Carrying trolley and its grouting system and application

A technology of carrying trolleys and grouting, applied in ceramic molding machines, die-casting molds, manufacturing tools, etc., can solve the problems of low efficiency, ununiform product quality, and large number of workers, and achieve the effect of saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

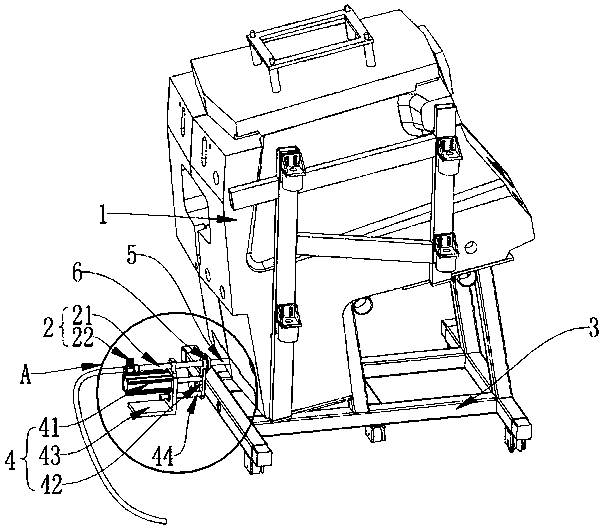

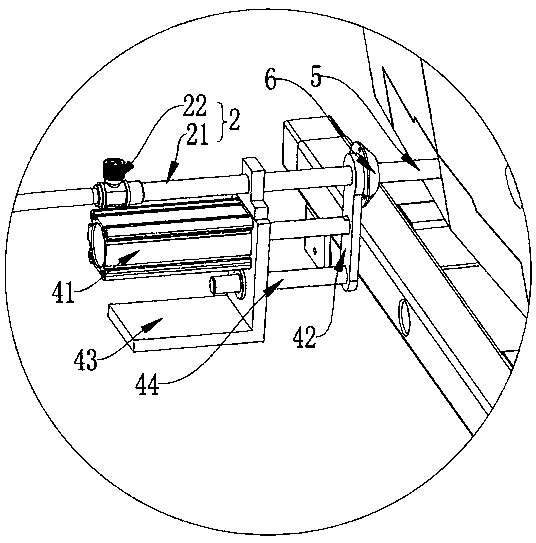

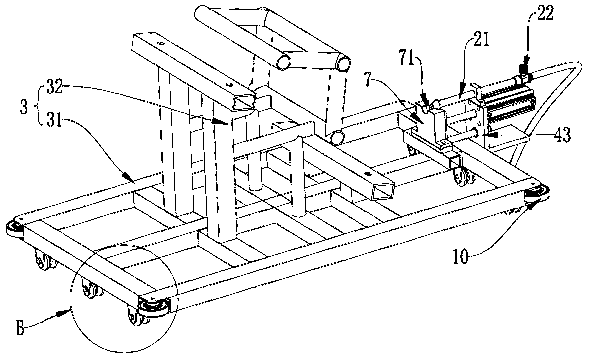

[0030] Such as figure 1 and figure 2 As shown, a grouting system includes a mold 1 and a sizing device 2; it also includes a carrier trolley 3 and a grouting drive assembly 4;

[0031] The mold 1 is fixed on the carrying trolley 3, and the grouting port of the mold 1 is outwardly connected with a grouting pipe 5;

[0032] The sizing device 2 includes a sizing pipe 21 and a switch valve 22 that controls the opening and closing of the sizing pipe 21. Each mold 1 is equipped with a set of the sizing device 1, and the molds 1 are driven by the carrying trolley 3. Transport to the grouting station, the sizing device 2 is fixed on the grouting station;

[0033] Driven by the grouting driving assembly 4 , the grouting pipe 21 communicates with or disconnects from the grouting pipe 5 .

[0034] A mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com