A coiled pipe device and a coiled pipe processing production line

A technology of coil pipe and water pipe, applied in the field of water pipe production equipment, can solve the problem of difficult to remove the water pipe, and achieve the effects of convenient operation, enhanced support and diversified functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

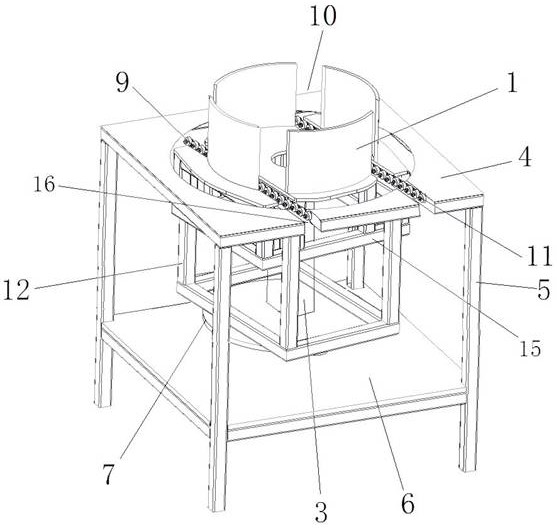

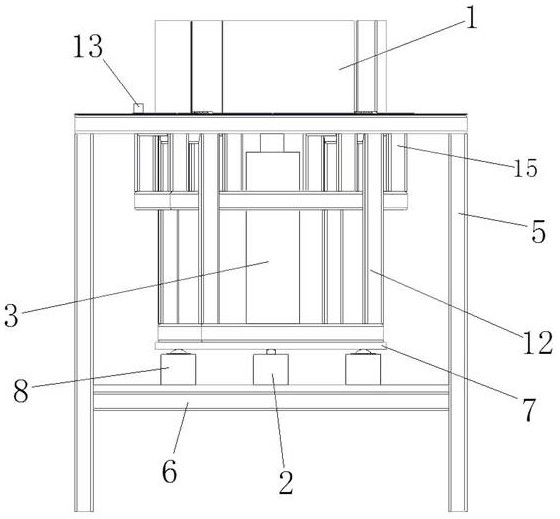

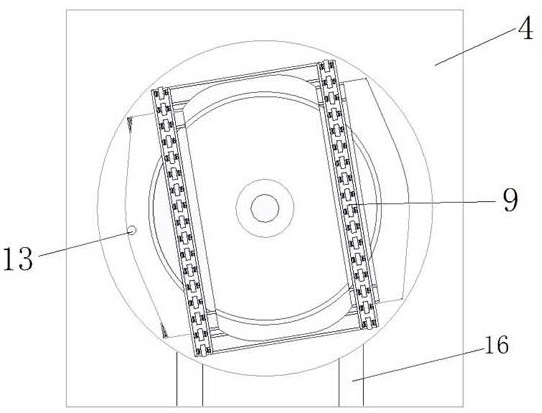

[0048] like Figure 1 to 5 A specific embodiment of the coil device shown in, for aluminum tube plate is provided, comprising: a drum vertically from top to bottom in turn connected to a set of lifting means 3 and the rotation mechanism 2, further comprising a first support frame 5, the lower end of the support frame 5 is provided with a first pallet 6, the rotation mechanism 2 is provided on the pallet 6, the upper end of the first bracket 5 is provided with a stopper portion 4 is provided with a fixing means on the drum 1 . By providing the fixing means is fixed to the head pipe drum 1, and is rotated by the rotation mechanism driving the drum 1, so that the outer wall of the pipe is wound around the drum 1 is coil, when the coil is completed, using the lifting drive means 3 moves the drum 1, the drum 1 during the movement of the water driven by the blocking force on the pipe section 4, so that water from off the drum 1, and placed on the stopper portion 4, the coil solved after ...

Embodiment 2

[0062] The present embodiment provides a specific embodiment the coil of a processing line, comprising the above coil unit, and a piping joint attachment means a pair of two head coil means wound around the water pipe is provided corresponding tube connector means comprises a nozzle mounting structure flared fittings and mounting structure.

[0063] like Figure 8 with 9 Flaring nozzle configuration shown, includes a driver 17, a slider 18 and 19 expand orally, and the driving end of the drive slide 17 fixedly connected to the rear end 18, 19 is fixedly connected to the front end of the oral expansion of the slider 18. An end portion in the driving driver 17, the slide 18 carries an enlarged orally 19 enters be flared mouthpiece, in which case expansion orally 19 in the positioned state; driving end of driver 17 is held stationary, after certain duration, drive 17 again driving the slider 18, the slider 18 driven into the interior 19 to be spread orally flared mouthpiece, to treat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com