Extractor

A puller and base rod technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of complex structure, weak structure and easy shaking of the puller, and achieves easy installation and disassembly, high reliability, The effect of quick and labor-saving plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

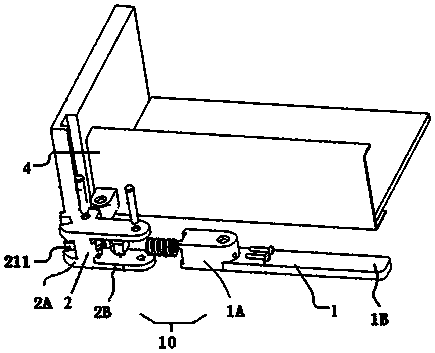

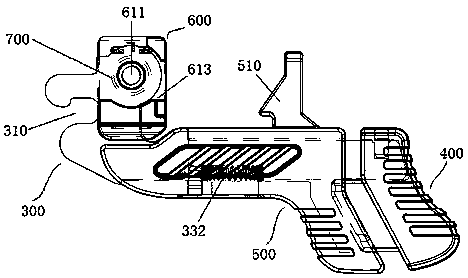

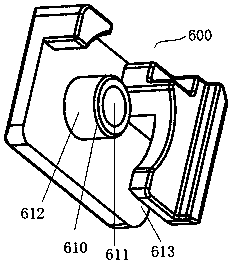

[0013] Such as figure 2 As shown, the extraction aid of the present invention has a rotatable base rod 300, a handle 400, a sliding rod 500, an anti-shaking clamping part 600, and a spring pad 700; Figure 4 As shown, one end of the rotatable base rod 300 has a bayonet 310, an anti-shake clamp mounting hole 320, and the other end is equipped with a handle 400, and the two ends are formed by a beam 330 connection, a groove 331 is opened on the beam 330, and a return spring 332 is installed in the groove; as Figure 5 As shown, the sliding rod 500 is sleeved on the crossbeam 330 and can slide reciprocatingly on it in the axial direction, and on the sliding rod 500, it is on the same side as the installation hole 320 of the anti-shake clamping member. , is provided with a locking hook 510; such as image 3 As shown, there is a cylindrical protrusion 610 on the anti-shake clamp 600, and the inner hole 611 of the protrusion is a PCB mounting hole, and the whole device is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com