Film dry bag isostatic press

A technology of isostatic press and dry bag, which is applied in the direction of press, material forming press, manufacturing tools, etc., can solve the problem that the dry bag thickness cannot be taken into account, and achieve the effect of novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

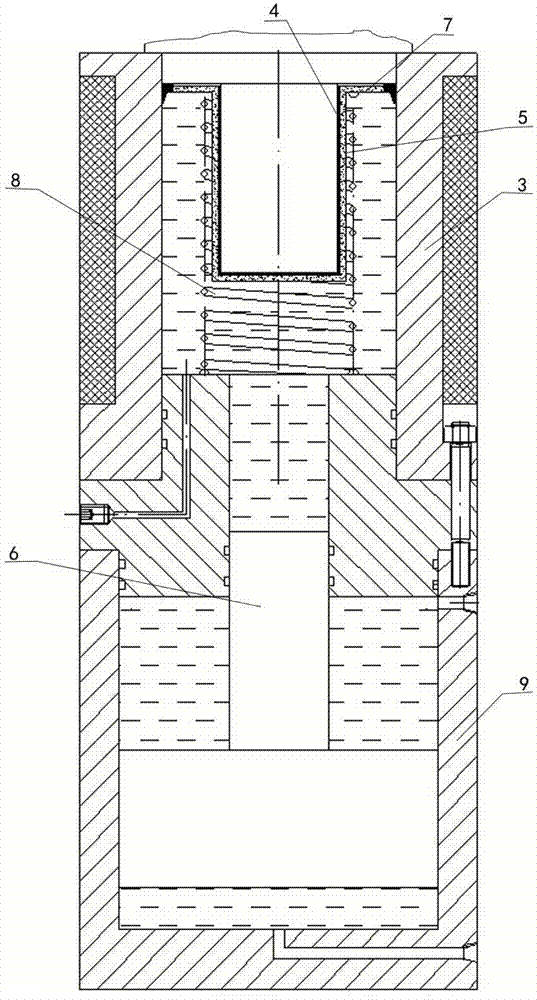

[0019] Film dry bag isostatic press, including frame 1, high-pressure oil cylinder 2 on the top of the frame, high-pressure chamber 3 in the lower part of the frame, dry bag 4 in the high-pressure chamber, and the dry bag 4 is sealed by the upper part and the inner wall of the high-pressure chamber 3 The connected supporting connection part and the working part of the lower part; the high-pressure cavity 3 is fixed with a porous and breathable rigid master 5, the working part of the dry bag 4 is located in the mold cavity of the master 5, and the working part of the dry bag 4 is made of film , the shape and volume of the working part of the dry bag 4 are compatible with the mold cavity of the master model, so that the powder added to the dry bag is shaken or compacted and the shape is consistent with the shape of the mold cavity of the master model without being affected by drying. The effect of poor fit between the working part of the bag and the inner wall of the formwork. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com