Magnesium alloy with high bulging and high heat resistance and preparation method thereof

A magnesium alloy, high heat-resistant technology, applied in the field of non-ferrous metal materials and processing, can solve the problems of Schmid factor reduction, contradictory effects of service performance, unfavorable room temperature bulging, etc., to improve room temperature bulging and medium-high temperature resistance Combination of heat, low cost, excellent plasticity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A magnesium alloy with high bulging property and high heat resistance of the present invention contains 0.8% Y, 0.2% Ca, 0.5% Mn and 0.1% In by mass %, and the balance is Mg.

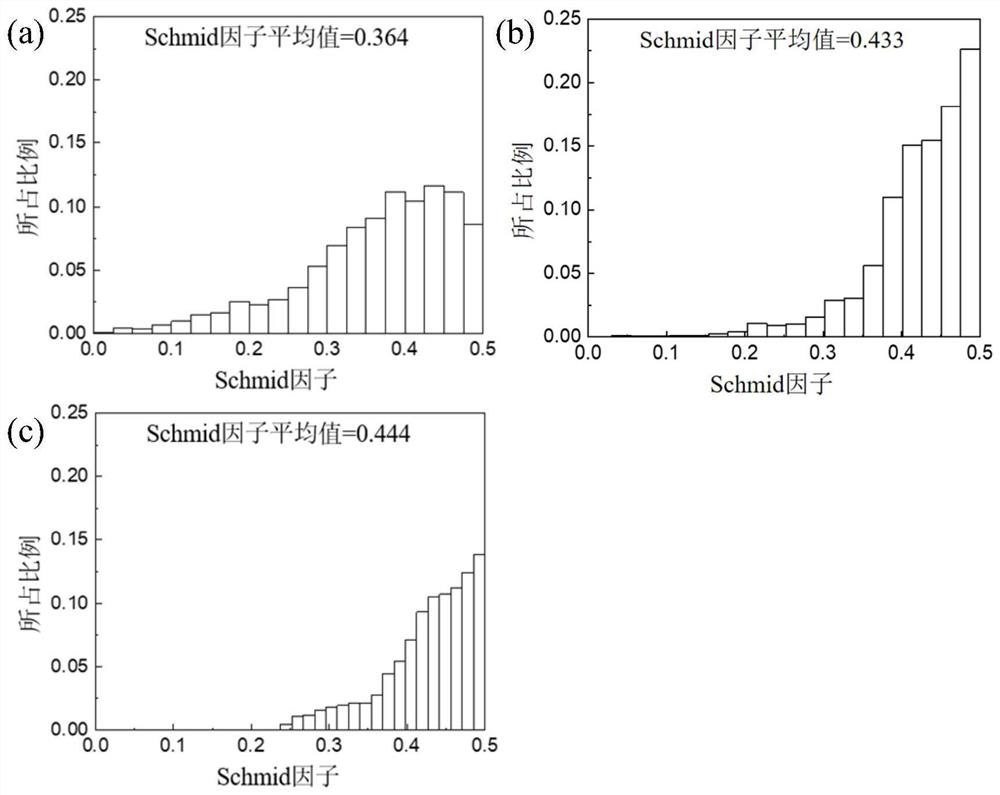

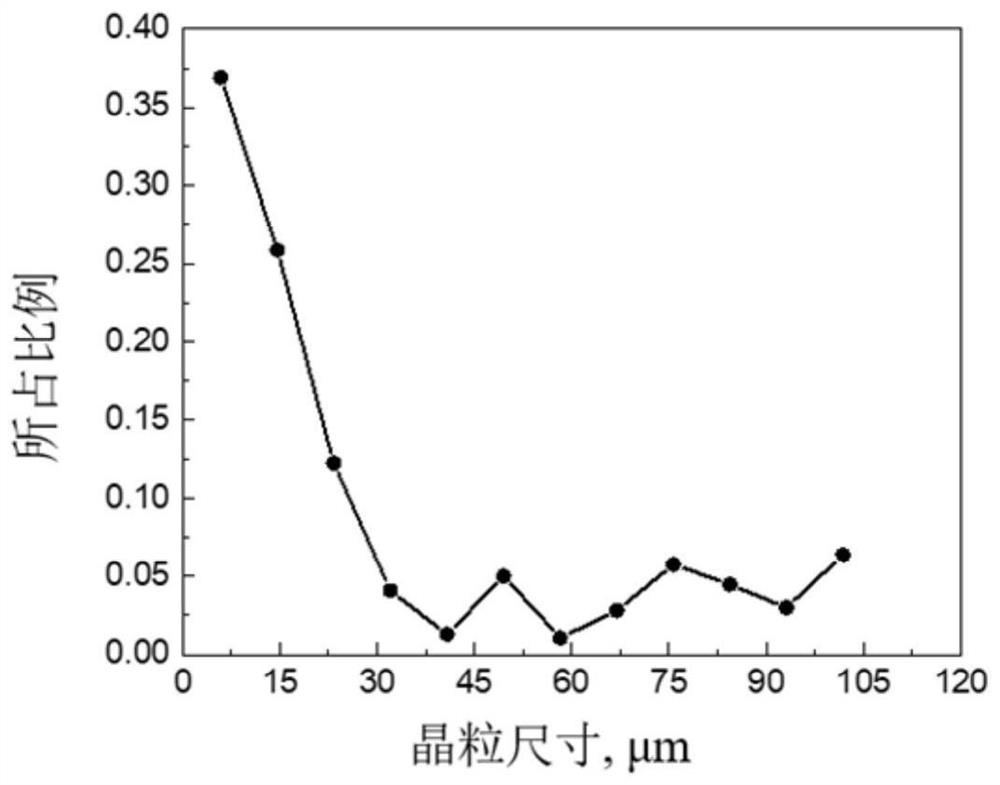

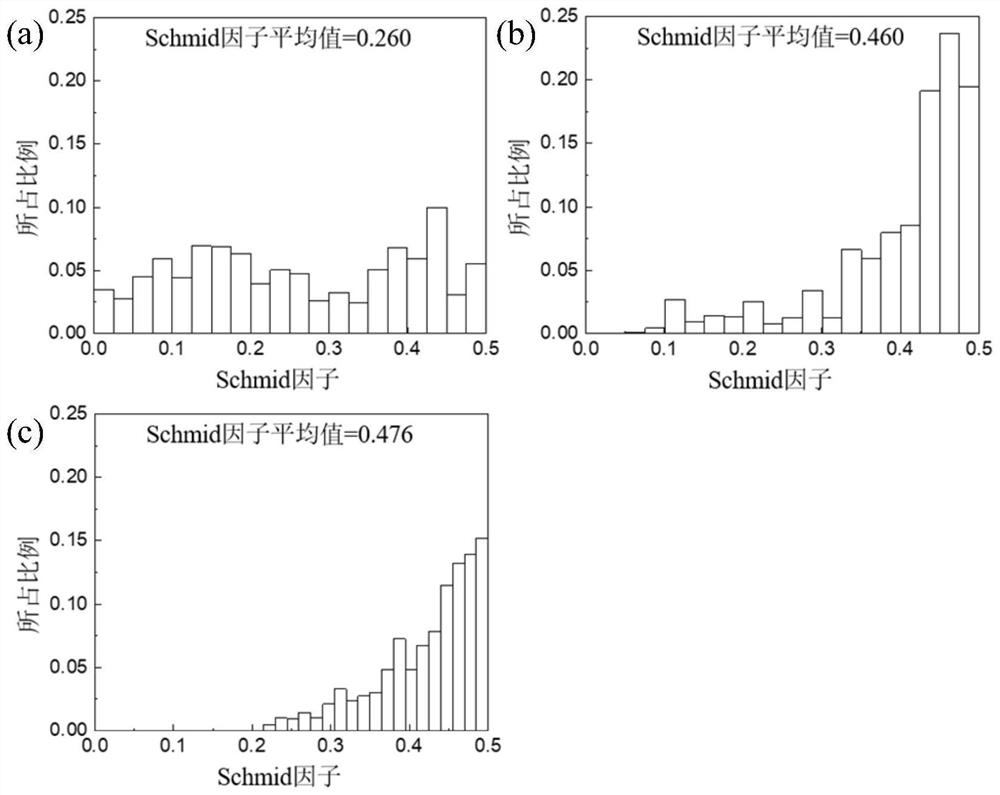

[0034] The high bulging high heat resistance magnesium alloy of the present embodiment, the Schmid factor ratio of its cylinder slip and basal slip is 1.19, the Schmid factor ratio of conical slip and basal slip is 1.22, this alloy With mixed grain sizes, the volume fraction of grains with a grain size ≤ 15 μm is 60%.

[0035] A preparation method of the high bulging high heat resistance magnesium alloy of the present embodiment, comprising:

[0036] S1. After the alloy is homogenized, thermal deformation is performed for 3 passes at 500°C, the cumulative true strain is 0.7, and the deformation direction of all passes is the same;

[0037] S2. The magnesium alloy is thermally deformed at 520° C. for one pass, the cumulative true strain is 0.8, and the thermal deformation direction is perpendicul...

Embodiment 2

[0052] A magnesium alloy with high bulging property and high heat resistance of the present invention contains 2.0% Gd, 0.2% Zr and 0.5% Zn by mass %, and the balance is Mg.

[0053] The high bulging high heat resistance magnesium alloy of the present embodiment, the Schmid factor ratio of its cylindrical surface slip and basal surface slip is 1.27, the Schmid factor ratio of conical surface slip and basal surface slip is 1.36, this alloy With mixed grain sizes, the volume fraction of grains with a grain size ≤ 15 μm is 50%.

[0054] A preparation method of the high bulging high heat resistance magnesium alloy of the present embodiment, comprising:

[0055] S1. After the homogenization treatment of the alloy, two passes of thermal deformation at 400°C are carried out, the cumulative true strain is 0.3, and the deformation direction of all passes is the same;

[0056] S2. Thermally deforming the magnesium alloy for one pass at 450° C., the accumulated true strain is 0.4, and t...

Embodiment 3

[0060] A magnesium alloy with high bulging property and high heat resistance of the present invention contains 2.0% of Gd and 0.5% of Zn by mass %, and the balance is Mg.

[0061] A method for preparing a highly bulging and high heat-resistant magnesium alloy of this embodiment differs from that of Embodiment 2 only in that the raw material composition is Mg-2.0Gd-0.5Zn.

[0062] The obtained Mg-2.0Gd-0.5Zn alloy is marked as sample No. 5, the ratio of the Schmid factor of cylindrical slip (0.428) to the Schmid factor of basal slip (0.315) is 1.36, and the Schmid factor of conical slip (0.482) The ratio to the basal slip Schmid factor (0.315) is 1.53, and the alloy has mixed grain sizes, and the volume fraction of grains with a grain size ≤ 15 μm is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com