Cutter abrasion monitoring method based on cutting force model

A tool wear and cutting tool technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of unstable threshold value, tool wear prone to error, misjudgment, etc., to achieve accurate results and simple calculation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the examples, but the present examples are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

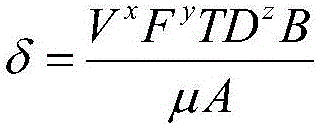

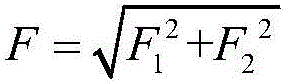

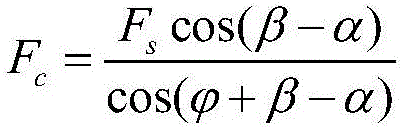

[0030] In the process of establishing the cutting force model of the tool, the cutting force under the action of the sharp tool caused by the formation of chips is firstly calculated by using the non-equal shear zone model, and then the plowing force caused by the blunt cutting edge is calculated, and the The comprehensive superposition of the two can get the cutting force when considering the blunt cutting edge.

[0031] In the process of chip formation, the force required for shear slip is transmitted by the rake face of the tool and through the chips. Since the chips flow out along the rake face at a certain speed, the cutting force should meet the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com