Shielding pump with inducting wheel

A technology of inducer and shielded pump, applied in pump, components of pumping device for elastic fluid, pump device, etc., can solve problems such as impeller cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

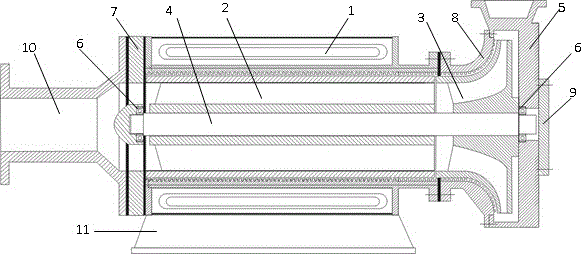

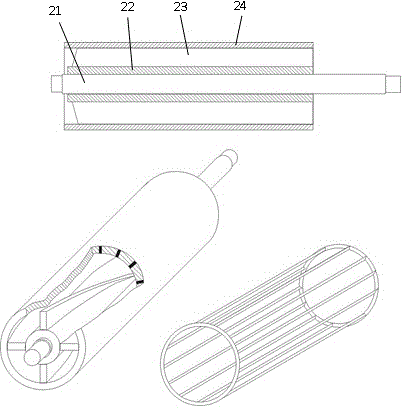

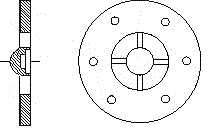

[0012] The following describes the specific implementation of the invention of a canned pump with an inducer with reference to the accompanying drawings. Such as Figure 1-Figure 3 The canned pump with inducer shown includes stator 1 with coil winding, rotor 2 with axial inducer and squirrel cage structure, centrifugal impeller 3, connecting shaft 4, centrifugal pump casing 5, bearing 6, bearing bracket 7 , the pump casing front cover 8, the pump casing rear cover 9, the inlet guide pipe 10, and the base 11. An interlayer of non-magnetic material is set between the stator 1 with coil winding and the rotor 2 with axial inducer and squirrel cage structure, and the rotor 2 with axial inducer and squirrel cage structure is composed of shaft 21, hub 22, the blade 23 and the cylindrical outer ring 24 containing the squirrel cage are formed. The inducer 2 and the centrifugal impeller 3 are fixed in series on the same shaft. The outer surface of the hub 22 of the rotor 2 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com