Integrated torque amplifier

A torque amplifier, integrated technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of complex structure of torque amplifier, inconvenient installation, and inability to directly connect the torque amplifier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

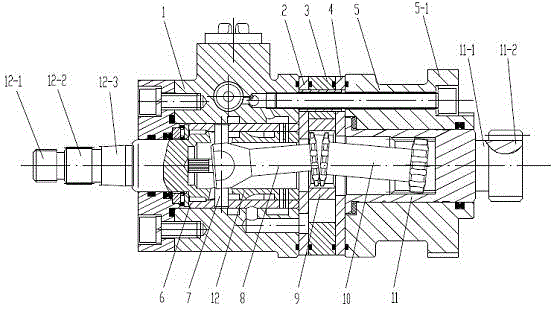

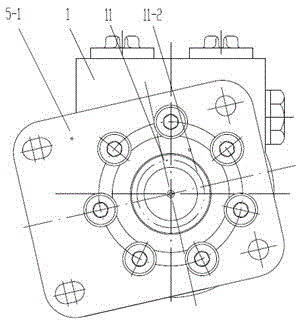

[0013] The torque amplifier of this embodiment is as figure 1 As shown, it includes a casing 1 fixedly connected in sequence along the main axis direction, a stator 3 clamped by front and rear spacers 2 and 3, and a casing composed of a rear cover 5 . A spool sleeve 6 supporting the input spool 12 is housed in the casing, a rotor 7 forming a cycloidal pin-wheel pair is housed in the stator 3 , and an output shaft 11 is supported in the back cover 5 . The inner hole of the rotor 7 is meshed with the opposite ends of the input linkage shaft 8 and the output linkage shaft 10 through an inner spline. The other end of the input linkage shaft 8 is connected with the valve core sleeve 6 through the dial pin 7, and the other end of the output linkage shaft 10 is connected with the output shaft 11 through the internal spline of the inner end hole of the output shaft 11. The input valve core 12 extends outwards with an input shaft with a connection structure, the connection structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com