Yarn coiler, automatic winder and splicing portion detection method

An inspection method and winding machine technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of labor and time-consuming, unable to maintain inspection accuracy constantly, and achieve the effect of easy inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

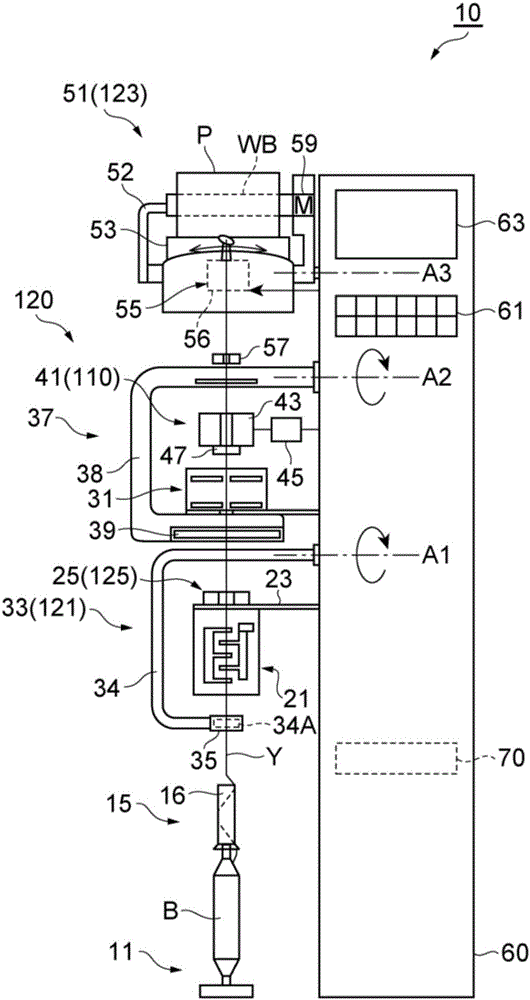

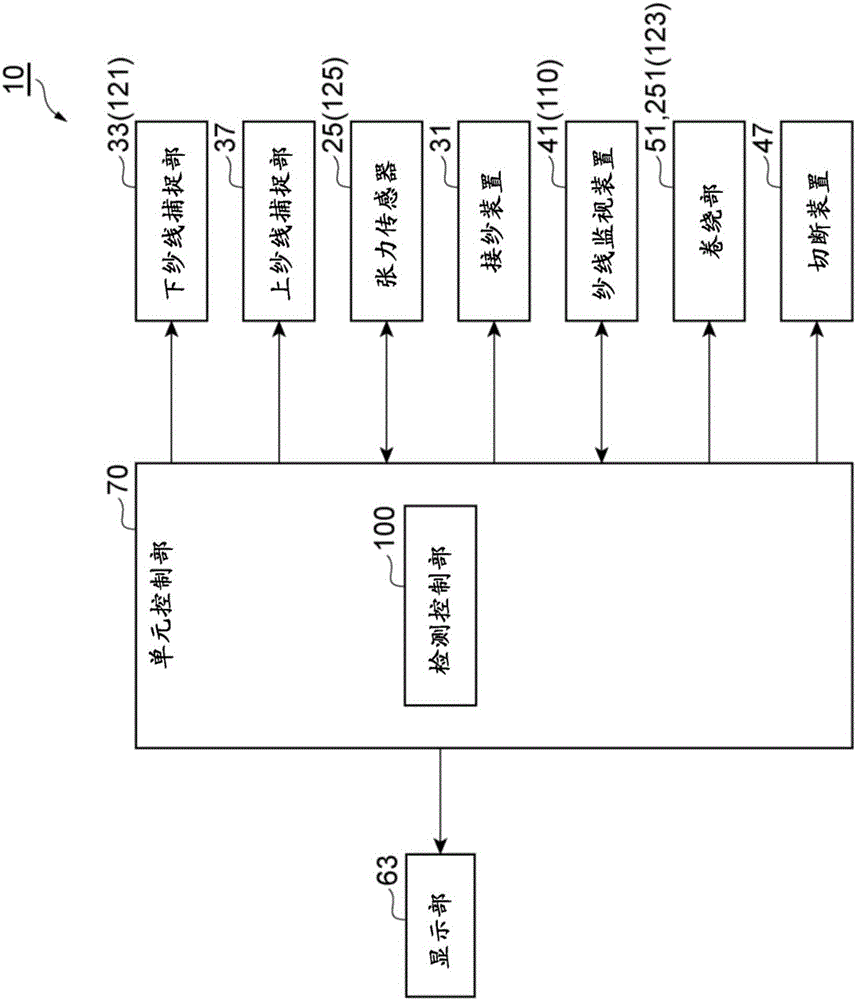

[0049] Hereinafter, an embodiment will be described with reference to the drawings. In the description of the drawings, the same reference numerals are attached to the same elements, and overlapping descriptions are omitted. The dimensional ratios of the drawings do not necessarily coincide with the device ratios described.

[0050] First, refer to figure 1 The overall structure of the automatic winder 1 including the winder unit (yarn winding machine) 10 according to one embodiment will be described. However, in this specification, "upstream" and "downstream" mean upstream and downstream in the moving direction of the yarn when the yarn is wound.

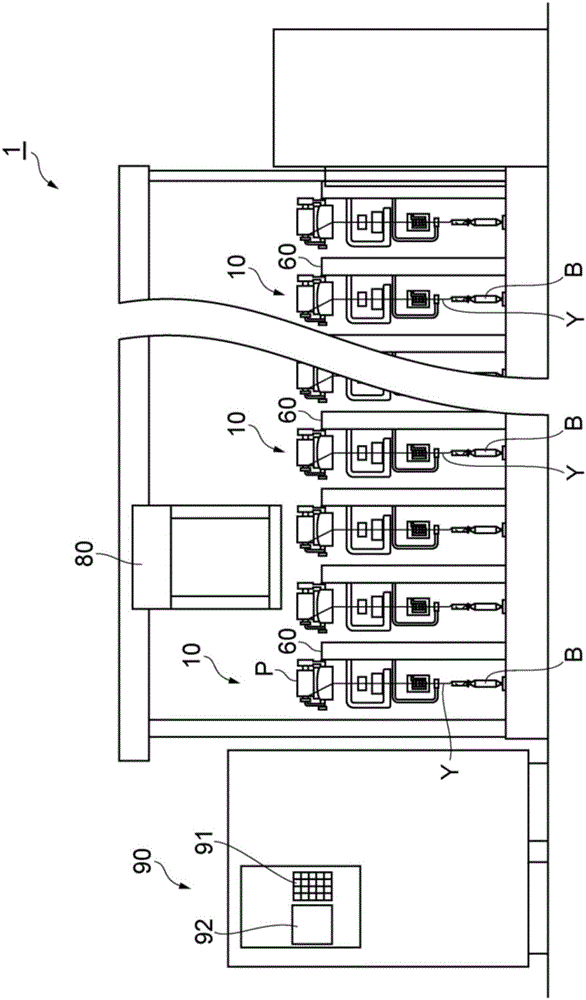

[0051] Such as figure 1 As shown, the automatic winder 1 mainly includes a plurality of winder units 10 arranged side by side, an automatic doffing device 80 , and a machine control device 90 as main components. The winding unit 10 is a device for manufacturing a package P by winding the yarn Y unwound from the yarn supplying b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com