An automatic feeding pouring machine

An automatic feeding and pouring machine technology, applied in the field of synthetic leather preparation, can solve the problems of increasing the unqualified rate, production impact, increasing labor and other problems, reducing the probability of introducing impurities, improving the yield, and saving feeding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

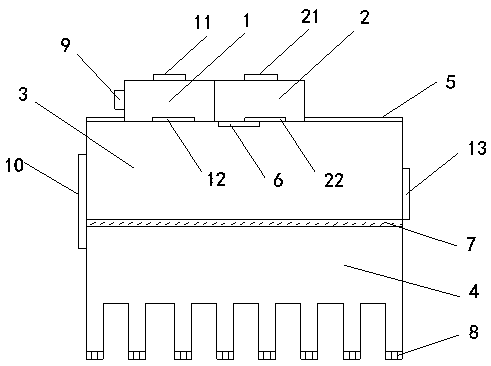

[0016] Such as figure 1 The shown automatic feeding pouring machine includes feeding chambers 1, 2, mixing chamber 3 and pouring chamber 4, feeding chambers 1, 2, mixing chamber 3 and pouring chamber 4 are longitudinally connected, and feeding chambers 1 and 2 pass through The track 5 at the top of the mixing chamber 3 moves back and forth, the tops of the feeding chambers 1 and 2 are provided with feeding ports 11, 21, and the bottom is provided with discharge ports 12, 22, and the discharge ports 12, 22 are the same size as the feed port 6 ; The top of the mixing chamber 3 is provided with a material inlet 6, and a filter screen 7 is provided between the mixing chamber 3 and the pouring chamber 4, and a group of pouring ports 8 are provided at the bottom of the pouring chamber 4, and the ends of the pouring port 8 are There are micropores; the feeding chambers 1 and 2 are drawn by the cylinder 9, and the cylinder 9 is controlled by a microcomputer 10, and the microcomputer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com