Damp and heat fermentation comprehensive harmless and resource processing system for kitchen waste

A kitchen waste and treatment system technology, applied in the field of organic solid waste recycling and harmless treatment, can solve the problems of unfavorable organic matter degradation, reduced urban drainage capacity, difficult cleaning, etc., and achieves significant environmental and social benefits. Resource utilization and the effect of alleviating bottleneck problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

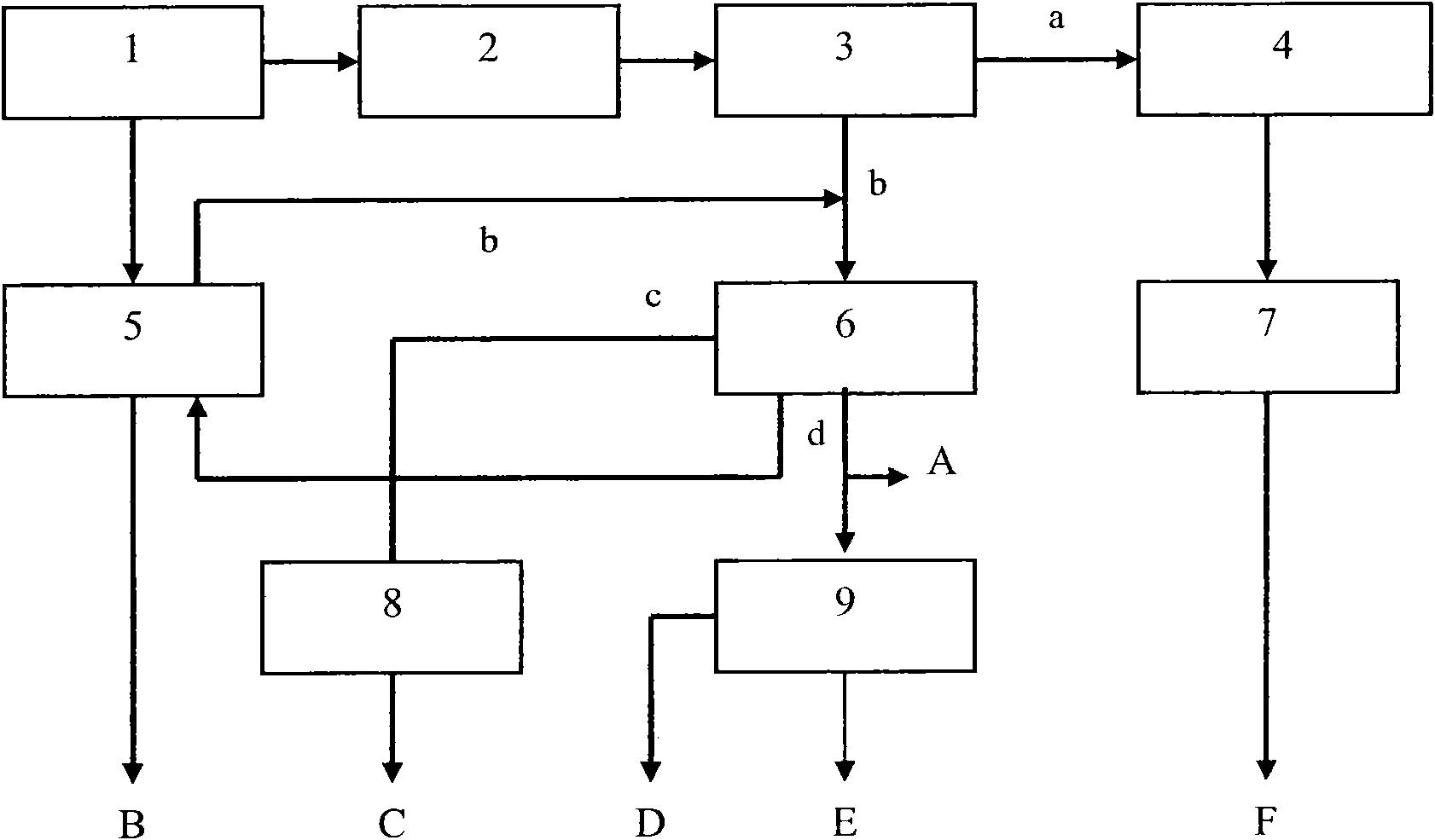

[0054] method one

[0055] Using the food waste heat-fermentation comprehensive resource treatment system shown in Figure 2 in the accompanying drawings can realize the complete sterilization of food waste and transform the food waste into multi-component microbial protein feed raw materials, fatty acid methyl esters, biogas, liquid Fertilizer, and recycle lunch boxes, chopsticks, glass, scrap metal, etc., to realize resource utilization, the whole process is airtight, and there is no secondary pollution.

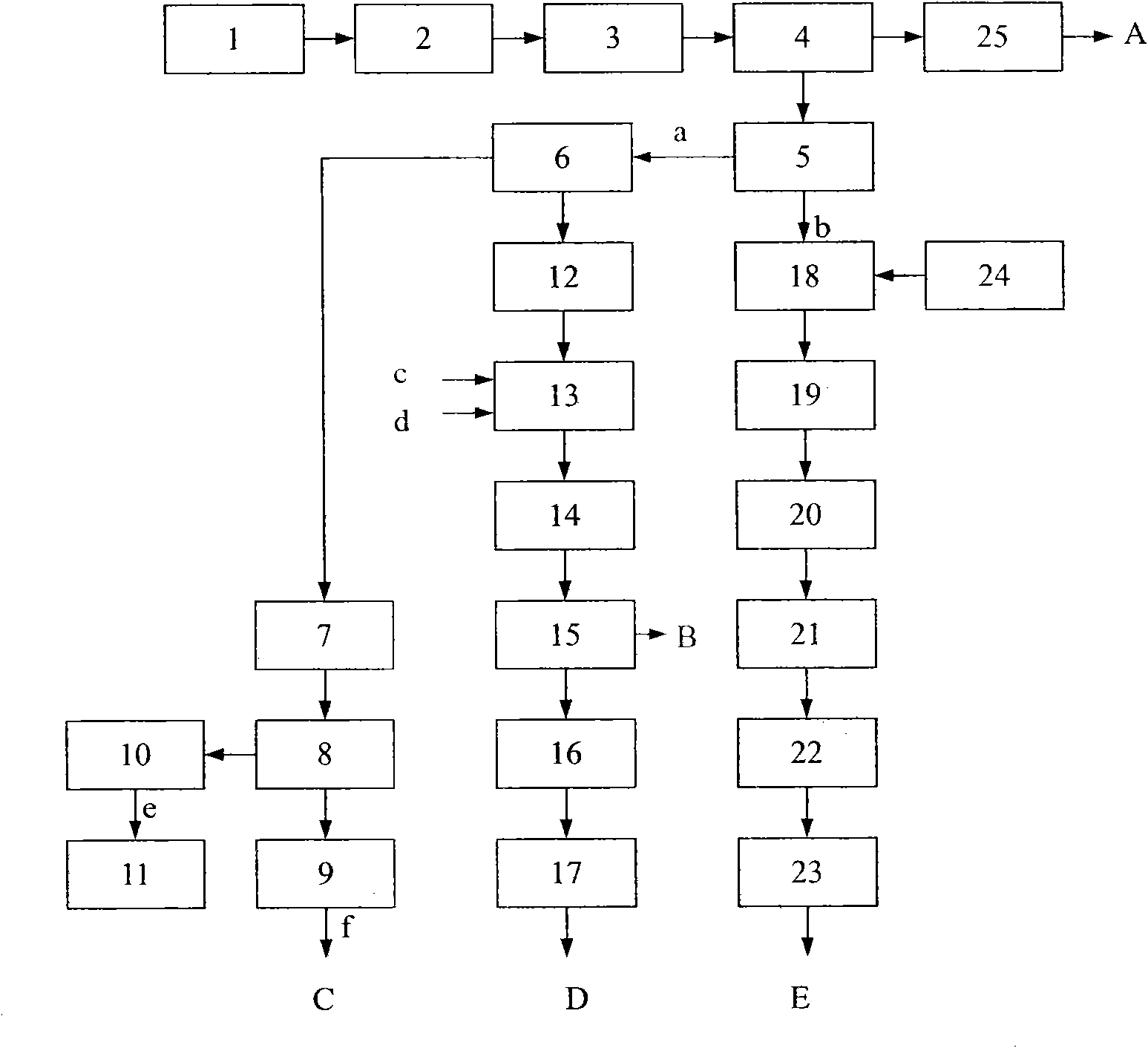

[0056] way two

[0057] Using the kitchen waste wet heat-fermentation comprehensive resource treatment system shown in Figure 3 in the accompanying drawings can realize the complete sterilization of kitchen waste and transform the kitchen waste into multi-component microbial protein feed raw materials, fatty acid methyl esters, and feeding nutrition liquid, and recycle the lunch boxes, chopsticks, glass, scrap metal, etc., to realize the utilization of resources, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com