Additive putting module and washing machine

A technology of additives and waterways, which is applied in the field of delivery modules, can solve the problems of complex assembly of delivery devices, increase of delivery device costs, unfavorable delivery of additives, etc., and achieve the effect of rational arrangement, suitable for popularization and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

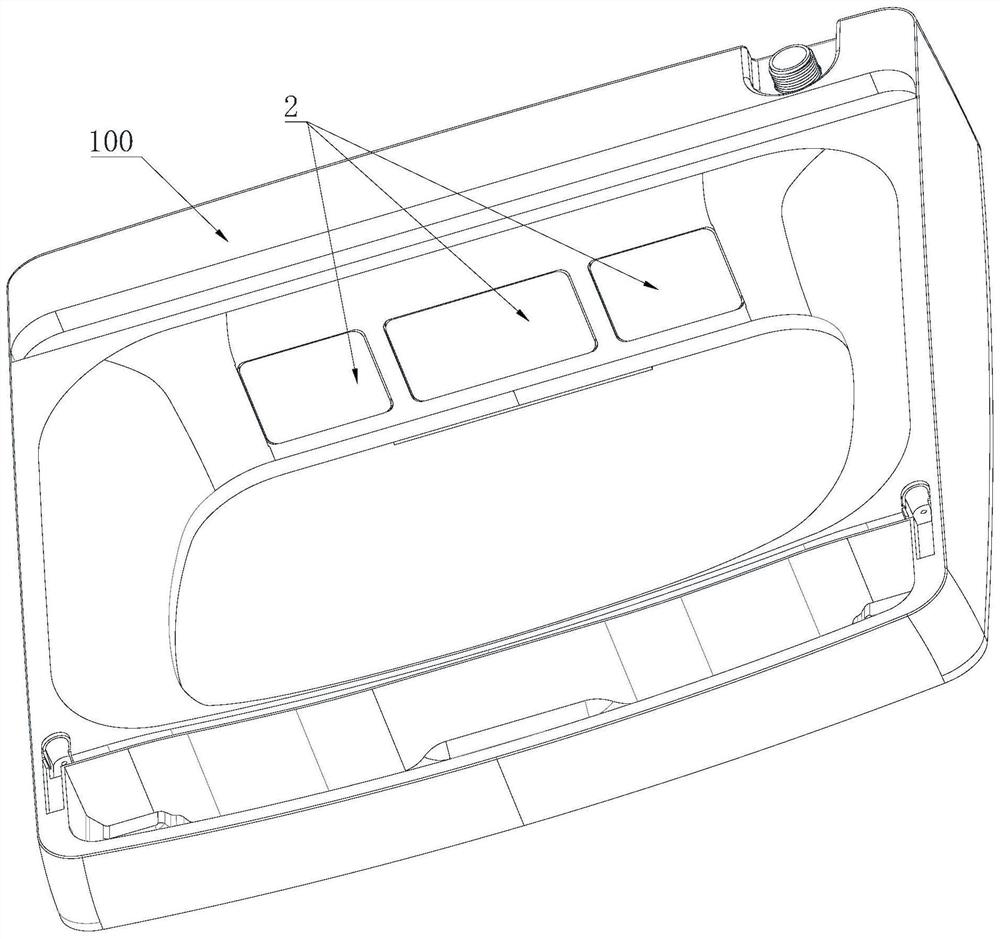

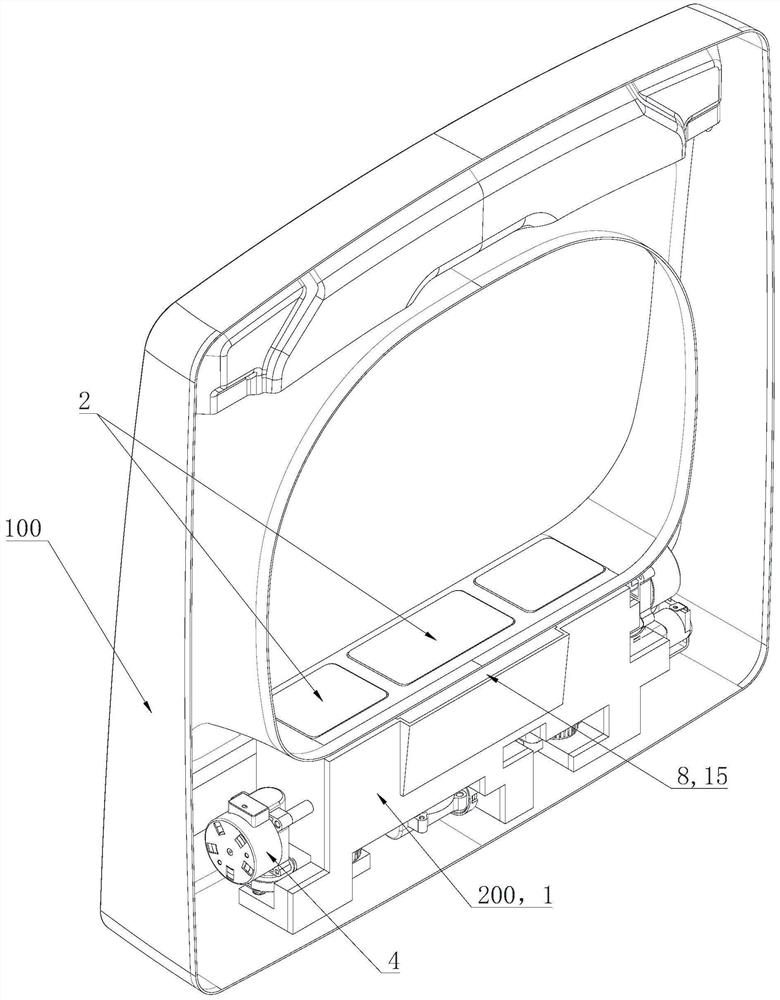

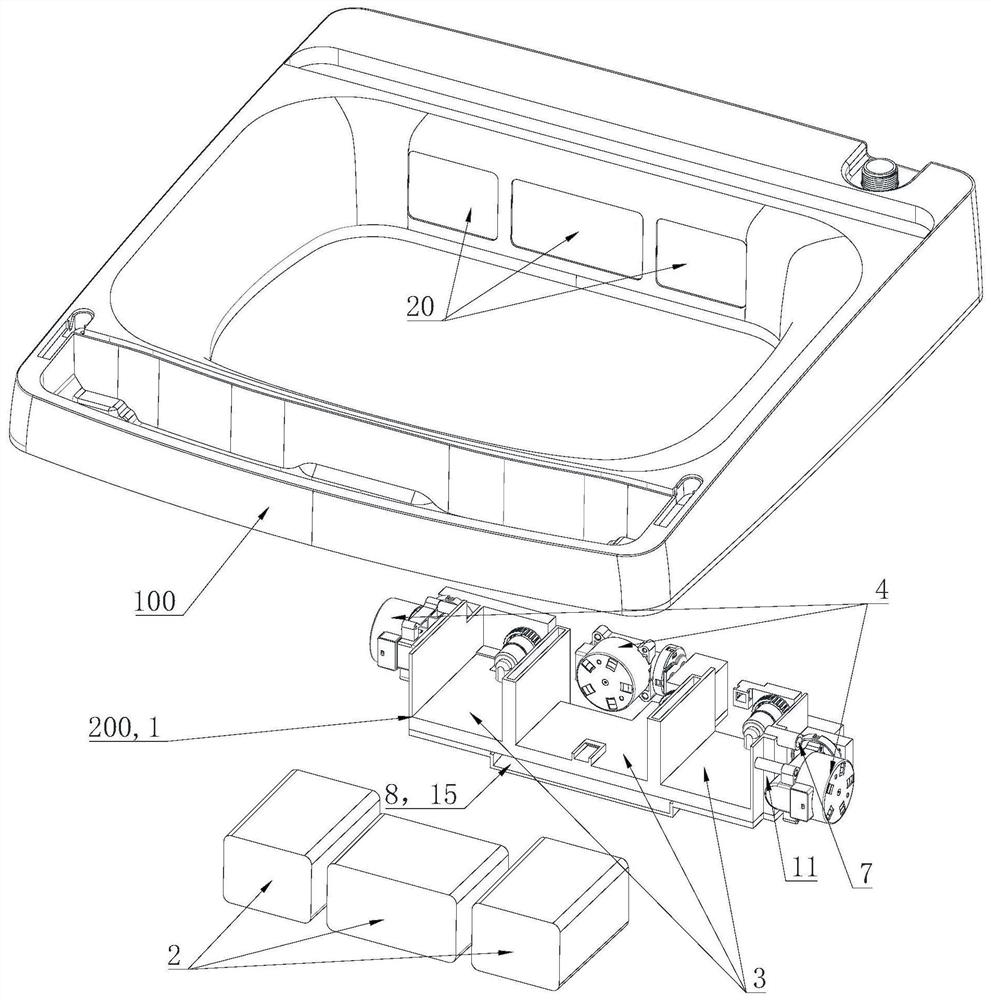

Embodiment 1

[0043] Such as Figure 1 to Figure 9 As shown, an additive dosing module is introduced in this embodiment, and the dosing module 100 includes: a body 1 composed of independent components. The main body 1 has at least one insertion slot 3 inside, and the opening of the insertion slot 3 is provided on the outer wall of the main body 1 to form a drawing opening 19 . A liquid storage box 2 is installed in the socket 3, which can be pulled out from the pull port and pushed inward. The liquid storage box 2 forms a sealed cavity for additive storage; preferably, the liquid storage box 2 is an ink cartridge-type sealed The container directly forms a sealed cavity, so that the ink cartridge type liquid storage box 2 is an independent container for storing additives; the above-mentioned ink cartridge type sealed container is a container similar to a printer ink cartridge. The body 1 of the dispensing module 100 is integrally provided with a water supply channel 5 through which water ca...

Embodiment 2

[0059] Such as Figure 1 to Figure 9 As shown, this embodiment introduces an additive dosing module. The bottom wall of the body 1 of the dosing module 100 is integrated with a water supply channel 5 . Through the above setting, the waterway structure of the delivery module 100 is integrated on the bottom wall of the delivery module 100, realizing the integrated setting of the whole delivery module 100; at the same time, by integrating the water supply channel 5 on the bottom wall of the delivery module 100 , so that the waterway is set under the feeding unit, so that the feeding waterway 5 can directly flow out from the bottom of the feeding module 100 and be fed into the washing tub, thereby realizing the rational arrangement of the feeding module 100 and improving the outlet water pressure of the feeding module 100 Significant technological progress.

[0060] Such as Figure 1 to Figure 9 As shown, in this embodiment, the bottom wall of the body 1 is composed of an upper ...

Embodiment 3

[0076] Such as Figure 1 to Figure 9 As shown, a washing machine is introduced in the embodiment of the present invention. The washing machine includes a housing on which is installed the dispensing module 100 described in any of the above-mentioned embodiments. The opening 20 opened, the water inlet 7 of the feeding module 100 is connected with the water inlet pipe of the washing machine, and the water flowing out of the water outlet structure 8 flows into the tub of the washing machine.

[0077] In the embodiment of the present invention, the washing machine described in the embodiment of the present invention can be an existing laundry washing equipment of any structure, for example: a pulsator type washing machine, a drum type washing machine, etc.; and, the washing machine described in the embodiment of the present invention can be an ordinary Washing machine, the bucket is a washing machine that only has the function of holding water and the outer bucket; it can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com