Design and production flow process of medicine development chemical reagent

A chemical reagent and production process technology, applied in the field of medicinal chemistry, can solve problems such as poor initiative, restriction of drug research and development process, and supplementation of compound structure types to achieve the effect of alleviating bottleneck problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

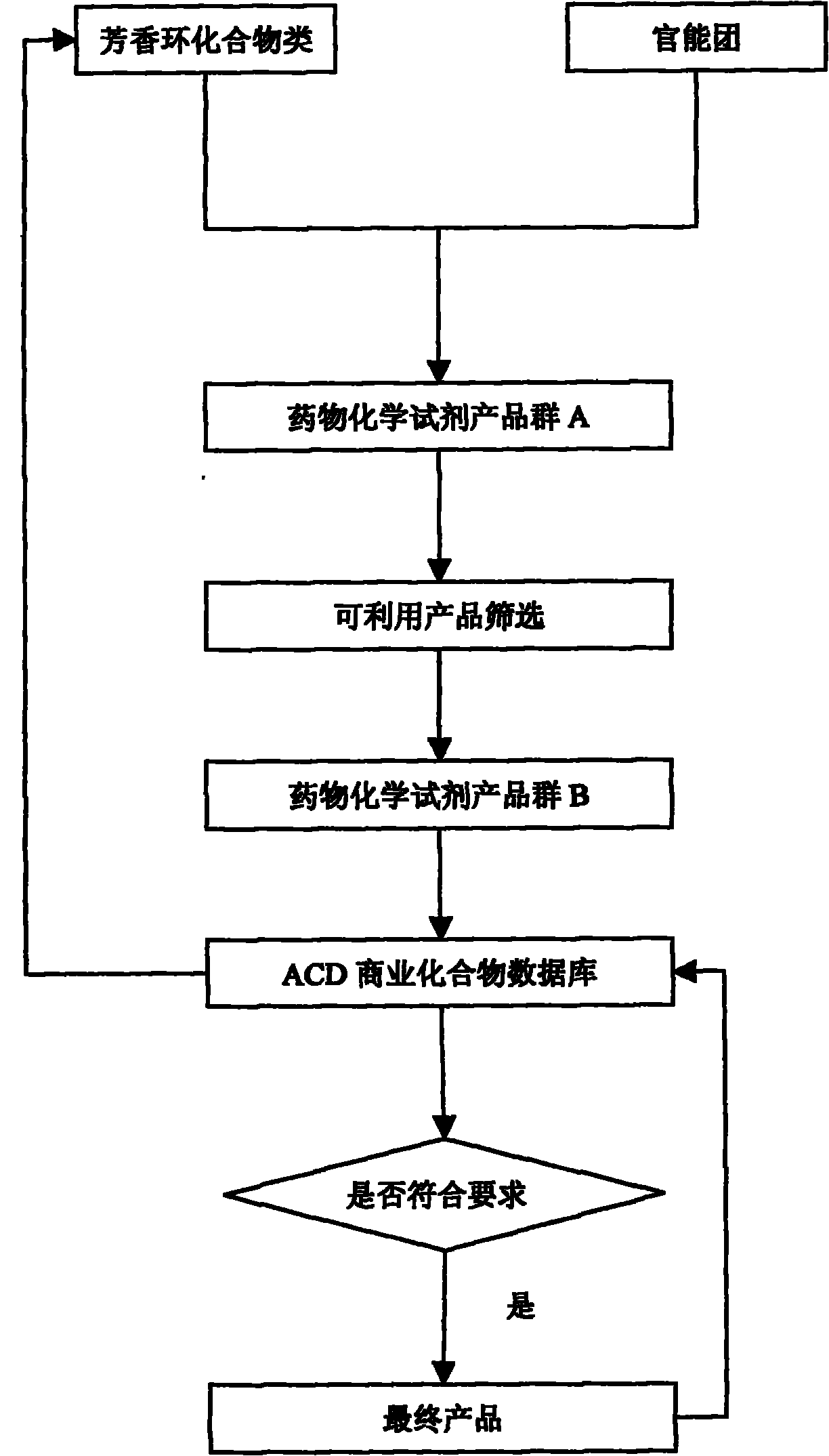

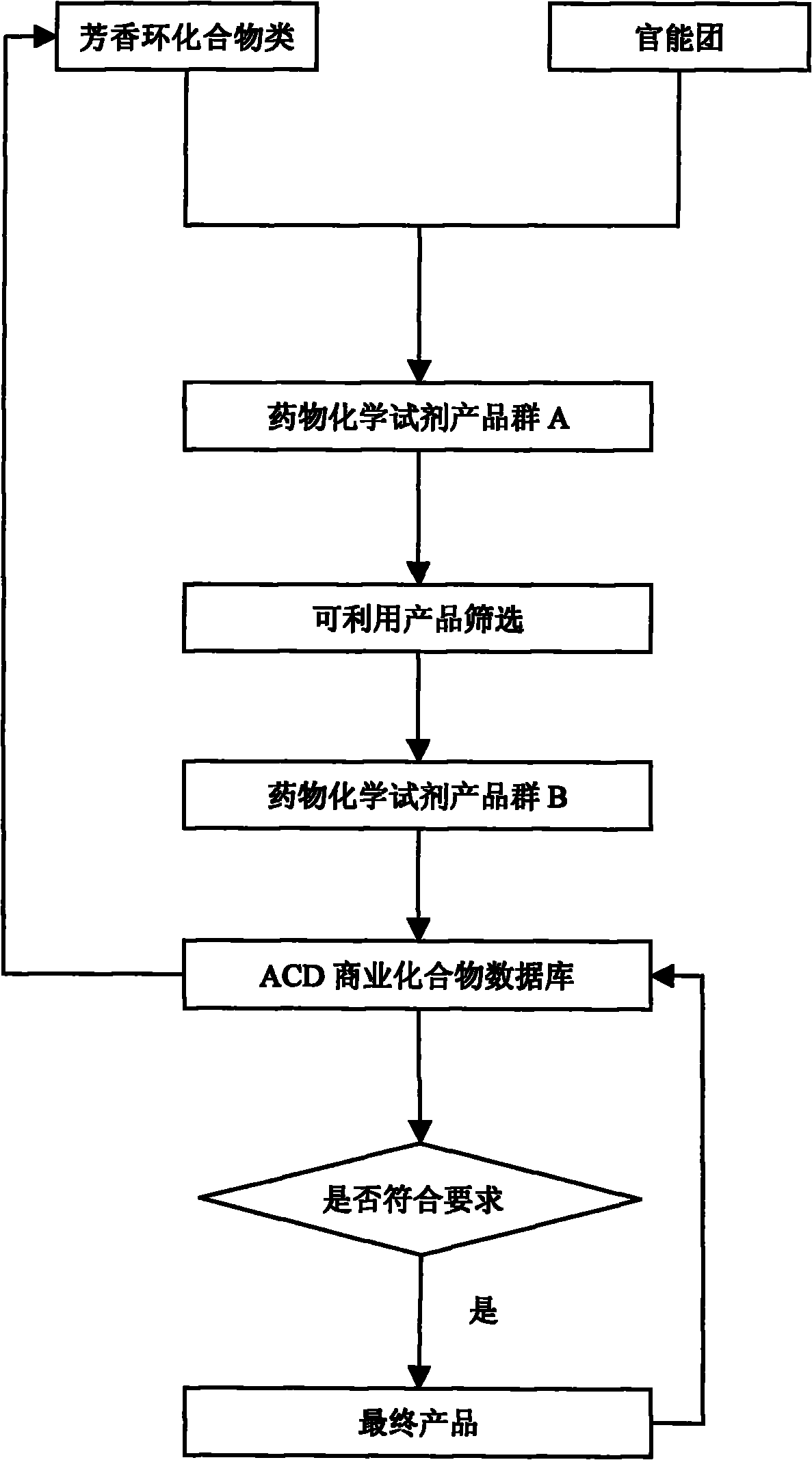

[0014] see figure 1 , a design and production process of a pharmaceutical research and development chemical reagent of the present invention, the specific steps are:

[0015] Step 1: Combining aromatic ring compounds and functional groups to form medicinal chemical reagent product group A;

[0016] Step 2: Identify and screen medicinal chemical reagent product group A according to raw materials, production process, biological activity, physicochemical properties, etc., to form medicinal chemical reagent product group B;

[0017] Step 3: Compare medicinal chemical reagent product group B with the ACD commercial compound database, if there is none, meet the screening requirements, form the final product, and add it to the ACD commercial compound database;

[0018] Step 4: After supplementing the aromatic ring compounds in the ACD commercial compound database and combining them with functional groups, the above steps are repeated to form new medicinal chemical reagents.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com