Fixed contact structure for non-excitation tap switch

A technology of tap changer and static contact, which is applied in the direction of transformers, electrical components, variable inductors, etc., can solve the problems of inconvenient manufacturing process of transformer lead wires, and achieve the effects of reducing tip discharge, improving practicability, and uniform electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

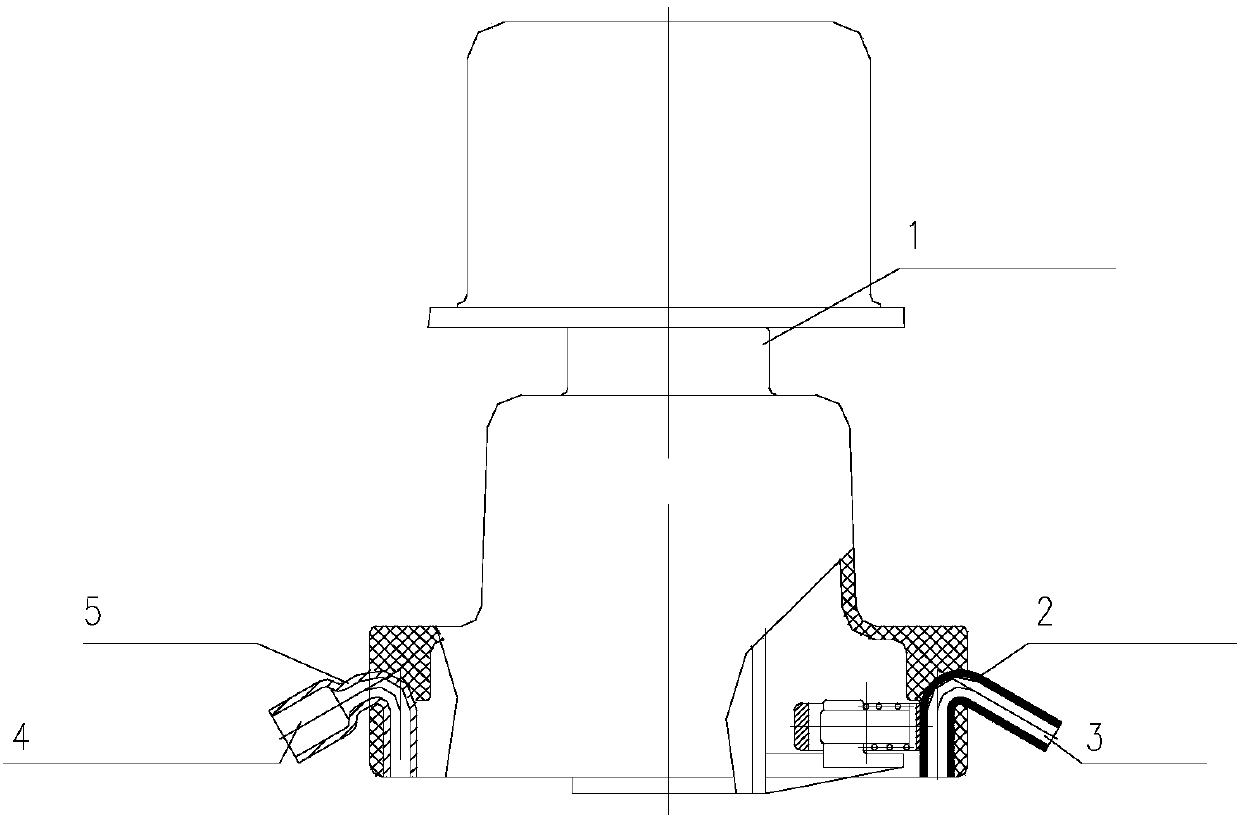

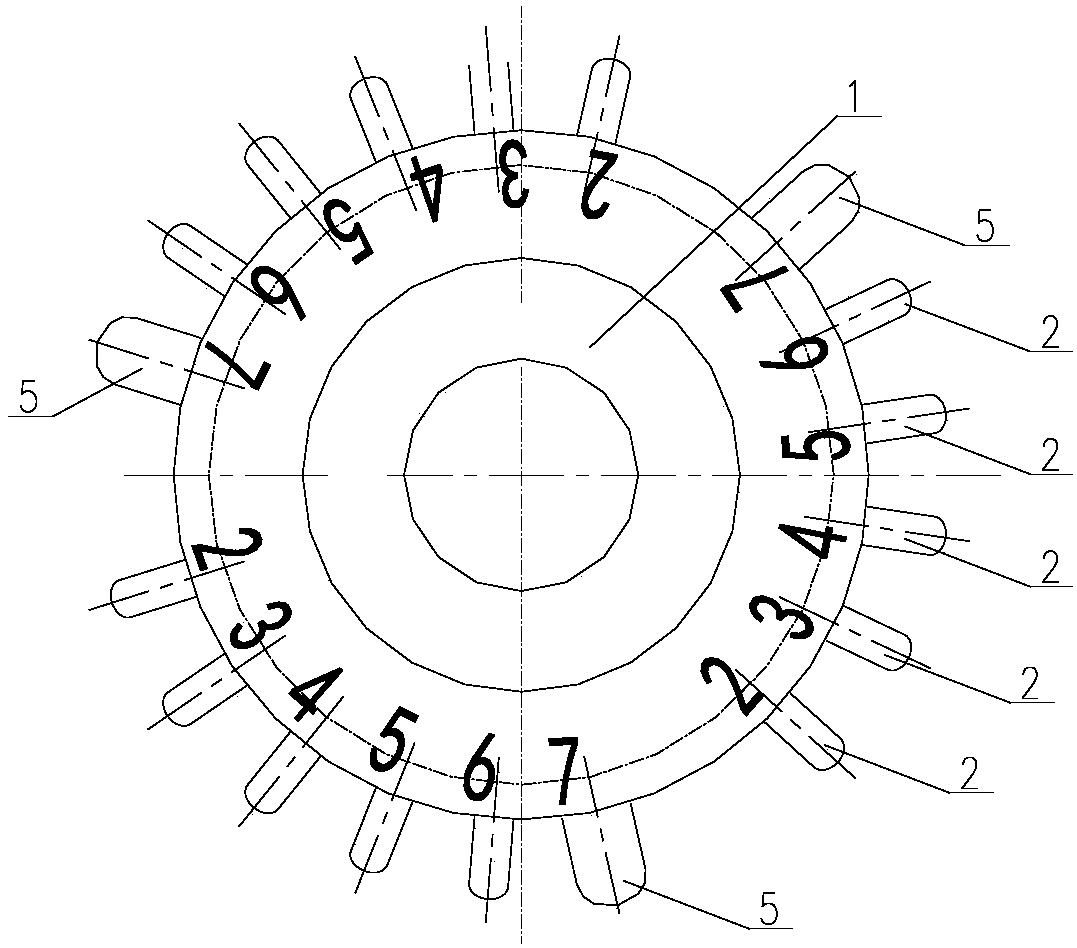

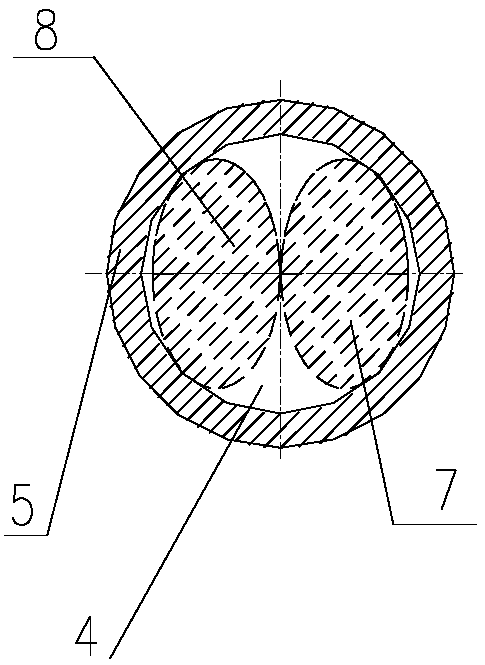

[0024] Such as Figure 1-6 As shown, this embodiment provides a static contact structure of a three-phase five-speed non-excitation voltage regulating tap changer, which includes a disc-shaped or bar-shaped switch body 1, and a three-phase static contact is arranged on the switch body 1, each The phase static contacts include five first static contacts 2 ( Figure 7 middle 2-6 heads) and 1 second static contact 5 ( Figure 7 middle 7 heads), the contact end of each static contact extends into the inner cavity of the switch body and is configured with the moving contact, the terminal extends out of the switch body, and the second static contact 5 is located at the static contact of each phase The head end or end of each static contact is provided with a lead hole. The lead hole 4 of the second static contact is located outside the switch body, and the diameter of the lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com