Mandrel fixing and adjusting device

An adjustment device and mandrel technology, which is applied in the field of product manufacturing systems with cavities, can solve the problems of difficult quick and accurate adjustment of the mandrel, and fluctuations in the wall thickness of pultrusion profiles, and achieve real-time automatic adjustment, stable and precise adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

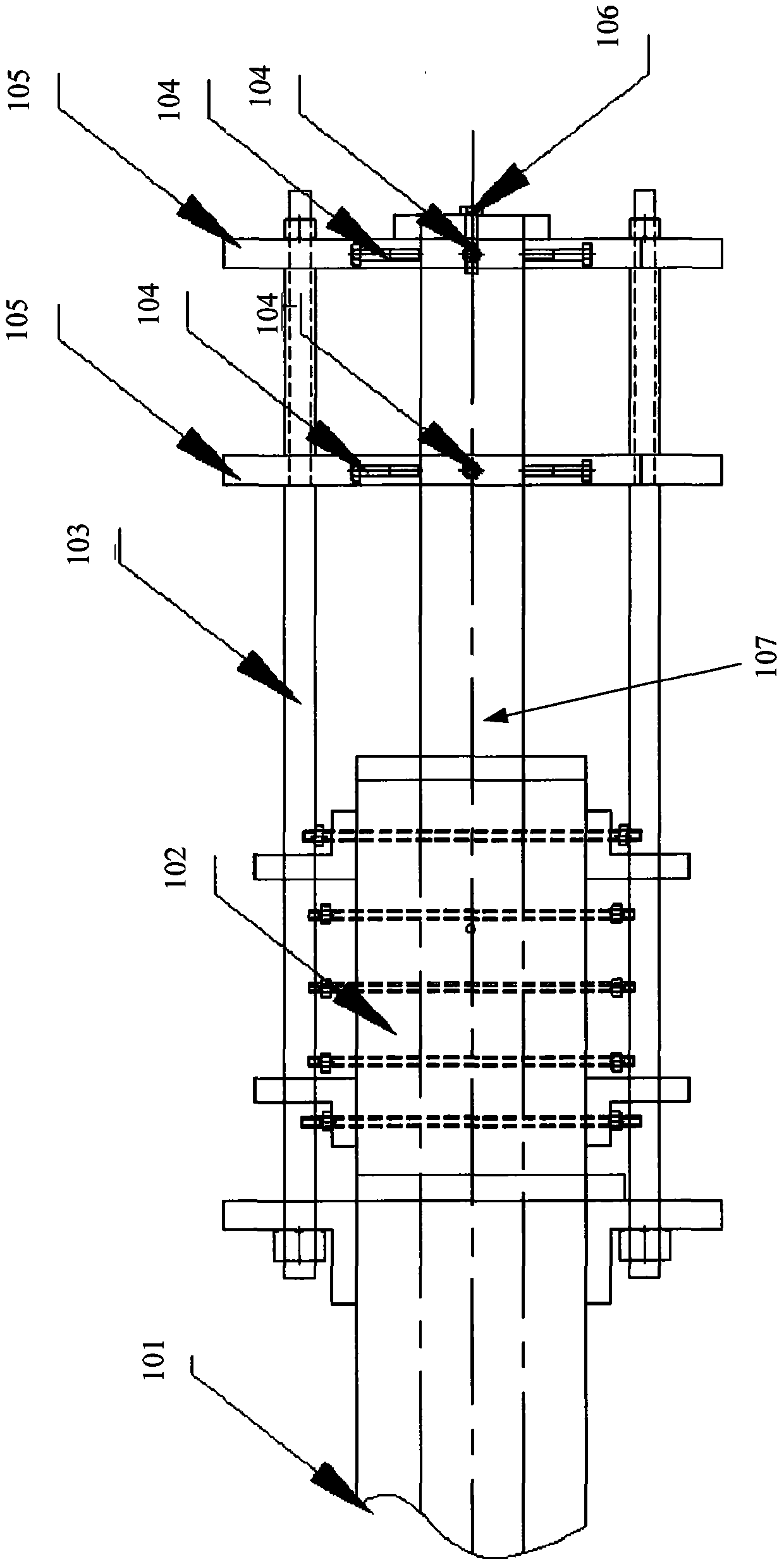

[0075] Figure 4 It is a side view of the first embodiment of the product manufacturing system with cavity equipped with the mandrel fixing and adjusting device of the present invention.

[0076] Such as Figure 4 As shown, the product manufacturing system with a cavity is arranged with a mandrel fixing and adjusting device 10 , a fiber impregnation system 13 and a mold 14 from the left side of the figure. The mandrel fixing and adjusting device 10, the fiber impregnation system 13 and the mold 14 are each firmly connected to the formwork 1 by at least one fastener. One end of the mandrel 8 remains inside the mandrel jacket 7 and maintains a fixed position relative to the mandrel jacket 7 , while the other end extends out from the mandrel jacket 7 .

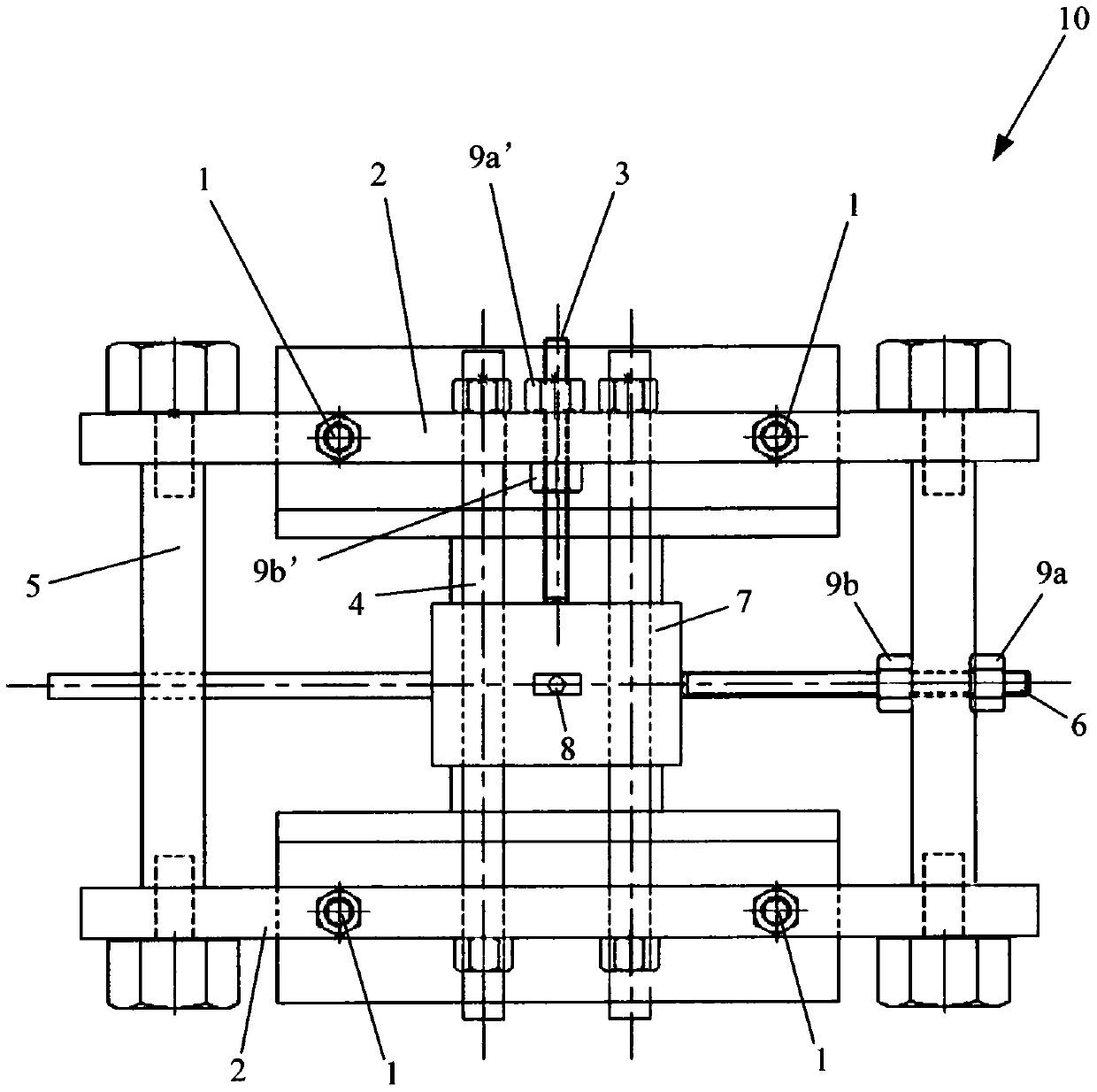

[0077] The vertical or horizontal position adjustment of the mandrel 8 integrated in the mandrel jacket 7 along its cross section can be realized by the vertical position adjustment screw rod 3 and the horizontal position adjus...

no. 2 example

[0079] Figure 5 It is a side view of the second embodiment of the product manufacturing system with cavity equipped with the mandrel fixing and adjusting device of the present invention. This embodiment is provided with a mandrel fixing and adjusting device similar to the first embodiment, and has the same mandrel adjustment method as the first embodiment, the difference being that the mold inlet is not connected with the fiber impregnation device. In this implementation, the fibers are impregnated with resin before entering the mold around a mandrel, where the shape is cured in the cavity formed by the mandrel and the inner wall of the mold.

no. 3 example

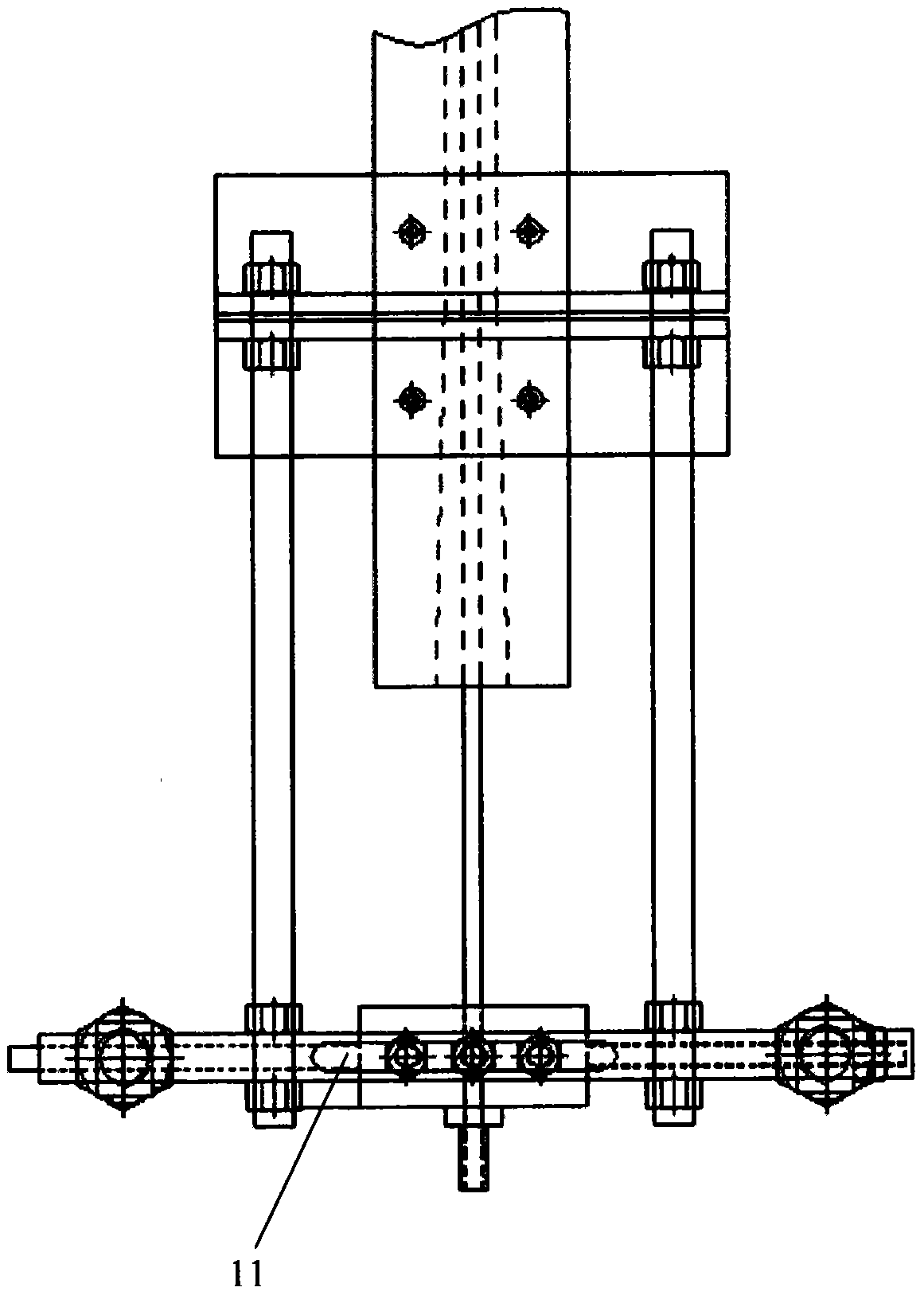

[0081] Figure 6 It is a side view of the third embodiment of the product manufacturing system with cavity equipped with the mandrel fixing and adjusting device of the present invention. This embodiment is equipped with a mandrel fixing and adjusting device similar to the first embodiment, and has the same mandrel adjustment method as the first embodiment, the difference is that the product manufacturing system with a cavity includes a front and rear direction along the mandrel Arranged two mandrel fixing and adjusting devices. As previously mentioned, each adjustment involves only any one of the two mandrel fixing and adjusting devices arranged along the front and rear directions of the mandrel, while keeping the other mandrel fixing and adjusting device unchanged, so that the mandrel jacket Move linearly along the horizontal or vertical axis of the cross-section of the mandrel without shaking, and change the angle between the mandrel 8 passing through the mandrel jacket 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com