An auxiliary device for injection molding holes

An auxiliary device and injection molding technology, which is applied in the field of machining and manufacturing to achieve the effect of convenient cleaning and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

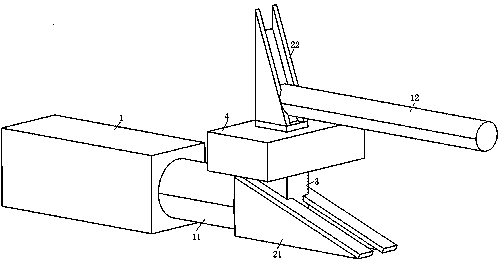

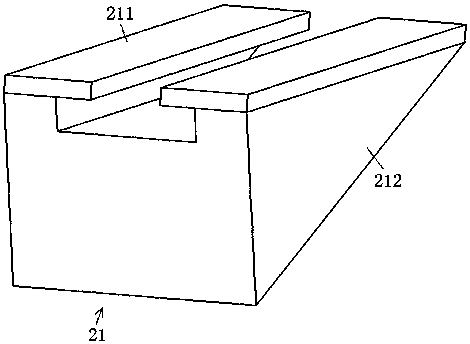

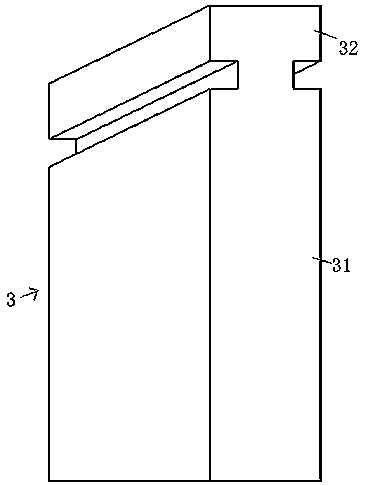

[0035] combine figure 1 , figure 2 , image 3 and Figure 4 , an auxiliary device for injection molding holes in this embodiment, such as figure 1 As shown, it includes the oil cylinder 1, the oil cylinder 1 includes the first piston rod 11, the auxiliary device of the injection molding hole also includes the oblique chute I21, the oblique chute II22, the linkage adapter block 3, the guide block 4 and the second Piston rod 12, wherein, the end of the first piston rod 11 is provided with an oblique chute I21, and the oblique chute I21 and oblique chute II22 are connected through the linkage adapter block 3, and the linkage adapter block 3 is covered with a guide block 4. The guide block 4 is installed on the injection mold, and the second piston rod 12 is arranged on the inclined chute II 22 .

[0036] In this embodiment, the materials of inclined chute I21, inclined chute II22, linkage adapter block 3 and second piston rod 12 are all 400c steel. The wear resistance requi...

Embodiment 2

[0048]An auxiliary device for injection molding holes in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that in this embodiment, the inclination angles of the inclined chute I21 and the inclined chute II22 are both 20°, and the inclination The number of the position chute I21 and the inclined position chute II22 are both two, and the number of linkage adapter blocks 3 is three.

Embodiment 3

[0050] An auxiliary device for injection molding holes in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that in this embodiment, the inclination angles of the inclined chute I21 and the inclined chute II22 are both 30°, and the inclination The number of the position chute I 21 and the inclined position chute II 22 are both three, and the number of linkage adapter blocks 3 is five.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com