Clamping device used for machining shaft products

A technology for clamping devices and processing axes, which is applied in the direction of workpiece clamping devices, auxiliary devices, metal processing equipment, etc., can solve the problems of low processing efficiency, increased labor costs, errors, etc., and achieve coaxiality and utilization. High, ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

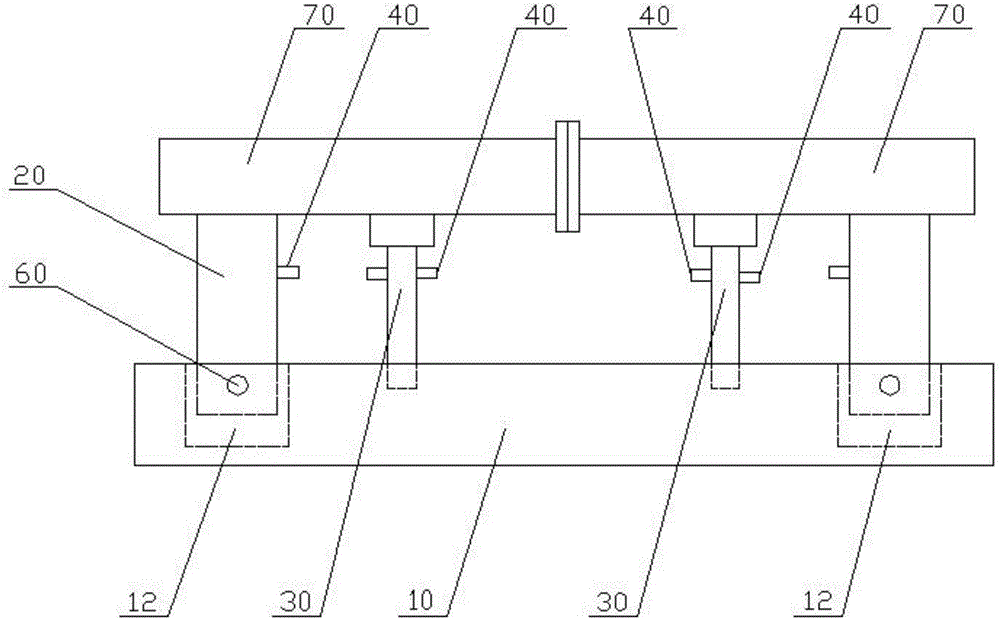

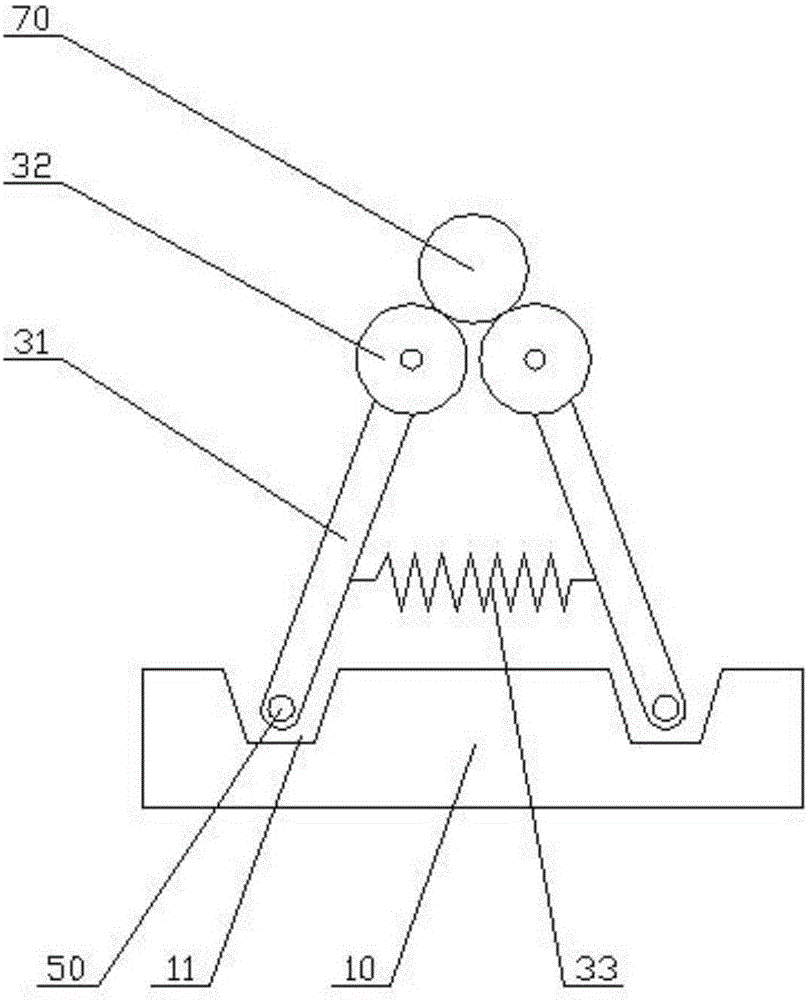

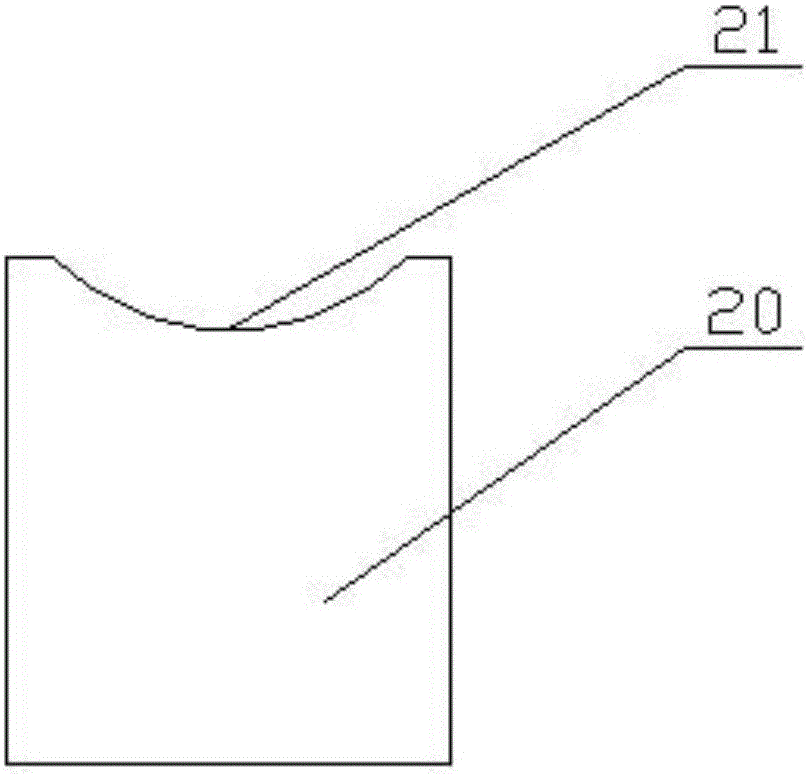

[0017] see figure 1 with figure 2 , a clamping device for processing shaft products described in a preferred embodiment of the present invention includes a base 10, the two ends of the base 10 are provided with brackets 20 that can move longitudinally relative to it, and the base 10 is also provided with adjacent The supporting mechanism 30 of the two brackets 20, the supporting mechanism 30 located on the same side of the center of the base 10 and the bracket 20 form a supporting group. It can be seen that each supporting group has two supporting points, and the shaft product 70 can be rested on the supporting group. The present invention uses two brackets 20 and two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com