Three-level integration auxiliary damping mechanism

A shock-absorbing mechanism and crawler technology, which is applied to motor vehicles, trolley accessories, sleds, etc., can solve problems such as ineffective shock-absorbing effects and damage to fragile goods, so as to reduce the time of manual handling, improve efficiency, and increase the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

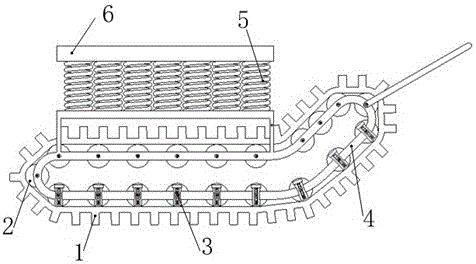

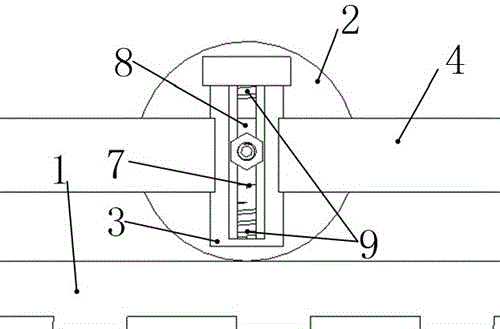

[0014] The specific structure of the patent tool of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The structural composition of patent tool of the present invention is as figure 1 and figure 2 shown. The three-stage integrated auxiliary damping mechanism includes a crawler damping structure, a sleeve spring damping structure and a bottom plate damping structure. The three-stage integrated auxiliary damping mechanism consists of crawler belt (1), roller (2), sleeve (3), frame (4), large spring (5), bottom plate (6), lower shaft seat (7), upper Axle seat (8) and little spring (9) form. Track damping consists of track (1) and rollers (2), both of which are made of soft rubber, so track (1) and rollers (2) have certain shock absorption Cushioning performance, the upper and lower sides of the track (1) are in contact with the rollers (2) and the ground respectively, and the moving track (1) can complete the trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com