Silkworm cocoon soaking device for spinning

A silkworm cocoon and cylinder technology, which is applied in textiles and papermaking, silk fiber production, mechanical treatment, etc., can solve the problems of low soaking efficiency, waste of water resources, and unusable water, so as to reduce soaking time and speed up water absorption. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

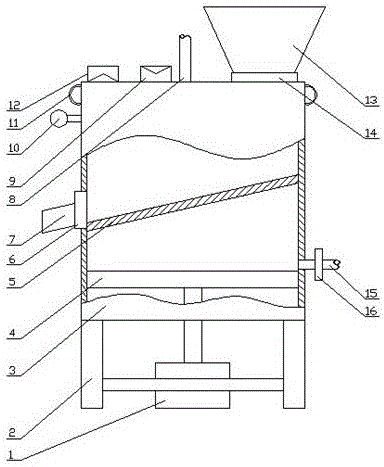

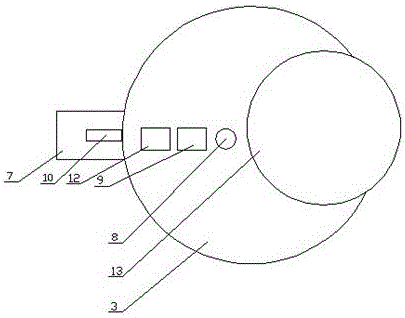

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

[0024] Such as figure 1 , figure 2 As shown, the silkworm cocoon soaking device for weaving has a structure including a cylinder body 3, which is a cylindrical hollow structure. When in use, the cylinder body 3 is used to carry water and silkworm cocoons to provide a space for silkworm cocoons to soak; the cylinder body The inner bottom of 3 is supported by the piston head 4 through the electro-hydraulic top 1, the electro-hydraulic top 1 runs through the bottom of the cylinder 3, the piston head 4 is a disc structure, the piston head 4 is placed horizontally, and the outer ring of the piston head 4 is close to the inner wall of the cylinder 3, When in use, the piston head 4 is pushed by the electro-hydraulic top 1, and can move up and down along the inner wall of the cylinder 3, increasing or decreasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com