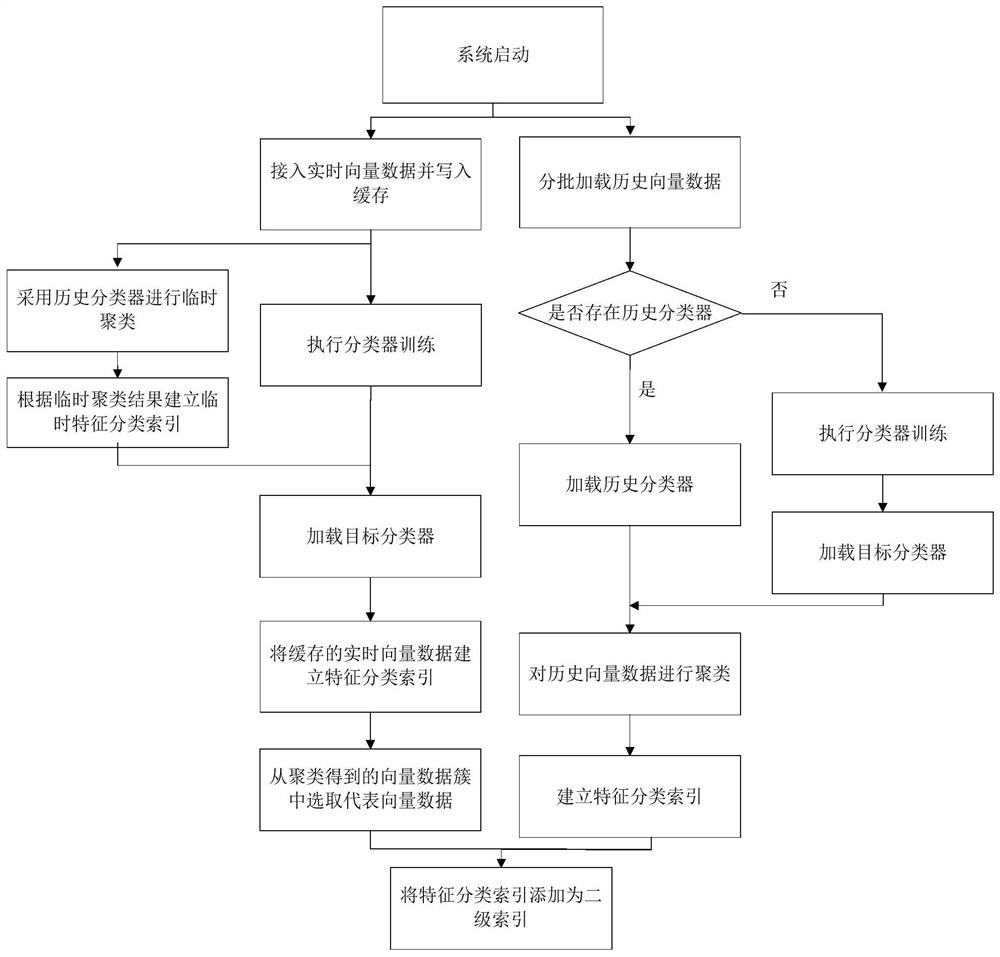

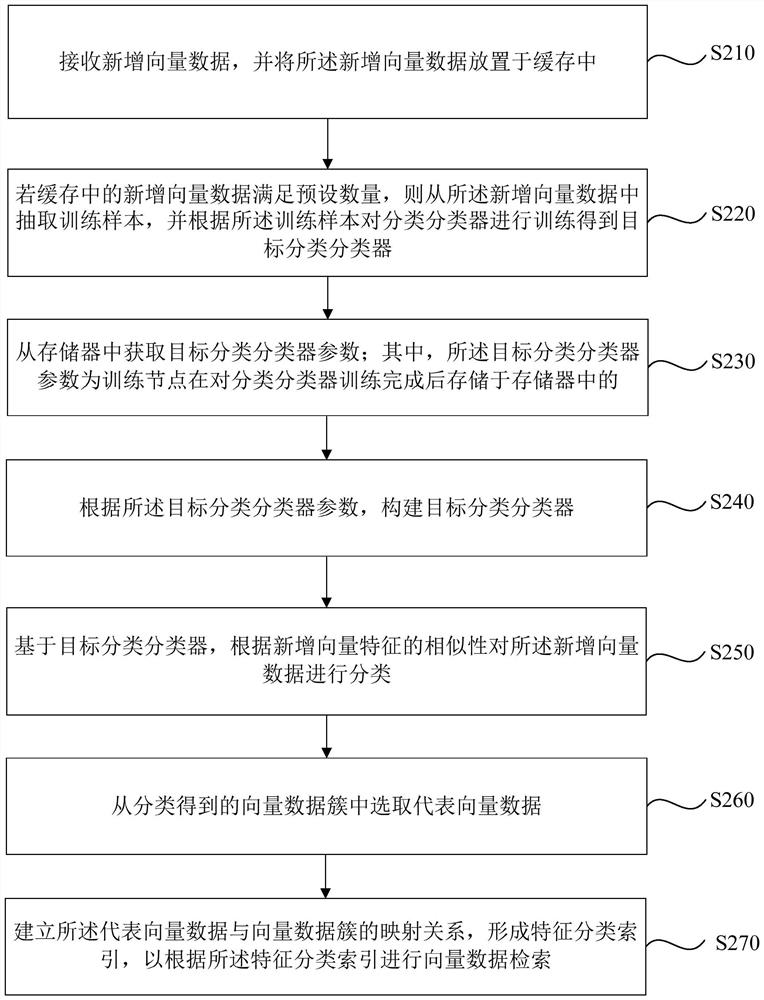

Vector data processing method and device, equipment and storage medium

PendingCN114077858AImprove efficiencyMeet quantity requirementsCharacter and pattern recognitionOther databases indexingData setData retrieval

The embodiment of the invention discloses a vector data processing method and device, equipment and a storage medium. The method comprises the following steps: receiving newly added vector data, and placing the newly added vector data in a cache; if the newly added vector data in the cache meets a preset quantity, extracting a training sample from the newly added vector data, and training a classifier according to the training sample to obtain a target classifier; based on a target classifier, classifying the newly-added vector data according to the similarity of newly-added vector features; and establishing a feature classification index according to a classification result, and performing vector data retrieval according to the feature classification index. According to the scheme, the newly added vector data can be trained in a targeted manner, the training time is saved under the condition that the vector data is continuously increased, the training complexity is reduced, the problem that the sampling and training time is increased when the data set is continuously expanded is solved, and the processing efficiency is improved.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

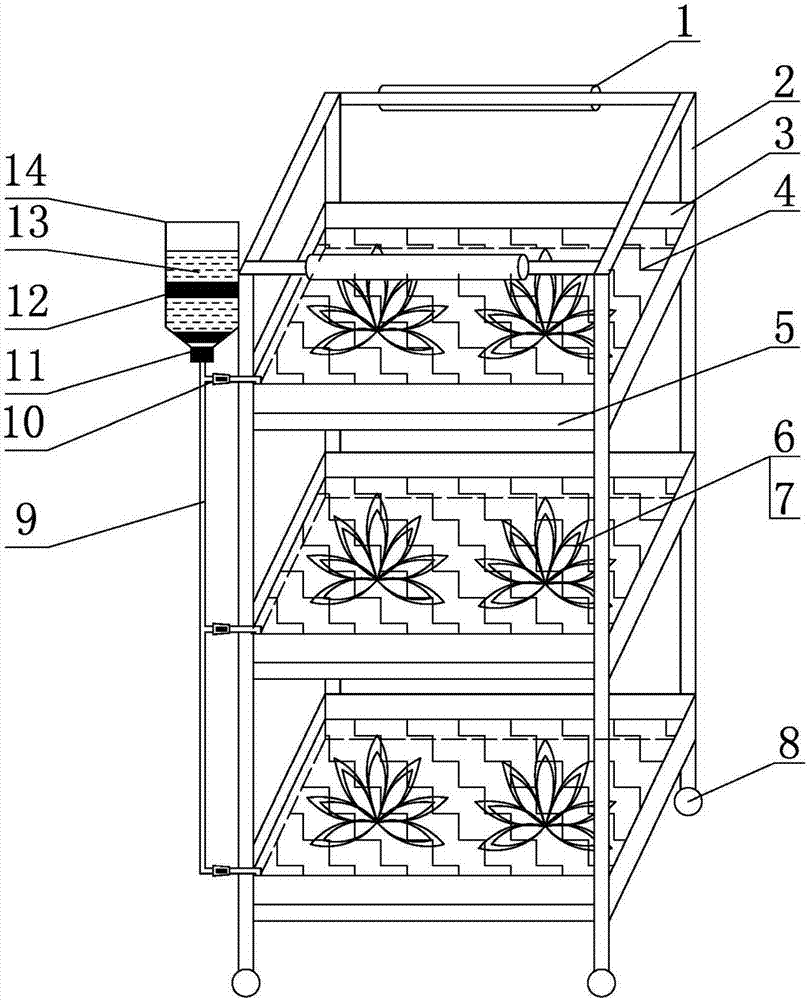

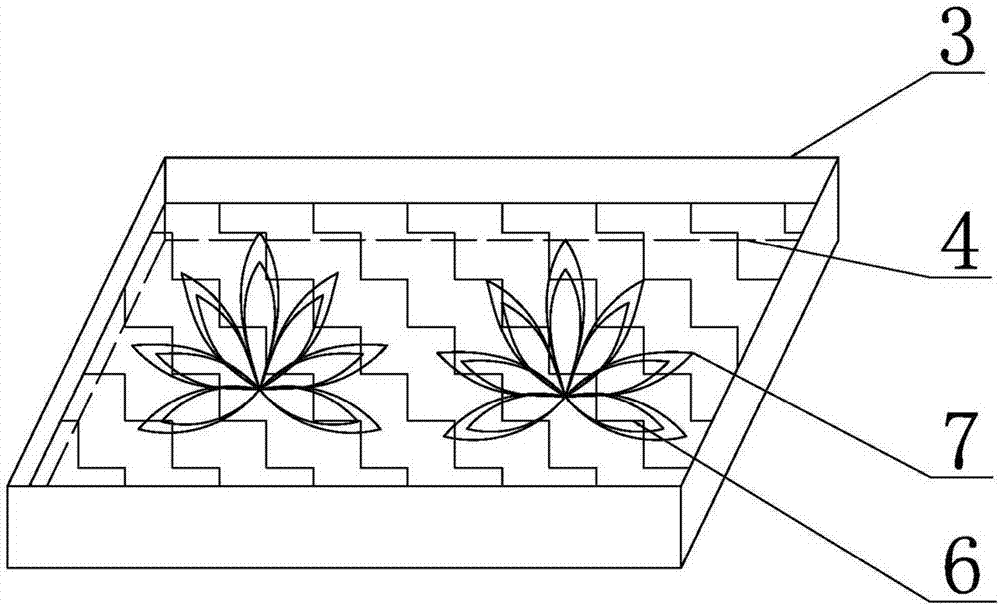

Mononychellus tanajoa experimental population feeding device and method

The invention provides a mononychellus tanajoa experimental population feeding device and method. The mononychellus tanajoa experimental population feeding device comprises an insect feeding frame, insect feeding trays, baffles and a water supplementing bottle, wherein the insect feeding frame is of a frame structure, the baffles are arranged on the insect feeding frame, the insect feeding trays are placed on the baffles, and slide rail sliding channels are formed in steel angles at the two sides of each baffle; the insect feeding trays can slide on the slide rail sliding channels in the insect feeding frame, sponge and host leaves are sequentially overlapped on the insect feeding trays, and tissue soaked in water is arranged on the side edges of the host leaves and makes contact with the host leaves; the water supplementing bottle is hung at the top end of the insect feeding frame and contains deionized water, a seal plug is arranged on an opening of the water supplementing bottle, a hose is inserted in the seal plug and stretches to the sponge in each insect feeding tray through a three-way valve, and control valves are arranged at the tail end of the hose to adjust the flow of water entering the insect feeding trays.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

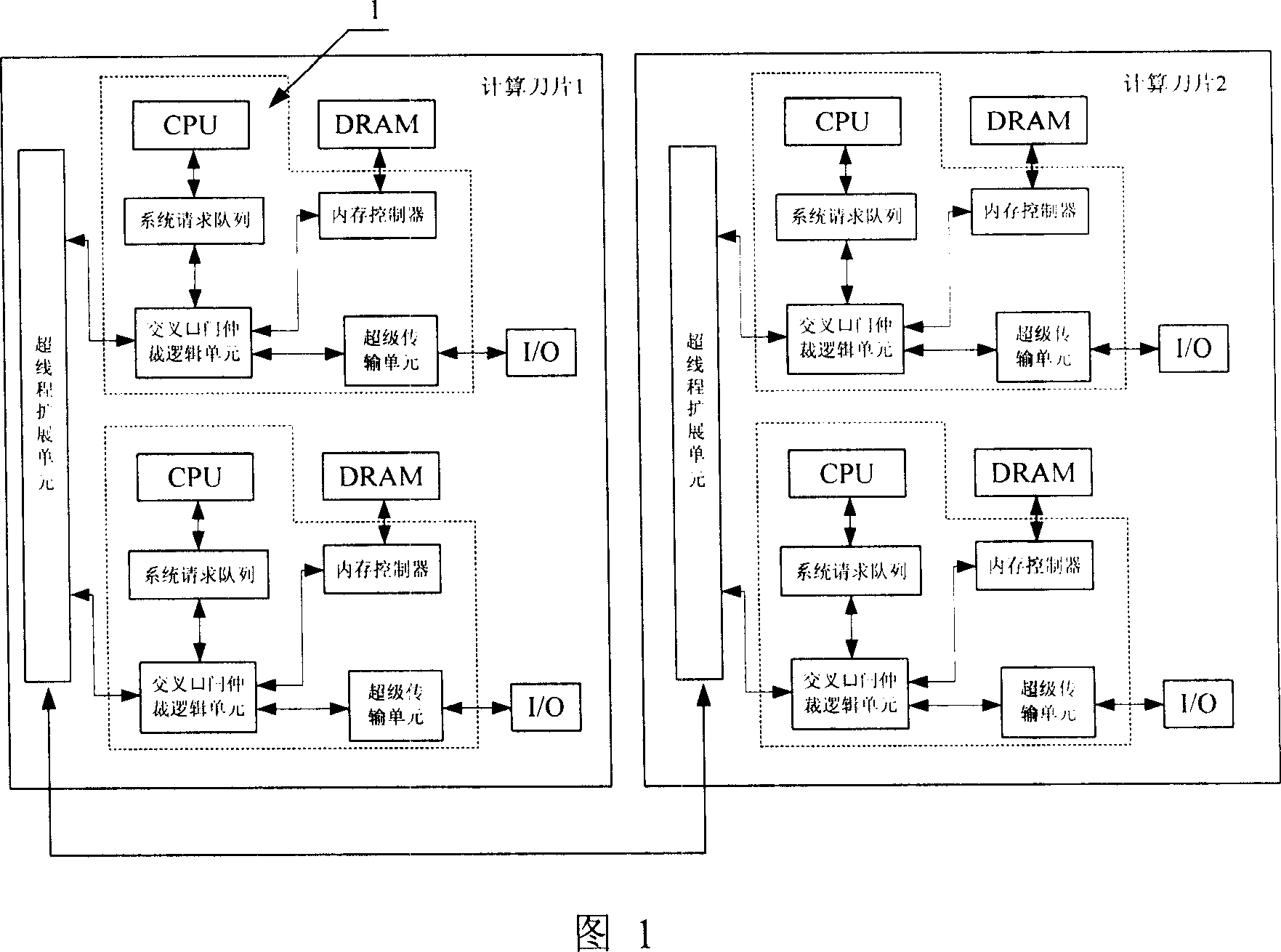

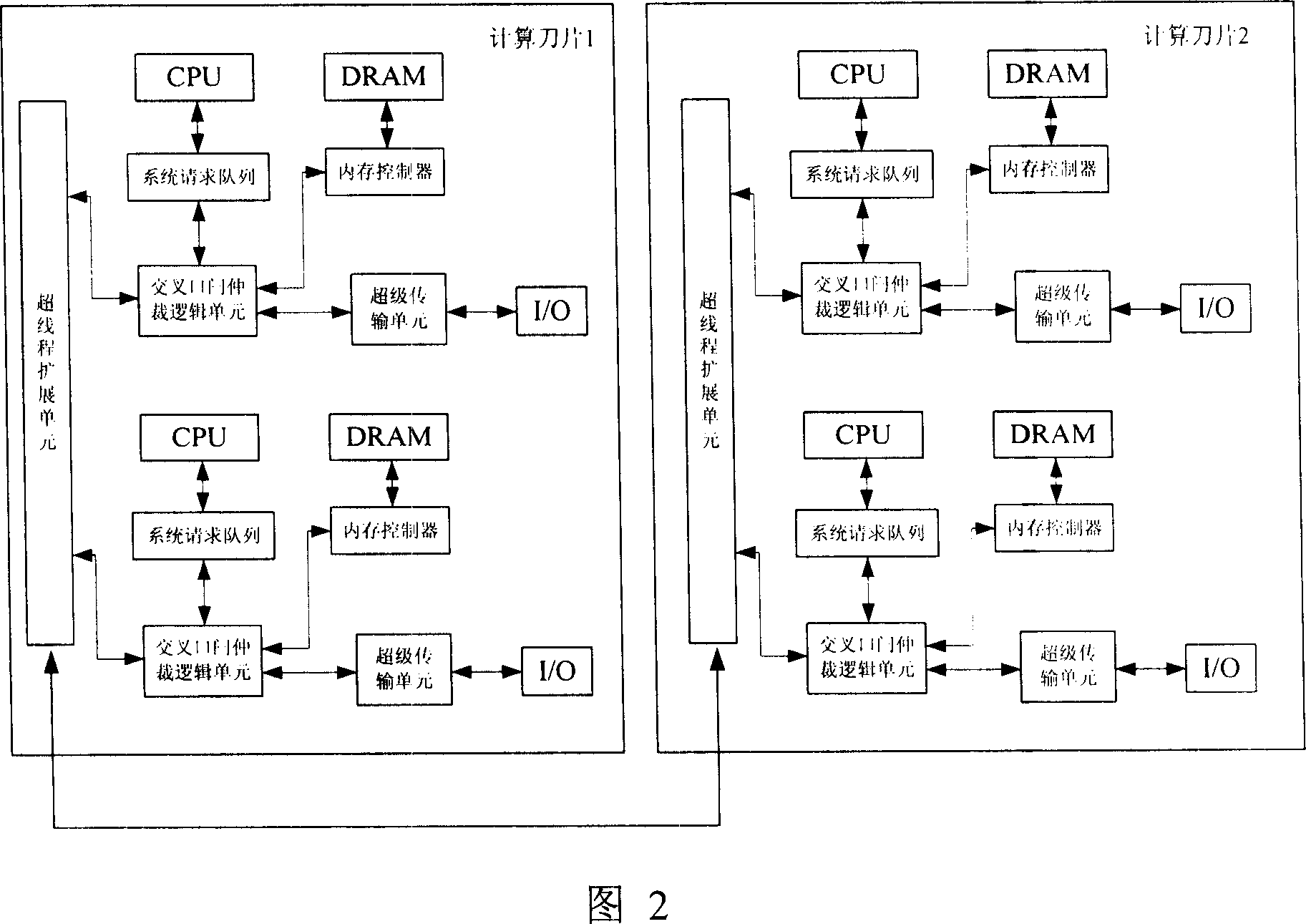

Symmetrical multiple processor blade server

ActiveCN101059792AFast operationImprove scalabilityMultiple digital computer combinationsMulti processorChipset

The invention discloses a symmetry multi-processor blade server, belonging to blade server technical field, for resolving the defects of prior blade server which has inadequate CPU number, to fail to meet applications. The invention can provide a multi-path operation condition with 8 paths, 16 paths or 32 paths, or the like to meet large operation need of user. The invention comprises at least two calculation blades, while each calculation blade is at provided with a CPU chip group, wherein each calculation blade is provided with an ultra-process expander, the CPU chip groups of each operation blade and the CPU chip groups of different calculation blades are connected via the ultra-process expander. The invention more particularly can be used for the application with massive data.

Owner:DAWNING INFORMATION IND BEIJING +1

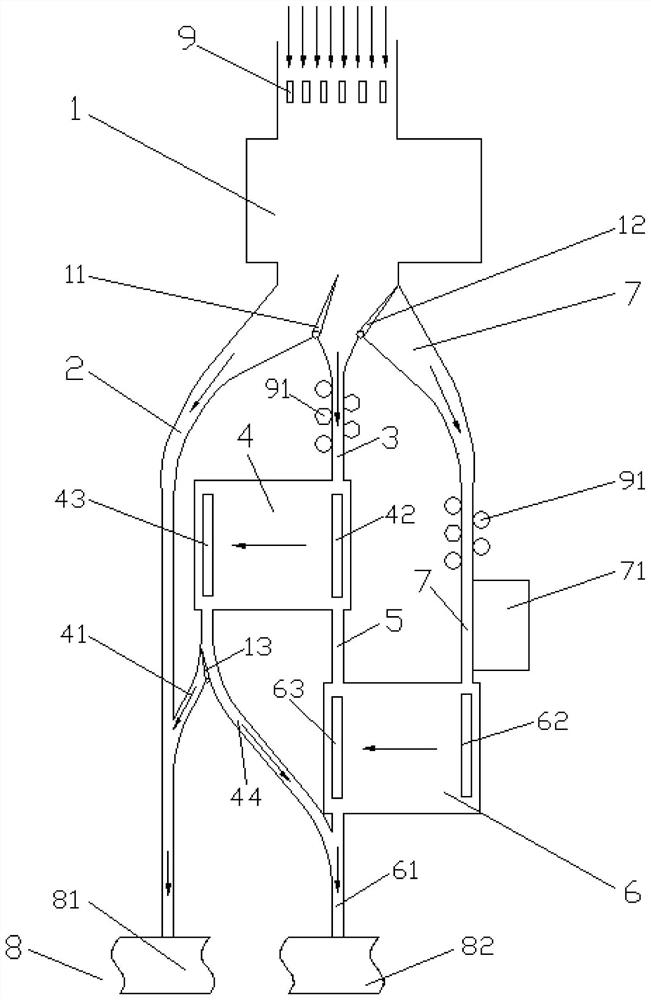

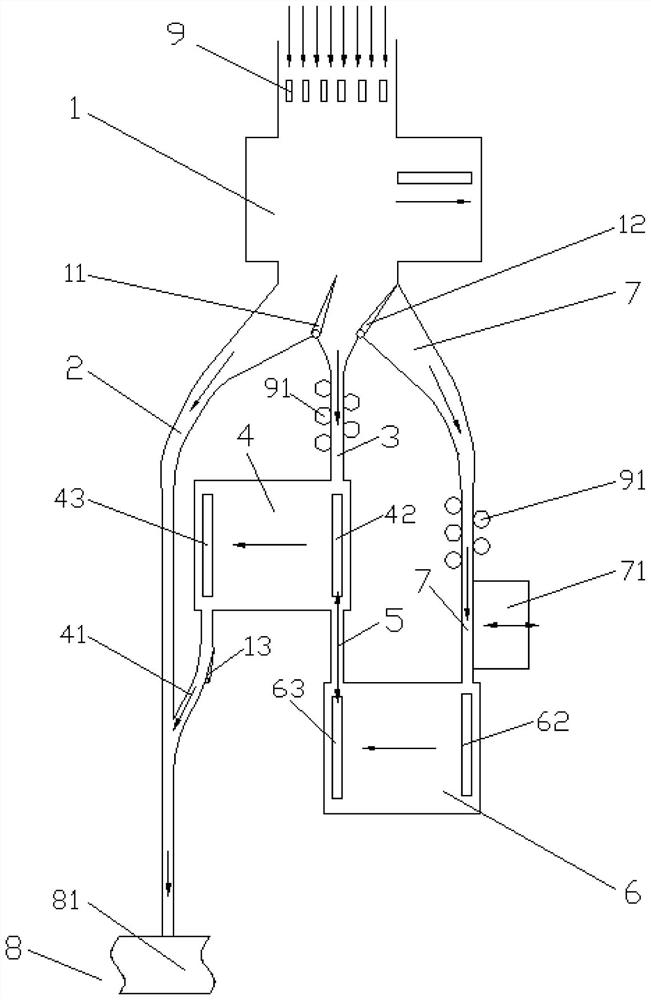

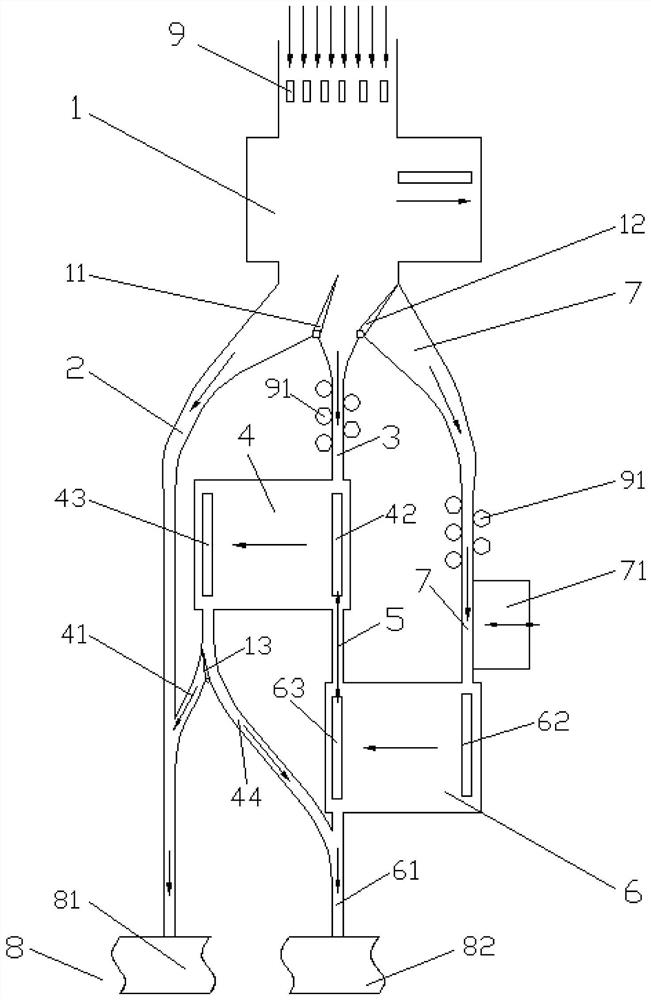

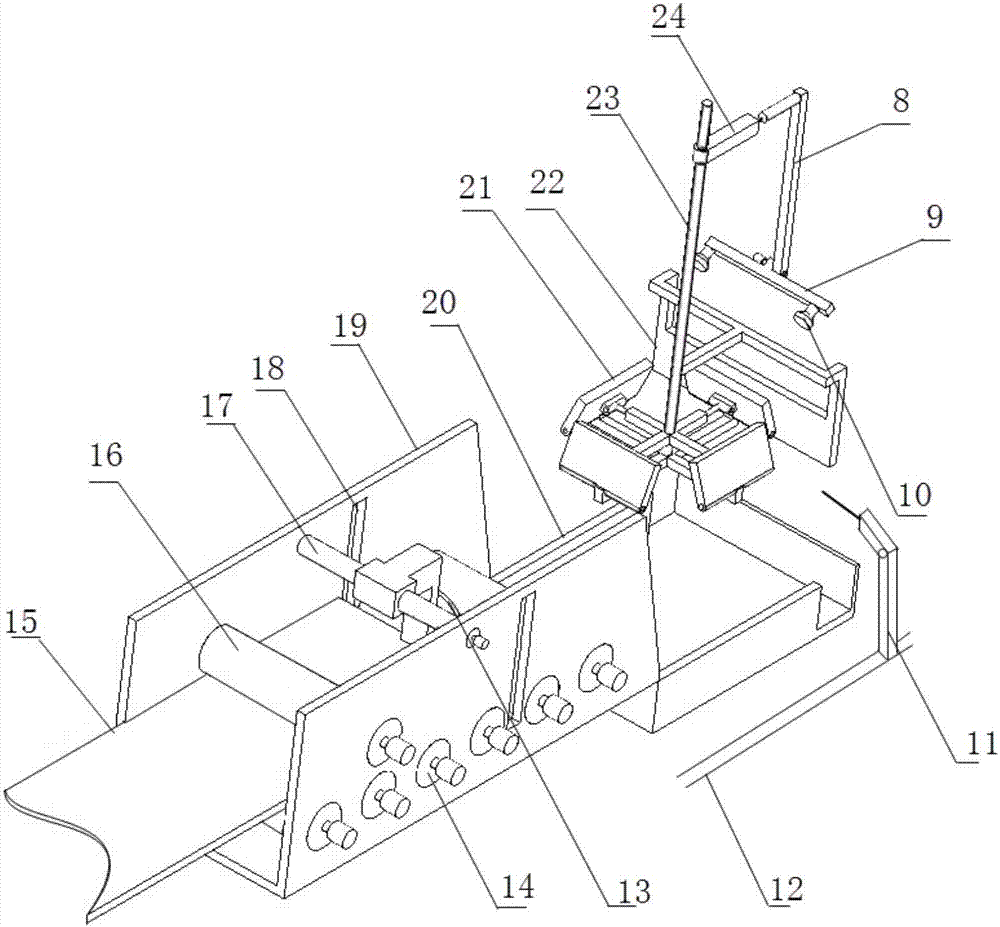

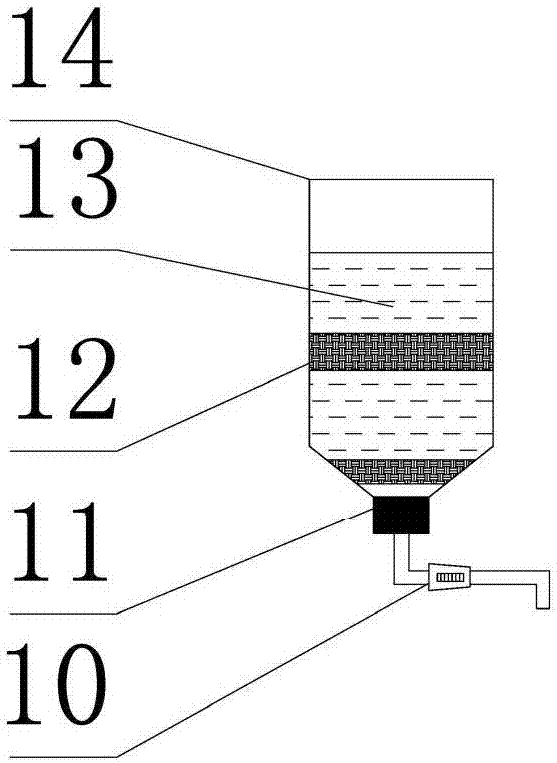

Tobacco seedling stock preparation apparatus

InactiveCN110432020AMeet quantity requirementsReduce infection rateGraftingPlant protectionInfection rateRootstock

The invention belongs to the field of tobacco planting, and particularly relates to a tobacco seedling stock preparation apparatus, comprising a rack, a cutting mechanism, a stock clamp, a clamp feeding mechanism and a tobacco seedling delivery mechanism. Industrialized work is realized with the tobacco seedling stock preparation apparatus; particularly, since strength support in cutting and limitin cutting direction and position are provided to tobacco seedlings through the clamp, the tobacco seedling stocks have the same cuts and are protected effectively; meanwhile, with cooperation between different drive mechanisms, cutting work of tobacco seedlings in batch can be realized well; further, with mechanical control of cutting tools, fixed overall operating environment and introduction of sterilize management, bacterial infection rate caused by cutting of the tobacco seedlings is decreased.

Owner:HENAN AGRICULTURAL UNIVERSITY

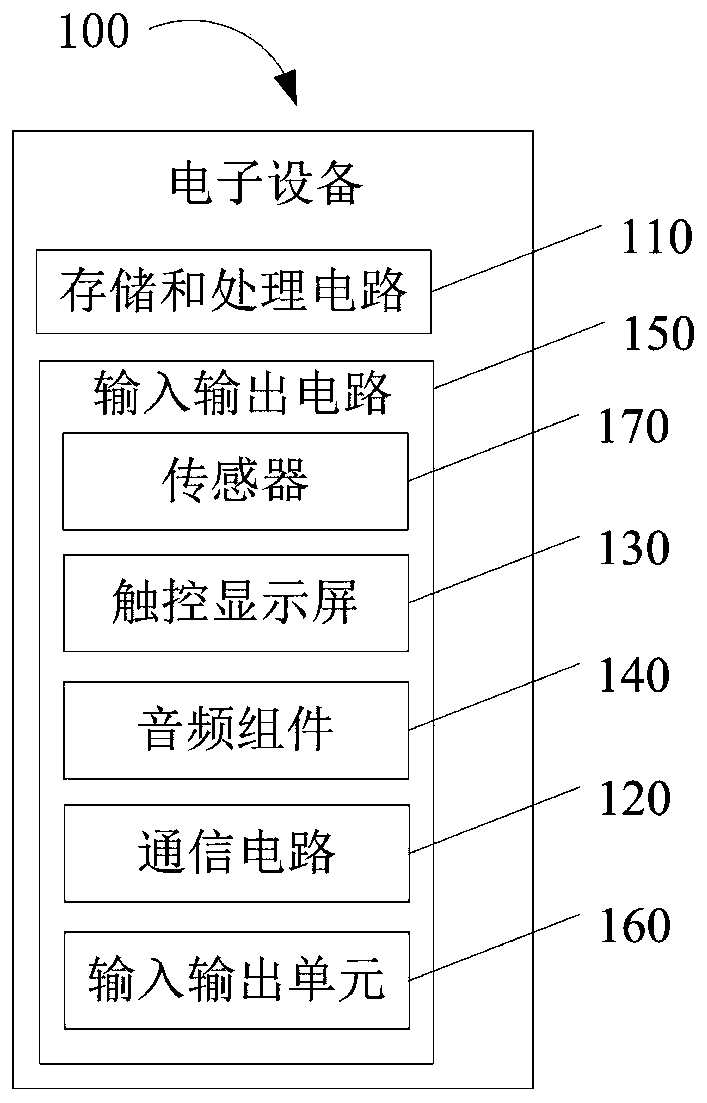

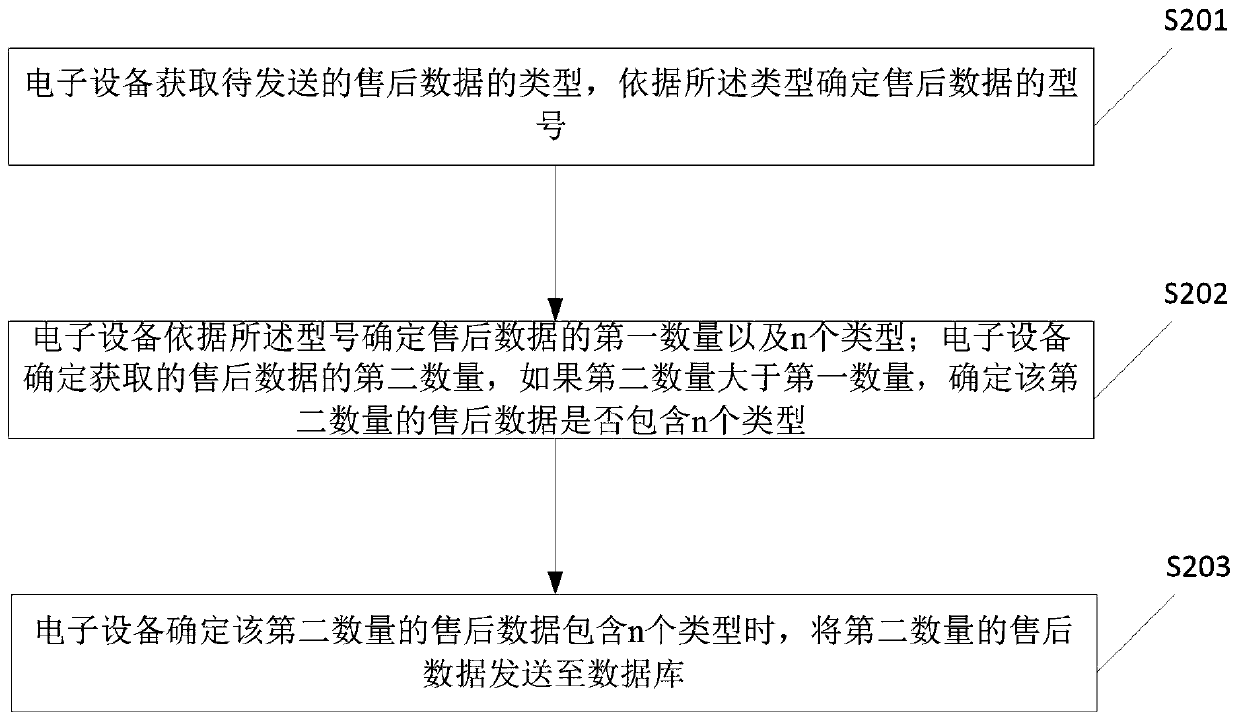

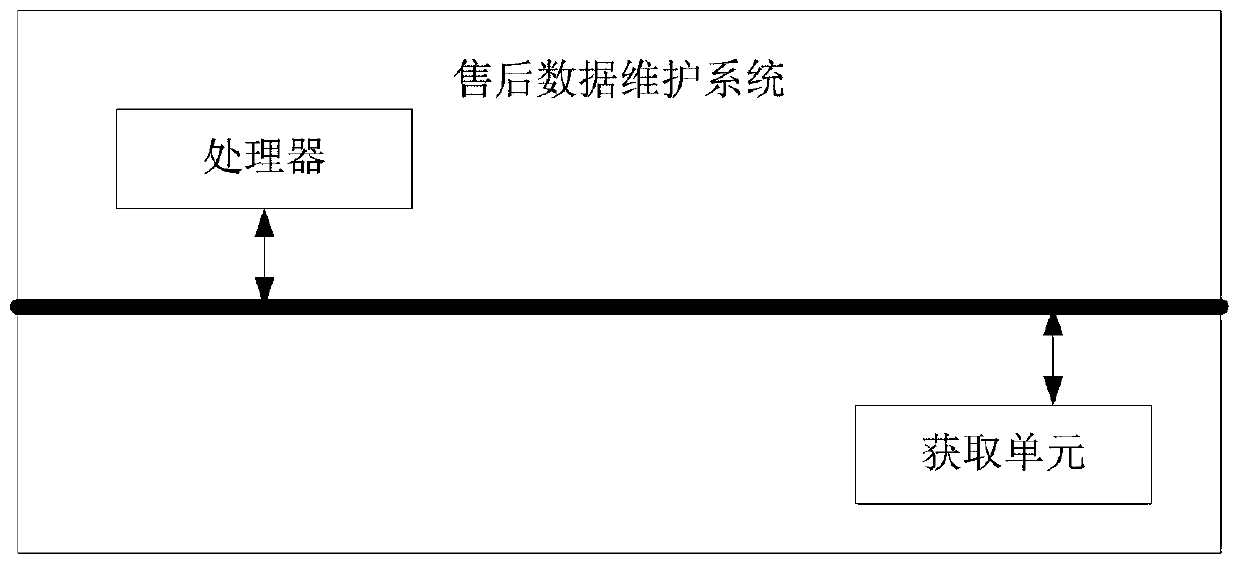

After-sales data maintenance method and system

The invention provides an after-sales data maintenance method and a related product, and the method comprises the following steps: electronic equipment obtains the type of to-be-transmitted after-sales data, and determines the type of the after-sales data according to the type; the electronic equipment determines a first quantity and n types of after-sales data according to the model; the electronic equipment determines a second quantity of the acquired after-sales data, and if the second quantity is greater than the first quantity, whether the second quantity of after-sales data contains n types is determined; and when the electronic equipment determines that the second quantity of after-sales data contains n types, the second quantity of after-sales data is sent to the database. The technical scheme provided by the invention has the advantage of maintaining data integrity.

Owner:深圳市智微智能软件开发有限公司

Magnesium alloy with high bulging and high heat resistance and preparation method thereof

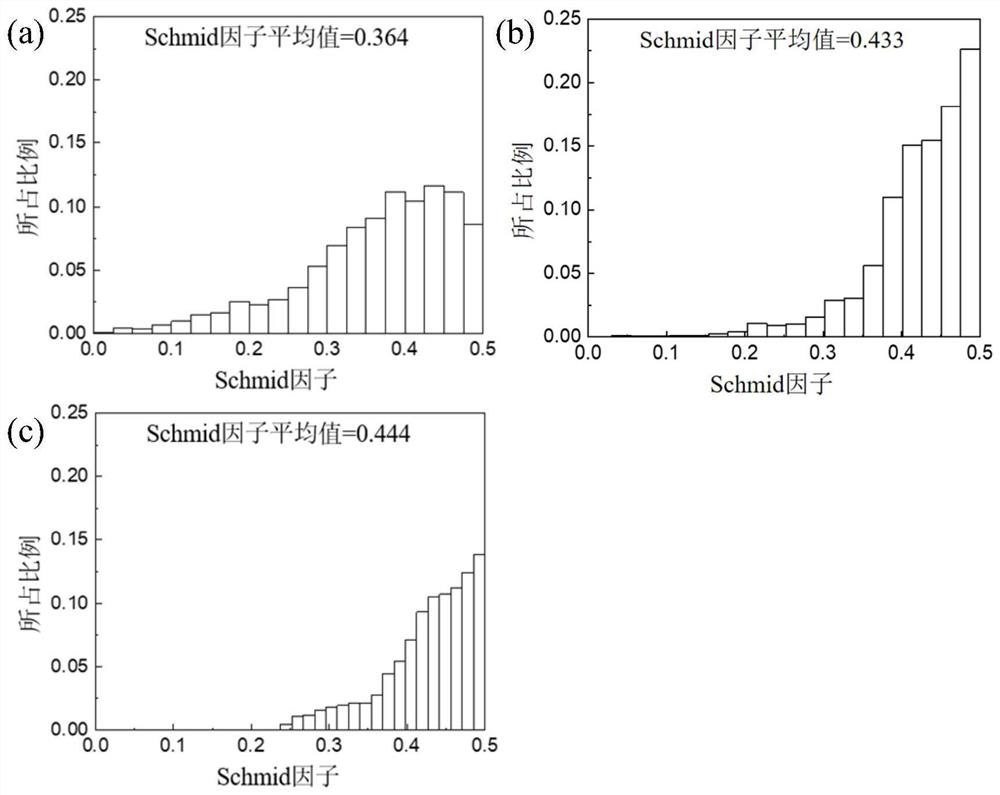

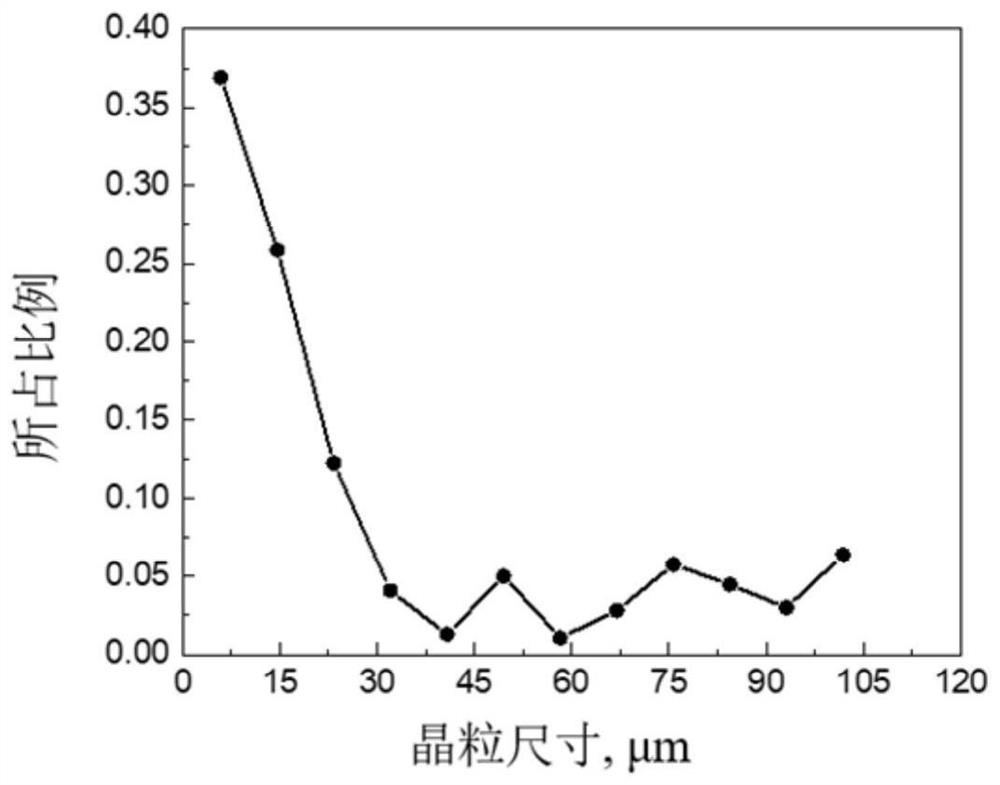

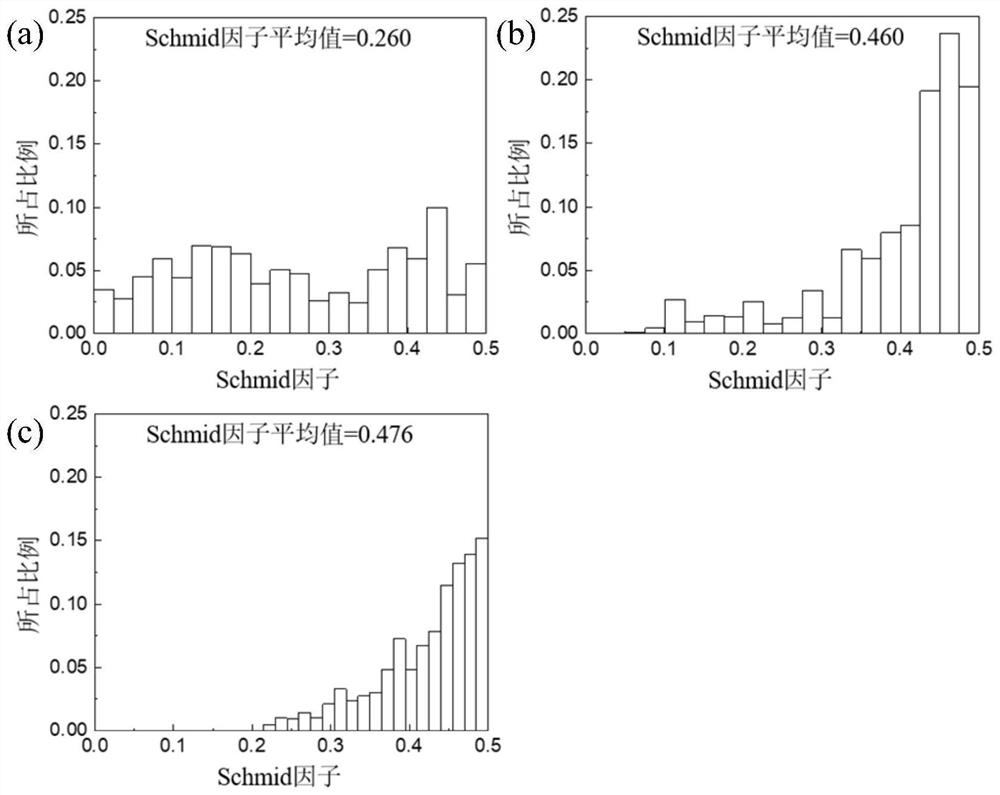

The invention discloses a magnesium alloy with high bulging property and high heat resistance. The magnesium alloy contains 0.5% to 2.0% of element X in terms of mass percentage, and the element X is one or more of rare earth elements and calcium elements. species; and the ratio of the Schmid factor of at least one of the non-basal slip and the Schmid factor of the basal slip in the cylindrical slip and the conical slip of the magnesium alloy is 1.0-1.4. A preparation method of the magnesium alloy is also disclosed. The composition of the magnesium alloy of the present invention is simple, and belongs to the category of low alloying. The Schmid factor ratio of the non-basal slip and the basal slip is 1.0 to 1.4, which effectively balances the relative activities of the non-basal slip and the basal slip. , which can not only meet the requirements of high bulging, but also avoid the damage of base surface slipping to heat resistance. The preparation method of the invention has reasonable process design, simple equipment requirements, convenient operation, low cost and high efficiency, and can stably prepare a magnesium alloy with high bulging property and high heat resistance.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com