A liquid pipeline stop valve structure and using method

A liquid pipeline and globe valve technology, applied in the hydraulic field, can solve the problems of complex structure, large volume, influence, etc., and achieve the effect of avoiding excessive volume, simple and reasonable structure, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

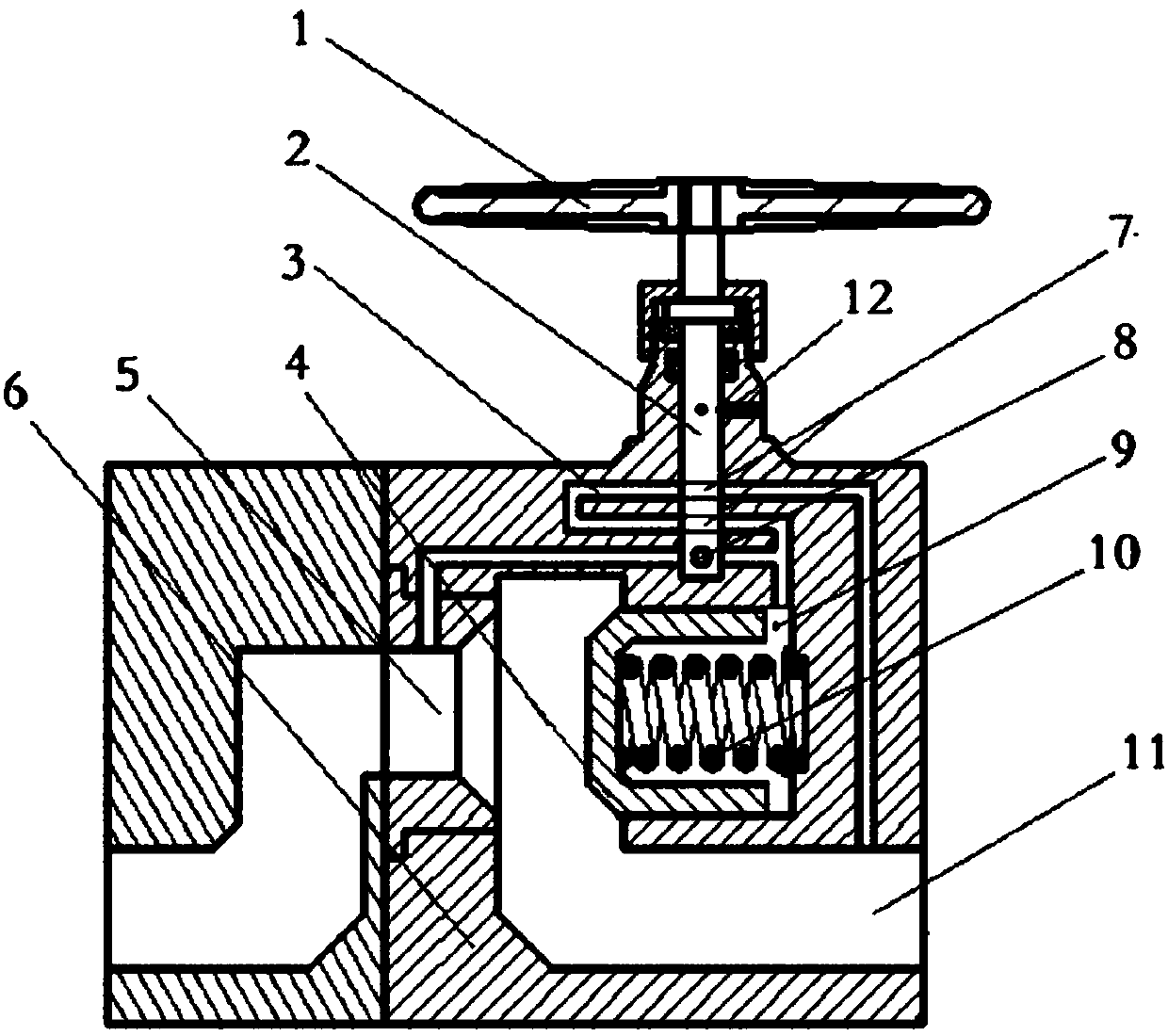

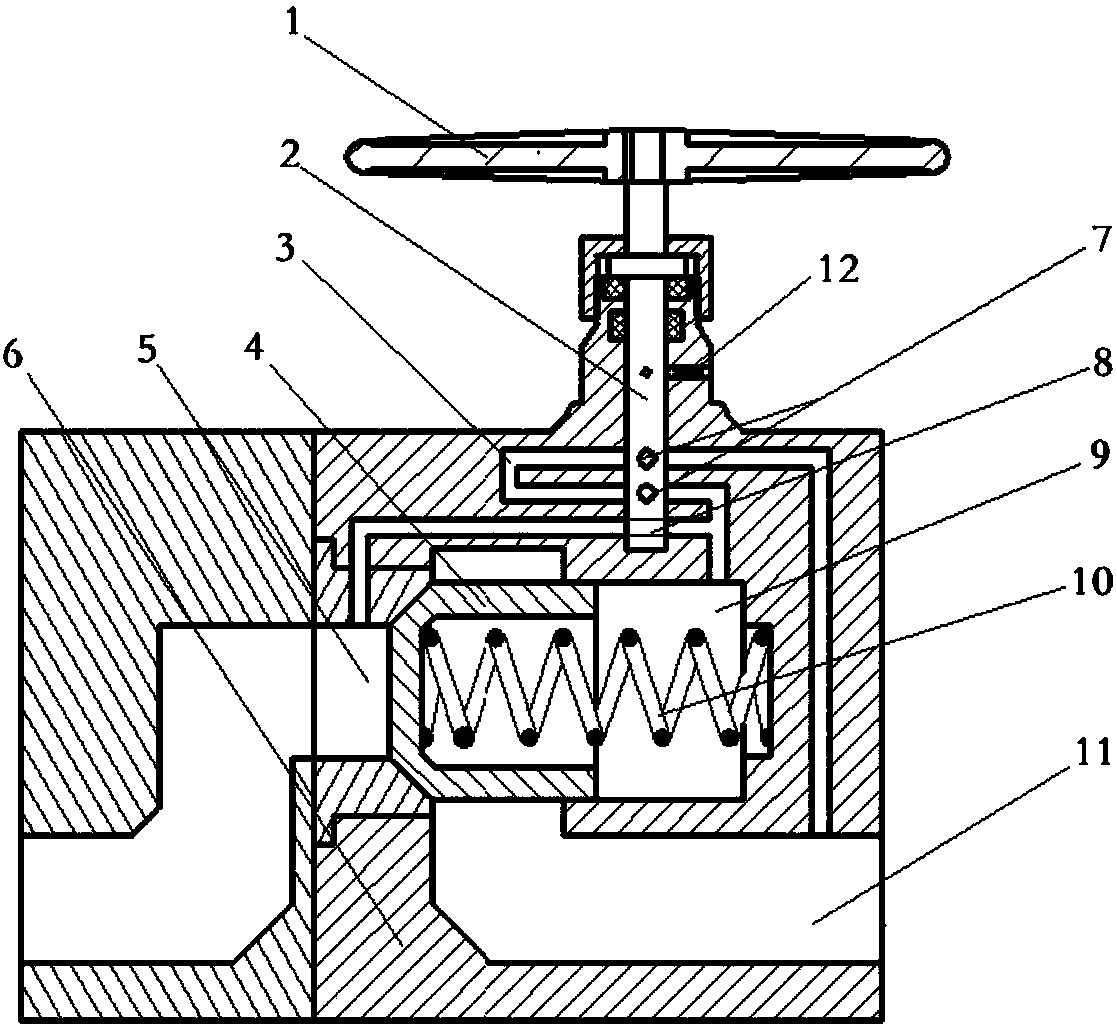

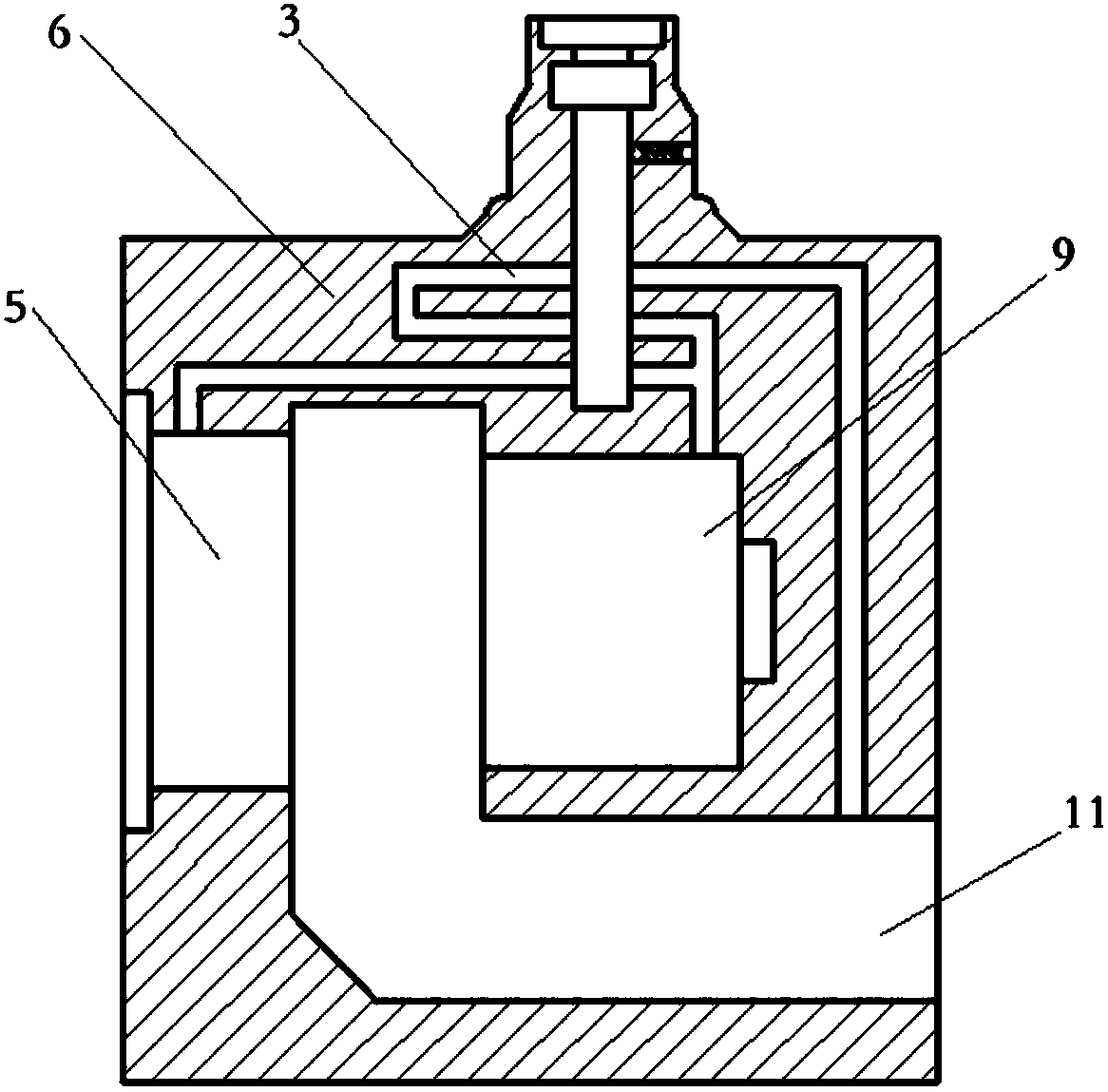

[0014] Referring to the accompanying drawings, the structure of the liquid pipeline cut-off valve includes a body 6 and a valve stem 2 and a valve core 4 assembled on the body. The inlet of the inner cavity, the rear end 11 of the inner cavity is connected to the outlet of the liquid pipeline, and the communication between the front end 5 of the inner cavity and the rear end 6 of the inner cavity is controlled by the expansion and contraction of the valve core 4, which is embedded in the body through a return spring 10 In the inner cavity 9, there is also a small pipeline 3 with a circuitous layout built in the body 6. The front end of the small pipeline 3 communicates with the front end 5 of the inner cavity of the body, and the rear end of the small pipeline is divided into two ways to connect with the rear of the inner cavity respectively. The end 11 communicates with the cavity 9, and the valve stem 2 is fixed on the body 6 through a bearing. Intersection, the intersection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com