Stabilizer for treating arsenic-containing waste residues, and preparation method thereof

A stabilizer and waste residue technology, applied in the field of stabilizer and its preparation, can solve the problems of secondary pollution, large dosage, re-release, etc., achieve impact resistance and wear resistance, simple preparation method, and improve the effect of compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

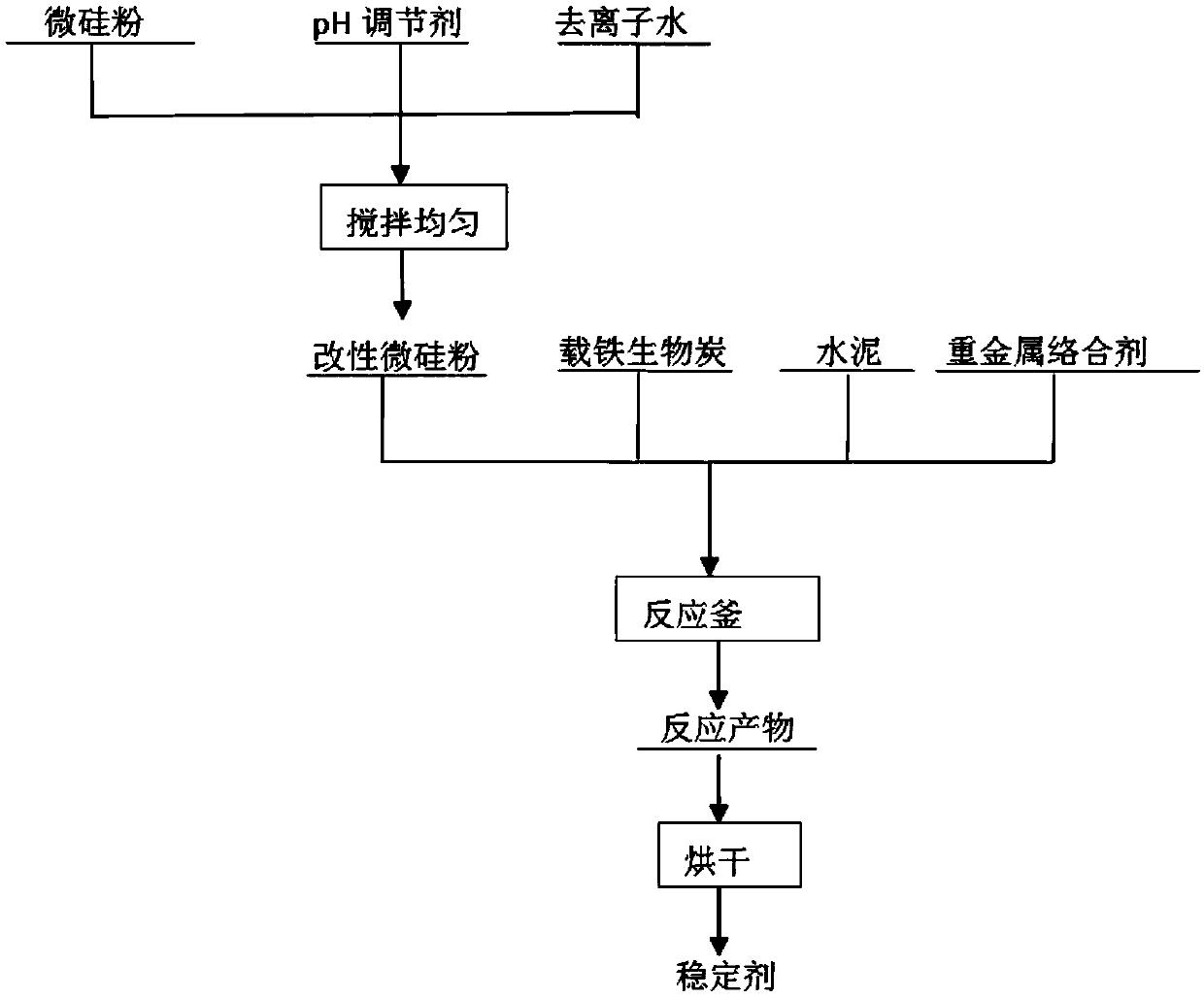

[0024] Example 1: This stabilizer for treating arsenic-containing waste residues, in terms of weight percentage, each component is 40% of silica fume, 20% of iron-carrying biochar, 10% of cement, 15% of pH regulator, heavy metal complexation The iron-loaded biochar is prepared by roasting distiller's grains and iron powder, and the mass ratio of iron powder and distiller's grains is 1:1, the roasting temperature is 300°C, the roasting time is 2 hours, and the pH regulator is calcium oxide. The heavy metal complexing agent is ethylenediaminetetraacetic acid, such as figure 1 Shown, the preparation method of this stabilizer is:

[0025] (1) First, add calcium oxide to the ground micro-silica powder by weight percentage, then add deionized water, and then stir and mix at 25°C to obtain modified micro-silica powder;

[0026] (2) Add iron-loaded biochar, cement, and ethylenediaminetetraacetic acid sequentially to the modified microsilica powder according to the weight ratio, and t...

Embodiment 2

[0029] Embodiment 2: This stabilizer for treating arsenic-containing waste residues, by weight percentage, each component is 50% microsilica fume, 10% iron-carrying biochar, 15% cement, 10% pH regulator, heavy metal complexation The iron-loaded biochar is prepared by roasting distiller's grains and iron powder, and the mass ratio of iron powder and distiller's grains is 1:2, the roasting temperature is 400°C, the roasting time is 3 hours, and the pH regulator is sodium hydroxide , the heavy metal complexing agent is lignin, and the preparation method of this stabilizer is:

[0030] (1) First, sodium hydroxide is added to the ground micro-silica powder by weight percentage, then deionized water is added, and then stirred and mixed at 25°C to obtain modified micro-silica powder;

[0031] (2) Add iron-loaded biochar, cement, and lignin to the modified micro-silica powder in sequence by weight, and then place them in a reactor for 2 hours to react to obtain a reaction product, whi...

Embodiment 3

[0034] Embodiment 3: This stabilizer for treating arsenic-containing waste residues, in terms of weight percentage, each component is 60% of microsilica fume, 15% of iron-carrying biochar, 5% of cement, 10% of pH regulator, heavy metal complexation The iron-loaded biochar is prepared by roasting distiller's grains and iron powder, and the mass ratio of iron powder and distiller's grains is 1:3, the roasting temperature is 500°C, the roasting time is 4 hours, and the pH regulator is sodium bicarbonate , the heavy metal complexing agent is sodium carboxymethyl cellulose, and the preparation method of this stabilizer is:

[0035] (1) First, sodium bicarbonate is added to the ground micro-silica powder by weight percentage, then deionized water is added, and then stirred and mixed at 25°C to obtain modified micro-silica powder;

[0036] (2) Add iron-loaded biochar, cement, and sodium carboxymethylcellulose sequentially to the modified micro-silica powder according to the weight ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com