Polyolefin blend used for continuous long fiber reinforced prepreg tapes, and preparation method thereof

A prepreg tape and polyolefin technology, applied in the field of continuous long fiber fiber reinforced prepreg tape, can solve the problem of limited compatibility between thermoplastic resin and fiber interface, low bonding force between thermoplastic resin and fiber, poor environmental stress resistance, etc. problems, to achieve excellent resistance to environmental stress, enhanced mechanical properties, and enhanced environmental stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

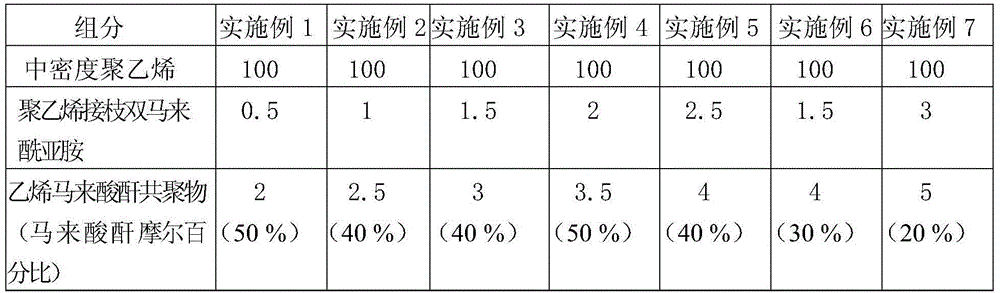

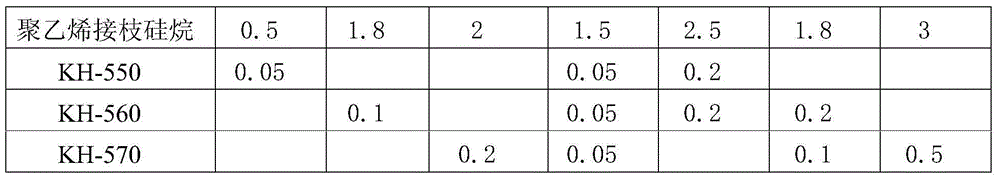

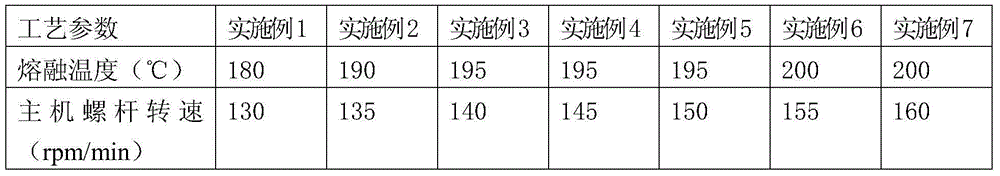

[0010] Invented polyolefin blend for continuous fiber reinforced prepreg tape, the components are calculated in parts by mass, including 100 parts of medium density polyethylene, 0.5-3 parts of polyethylene grafted bismaleimide, 2 -5 parts of ethylene maleic anhydride copolymer and 0.5-3 parts of polyethylene grafted silane and 0.05-0.5 parts of silane coupling agent, wherein the ethylene maleic anhydride copolymer contains 20%-50% by mole The maleic anhydride, the silane coupling agent is one of KH-550, KH-560 or KH-570 or a mixture of any two or more. The invention uses medium-density polyethylene as the matrix resin to make it have excellent environmental stress resistance, and is melted with polyethylene grafted bismaleimide, ethylene maleic anhydride copolymer, polyethylene grafted silane and silane coupling agent Blending can not only improve the heat resistance of the matrix resin, but also through the maleic anhydride group of the ethylene maleic anhydride copolymer and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap