Mine car capable of being automatically moved out of rail and method

A mine car and track technology, applied in the field of mine cars that automatically move out of the track, can solve the problems of wasting manpower and material resources, and the mine car cannot be automatically moved out or into the track, etc., to achieve the effect of smooth expansion, manpower saving, and operation time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

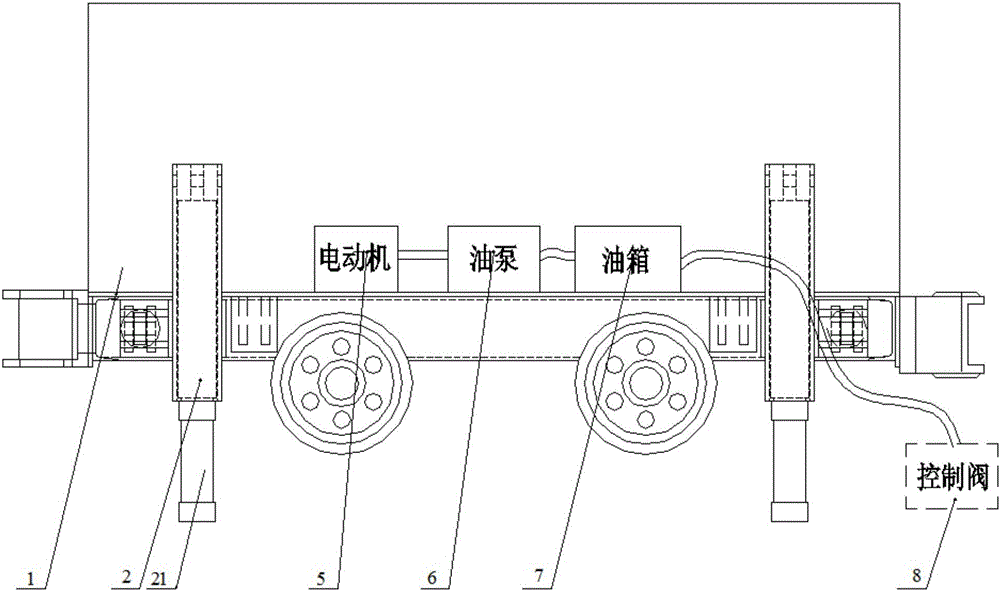

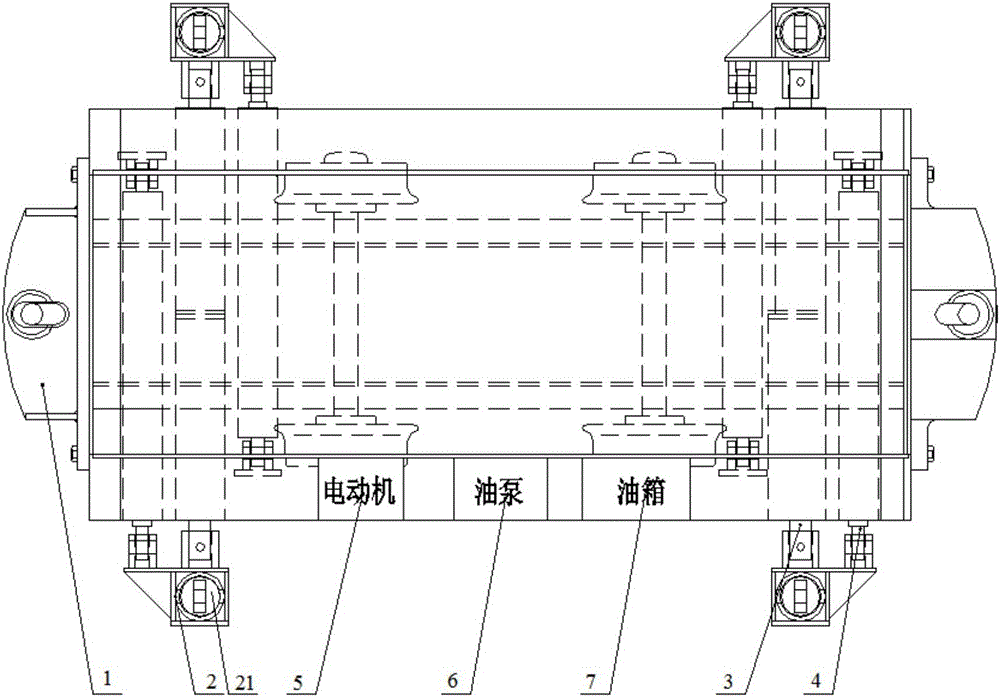

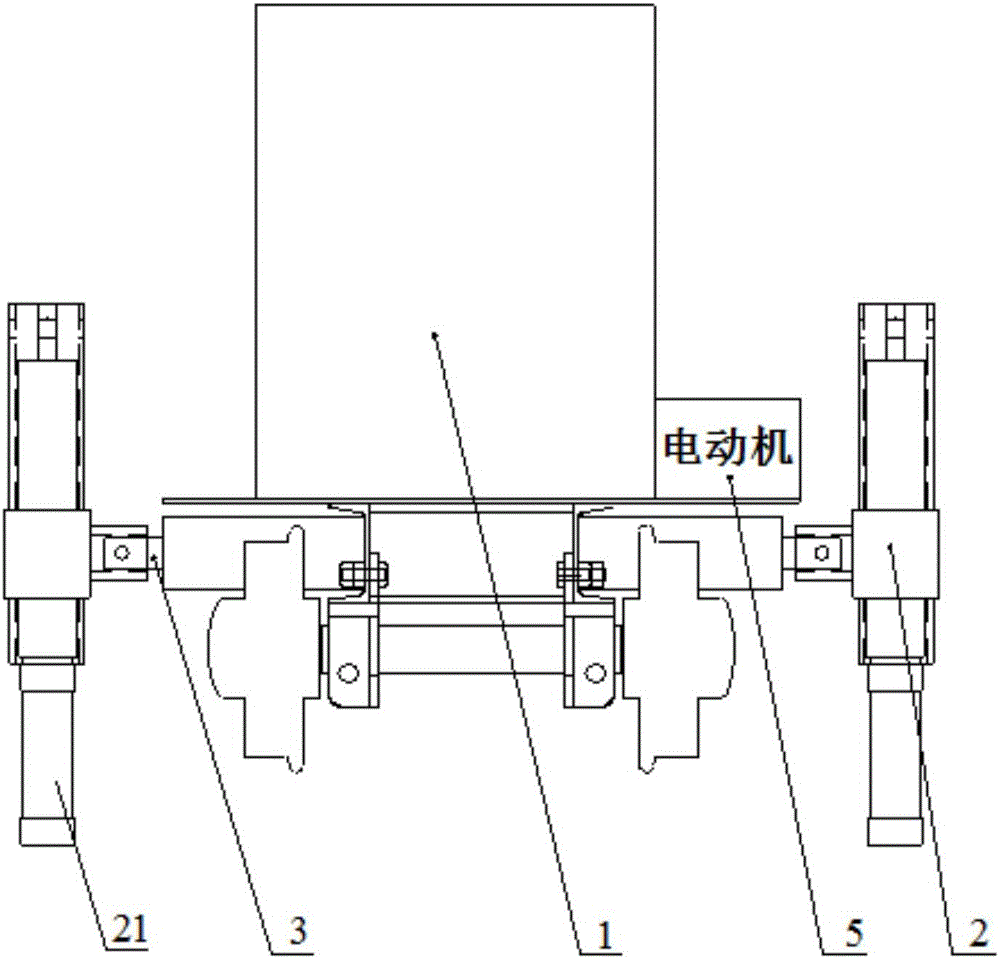

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] A mine car that can automatically move out of the track, the structure is as follows Figure 1~3 As shown, it includes a mine car body 1 for holding goods, four outriggers 2 arranged at the front and rear positions on both sides of the mine car body 1, horizontally arranged in the bottom frame of the mine car body 1, and one end is connected with the outriggers 2 4 telescopic arms 3, 4 moving jacks 4 connected to the legs 2 at one end in the bottom frame of the mine car body 1, the other ends of the moving jack 4 and the telescopic arms 3 are connected with the mine car body 1, The jack 4 is parallel to the telescopic arm 3, and when the jack 4 is stretched, the telescopic arm 3 is stretched, so that the mine car moves along a direction perpendicular to the track in the horizontal plane. Each leg 2 is provided with a leg jack 21 vertically fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com