A hydraulic pipeline system online circulation cleaning process

A hydraulic pipeline and process technology, which is applied in the field of online cleaning technology for long, complex and large hydraulic pipelines, and can solve problems such as lack of corresponding research on the shortcomings of the background technology, affecting cleaning quality and efficiency, and cleaning oil resistance. , to achieve the effect of reducing difficult-to-clean parts and dead-angle parts, improving cleaning quality and efficiency, and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

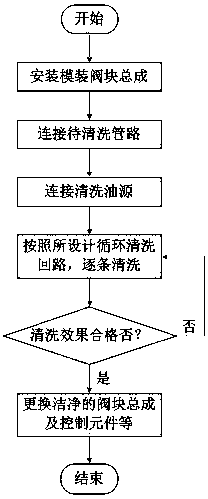

[0020] Such as figure 1 As shown, an online circulation cleaning process of a hydraulic pipeline system is carried out in accordance with the following steps:

[0021] The first step is to disconnect the hydraulic pump station, actuators, control valves and real valve block assembly;

[0022] The second step is to design the cleaning circuit, sort out each pipeline that needs to be cleaned according to the pipeline diagram of the hydraulic system, and connect the pipelines to be cleaned with the same diameter or a small difference in diameter; connect the pipelines with inconsistent diameters , connected in order from thick to thin;

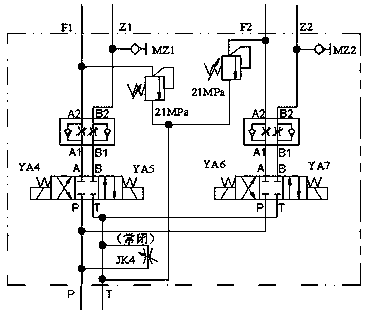

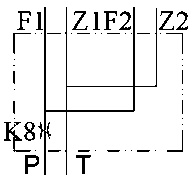

[0023] The third step is to design the channels in the molded valve block assembly according to the cleaning circuit in the second step;

[0024] The fourth step is to connect the molded valve block assembly designed in the third step to the circuit to be cleaned, and connect the pipeline to be cleaned in the order of coarse to fine along the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com