Display panel and manufacturing method thereof

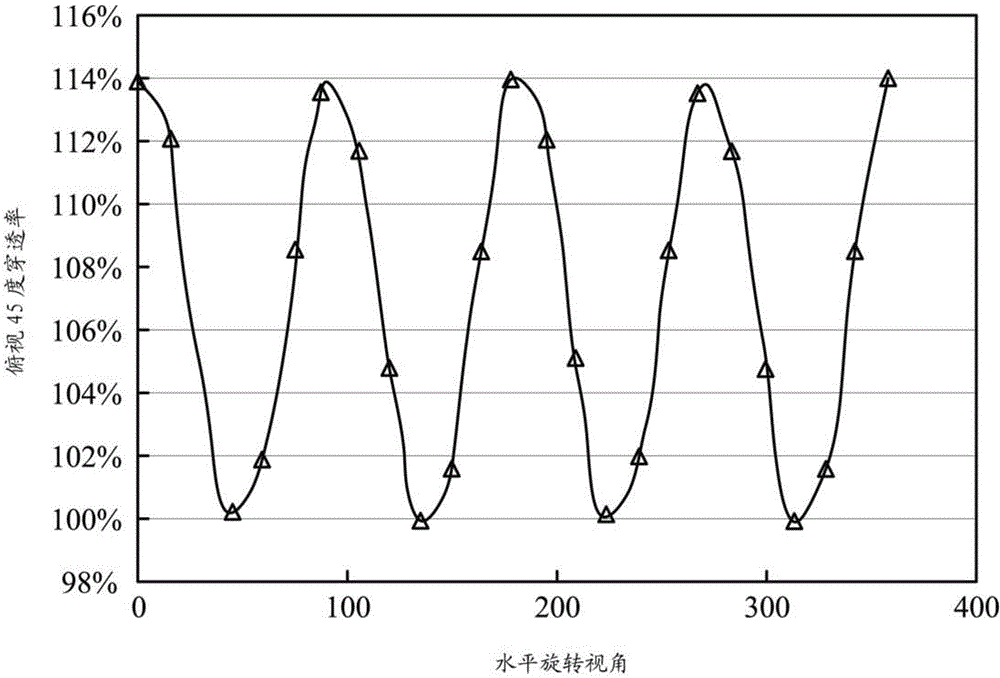

A display panel and manufacturing method technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of increased transmittance of display panels, obvious changes in brightness and darkness, poor visual experience, etc., and achieve horizontal rotation penetration Improvement of change in transmittance and low loss of aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

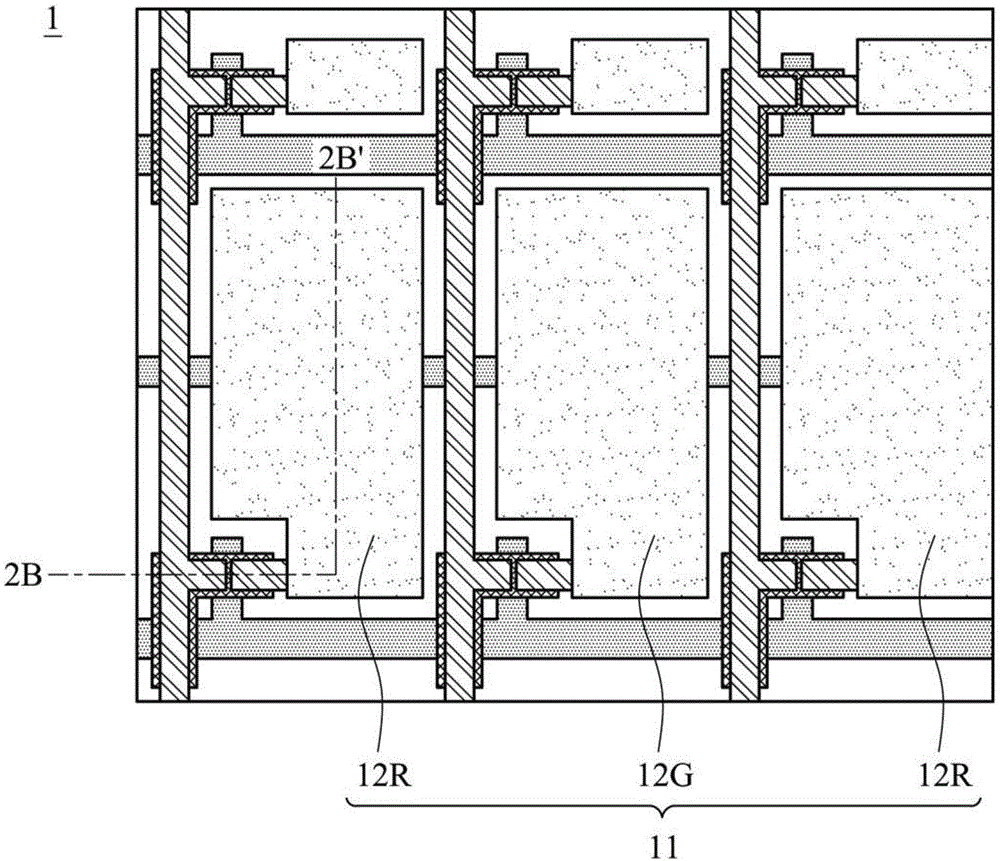

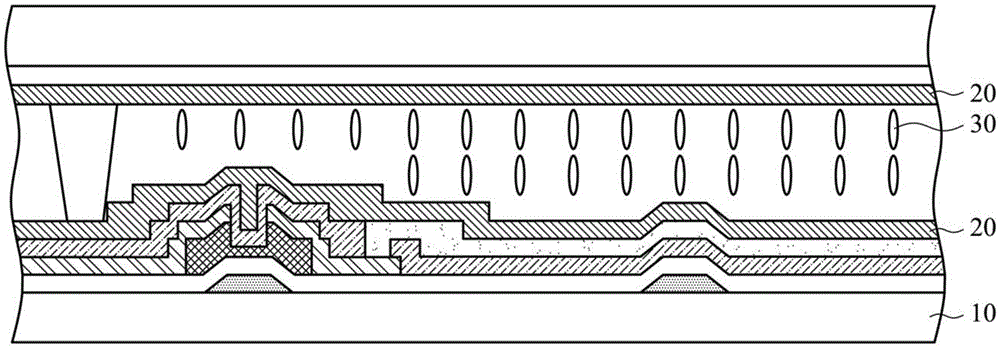

[0055] refer to Figure 2A , Figure 2B , Figure 2A A partially enlarged view showing the thin film transistor substrate 10 of the display panel 1 according to the embodiment of the present invention, Figure 2B for Figure 2A 2B-2B' in the sectional view, the display panel 1 includes a thin film transistor substrate 10 , a photo-alignment layer 20 and a liquid crystal layer 30 . collocation reference Figure 2A , Figure 2B , the thin film transistor substrate 10 has a plurality of pixel units 11, wherein each pixel unit 11 has a plurality of sub-pixels 12, in one embodiment, each pixel unit 11 has a red sub-pixel 12 (R), a green sub-pixel 12 (G) and blue sub-pixel 12 (B). The photo-alignment layer 20 is formed on the TFT substrate 10 and located on the pixel units 11 , and has at least two alignments in different directions corresponding to each of the sub-pixels 12 . The liquid crystal layer 30 is disposed on the alignment layer 20 and has a plurality of liquid crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com