Circuit board splice board

A circuit board and board body technology, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of increasing the number of circuit boards, weakening the strength of circuit board puzzles, and affecting the effect of spliced circuit patching, etc. To achieve the effect of strengthening the connection strength and good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

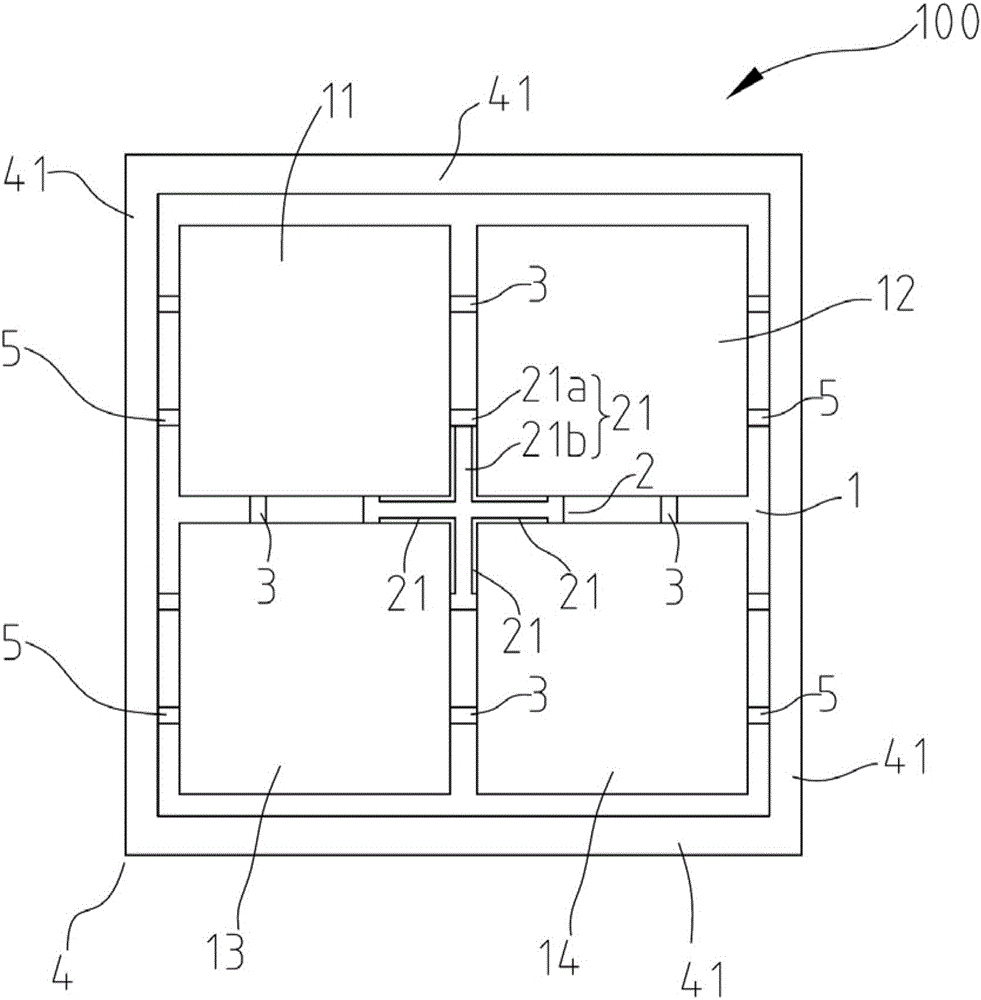

[0019] Please refer to figure 1 , a circuit board assembly 100 provided by the present invention includes a board body 1 and cross ribs 2, the board body 1 includes at least four circuit boards, and the cross ribs 2 are arranged in the middle of the four circuit boards to connect the four circuits The boards are connected together to enhance the connection strength between the four circuit boards, thereby providing a circuit board assembly 100 with better connection strength.

[0020] In this embodiment, the plate body 1 is roughly rectangular. The quantity of the circuit boards spliced into the board body 1 is correspondingly set according to actual needs. It can be understood that the number of boards 1 in this embodiment is four, and for the convenience of description, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com