A connection structure of pultruded composite pipe

A connection structure and composite pipe technology, which is applied in the direction of hose connection devices, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as unsatisfactory use, achieve high work efficiency, good sealing performance, and low labor intensity in production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

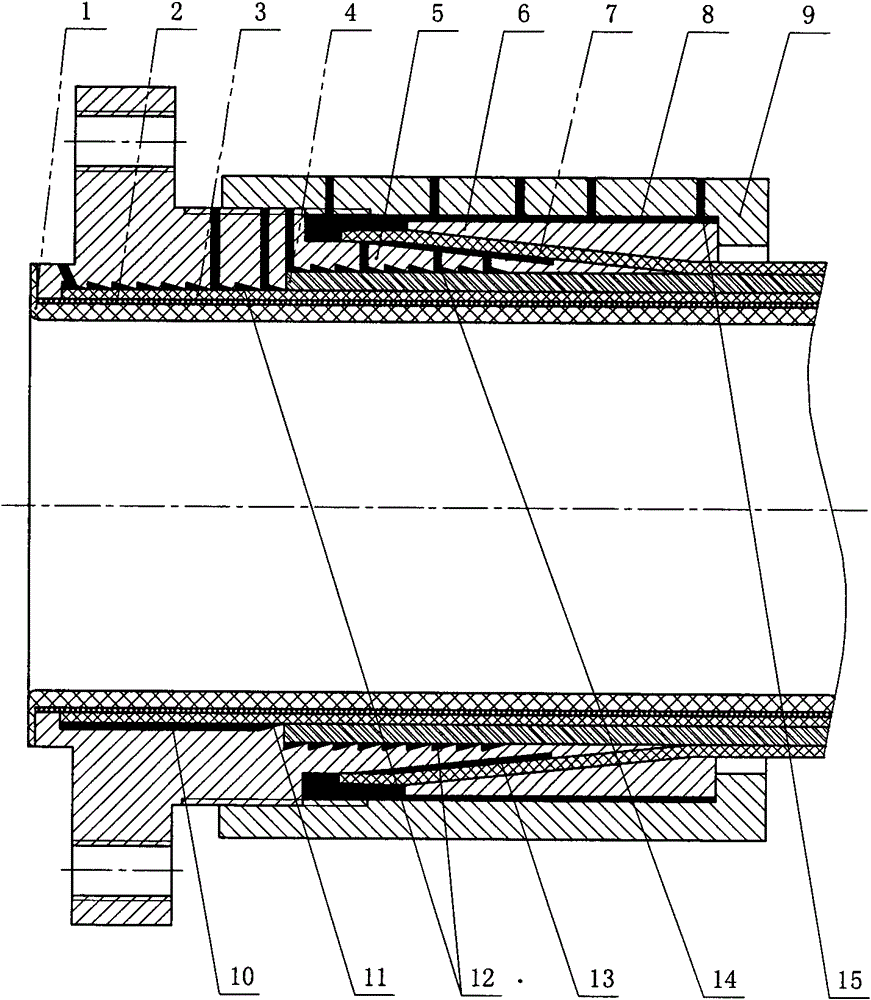

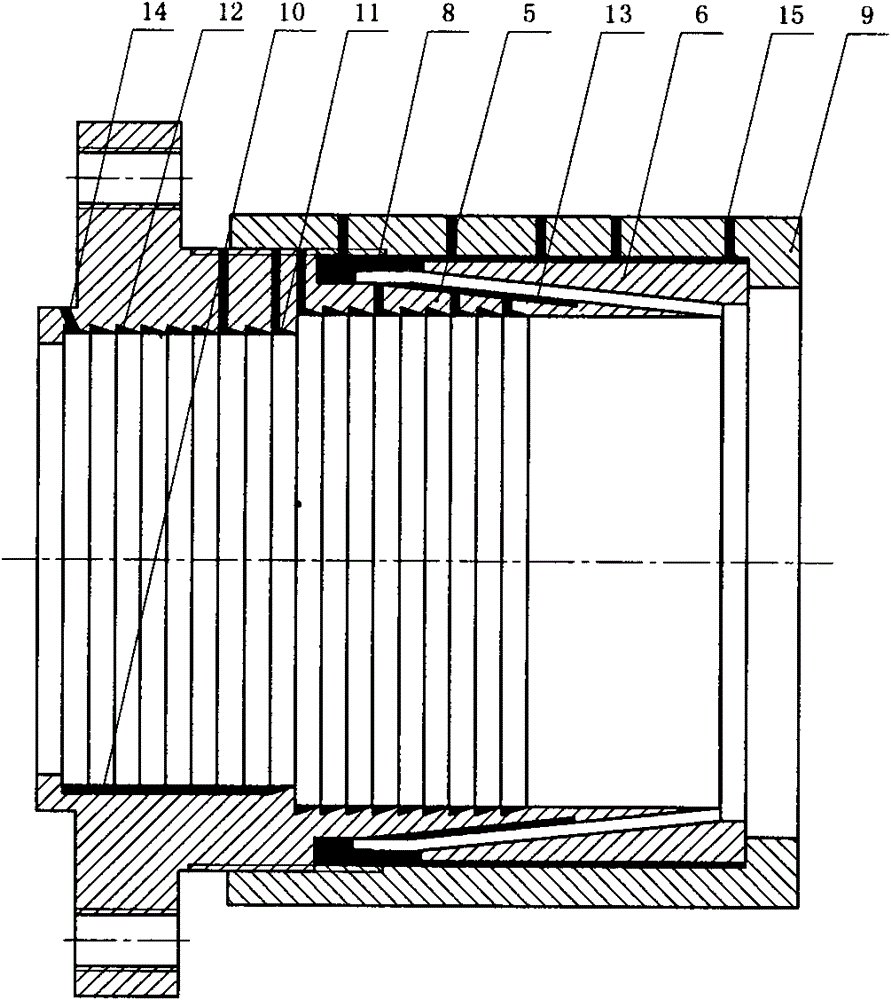

[0014] Such as figure 1 , figure 2 As shown, before installing the connection structure of the present invention, the inner lining layer 1, the hoop layer 2, the inner drawing layer 3, the skeleton layer 4, and the outer drawing layer 7 at the same end of the pultrusion composite pipe are first polished and smoothed synchronously, and the drawn The tightening nut 9 and the locking overcoat 6 are set outside the outer tensile layer 7 of the pultruded composite pipe, and then the tightened inner core 5 is installed on the end of the polished and smooth pultruded composite pipe, and the tightened inner core 5 is connected with each layer The axial relative positions between them should be guaranteed to correspond, and interference fit should be adopted between them. Use a glue injector to inject the inner filler 11 from the inner injection hole 14, and the inner filler fills the groove 12 and the inner torsion groove 10; the locking outer layer 6 is close to the outer tensile l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap