Flat-milling clamp for valve core

A valve core and flattening technology, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of increasing labor intensity of workers, difficulty in ensuring the flat size, and damage to the cone surface of the valve core, etc., and achieves a compact structure , Alleviate the "throat" bottleneck and meet the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

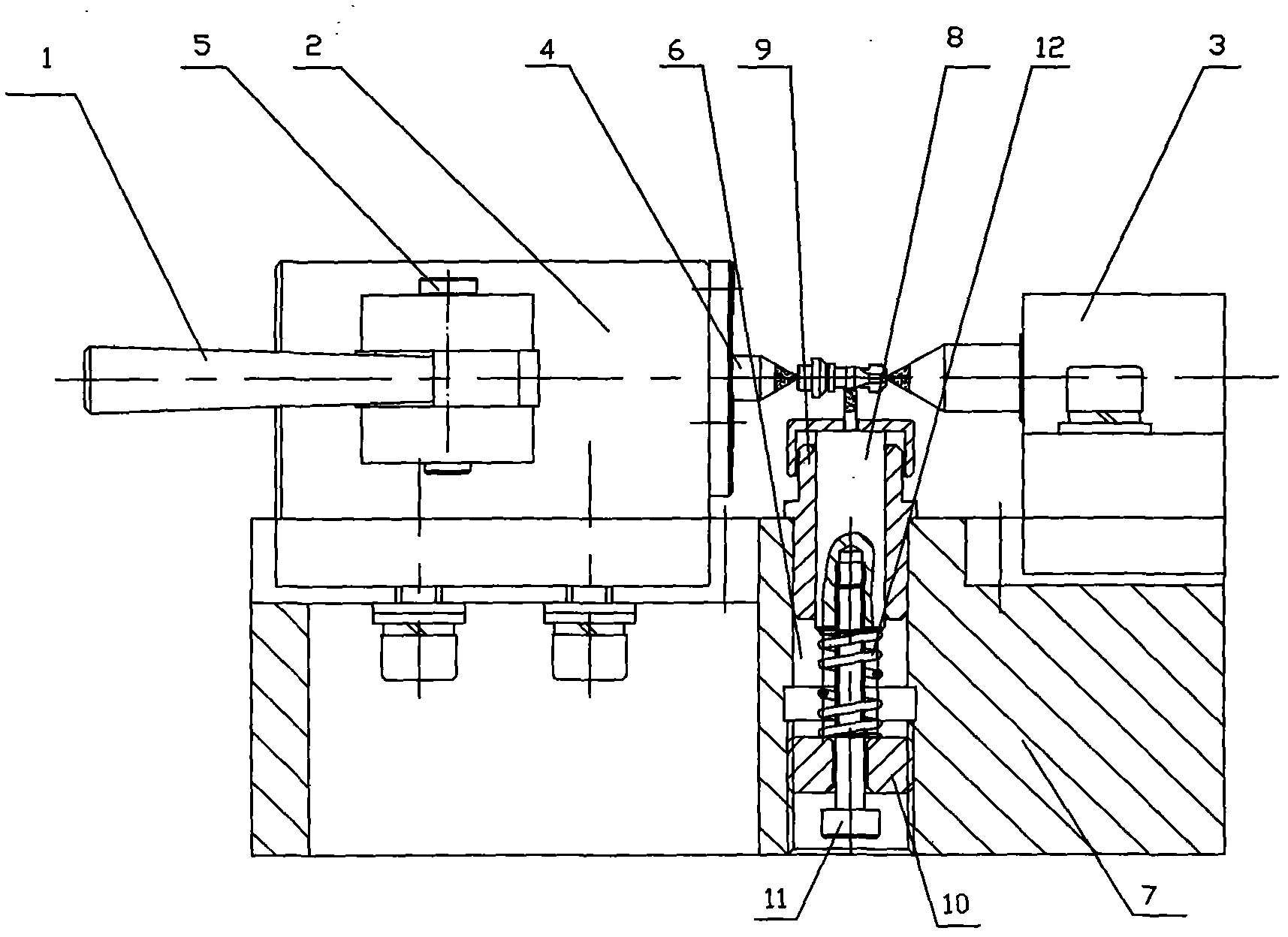

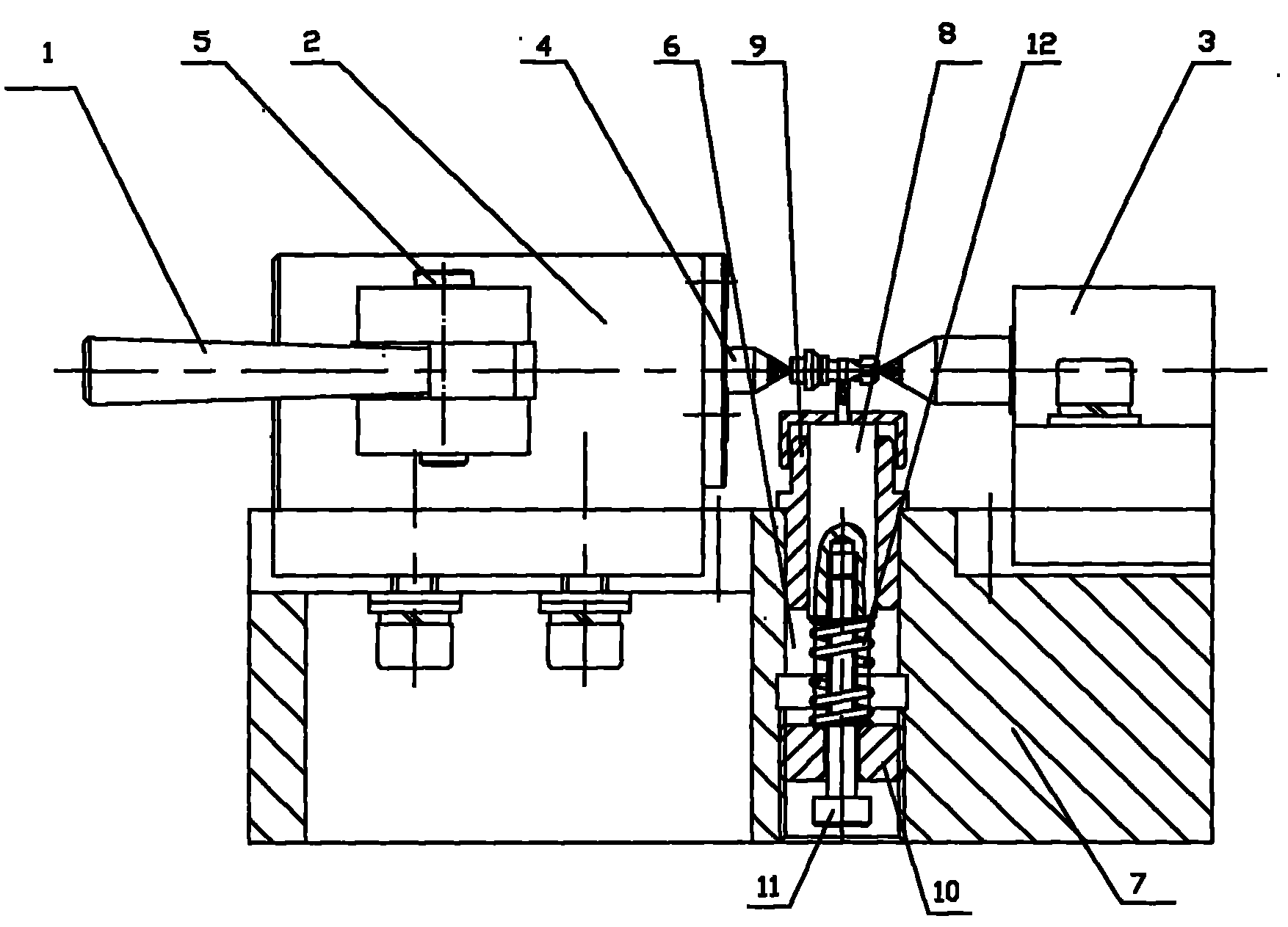

[0009] A valve core grinding flat position fixture, comprising a left thimble seat 2, a right thimble seat 3 and a clamping body 6, the left thimble seat 2 and the right thimble seat 3 are respectively provided with a thimble 4, and the left thimble seat 2 is also provided with a thimble 4. The handle 1 and the positioning pin 5, the valve core is fixed in the middle of the left and right thimbles 4, and the outer periphery is covered with a dust cover. A clamping body 6 is set in the direction perpendicular to the axis of the valve core. The clamping body 6 is set on the base 7, and the front end is provided with Positioning block 8, the outer side of the positioning block 8 is a bushing 9, the clamping body 6 is provided with a through-hole screw plug 10, which is provided with a screw 11, the front end of the screw 11 is set in the positioning block 8 and is connected with a spring 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com