Clamp suitable for hoisting motor stators of different sizes

A motor stator, adapting to different technologies, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inconvenient lifting of the iron core, inconvenient production, increased procurement costs, etc., to achieve the goal of reducing procurement costs and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

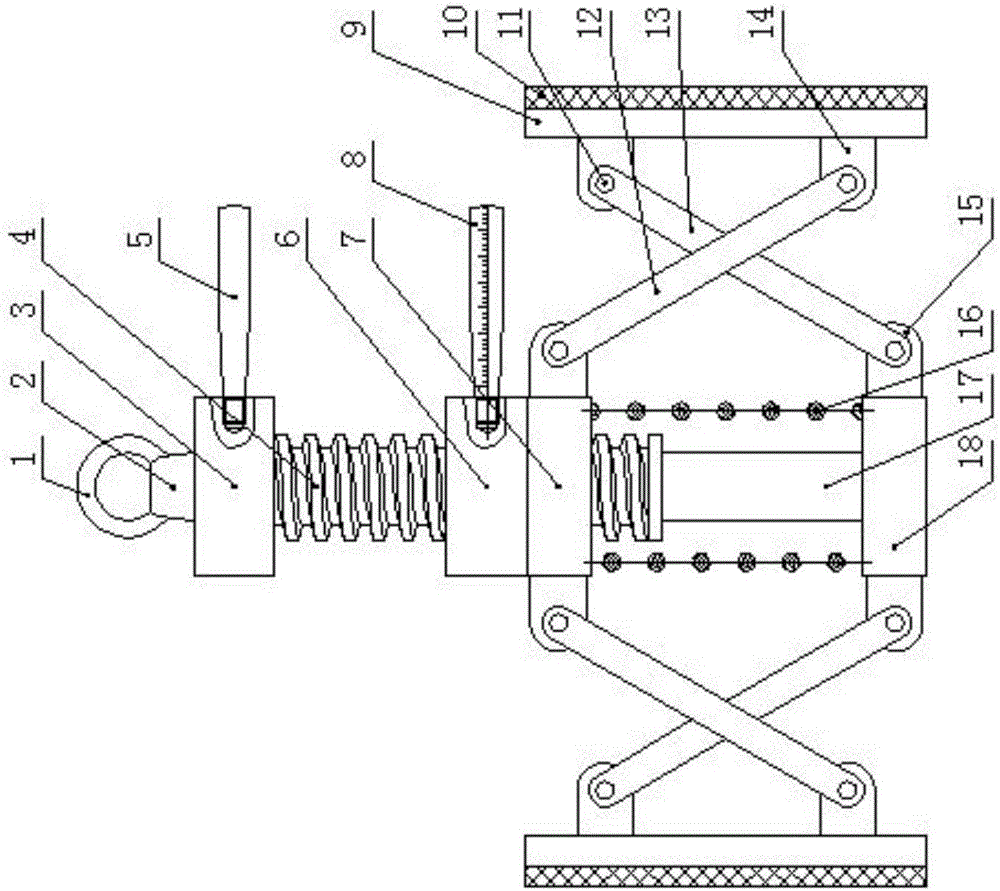

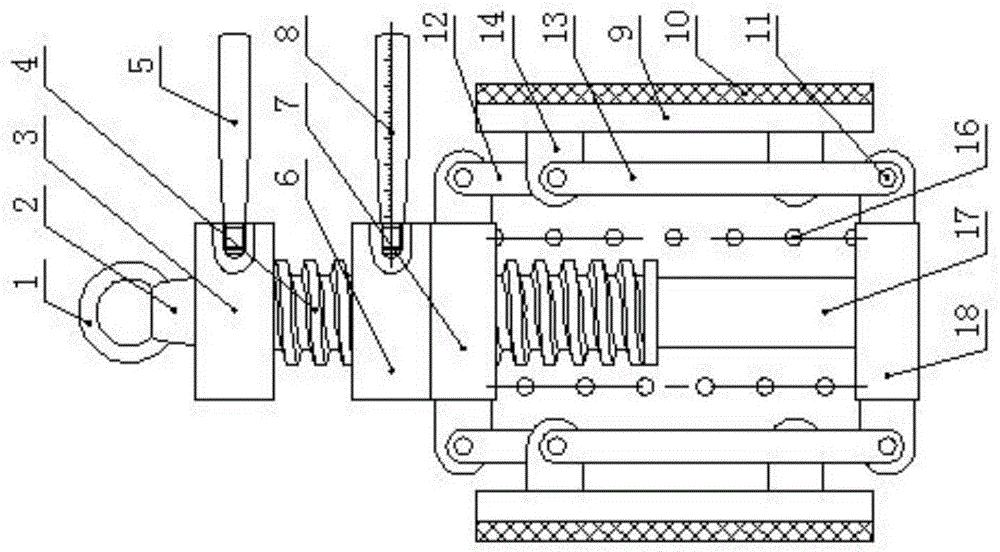

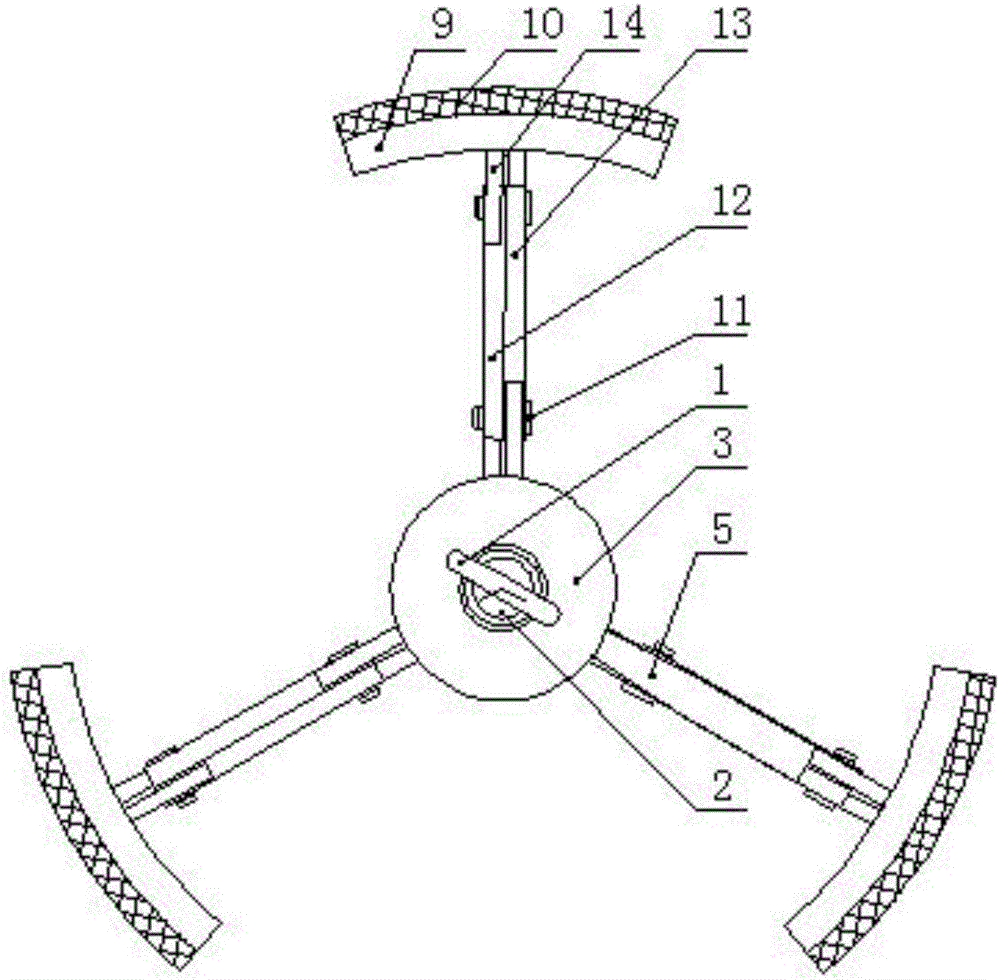

[0016] A fixture suitable for hoisting motor stators of different sizes, such as figure 1 , 2 , Shown in 3, the innovation of the present invention is: comprise leading screw 2, rotating block, telescopic connecting rod, splint 9 and spring 16, the upper end of leading screw installs lifting lug 1, on the screw thread of leading screw outer edge below lifting lug The rotating block is engaged and rotated, and the lower end 17 of the leading screw is installed with the lower connecting rod mounting block 18. The rotating block and the lower connecting rod mounting block are provided with a plurality of telescopic connecting rods along the radial direction of the leading screw, and each telescopic connecting rod A vertical splint is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com