Surface ship buttock impact environment simulator

A shock environment and simulator technology, which is applied to ship components, ships, ship construction, etc., can solve the problems of the difference in lateral and vertical impact strength, achieve the effects of lowering the center of gravity, improving the stability of the platform, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

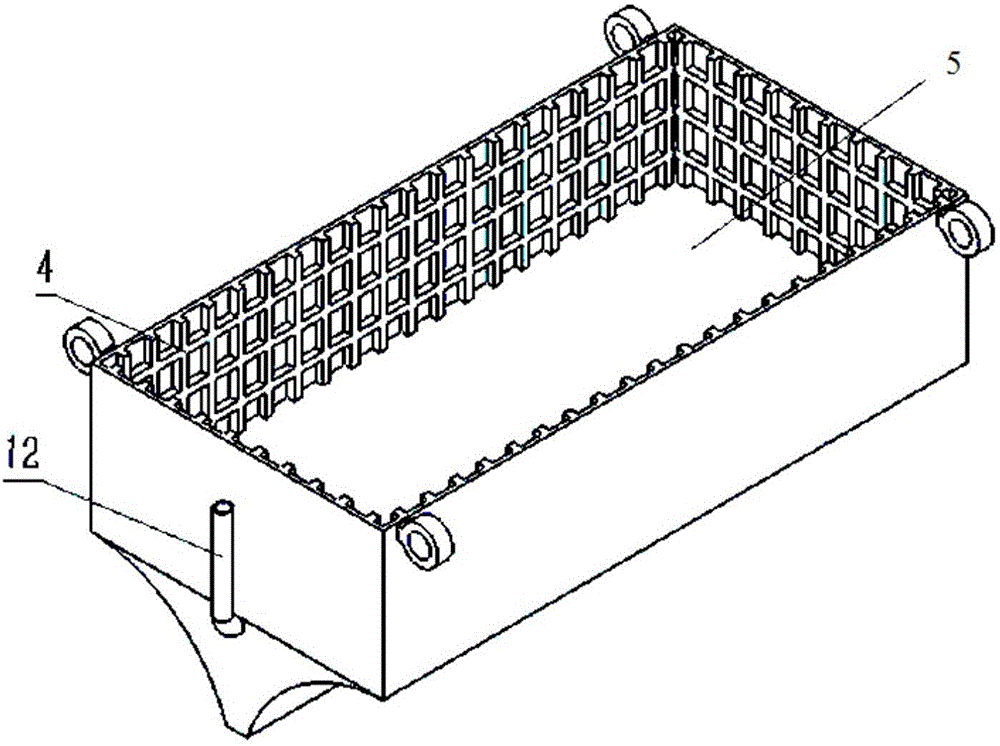

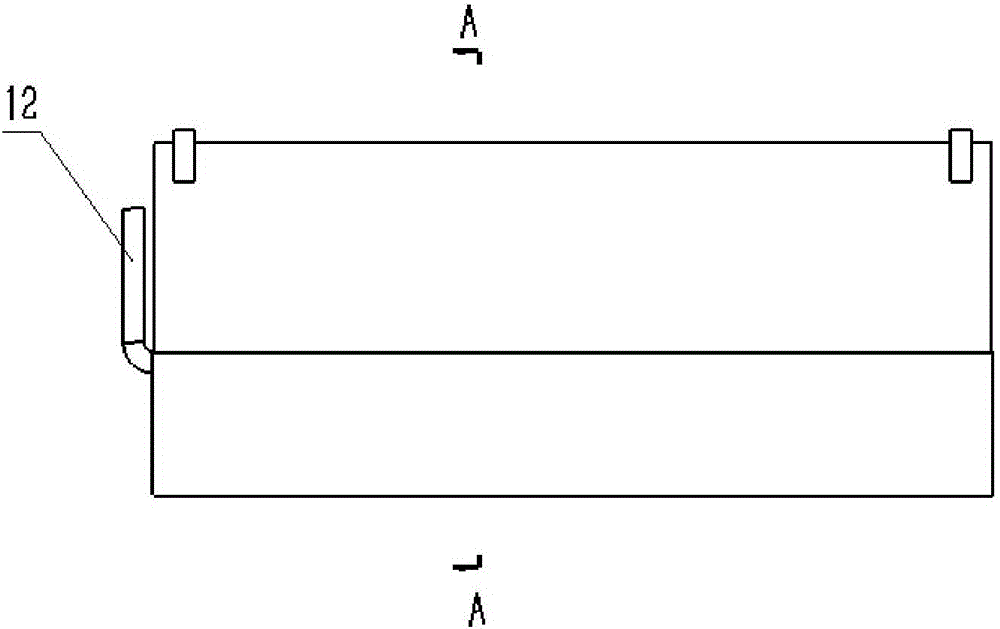

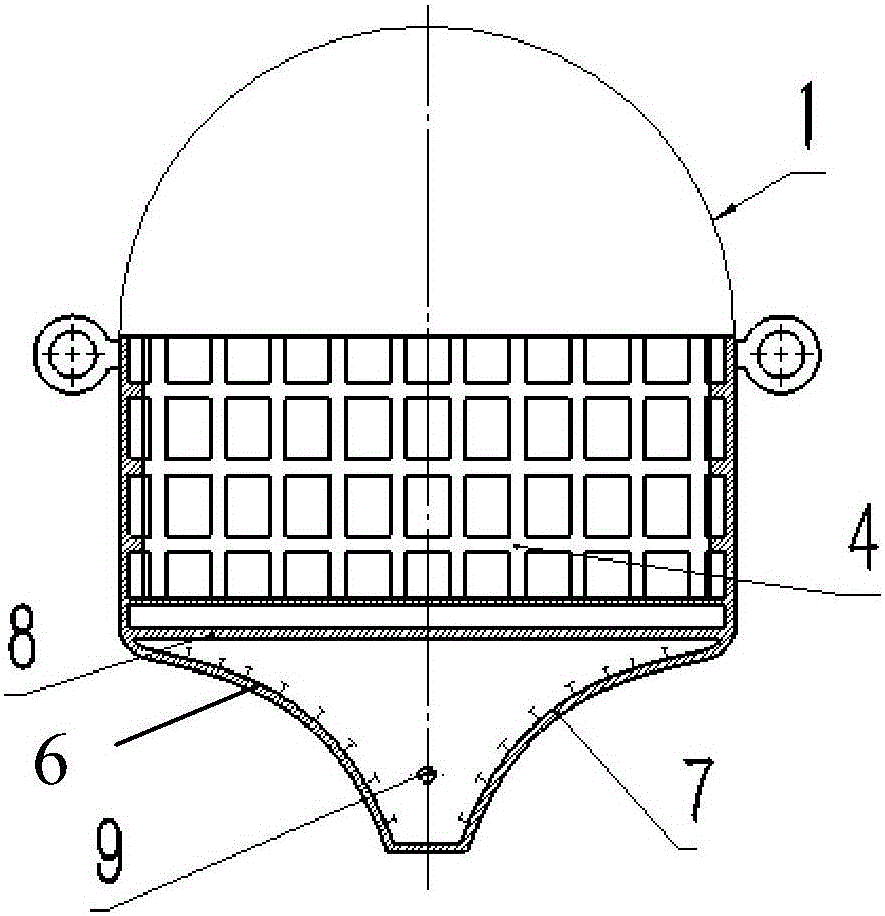

[0017] combine Figure 1-4 , the present invention includes waterproof curtain 1, simulator main body 2, lifting lug 3, rib structure 4, equipment installation platform 5, symmetrical concave baffles 6, 7, ballast water tank 8, communication hole 9, sensor 11, Ballast water tank partition 10, water injection port 12, and the waterproof curtain 1 is covered on the top of the simulator, which can prevent splashed water from falling into the simulator, causing damage to the circuit of the detection instrument such as short circuit; simulator main body 2 To carry the equipment to be assessed, test instruments and sensors that need to be installed; four lifting lugs 3-1, 3-2, 3-3, 3-4 are evenly distributed around the simulator, which is convenient for hoisting operation on the one hand, and can be used on the other hand. It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com