An experimental method for studying the microscopic mechanism of material damage based on in-situ analysis technology

A technology of in-situ analysis and experimental method, which is applied in the analysis of materials, material analysis by radiation, and material analysis by optical means. Reproduce damage evolution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

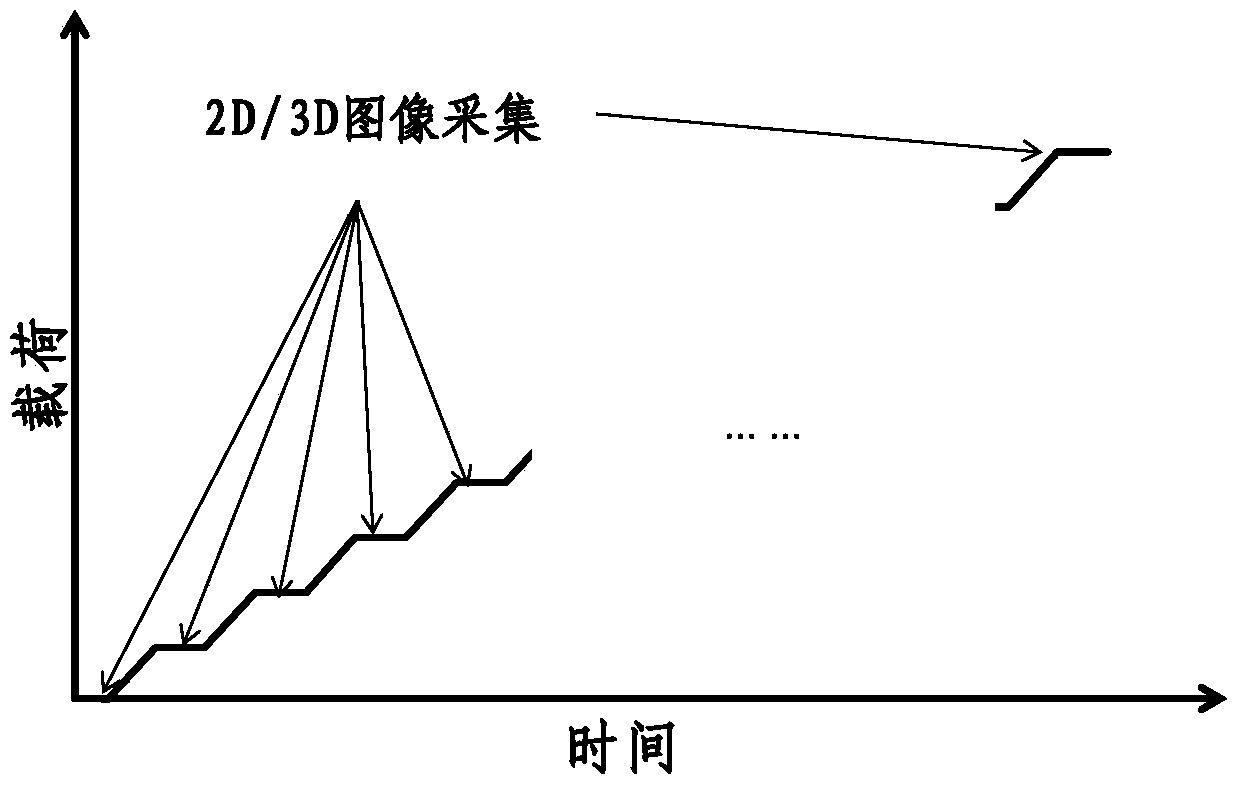

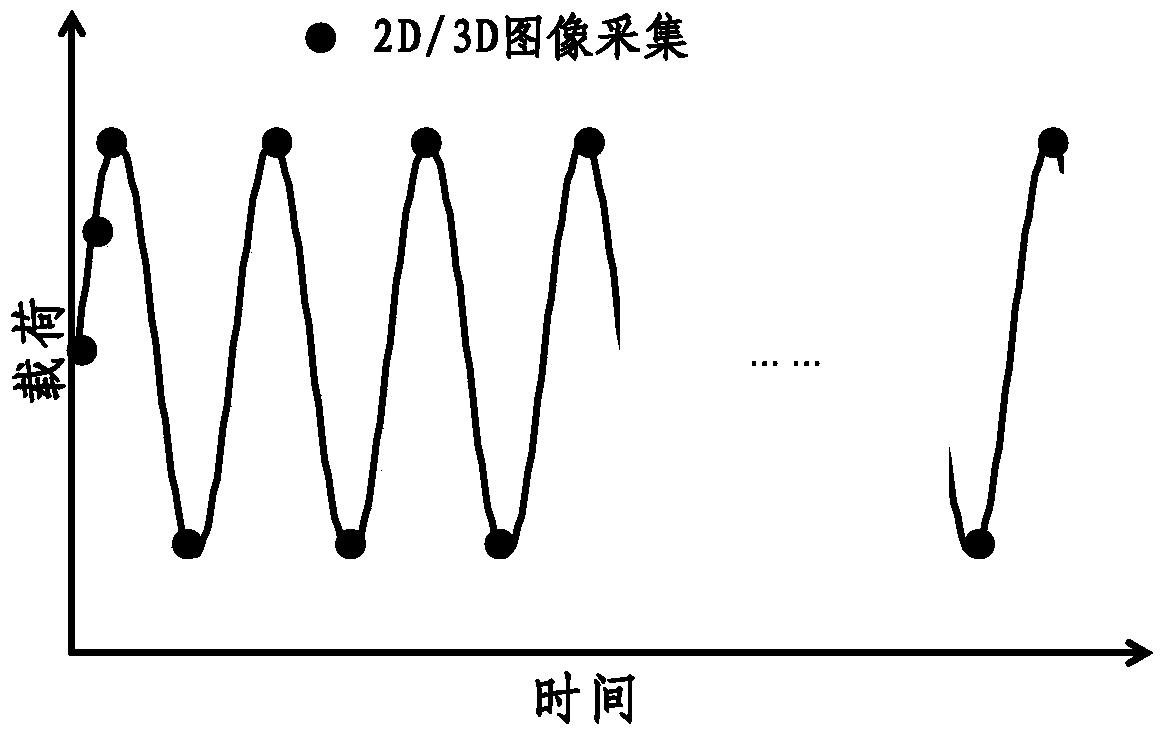

[0046] Experimental approach to 2D in situ analysis techniques

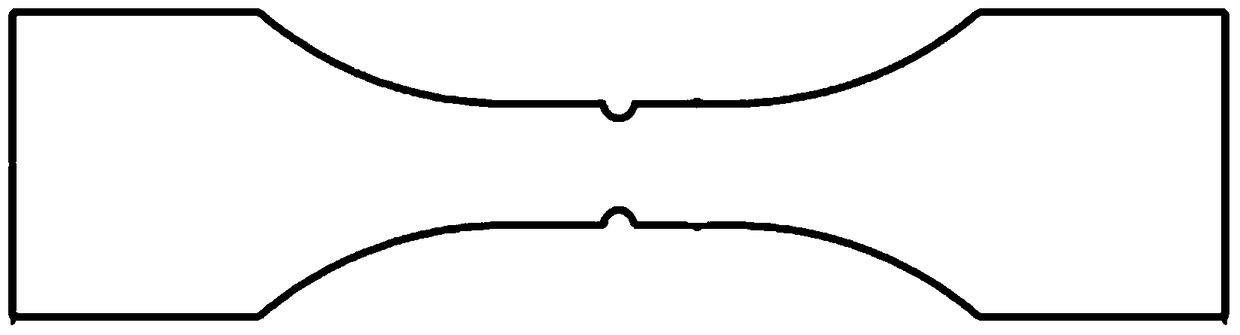

[0047] (1) The 2D sample used is as image 3 shown. The surface of the 2D sample was ground, polished (~1 / 4 micron). The chemical erosion method is used to form "natural speckle" on the surface of the sample, so that the subsequent full-field measurement based on digital image correlation technology can achieve ideal accuracy without adding a layer of artificial spray speckle to the surface.

[0048] (2) The lost foam casting aluminum-silicon alloy contains a large number of casting defects (pores, shrinkage cavities, etc.), and the large-scale defects near the surface are most likely to become the crack initiation area. The casting defect in the notch area of the sample was characterized by using a laboratory X-ray tomography device, so as to determine the next area to be observed.

[0049] (3) 2D in situ observation test device such as Figure 4 As shown, the fatigue loading is carried out by a standard h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com