Sheet inspection device

A technology for inspecting devices and sheets, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of large-scale devices, increased costs, low detection accuracy, etc., and achieve the effect of miniaturization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

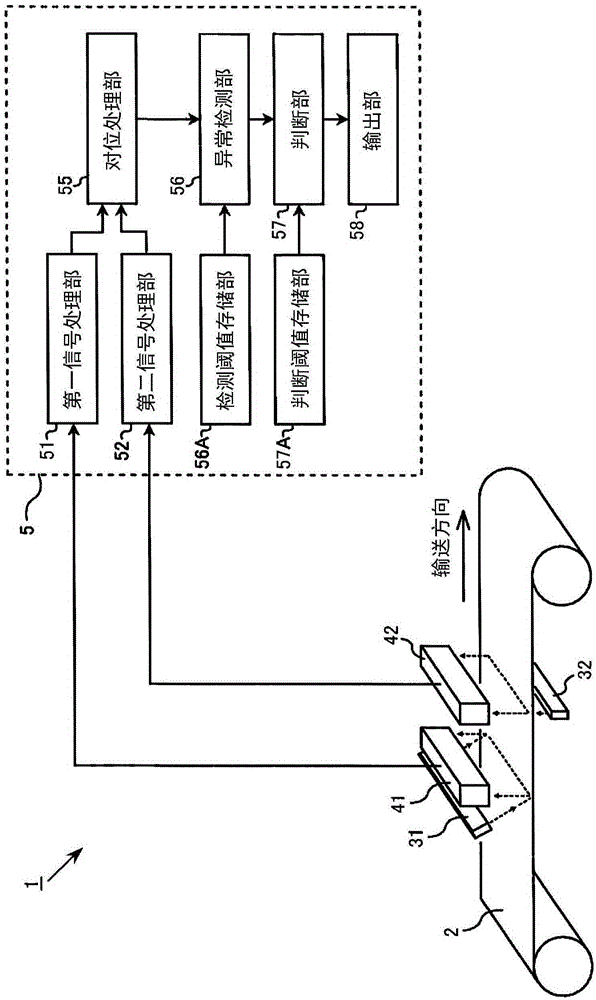

[0072] figure 1 It is a block diagram of the sheet inspection device 1 of this embodiment. The sheet inspection device 1 is a system used to automatically detect abnormalities and defects of sheet articles in a production line that manufactures and processes sheet articles.

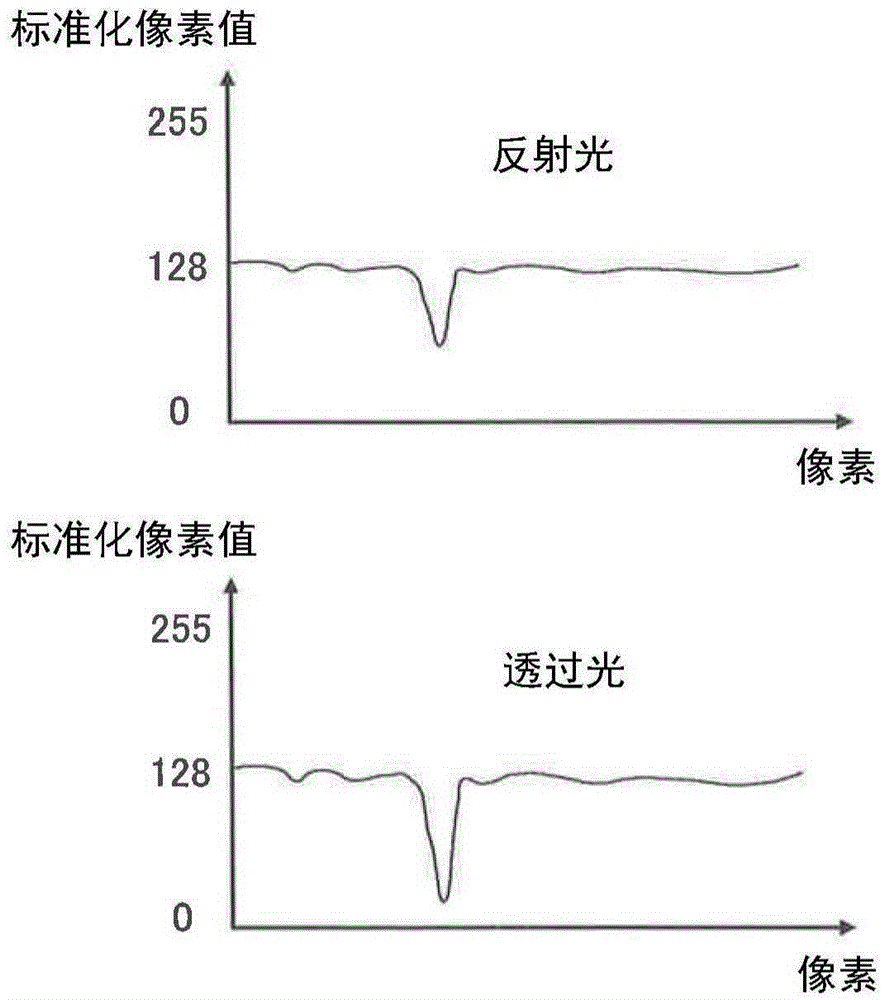

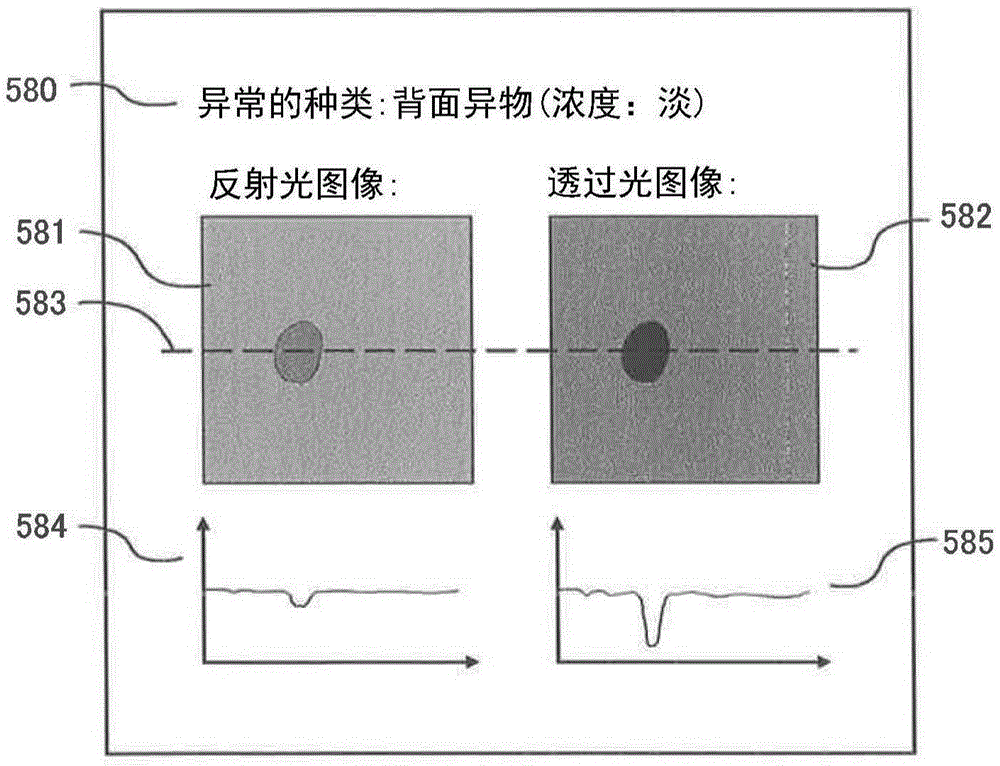

[0073] The sheet inspection apparatus 1 includes, as an illumination system: a first light source 31 for irradiating visible light to the front (first surface) of a sheet-shaped inspection object 2; ) irradiates visible light. In addition, the sheet inspection apparatus 1 has, as a measurement system, a first imaging sensor 41 and a second imaging sensor 42 arranged on the front side of the inspection object 2 . The first imaging sensor 41 is a reflected light measurement system, and is configured to capture light irradiated from the first light source 31 and diffusely reflected by the object 2. The second imaging sensor 42 is a transmitted light measurement system, and is configured to capture light fr...

no. 2 example

[0106] Next, a sheet inspection device related to the second embodiment will be described. The second embodiment is characterized in that by adding a reflected light measurement system using infrared light to the structure of the first embodiment, it is possible to discriminate whether the front foreign matter is metal or non-metal.

[0107] Figure 7 It is a block diagram of the sheet inspection apparatus 1 of the second embodiment. In addition to the structure of the first embodiment (refer to figure 1 ), a third light source 33 that irradiates infrared light to the front (first surface) of the object 2 to be inspected, and a third imaging sensor 43 disposed on the front (first surface) of the object 2 to be inspected. The third imaging sensor 43 is an image sensor sensitive to the wavelength of infrared light, and is configured to capture infrared light irradiated from the third light source 33 and diffusely reflected by the inspection object 2 .

[0108] The sheet inspe...

no. 3 example

[0118] Figure 10A The configurations of the lighting system and the measurement system of the sheet inspection apparatus 1 of the third embodiment are shown. In the third embodiment, the reflected visible light of the first light source 31 , the transmitted visible light of the second light source 32 , and the reflected infrared light of the third light source 33 are captured by one imaging device 4 . As a shooting device 4, such as Figure 10B As shown, the three line sensors of the first imaging sensor 41 , the second imaging sensor 42 , and the third imaging sensor 43 use 3-line cameras arranged staggered in the conveying direction.

[0119] In this structure, when the imaging device 4 is arranged on the front side (first surface side) of the object 2 to be inspected, the first light source 31 and the third light source 33 are arranged on the same front side as the imaging device 4, and the second light source 31 is arranged on the same front side as the imaging device 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com