An industrial circulating water online oil monitoring and degreasing device

An industrial circulating water and oily technology, which is applied in the direction of grease/oily substance/floating matter removal device, general water supply saving, centrifugal separation water/sewage treatment, etc., can solve the problem of unstable fluid form, unstable and fluctuating oil content, increasing The difficulty of separation and dehydration again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below with reference to the accompanying drawings, and embodiments of the present invention are given.

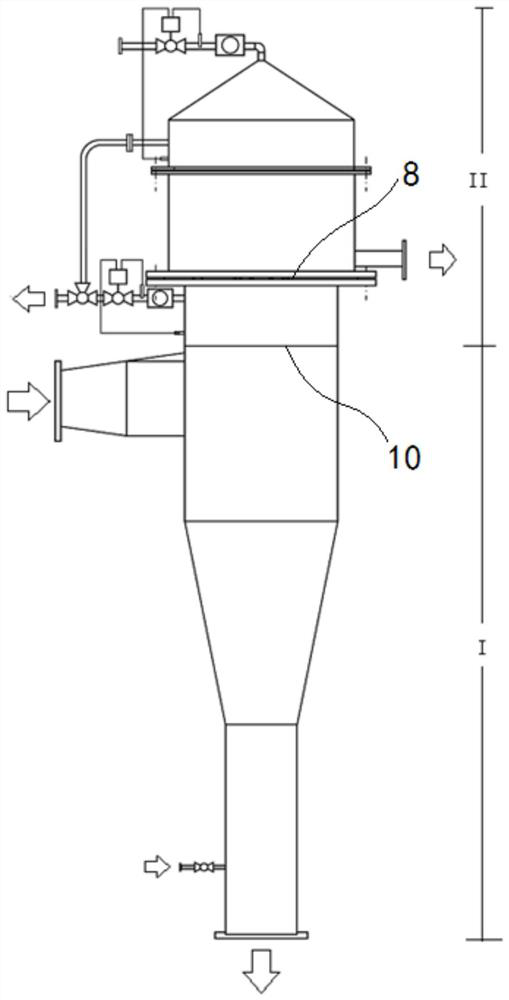

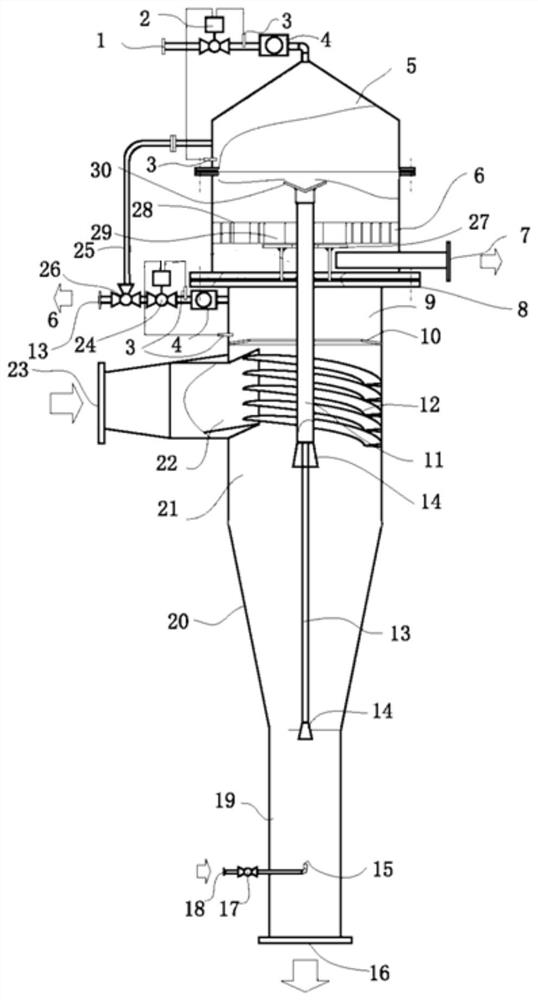

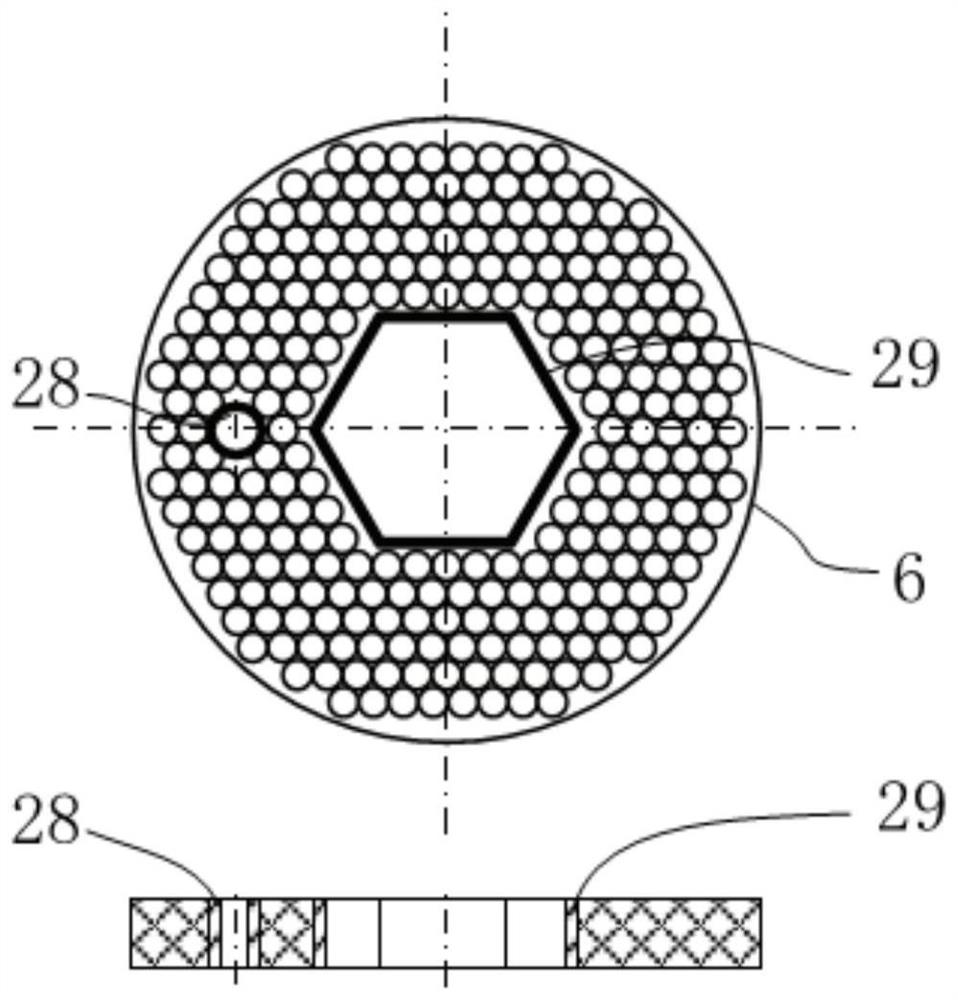

[0036] This industrial circulating water on-line oil monitoring and degreasing device consists of an inverted bottle-shaped cavity at the bottom and an upper part of the inverted bottle-shaped cavity, which is connected to the inverted bottle-shaped cavity through a partition plate 8. The isolated conical frustum-shaped cavity is connected and assembled. The inverted bottle-shaped cavity below the plate 10 is divided into a hydrocyclone separation unit I, and the above part of the annular perforated arch baffle 10 and the entire frustum-shaped cavity part form a sewage oil sedimentation separation and collection unit II;

[0037] The described hydrocyclone separation unit 1 consists of a rapid separation cavity 21, a conical separation cavity 20 in the middle and a deep separation cavity 19 in the tail, which are sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com