Patents

Literature

33results about How to "Maximize reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

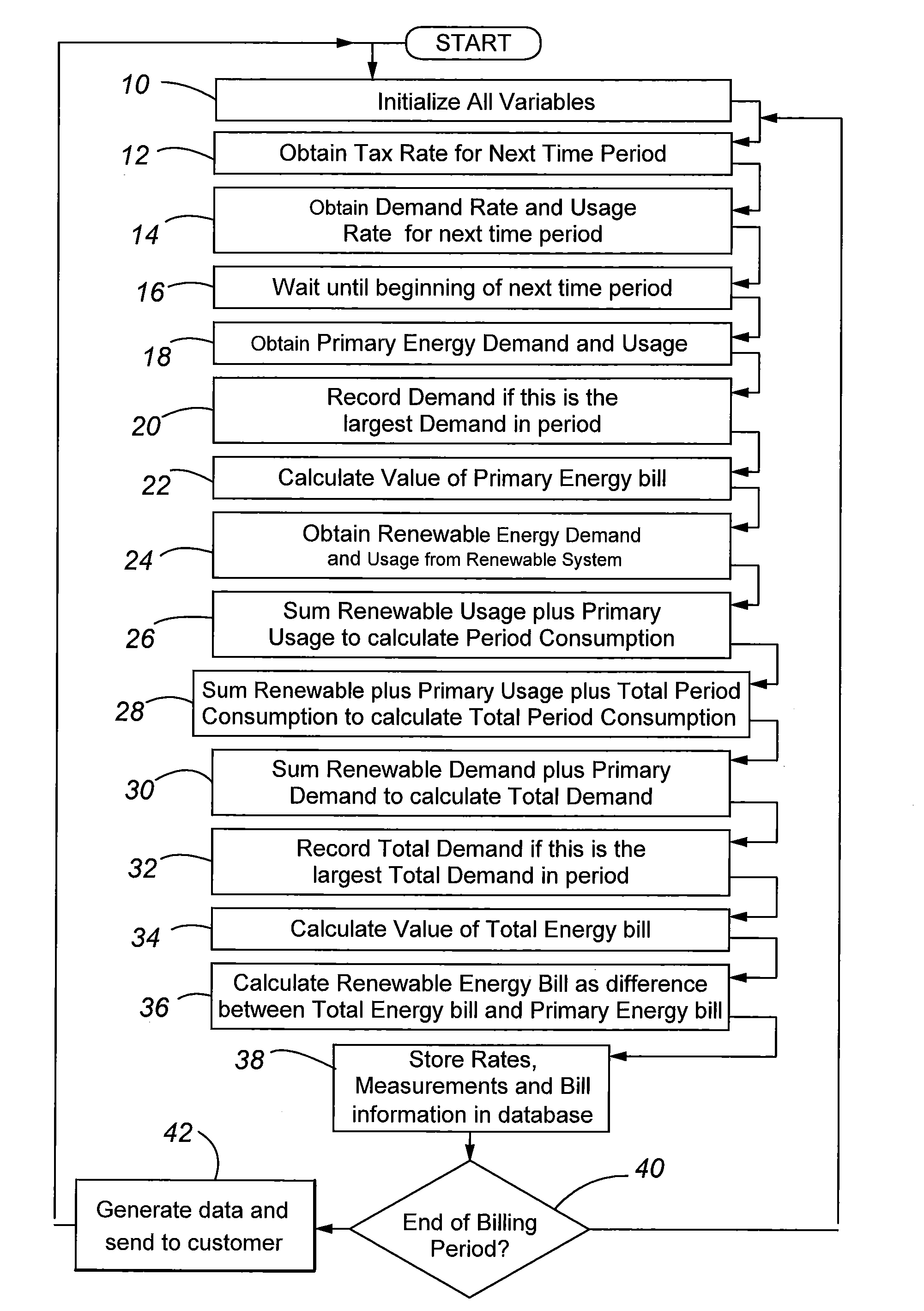

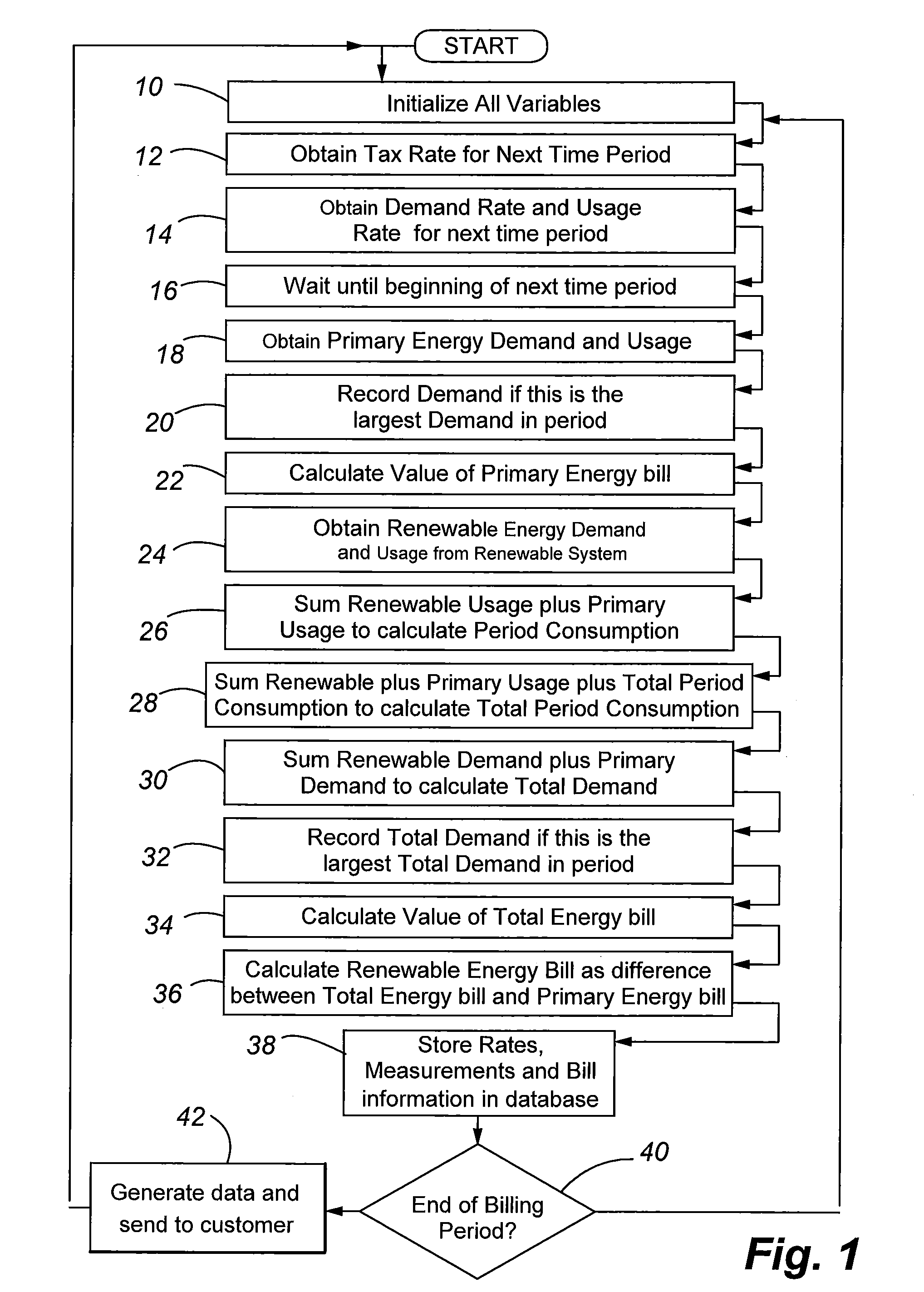

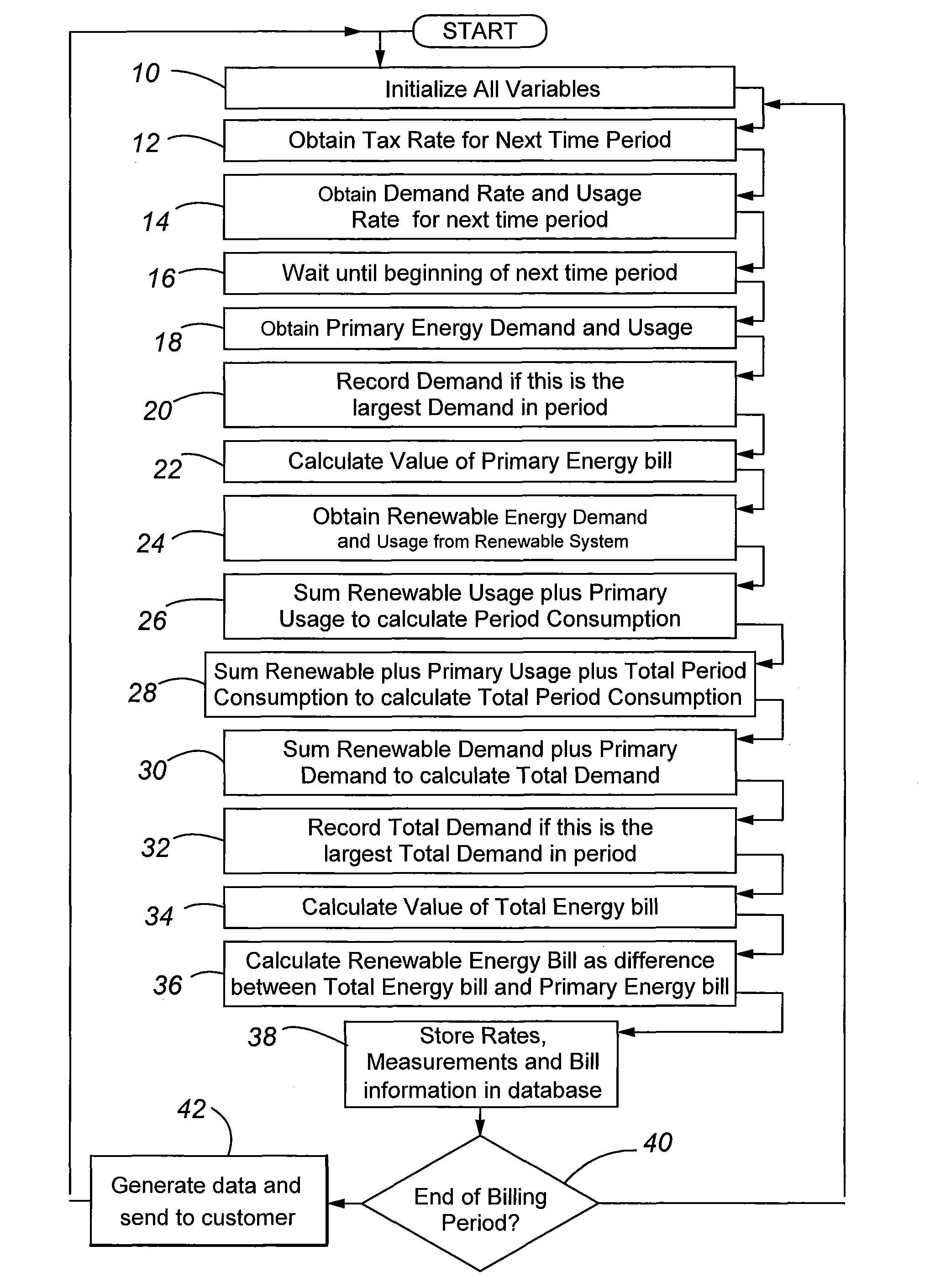

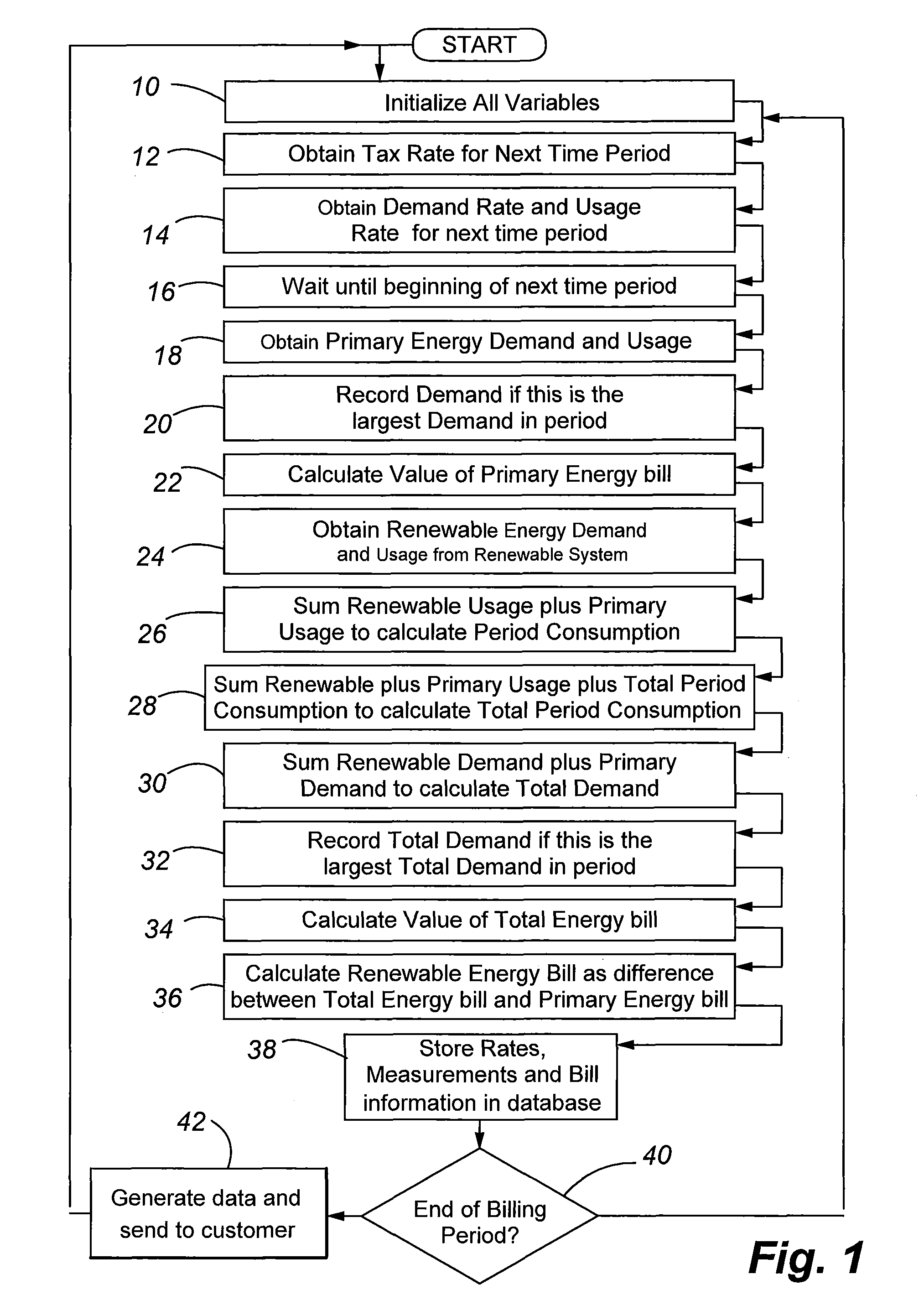

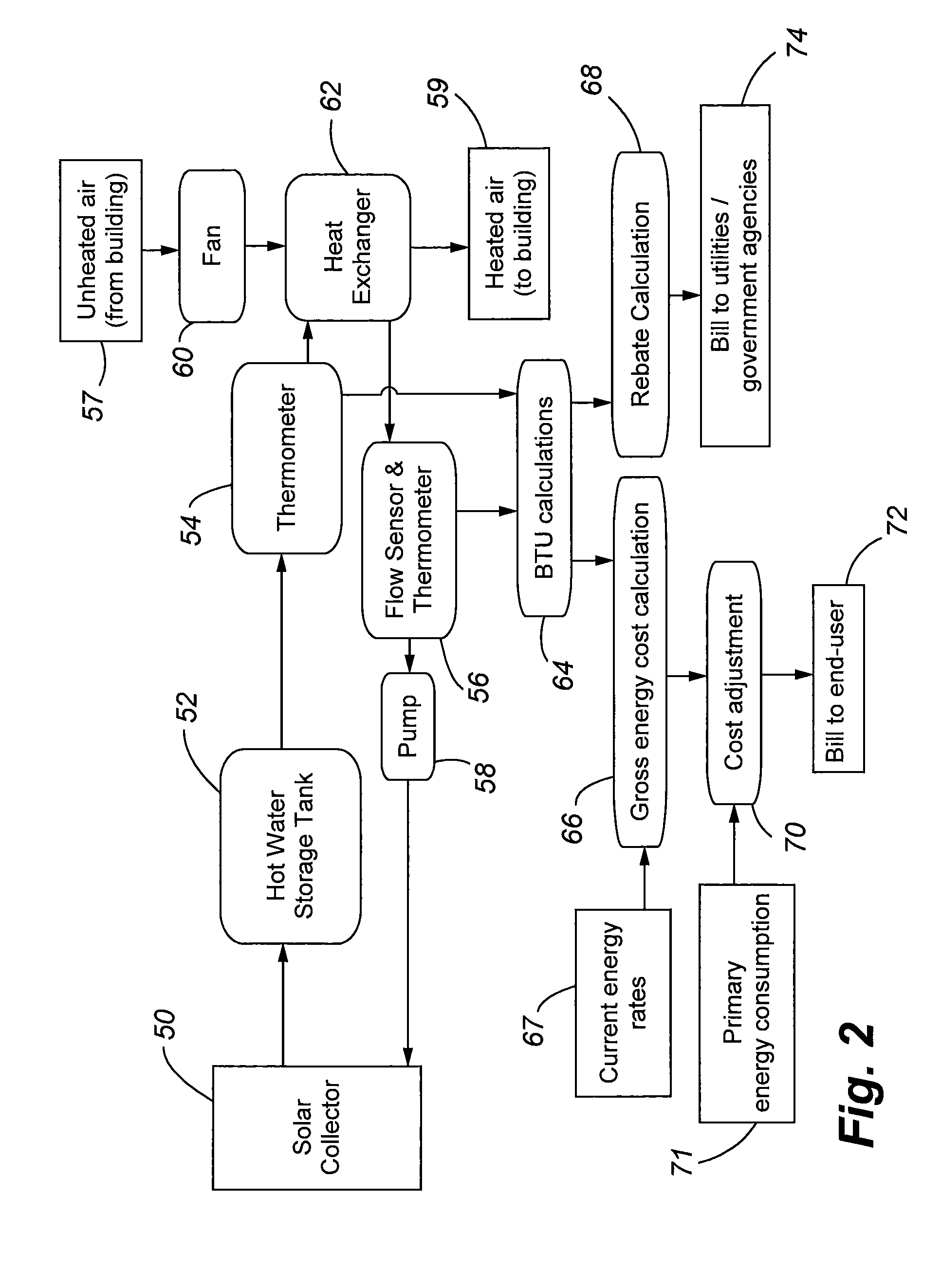

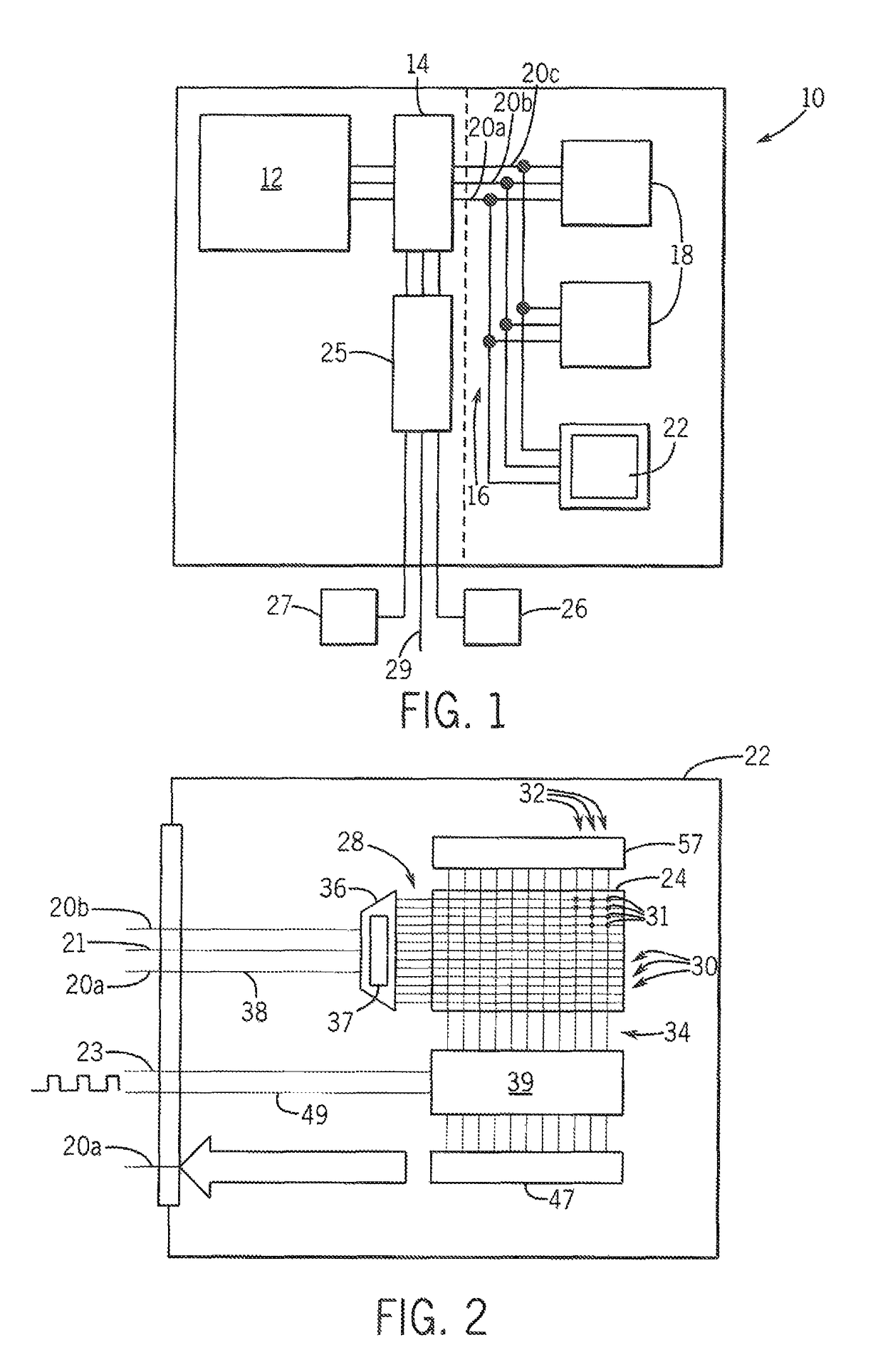

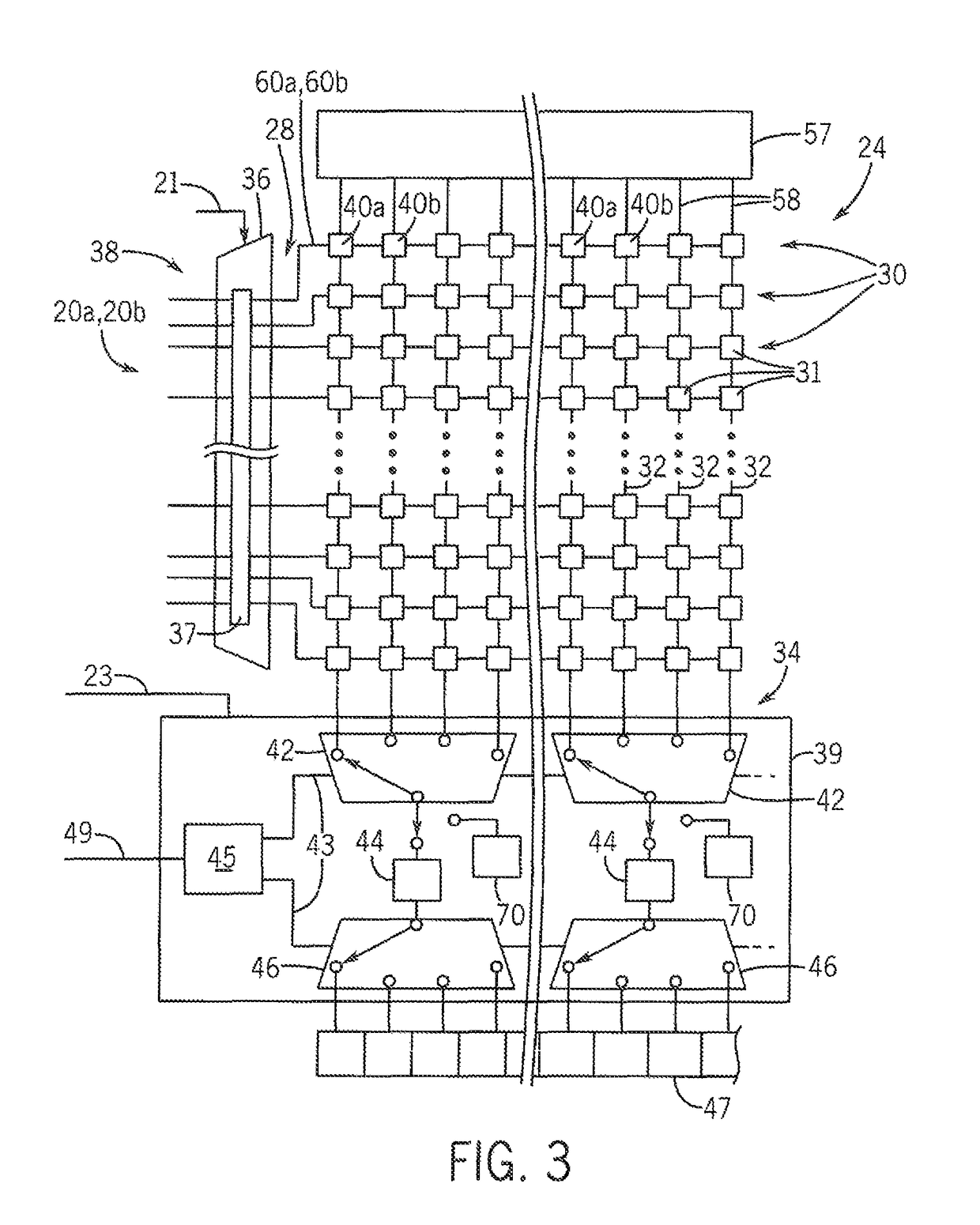

System and method for integrating billing information from alternate energy sources with traditional energy sources

ActiveUS20100174643A1Lower requirementLow costComplete banking machinesElectric devicesEngineeringPredictive analytics

The method and system of the present invention provides for data gathering of energy systems, calculation of billing information for the energy systems to include both traditional energy sources and renewable energy sources, and creation of various outputs to include various user interfaces applicable to overall management of the energy systems. The user interfaces can include integrated, real-time billings to a consumer that measure the cost of the primary energy as well as savings provided by renewable energy sources. The present invention also provides predictive analysis for various aspects of energy use in order to better manage particular facilities that may incorporate renewable energy sources. The gathered data and the various user interfaces enables a user to modify or adjust the use of the renewable energy sources at selected sites to maximize their impact on reducing the cost of the primary energy bill.

Owner:ALSO ENERGY

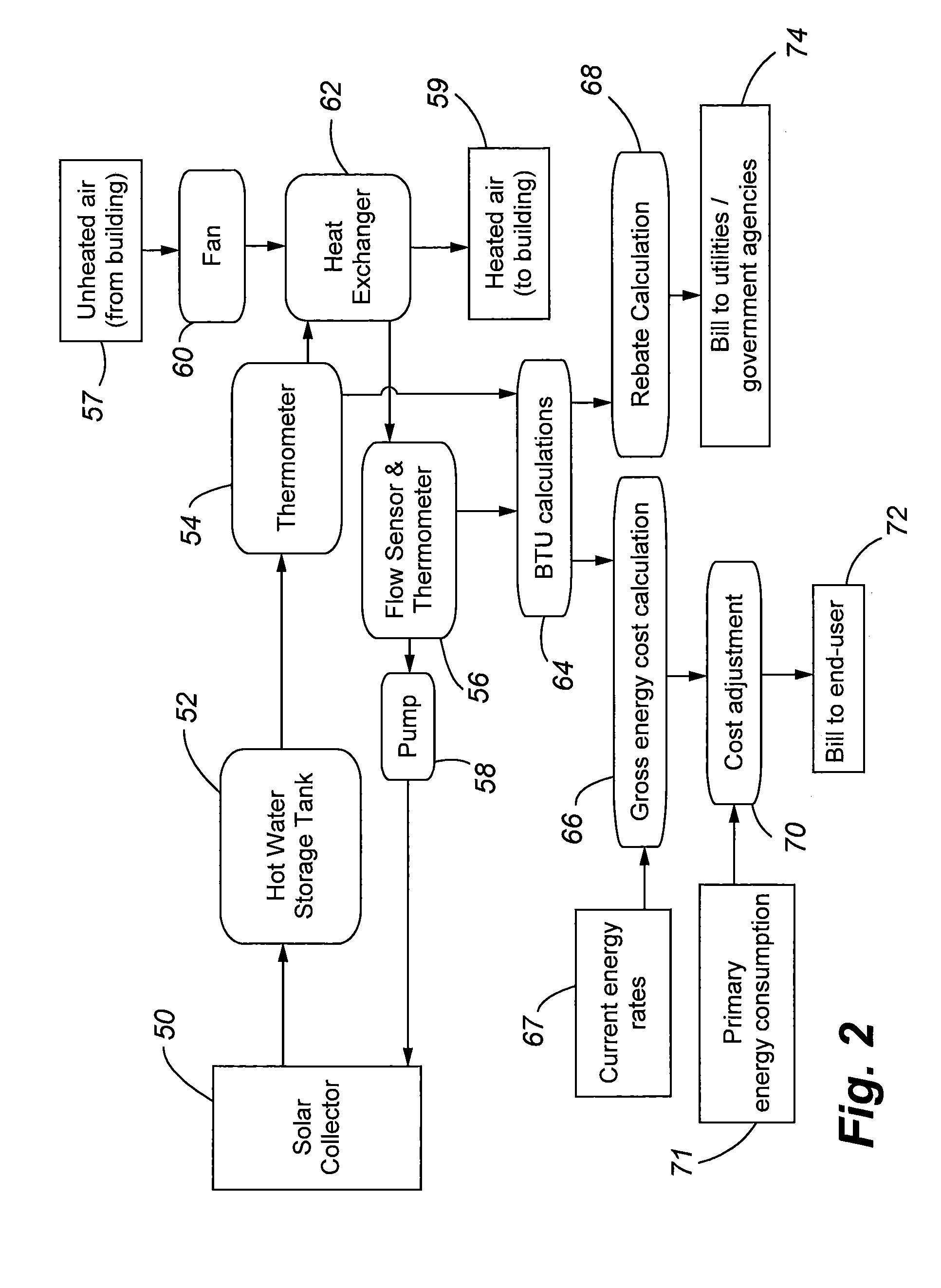

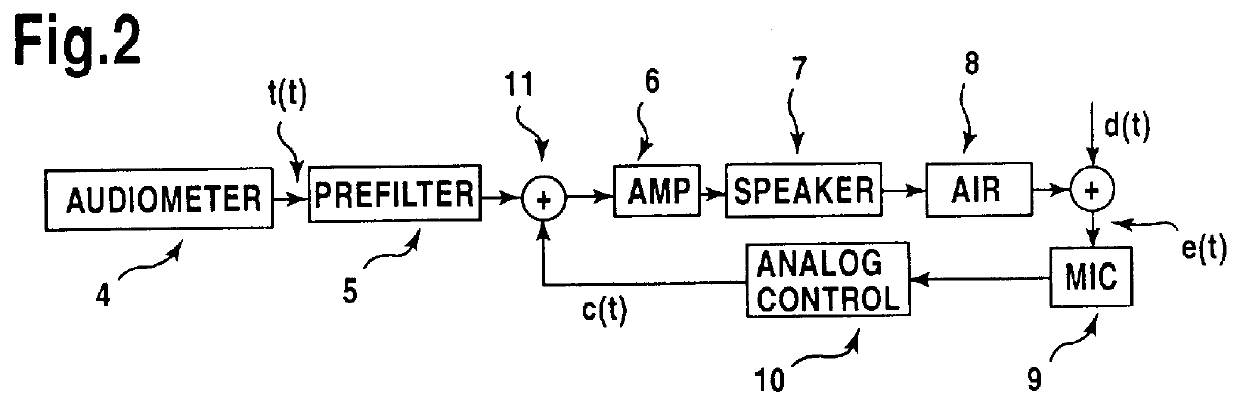

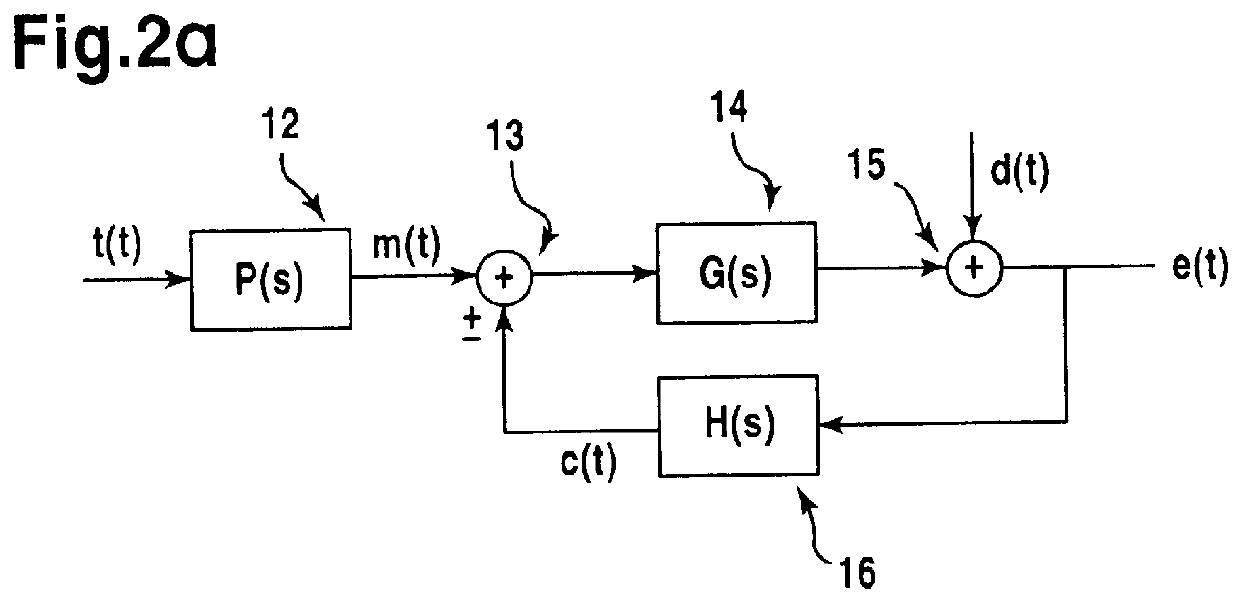

First draft-switching controller for personal ANR system

InactiveUS6160893AReduce environmental noiseReduced and accurate threshold measurementEar treatmentHeadphones for stereophonic communicationPre filteringThreshold shift

An active noise control system for use in testing hearing using a pure tone audiometry testing procedure and employing multiple switching controllers with pre-filtering means and a switch to select any one controller to provide a predetermined one and having the ability to configure each switching controller so that the maximum threshold shift occurs for the frequency of the test tone and for modifying each test tone in accordance with a standard calibration frequency.

Owner:GENTEX CORP

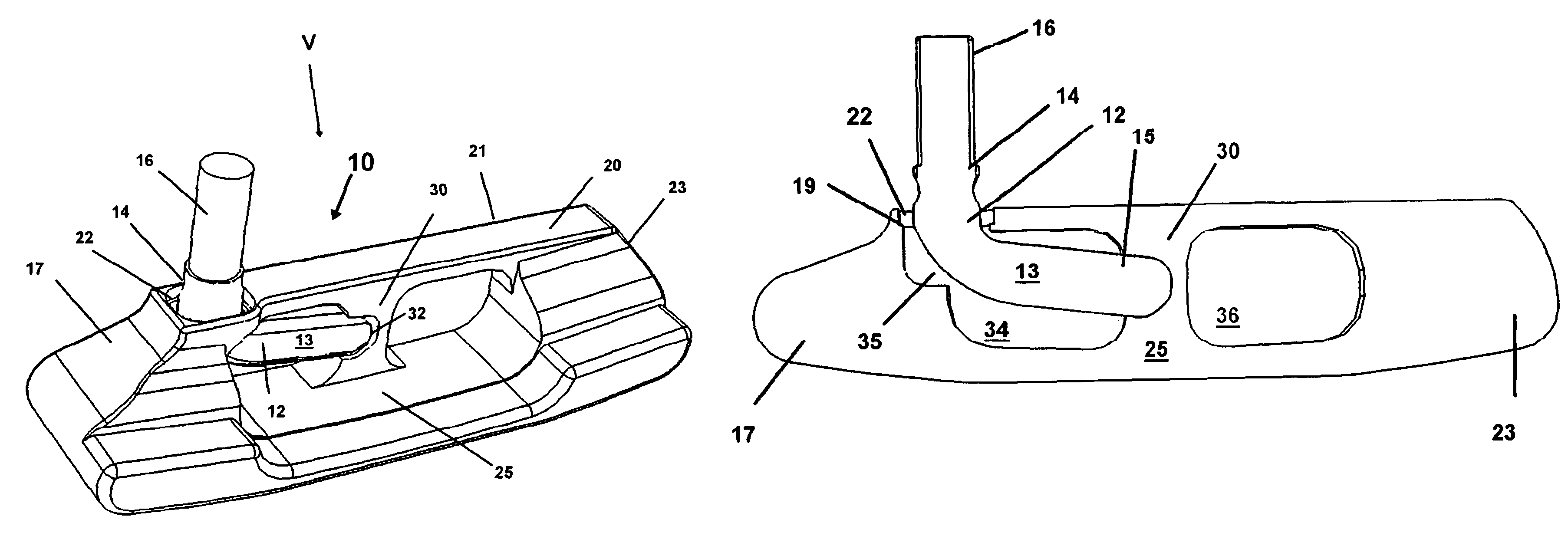

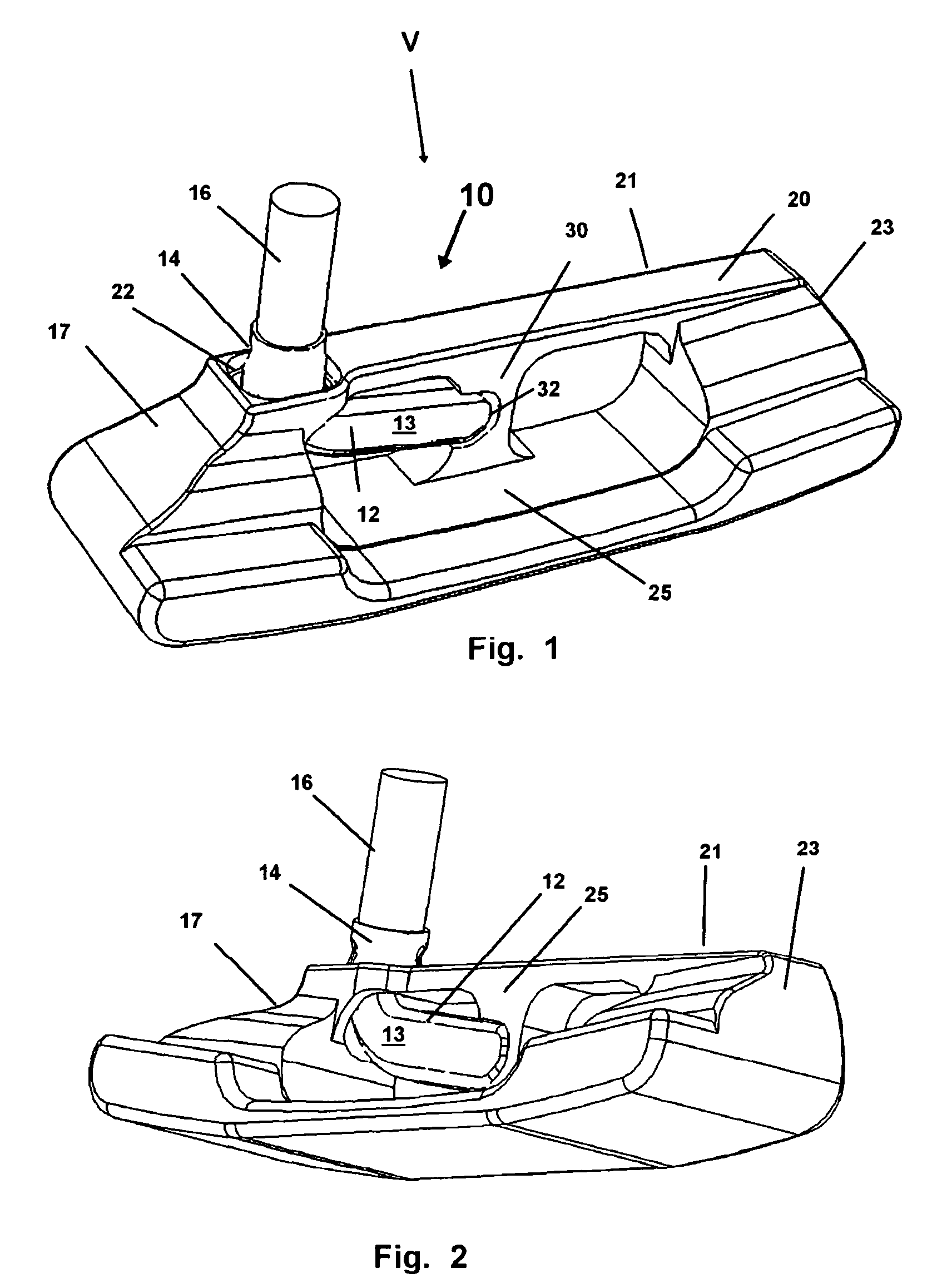

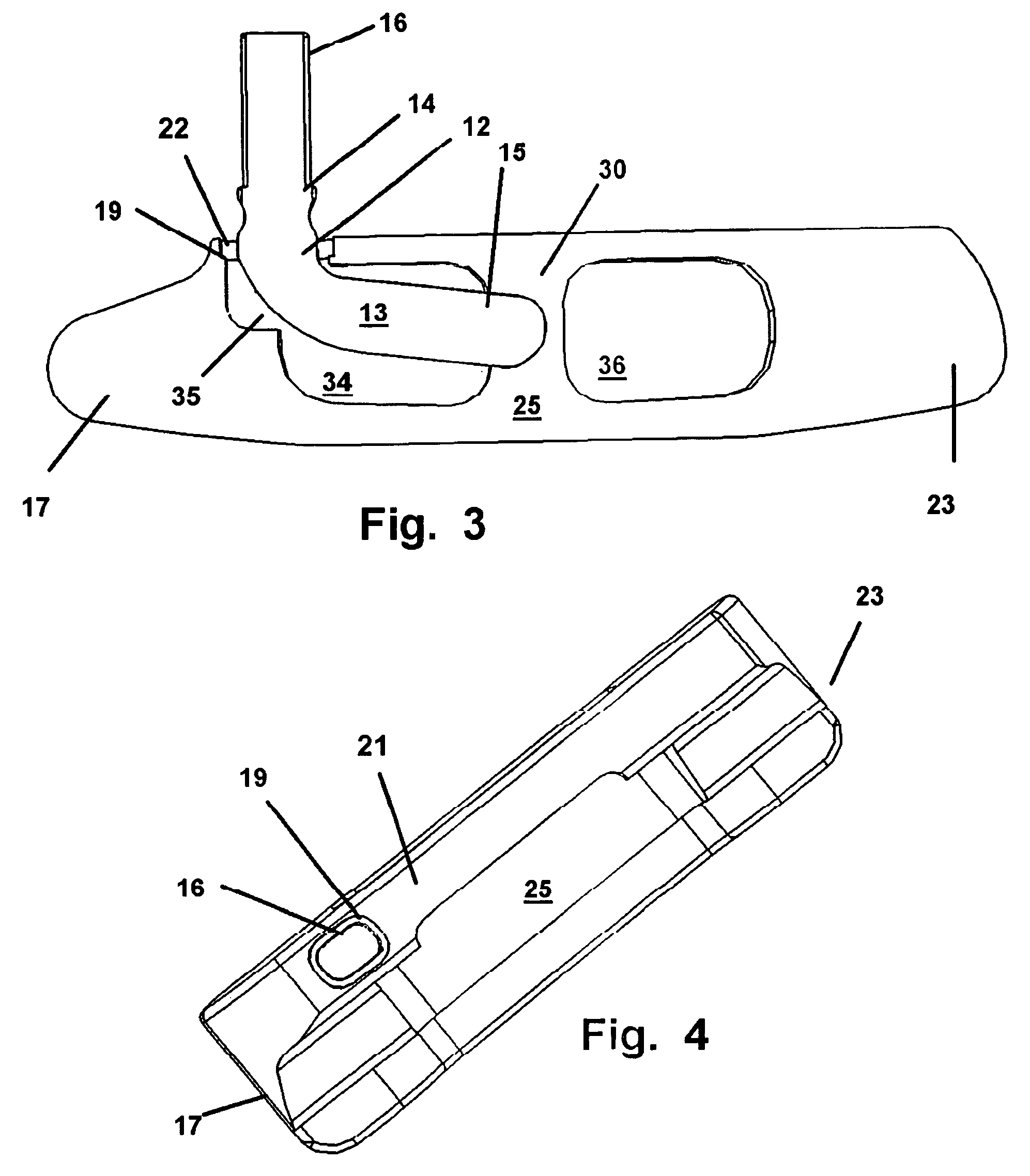

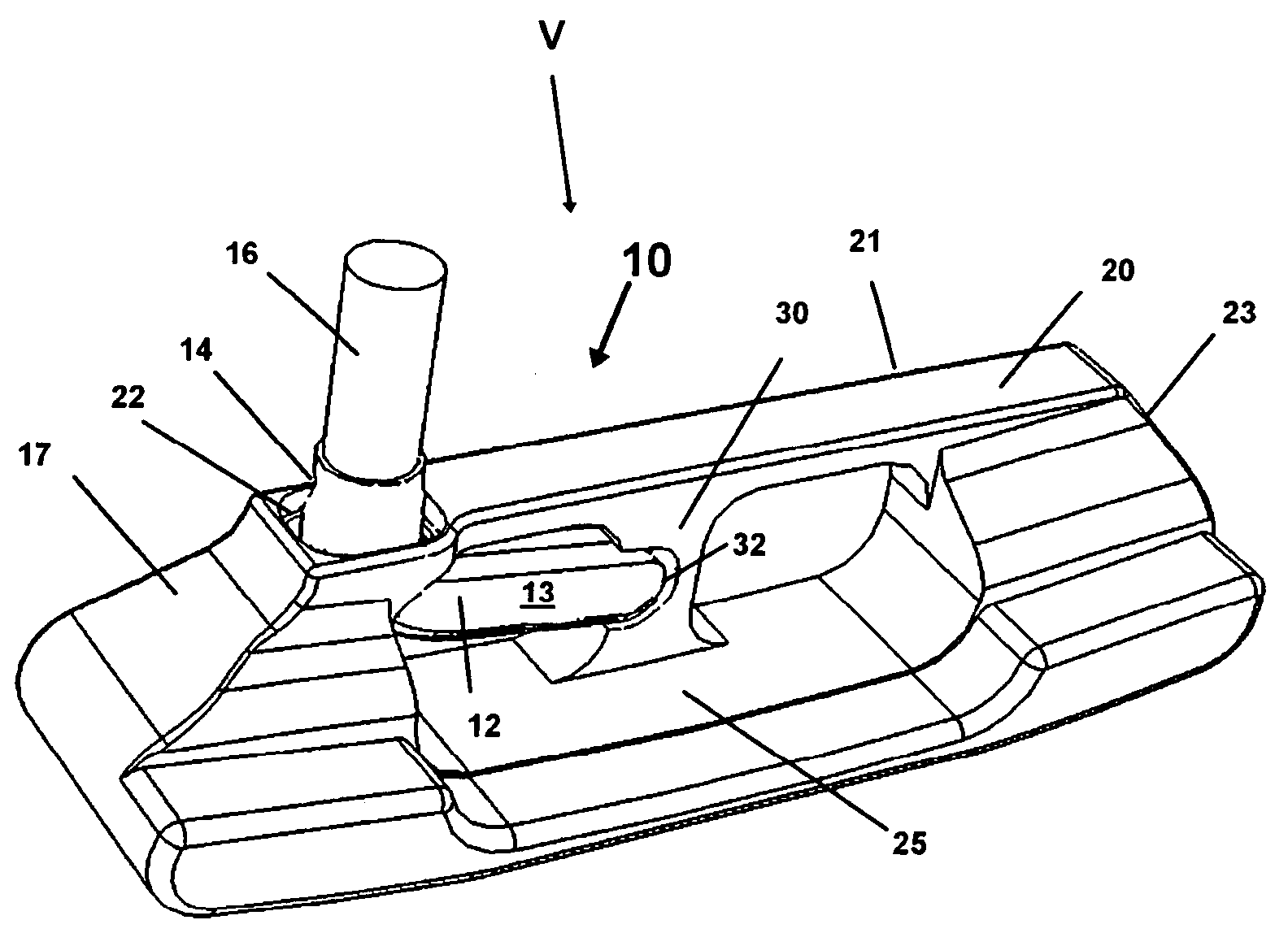

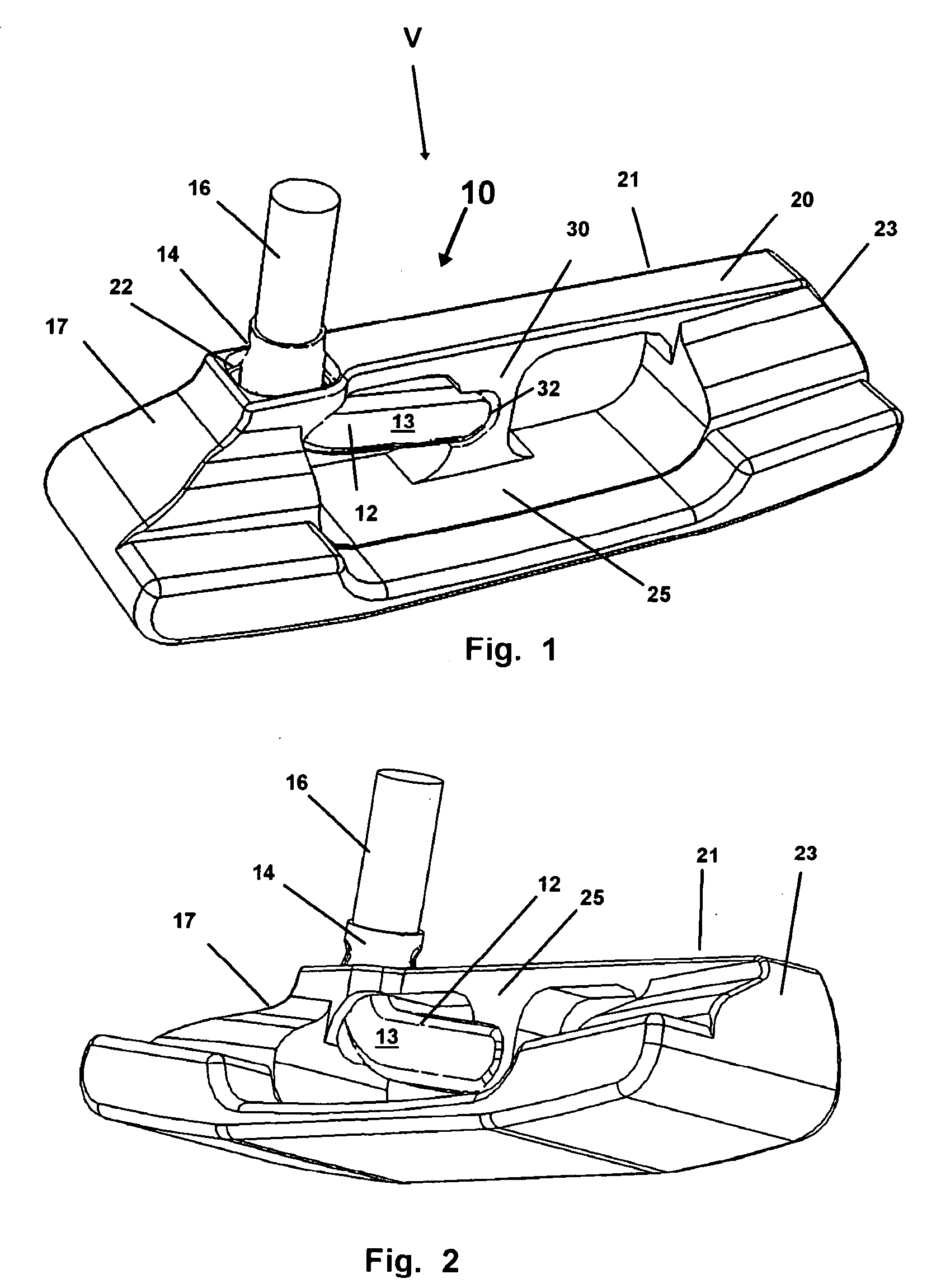

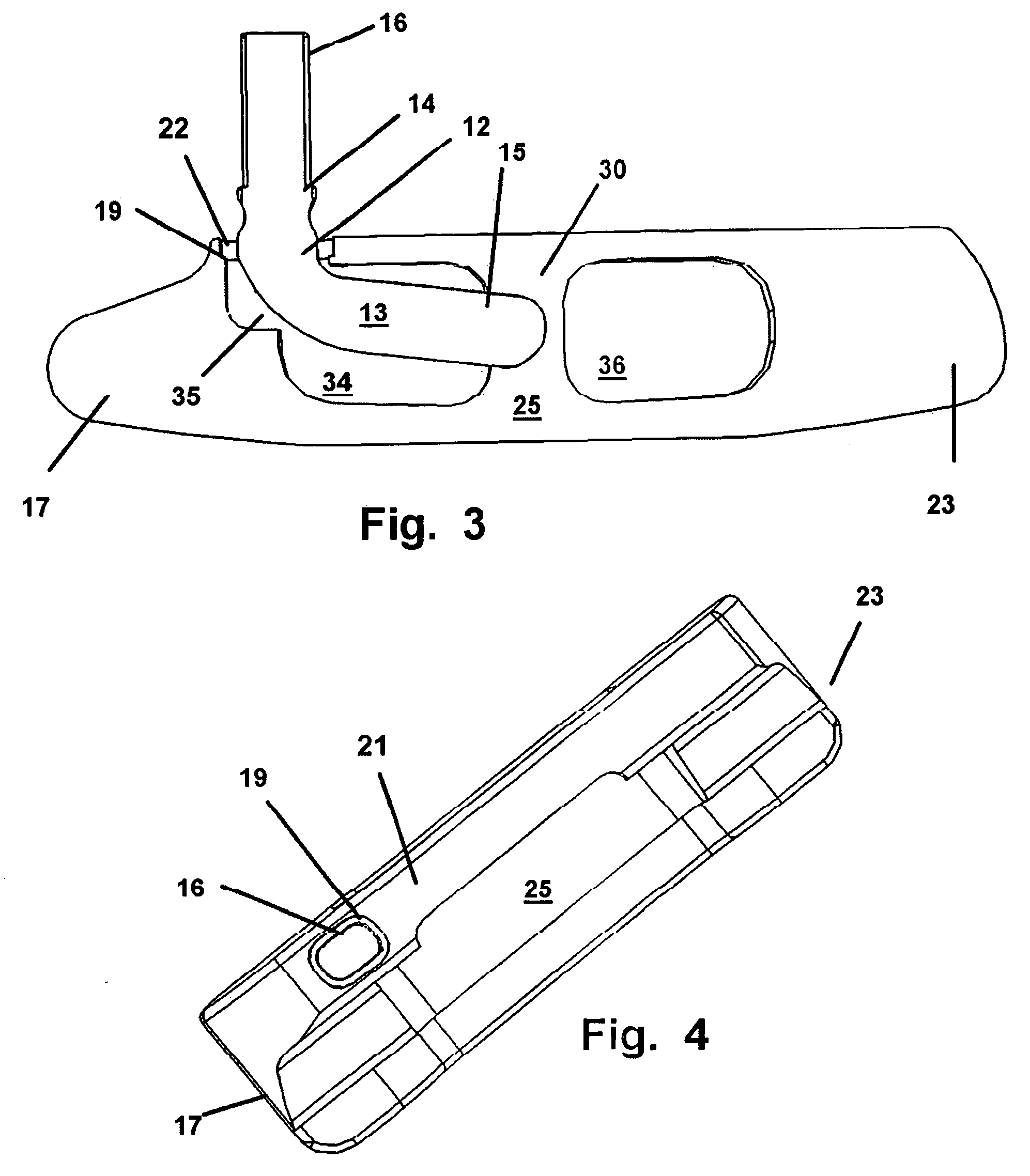

Golf putter

InactiveUS8070622B2Maximize reductionEliminate and reduce amount of initial skidding and back spinningGolf clubsRacket sportsMoment of inertiaEngineering

A golf putter providing a center mount of the hosel to the club head and a shaft engagement to the hosel at the heel end of the club head. The center mount provides the sole engagement of the hosel to the head as a gap is formed by a pathway formed through the body of the head which is larger than the circumference of the hosel in its communication therethrough. The centered engagement provides better touch to the user and feedback on striking a ball while concurrently removing the shaft from the user's line of sight to the ball and club face and reduces the twist or torque at impact with a golf ball, thereby increasing the moment of inertia.

Owner:SCHMIDT JACOB H

System and method for integrating billing information from alternate energy sources with traditional energy sources

ActiveUS8214270B2Reduce needReduce primary energy consumptionComplete banking machinesTelephonic communicationReal-time chargingPredictive analytics

The method and system of the present invention provides for data gathering of energy systems, calculation of billing information for the energy systems to include both traditional energy sources and renewable energy sources, and creation of various outputs to include various user interfaces applicable to overall management of the energy systems. The user interfaces can include integrated, real-time billings to a consumer that measure the cost of the primary energy as well as savings provided by renewable energy sources. The present invention also provides predictive analysis for various aspects of energy use in order to better manage particular facilities that may incorporate renewable energy sources. The gathered data and the various user interfaces enables a user to modify or adjust the use of the renewable energy sources at selected sites to maximize their impact on reducing the cost of the primary energy bill.

Owner:ALSO ENERGY

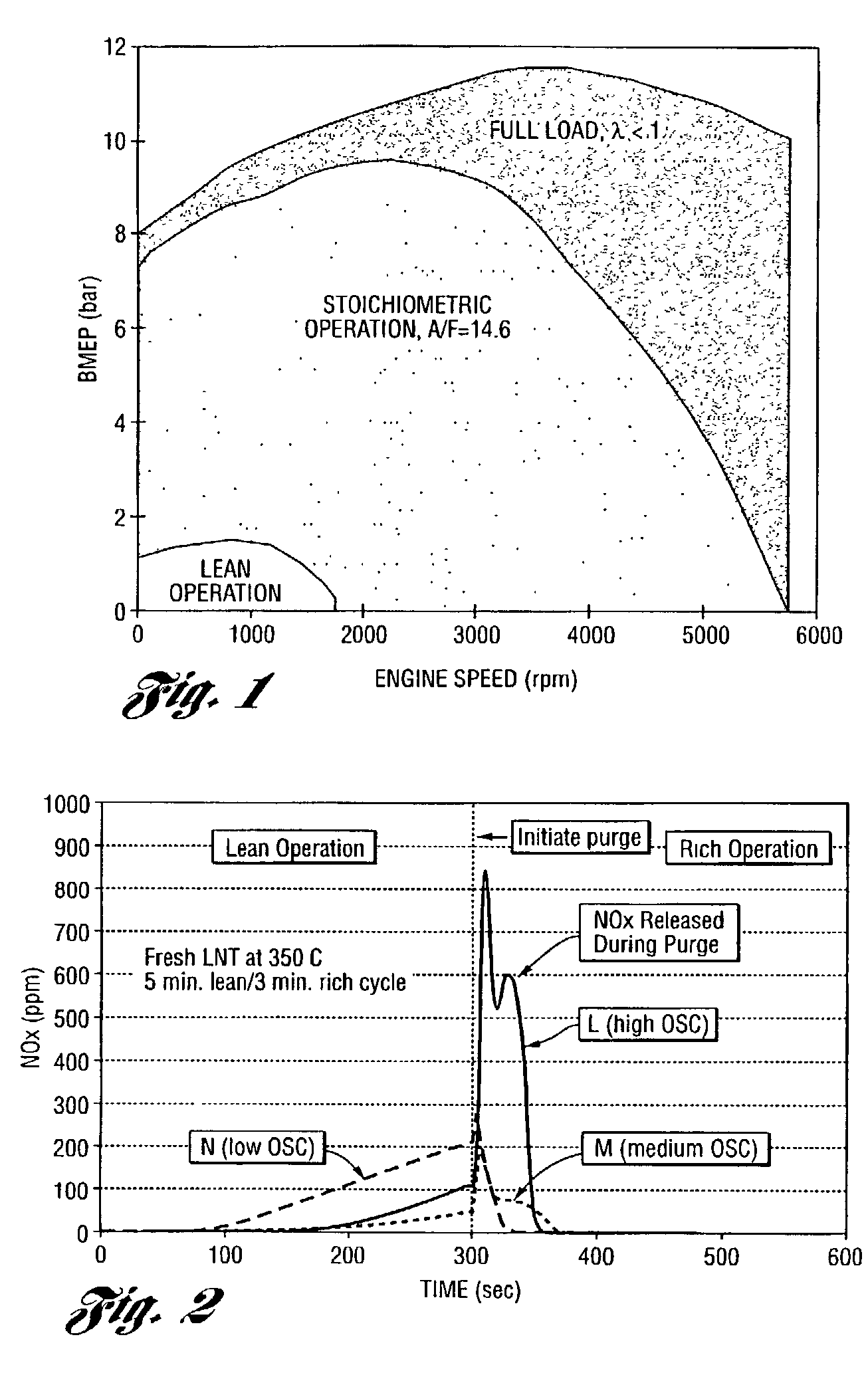

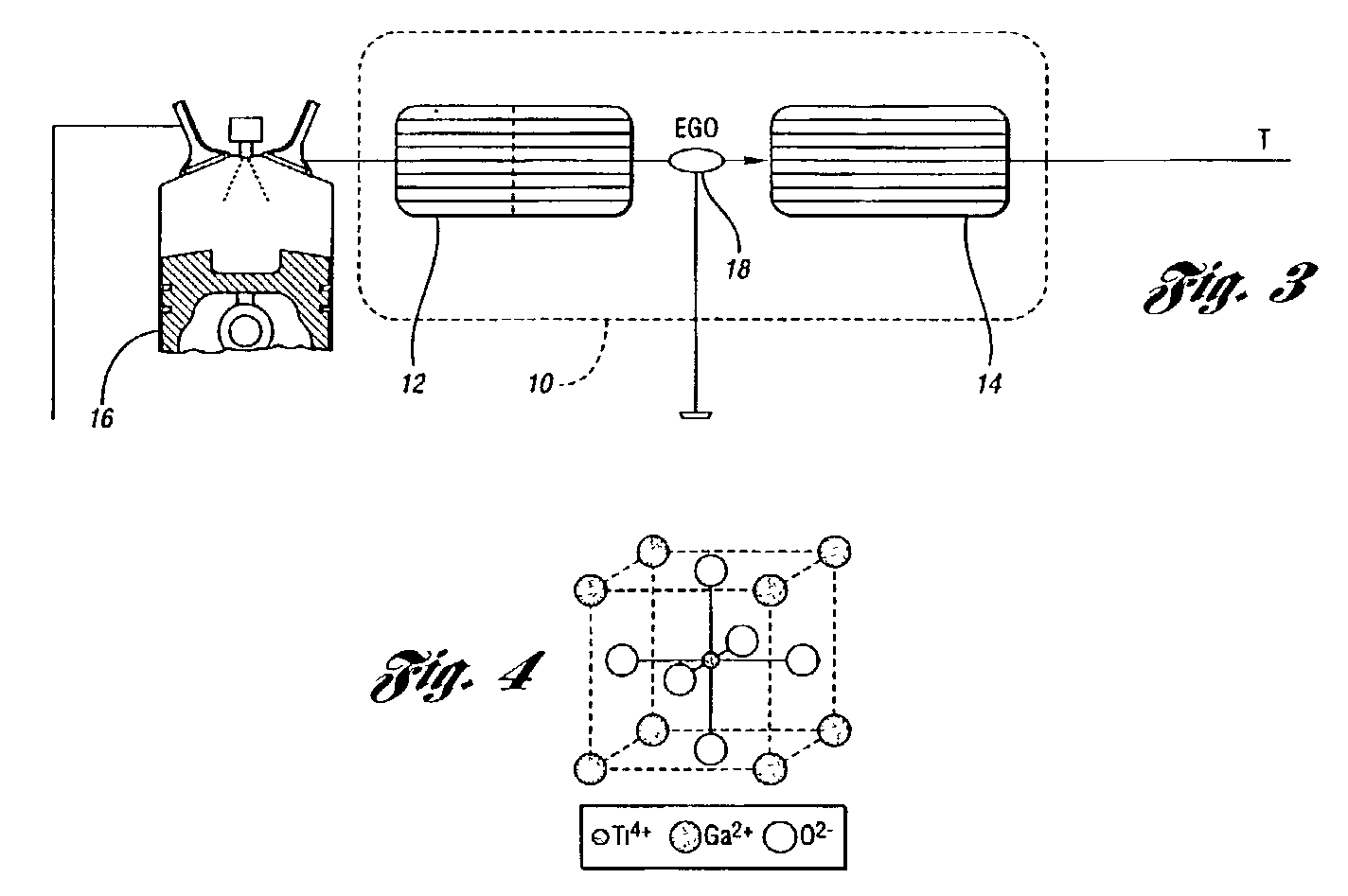

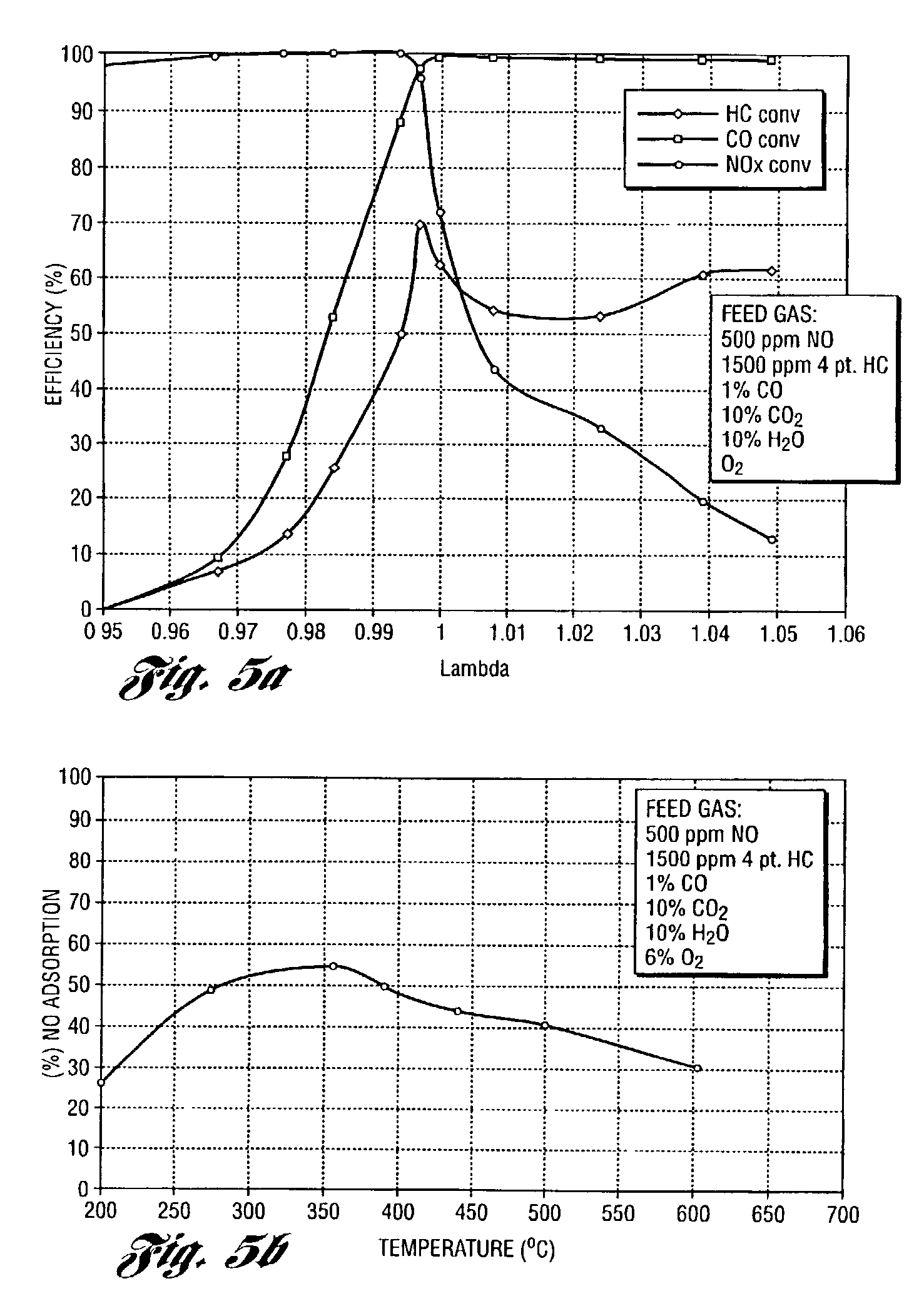

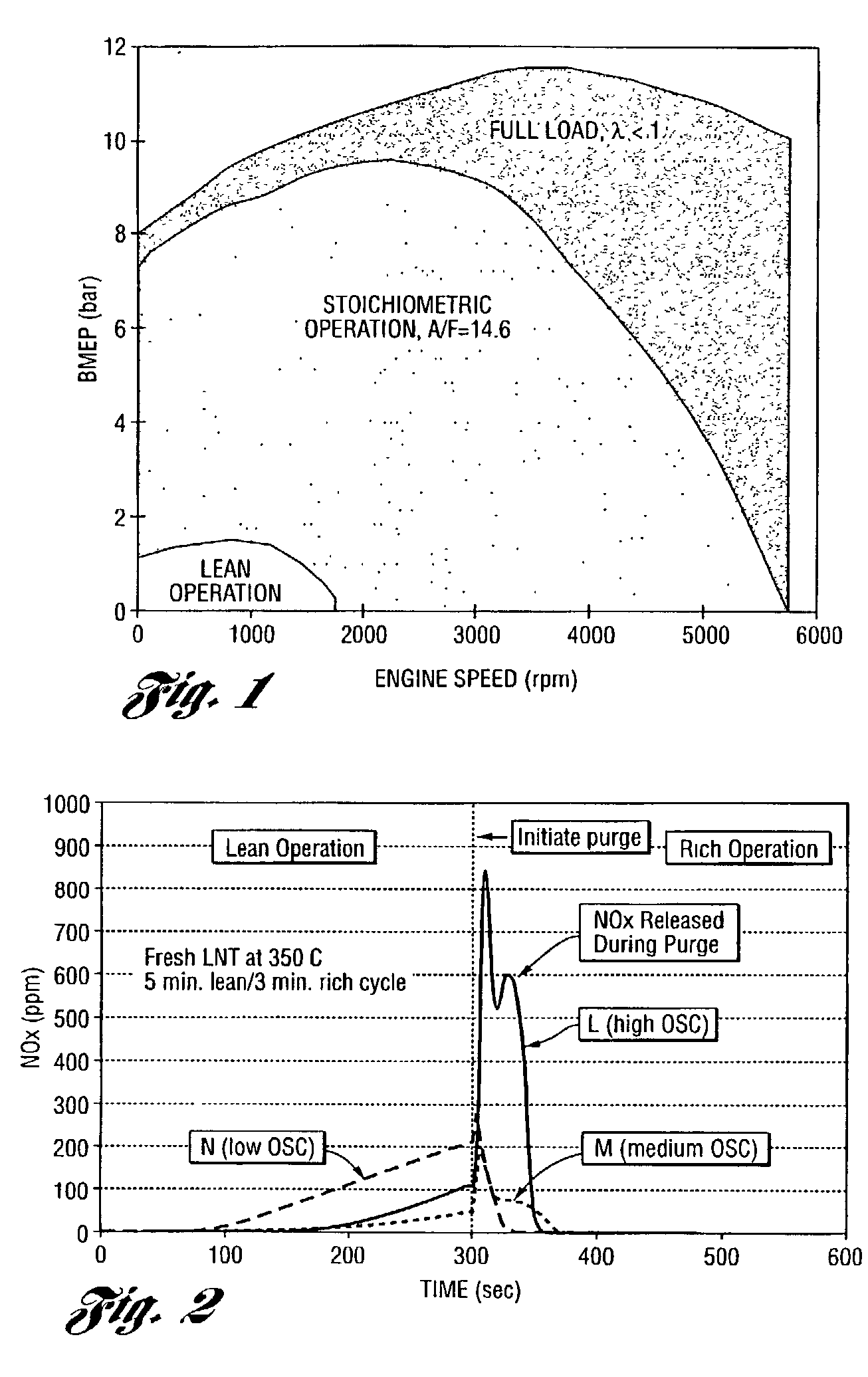

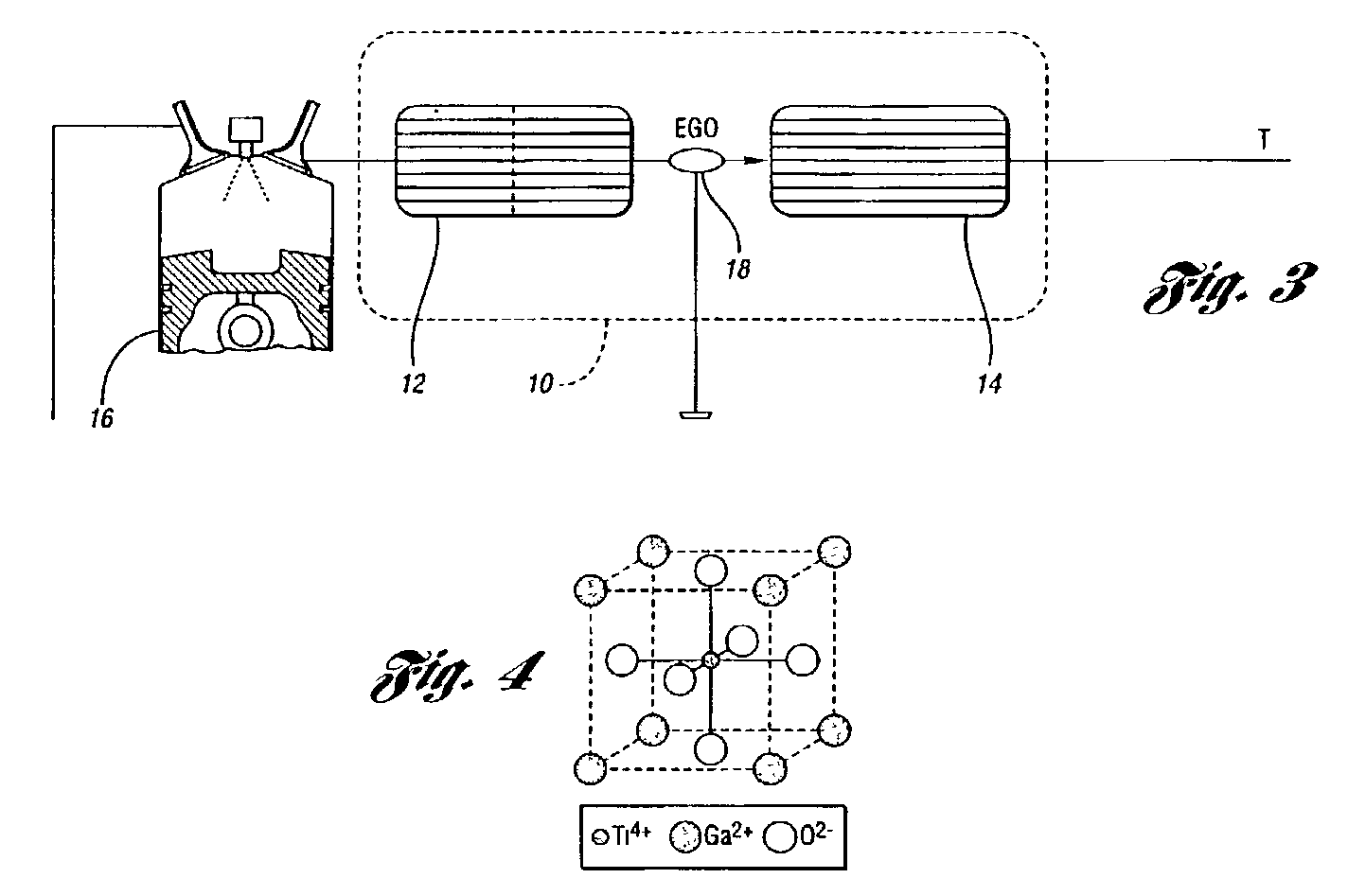

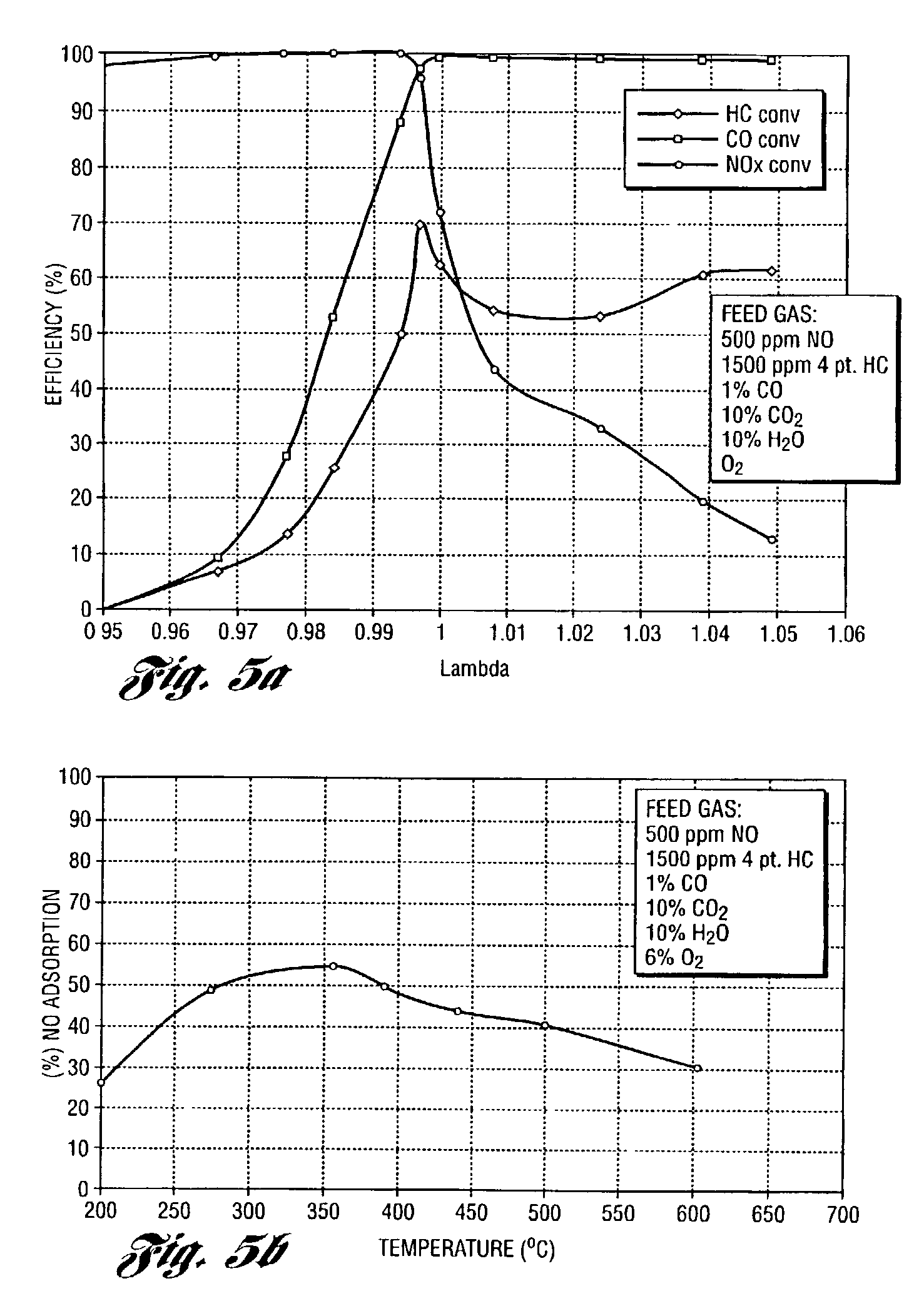

Perovskite catalyst system for lean burn engines

InactiveUS7071141B2Maximize reductionMaximize the reduction of HCInternal combustion piston enginesHeterogenous catalyst chemical elementsTrappingCrystal structure

Owner:FORD GLOBAL TECH LLC

Perovskite catalyst system for lean burn engines

InactiveUS20040082469A1Maximize reductionMaximize the reduction of HCInternal combustion piston enginesHeterogenous catalyst chemical elementsTrappingCrystal structure

A catalyst system for use with an internal combustion engine to provide emissions reductions under lean and stoichiometric operating conditions. The catalyst system comprises a first catalyst comprised of a newly developed Perovskite-based formulation having an ABO3 crystal structure designed to bring the precious metal and NOx trapping elements close together. The first catalyst acts primarily to maximize the reduction of emissions under lean operating conditions. The catalyst system also comprises a second catalyst comprised of precious metals which acts primarily to maximize the reduction of emissions under stoichiometric conditions.

Owner:FORD GLOBAL TECH LLC

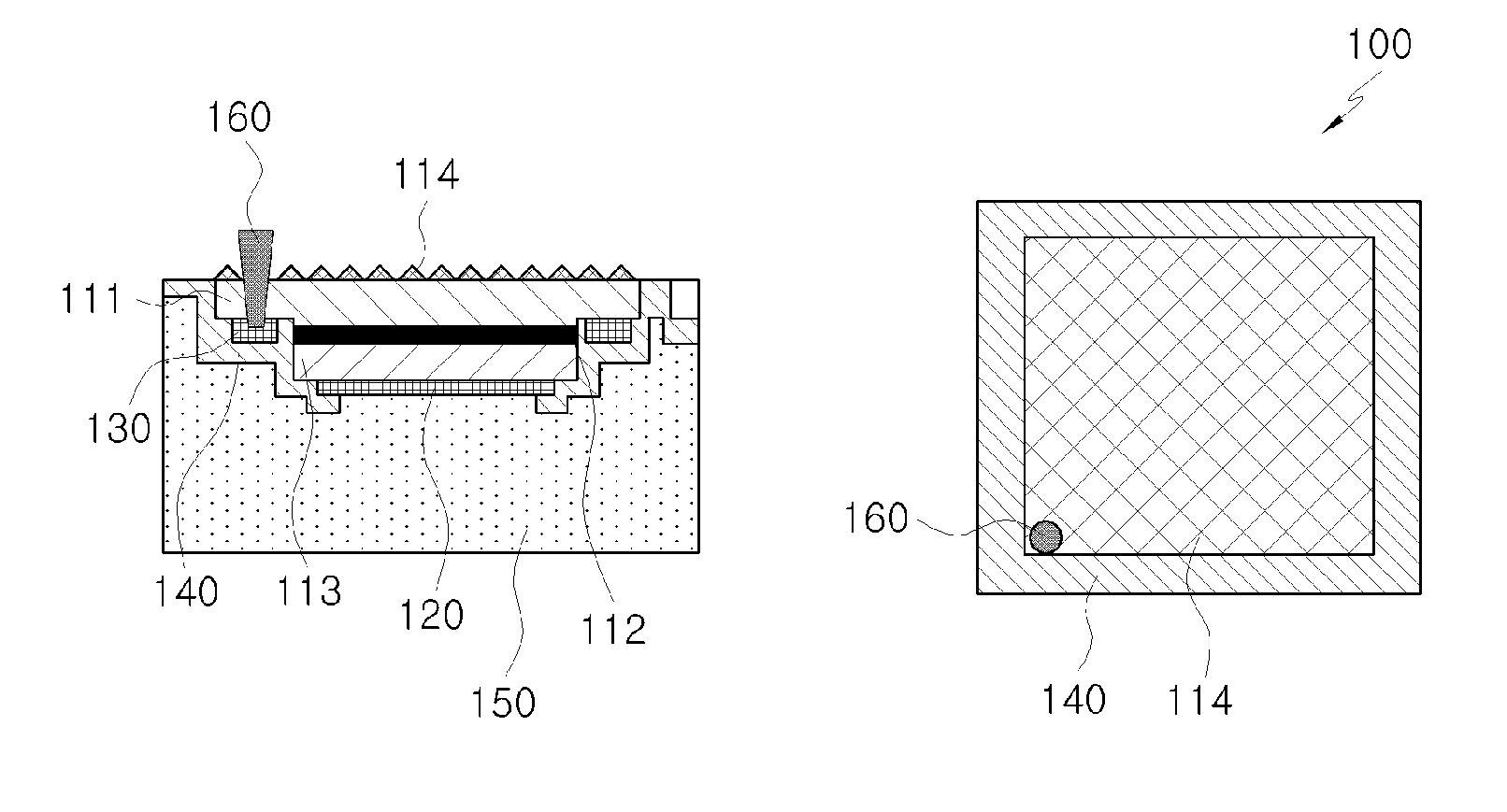

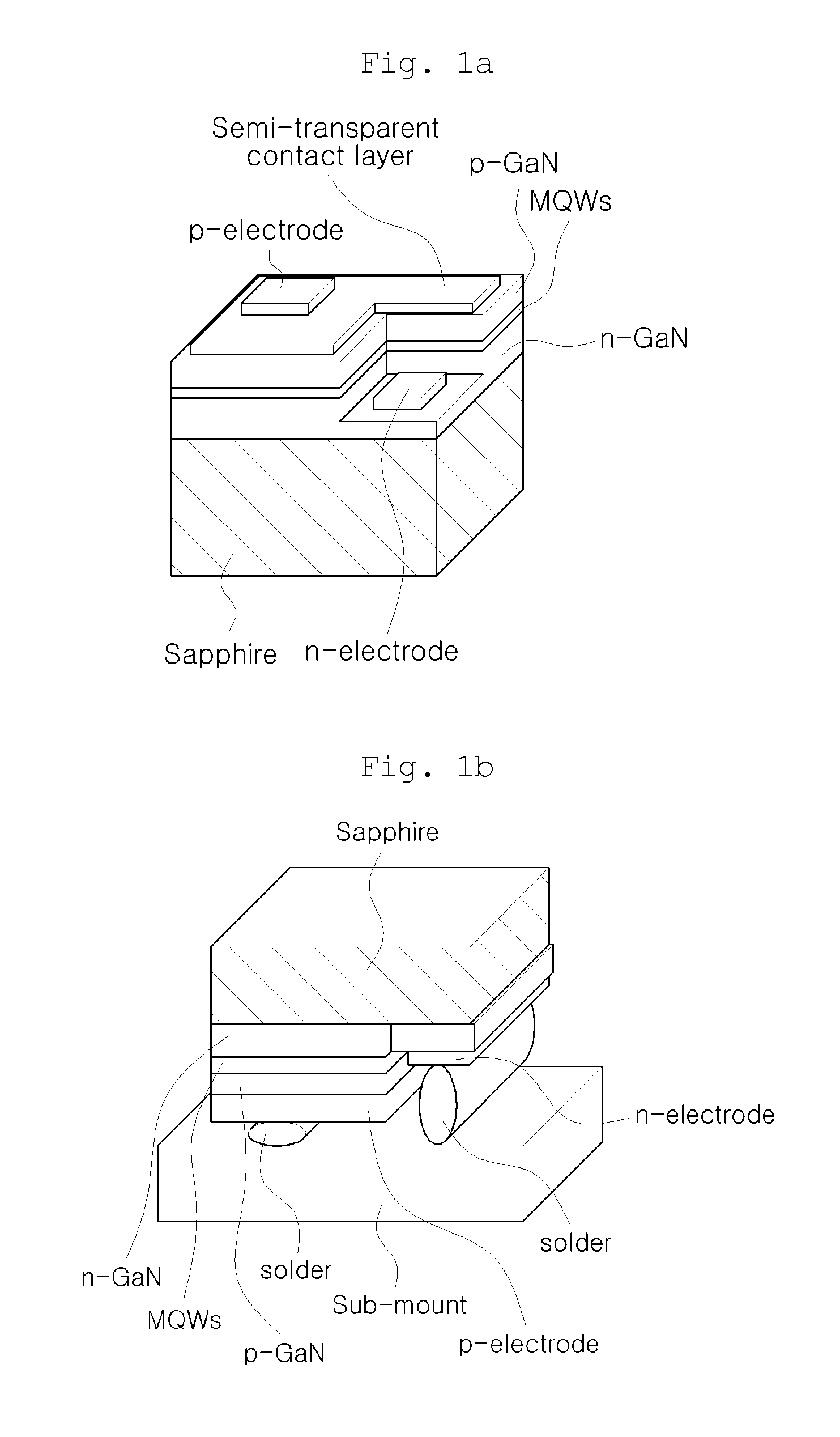

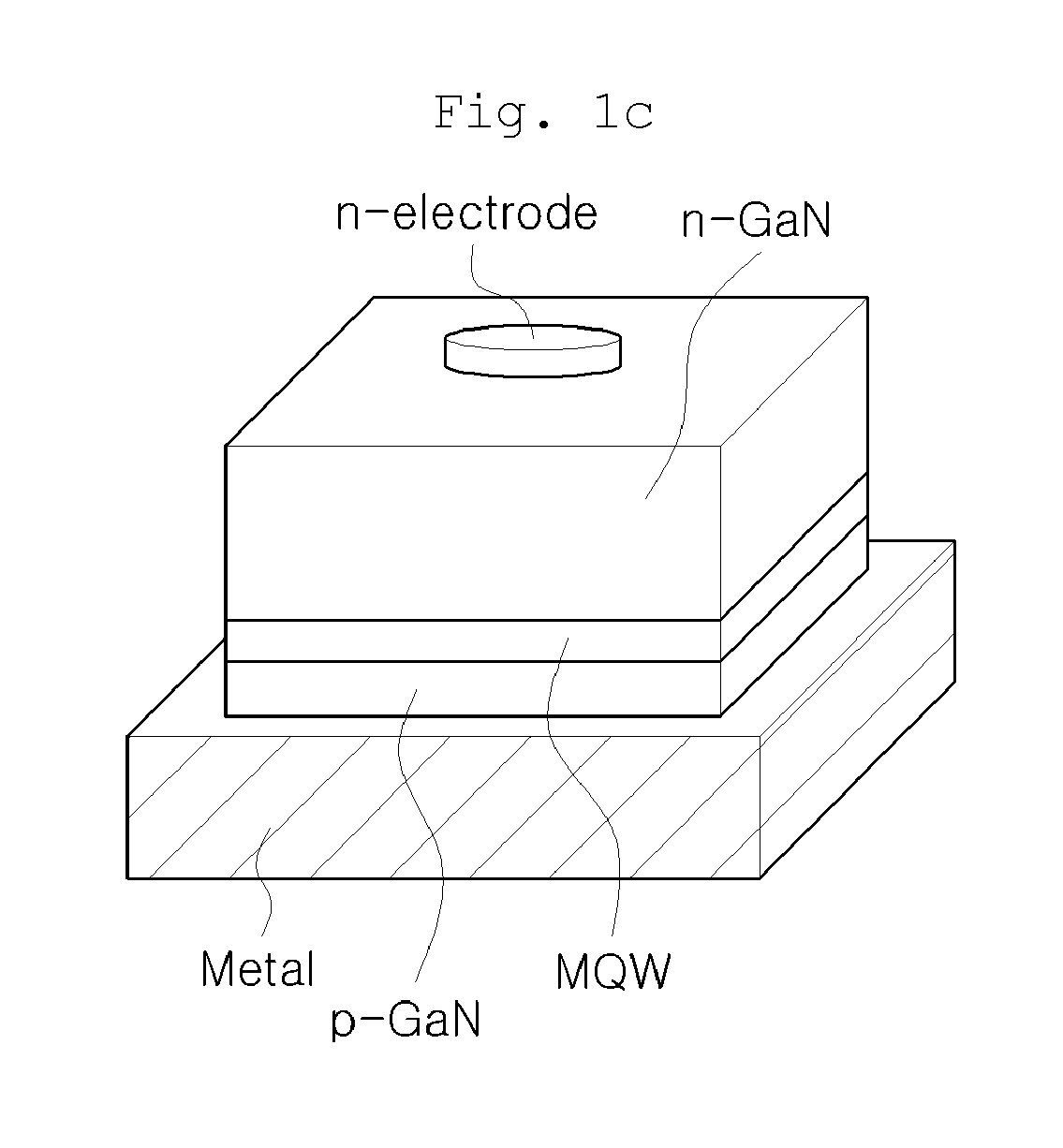

Horizontal power LED device and method for manufacturing same

ActiveUS20150053995A1Increase powerImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesMechanical engineeringMaterials science

The present invention relates to a horizontal LED device and a method of manufacturing the same. More particularly, the present invention relates to a high-power and high-efficiency horizontal LED device manufactured using the advantages of conventional horizontal and vertical LEDs, and a method of manufacturing the same.

Owner:BAE JEONG WOON +2

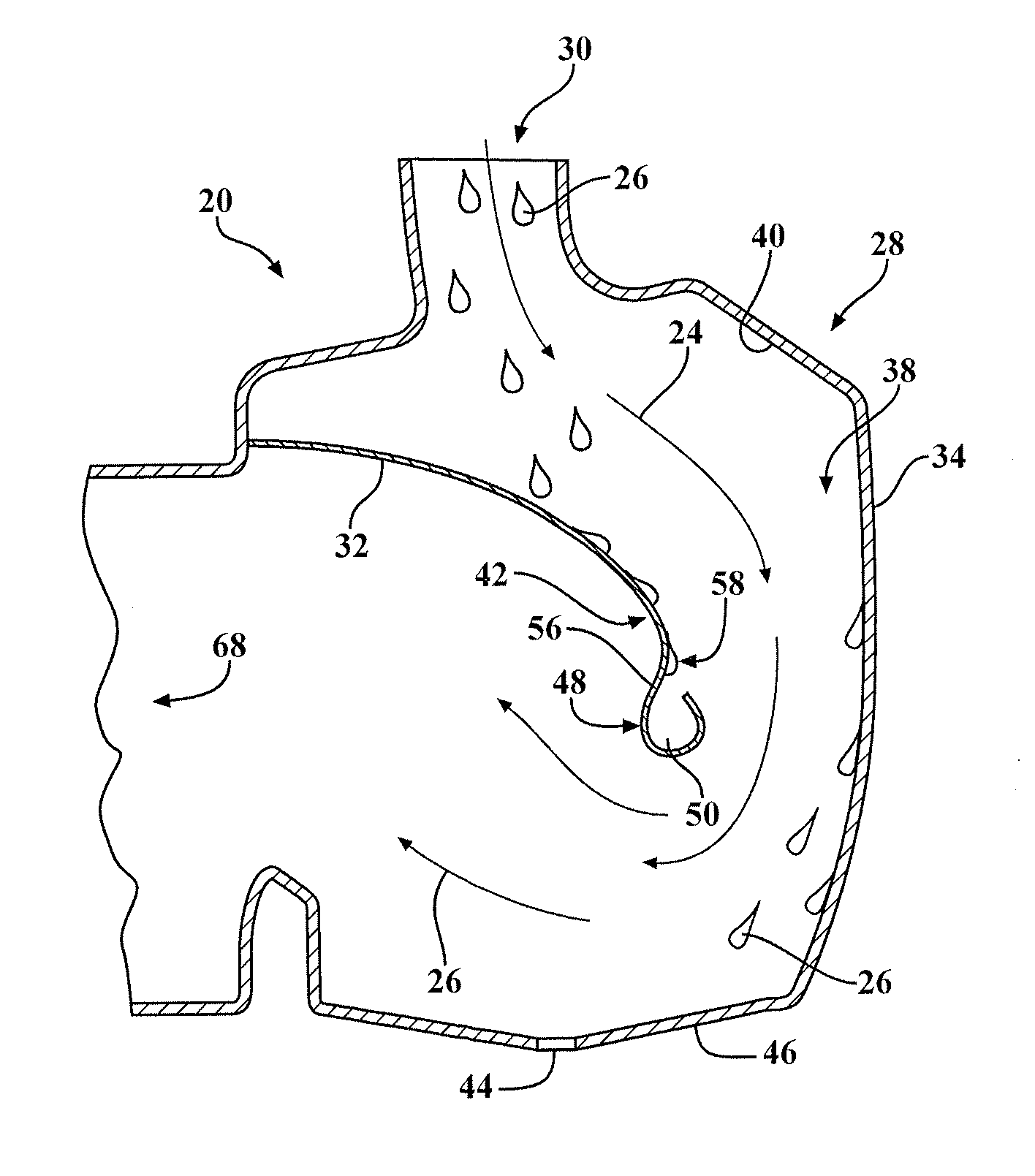

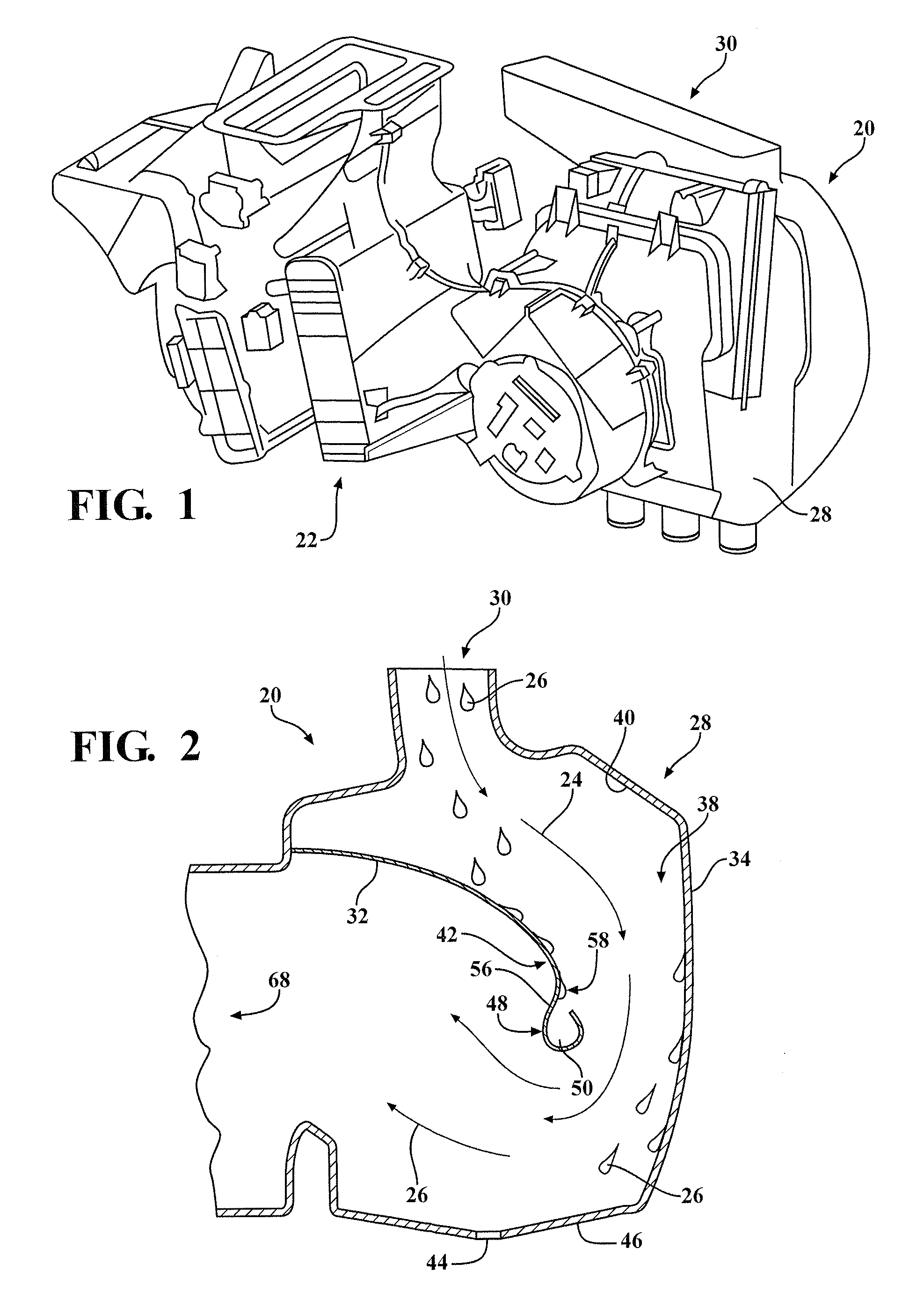

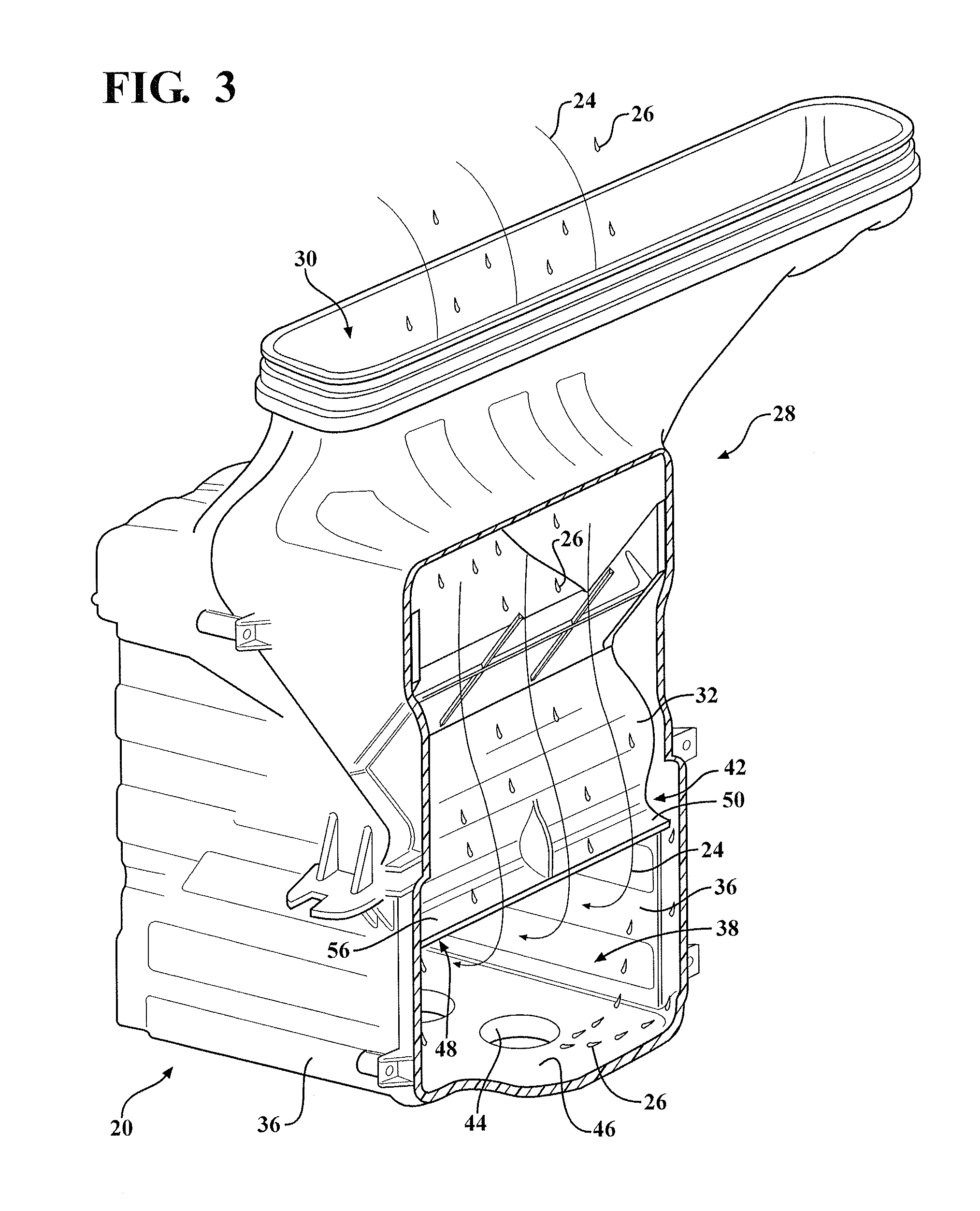

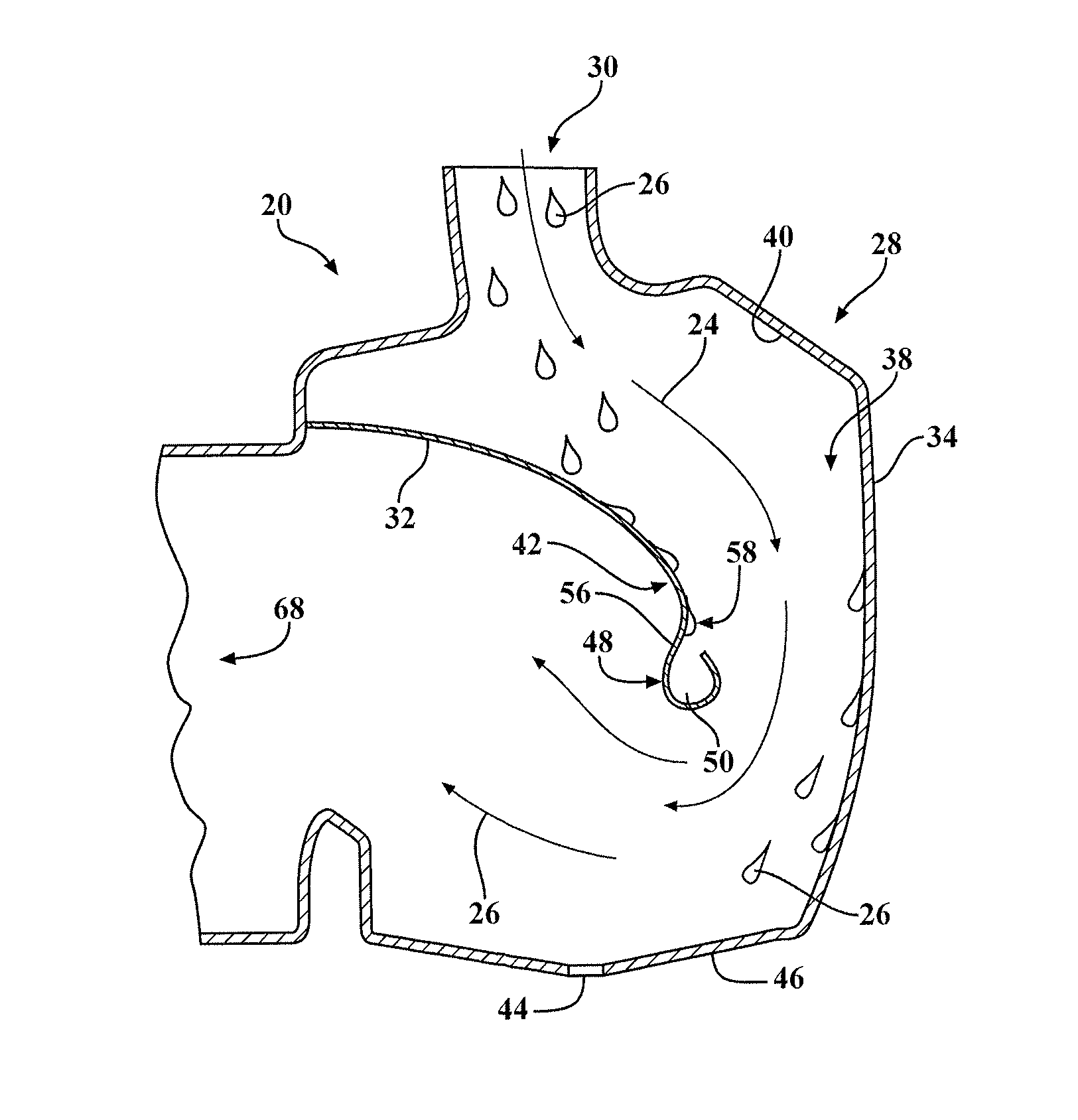

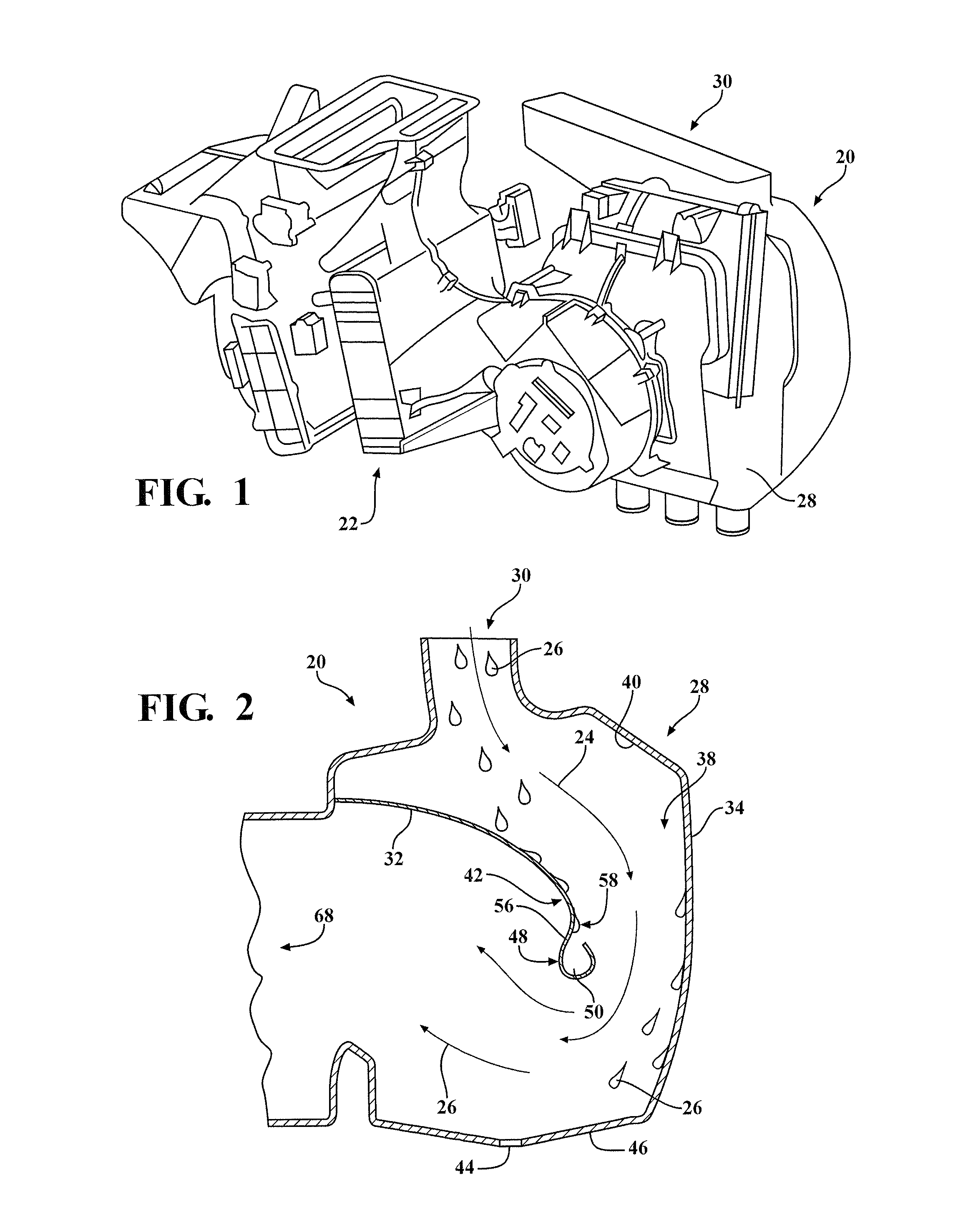

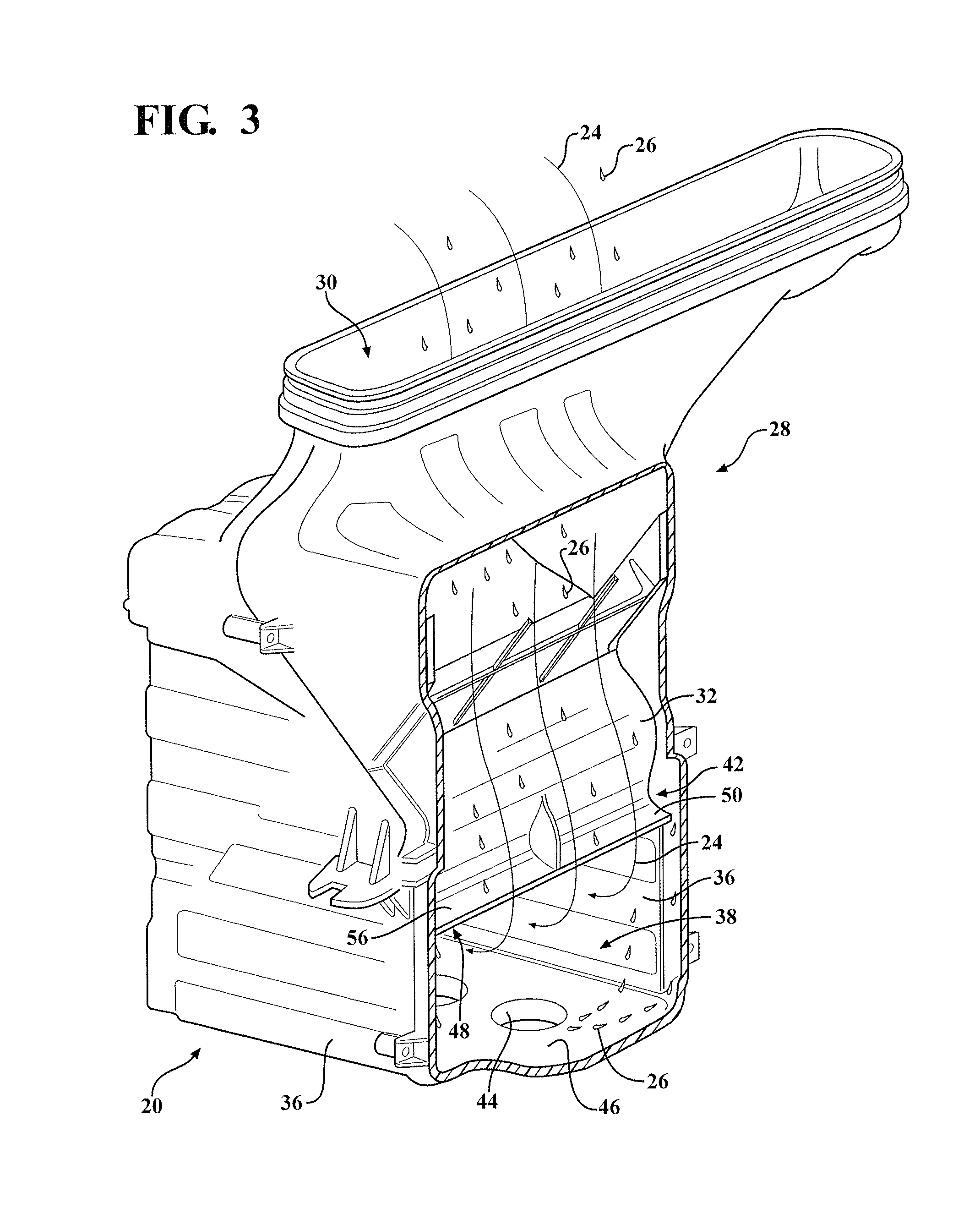

Water separator having a gutter

ActiveUS20130160649A1Maximize reductionReduce air contentCombination devicesAuxillary pretreatmentWater contentWaste management

A water separator reduces a water content of an air stream, which is used in an HVAC unit for a vehicle. The water separator includes a diverter wall and an adjacent wall spaced from the diverter wall to define an air passage. The diverter wall has a terminal end extending into the air passage for changing a direction of the air stream flowing through the air passage to separate water droplets from the air stream to reduce the water content of the air stream. A gutter is coupled to the terminal end of the diverter wall and extends into the air passage. The gutter defines a drainage channel configured to receive the water droplets that form on the diverter wall for preventing the water droplets from reentering the air stream flowing through the air stream passage.

Owner:VALEO CLIMATE CONTROL

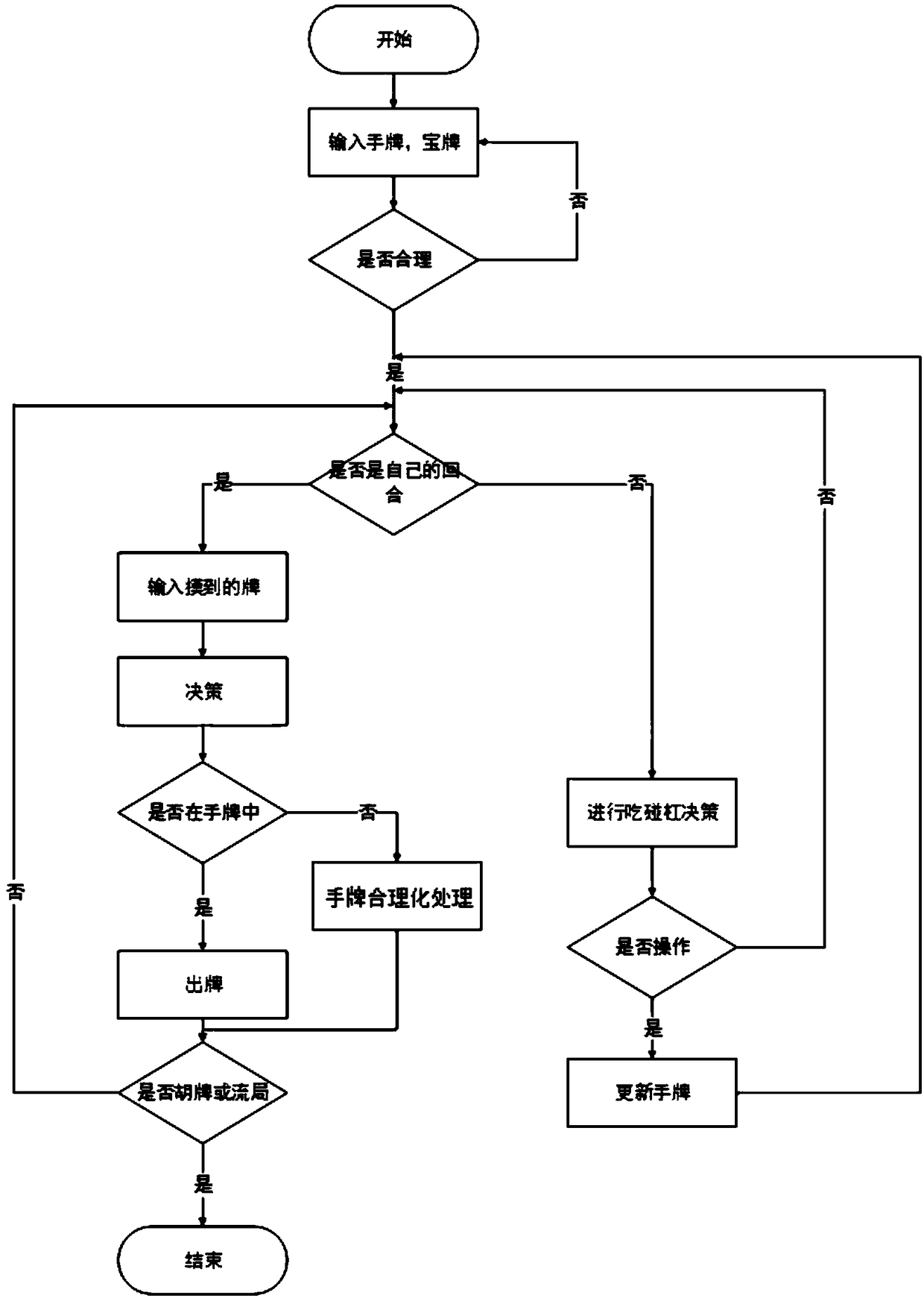

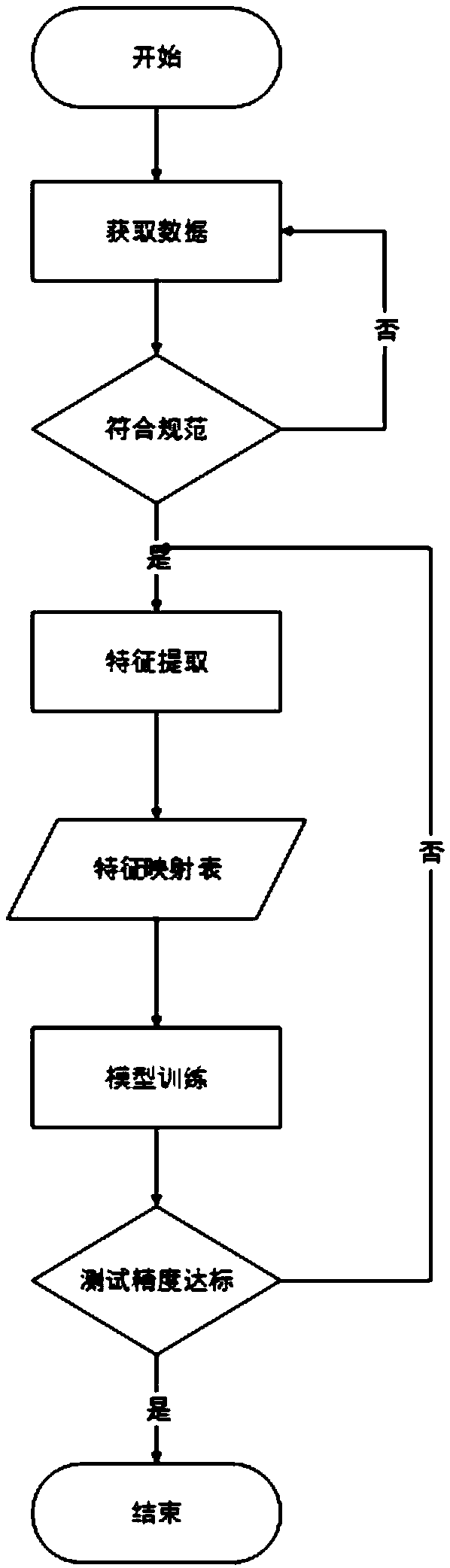

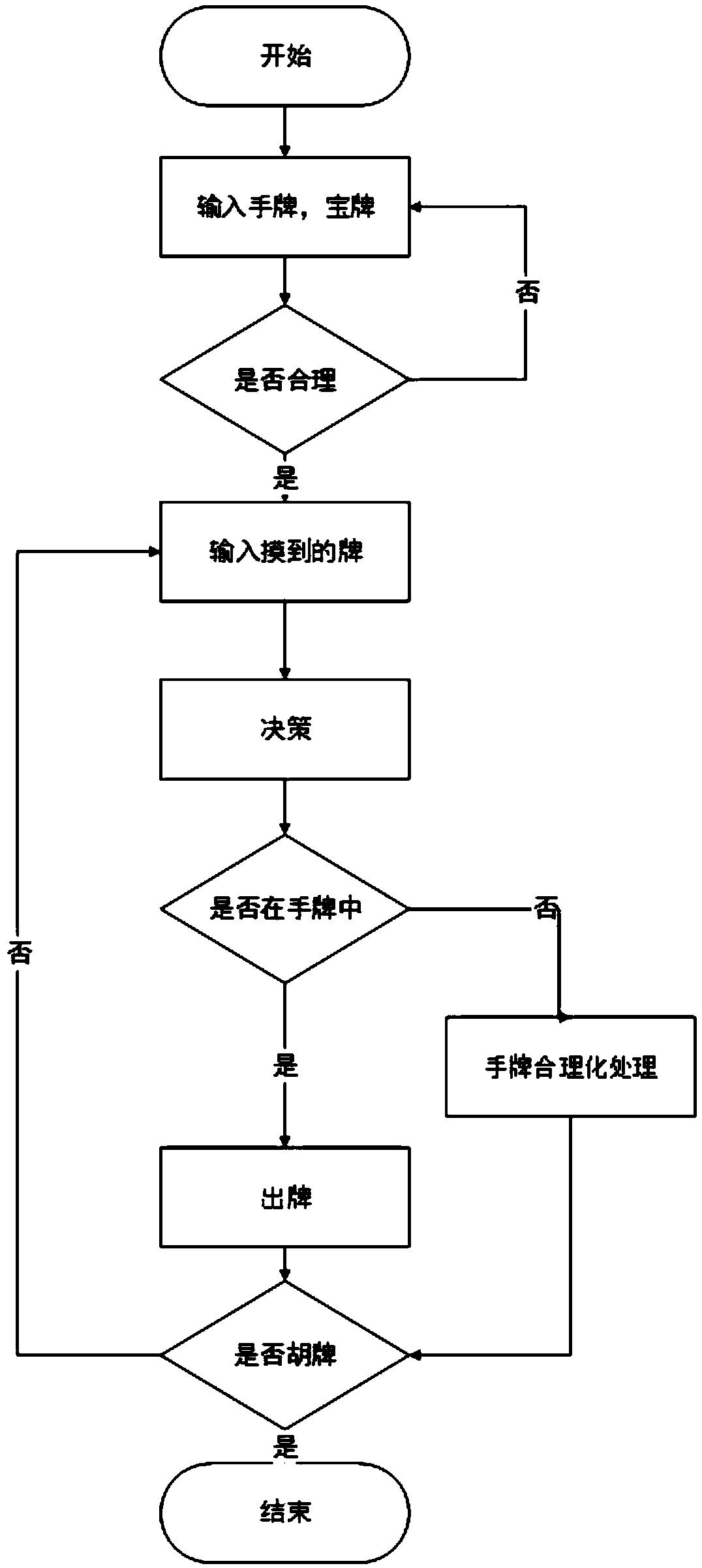

An intelligent decision model and a method for mahjong

PendingCN109409530AHigh precisionGood universalityIndoor gamesMachine learningTransplantationFeature extraction

The invention discloses an intelligent decision model and a method for mahjong, comprising a feature extraction module, wherein the feature extraction module comprises a directional listening number,various hand card counting, a lapping count, a dark streamer count, a sub-dew number, a sub-dew streamer, a treasure card, a carving, a bar and a broken card feature number. For the feature extractionmethod of simple rule matching, the feature number obtained by the feature extraction method proposed by the intelligent decision model of the invention is more comprehensive and concrete, and the application on the later model has higher precision; compared with the feature extraction method proposed by Tokyo University in Japan, the invention has better universality, more universality, convenient transplantation and higher commerciality.

Owner:中至数据集团股份有限公司

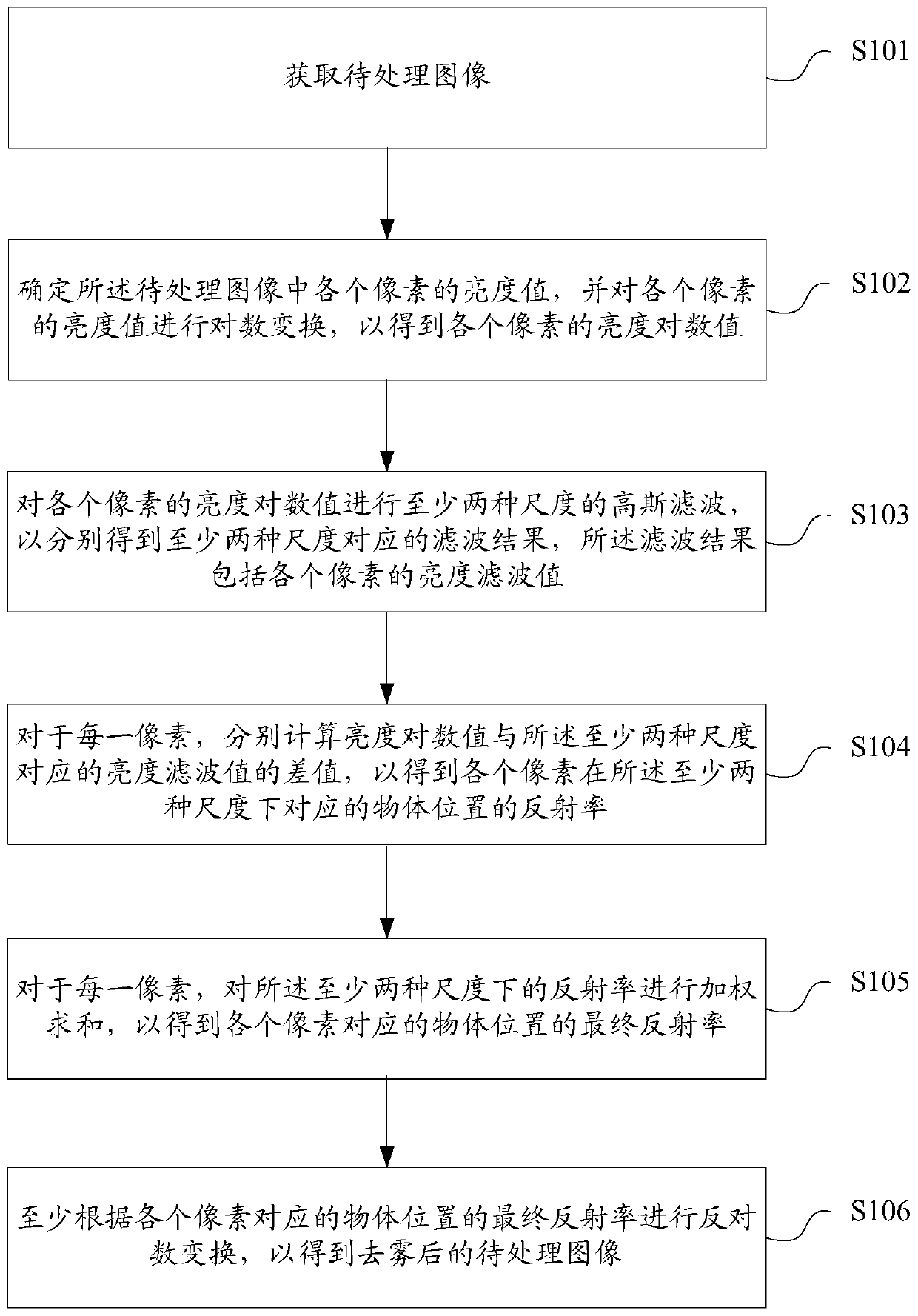

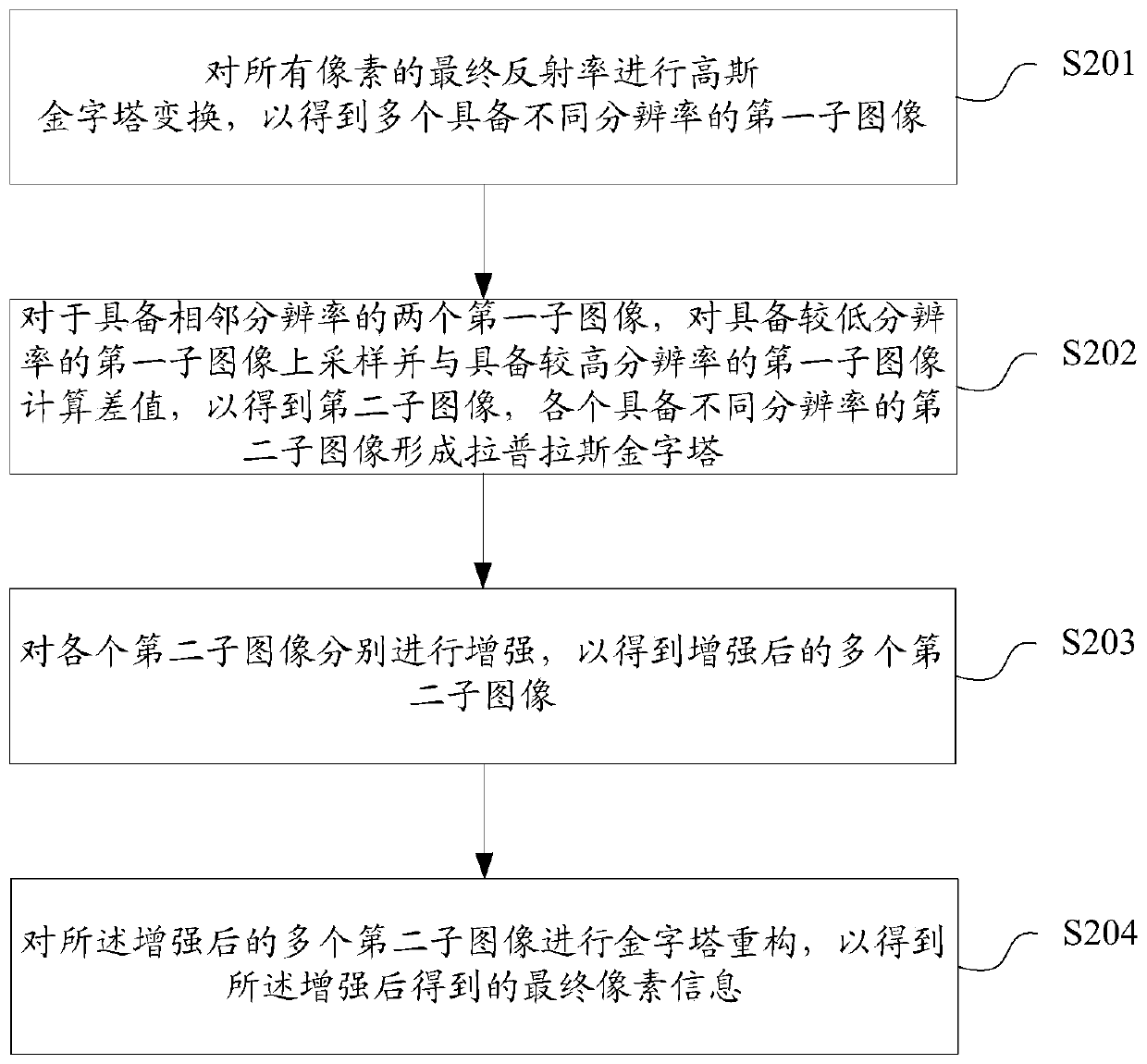

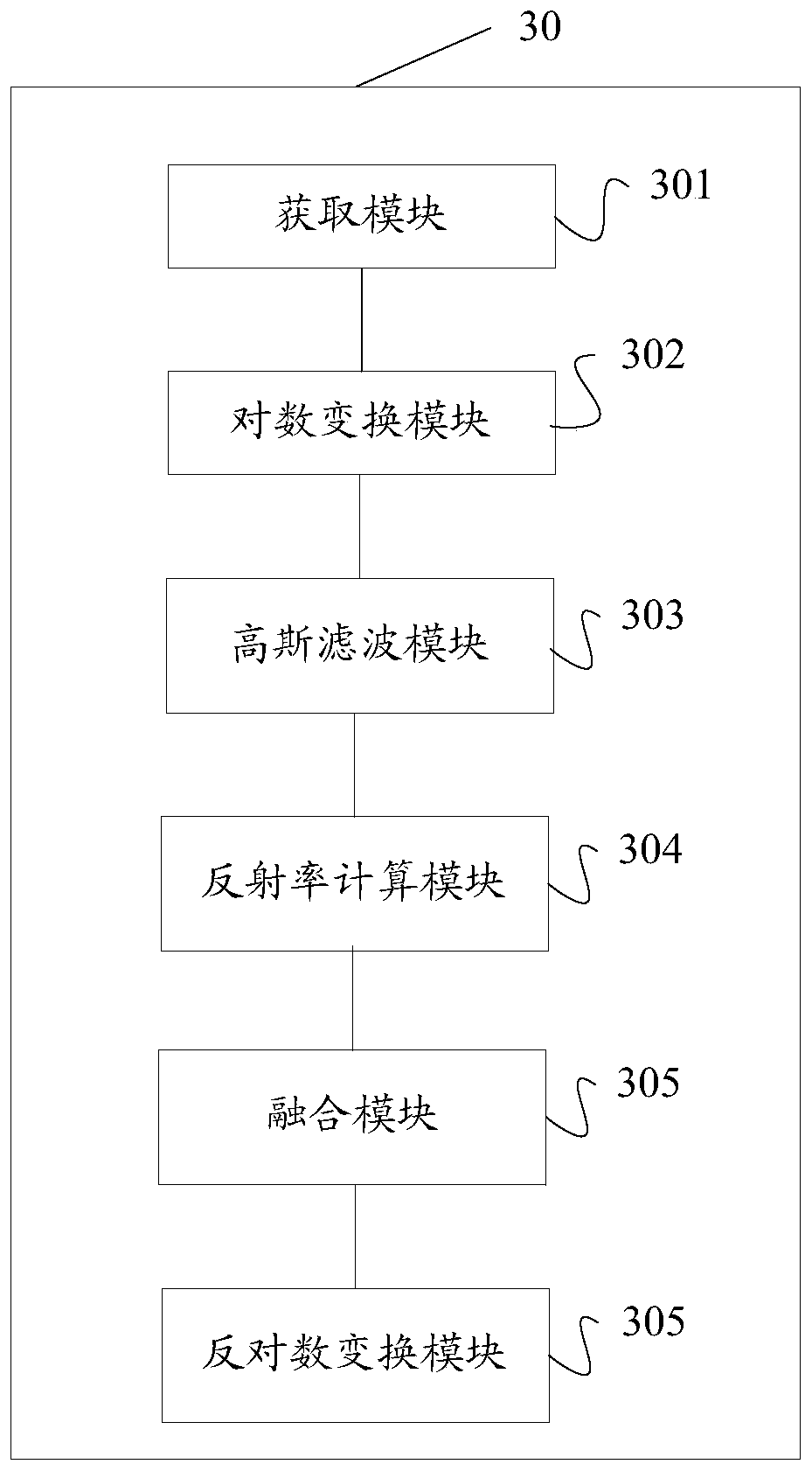

Image enhancement method and device, storage medium and terminal

ActiveCN111383181AImprove clarityGuaranteed growthImage enhancementImage analysisImaging qualityComputational physics

The invention discloses an image enhancement method and device, a storage medium and a terminal. The image enhancement method comprises: obtaining a to-be-processed image; determining a brightness value of each pixel in the to-be-processed image, and performing logarithm transformation on the brightness value of each pixel to obtain a brightness logarithm value of each pixel; carrying out Gaussianfiltering of at least two scales on the brightness logarithm value of each pixel to obtain filtering results corresponding to the at least two scales; for each pixel, respectively calculating the difference between the brightness logarithm value and the brightness filtering values of at least two corresponding scales to obtain the reflectivity of the corresponding object position of each pixel under at least two scales; for each pixel, performing weighted summation on the reflectivity under at least two scales to obtain the final reflectivity of the object position corresponding to each pixel; and performing inverse logarithm transformation at least according to the final reflectivity of the object position corresponding to each pixel. According to the technical scheme, the defogging effect can be improved, and the image quality is improved.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

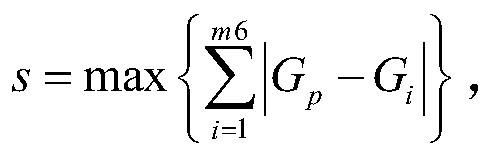

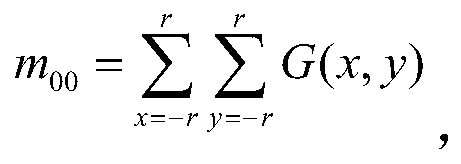

Image splicing and fusing method and system

PendingCN111353933AMaximize reductionHigh speedImage enhancementGeometric image transformationImage scaleScale space

The invention discloses an image splicing and fusing method and system. The method comprises the following steps: acquiring an image to be spliced; establishing an image scale space to obtain an imageof each image in m different scale spaces; solving feature points of the image in all scale spaces, and solving an optimal feature point through a non-maximum suppression method; solving the direction of the optimal feature point; establishing a feature descriptor, and performing feature point matching by utilizing the feature descriptor; acquiring an image registration mapping matrix, and completing registration of the two images; and after the registration of the two images is completed, fusing the overlapping regions of the two images to complete image splicing. The feature point solving method and the feature point descriptor solving method are high in speed, small in calculated amount, good in robustness and insensitive to geometric deformation. The image registration method is highin precision, high in reliability and high in anti-interference performance. Based on wavelet fusion, two spliced images can be better transited, information is not lost, and detail information is restored to the maximum extent.

Owner:重庆金山医疗技术研究院有限公司

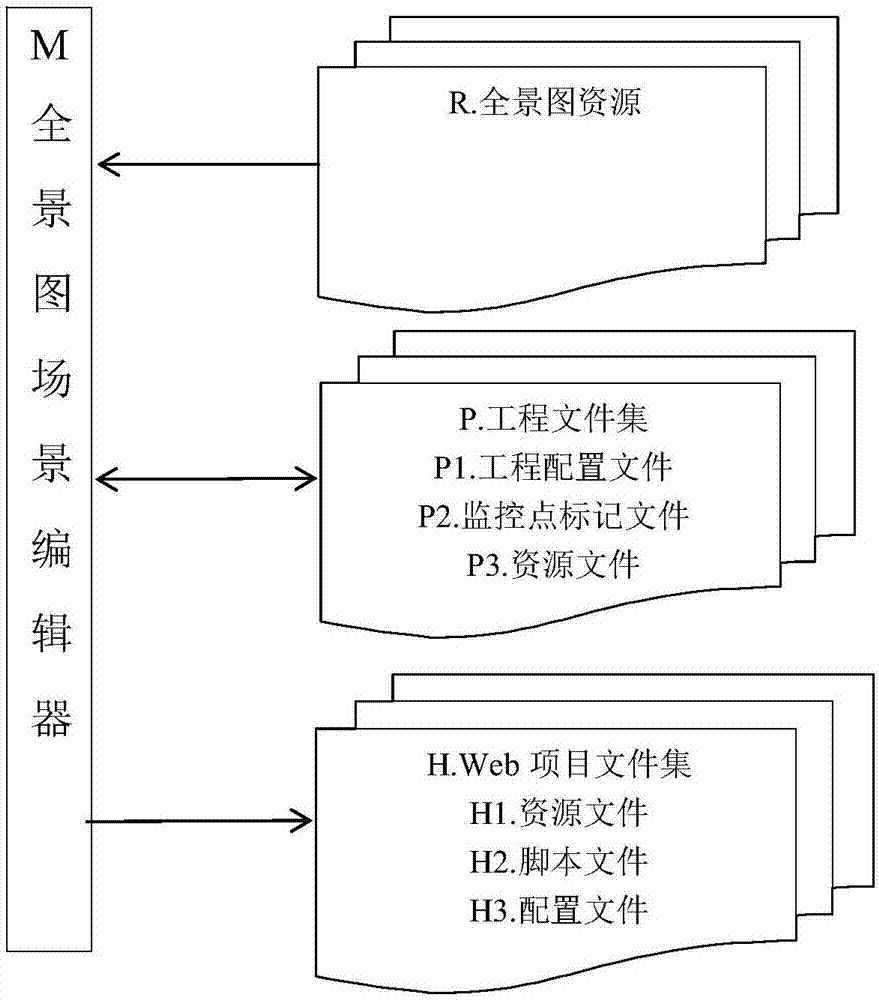

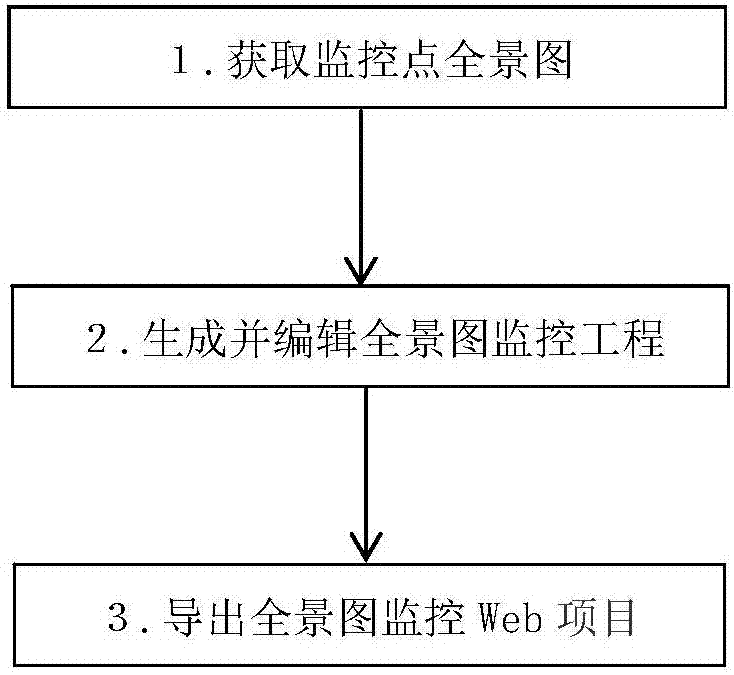

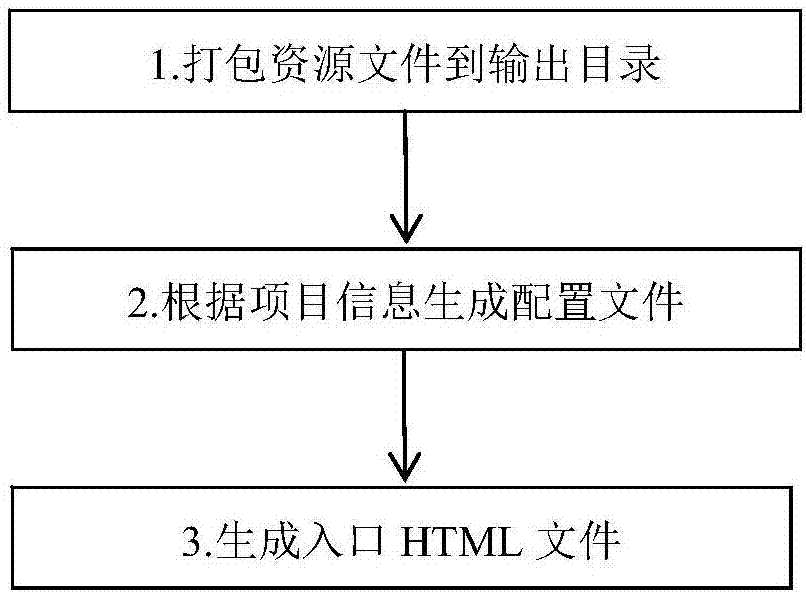

Graph Web display method and device based on panorama for industrial monitoring system

InactiveCN107483840AShort development cycleLow costImage enhancementTelevision system detailsTwo-dimensional graphIndustrial monitoring

The invention discloses a graph Web display method based on a panorama for an industrial monitoring system. The method includes the steps of using a panorama scene editor to import a panorama resource set and edict and generate a panorama monitoring engineering file set; exporting the panorama monitoring engineering file set as a Web item file set to be imported into a Web server for conducting Web display. According to the method, construction is conducted on the basis of the panorama; the graph Web display method has the advantages of being not only short in development period of two-dimensional graphs and low in cost, but great in universality and interactivity of three-dimensional models, and meanwhile, real scenes can be restored to the maximum degree, and the method can cooperate with the existing industrial monitoring systems for usage to meet the demands for display and interactivity in complex scenes.

Owner:北京紫优能源科技有限公司

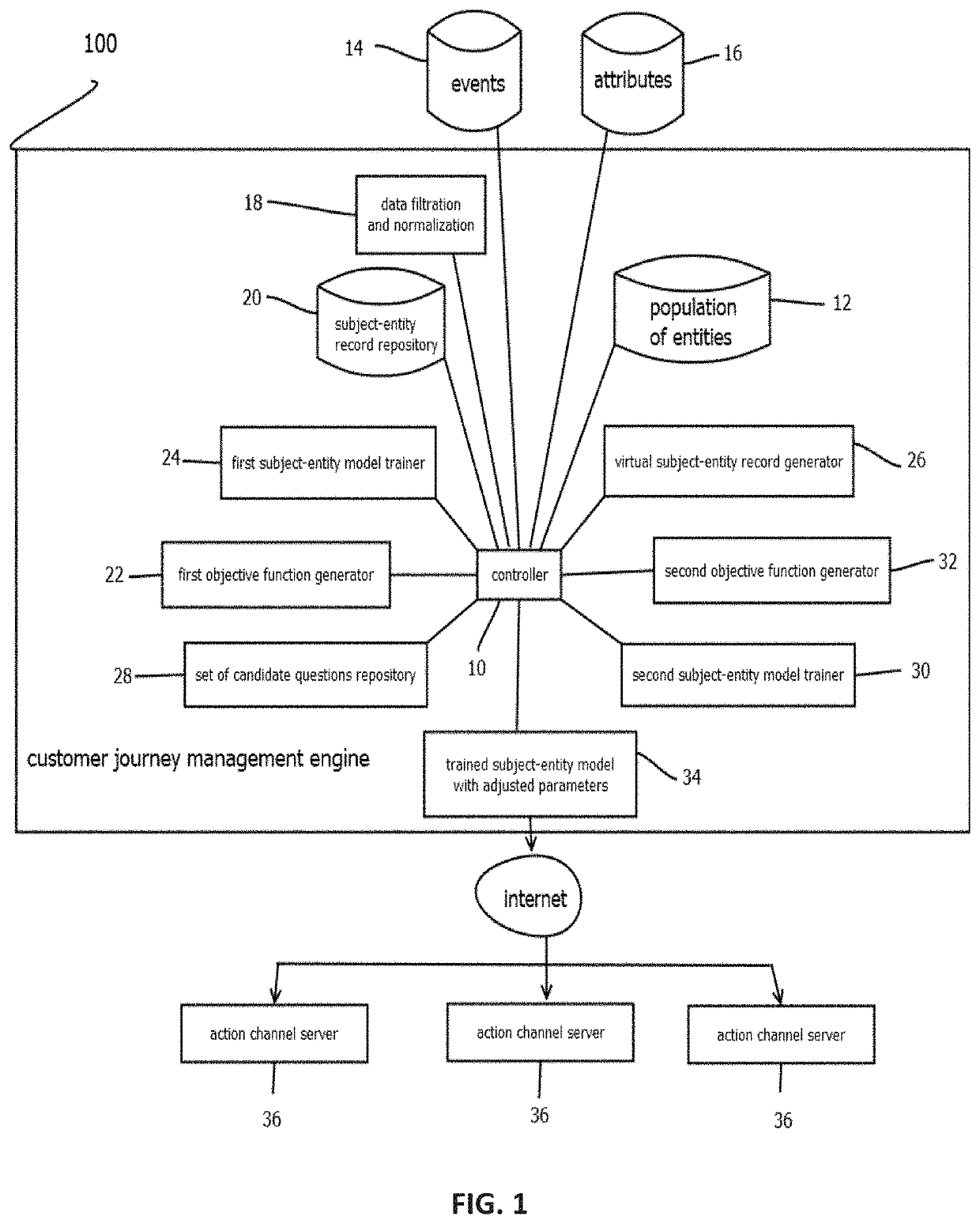

Customer journey management engine

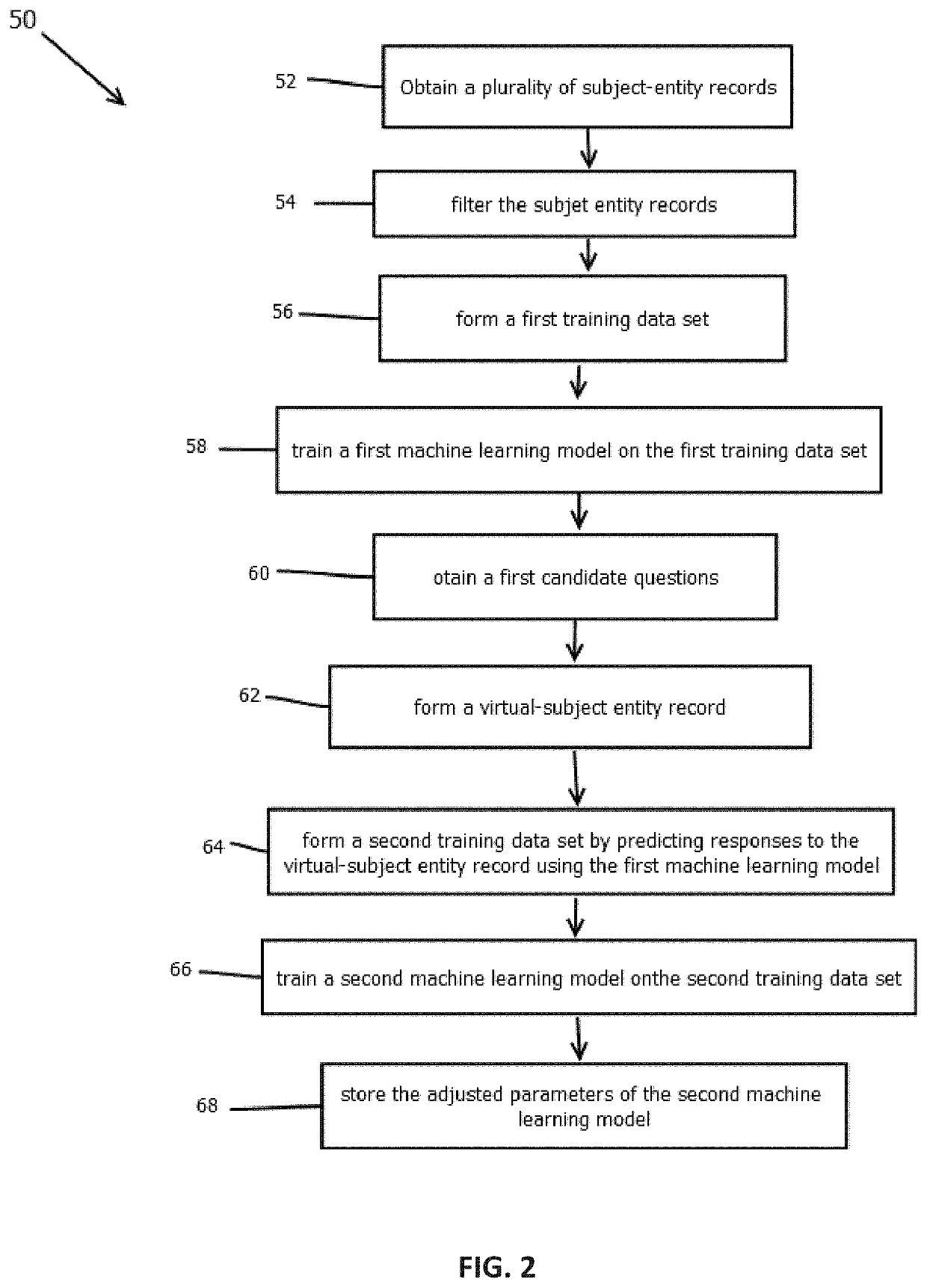

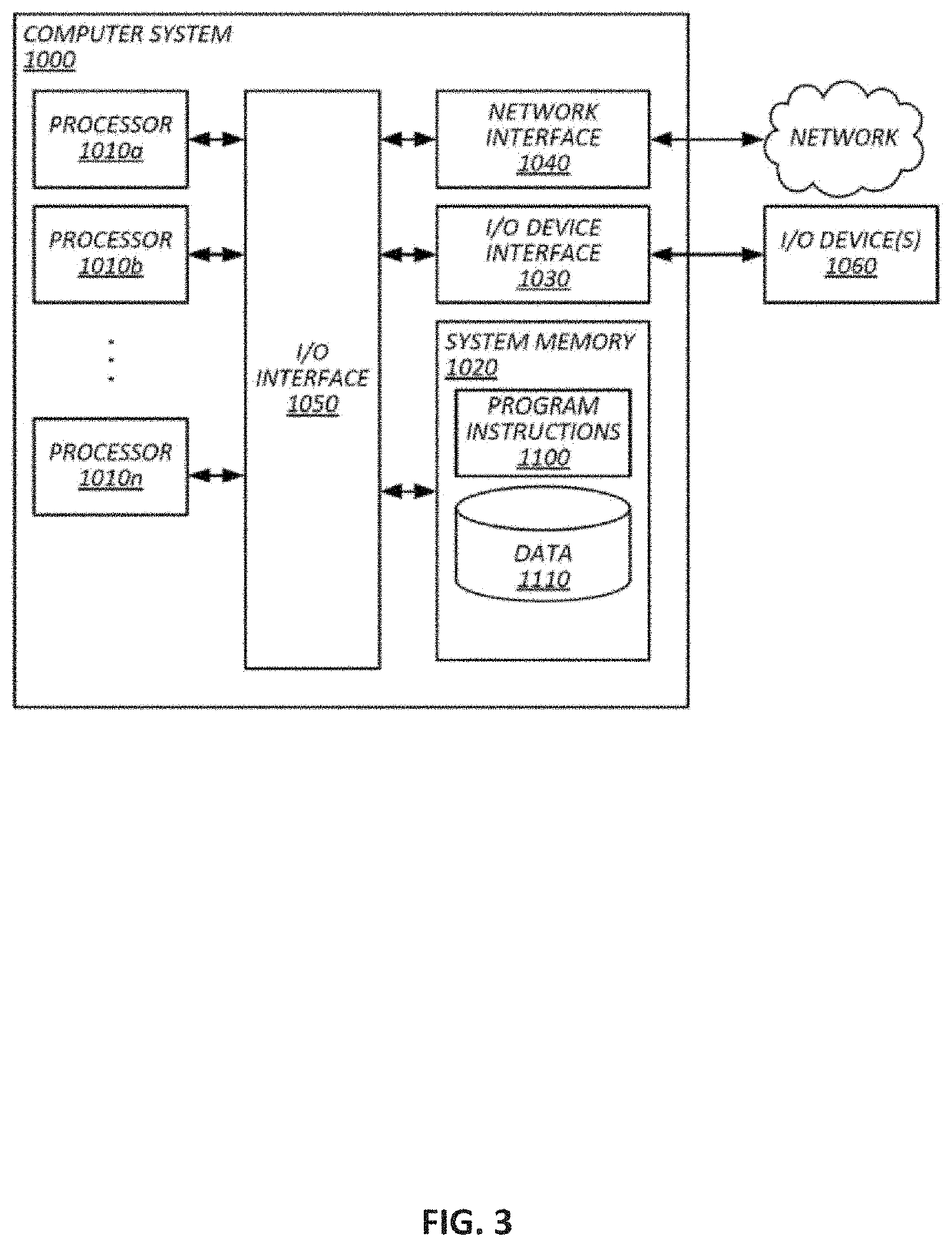

ActiveUS11068942B2Degrades knowledgeReduction in CJKDMathematical modelsEnsemble learningData setEngineering

Provided is a process, including: obtaining a first training dataset, training a first machine-learning model on the first training dataset, obtaining a set of candidate question sequences, forming virtual subject-entity records, forming a second training dataset, training a second machine-learning model, and storing the adjusted parameters of the second machine-learning model in memory.

Owner:CEREBRI AI INC

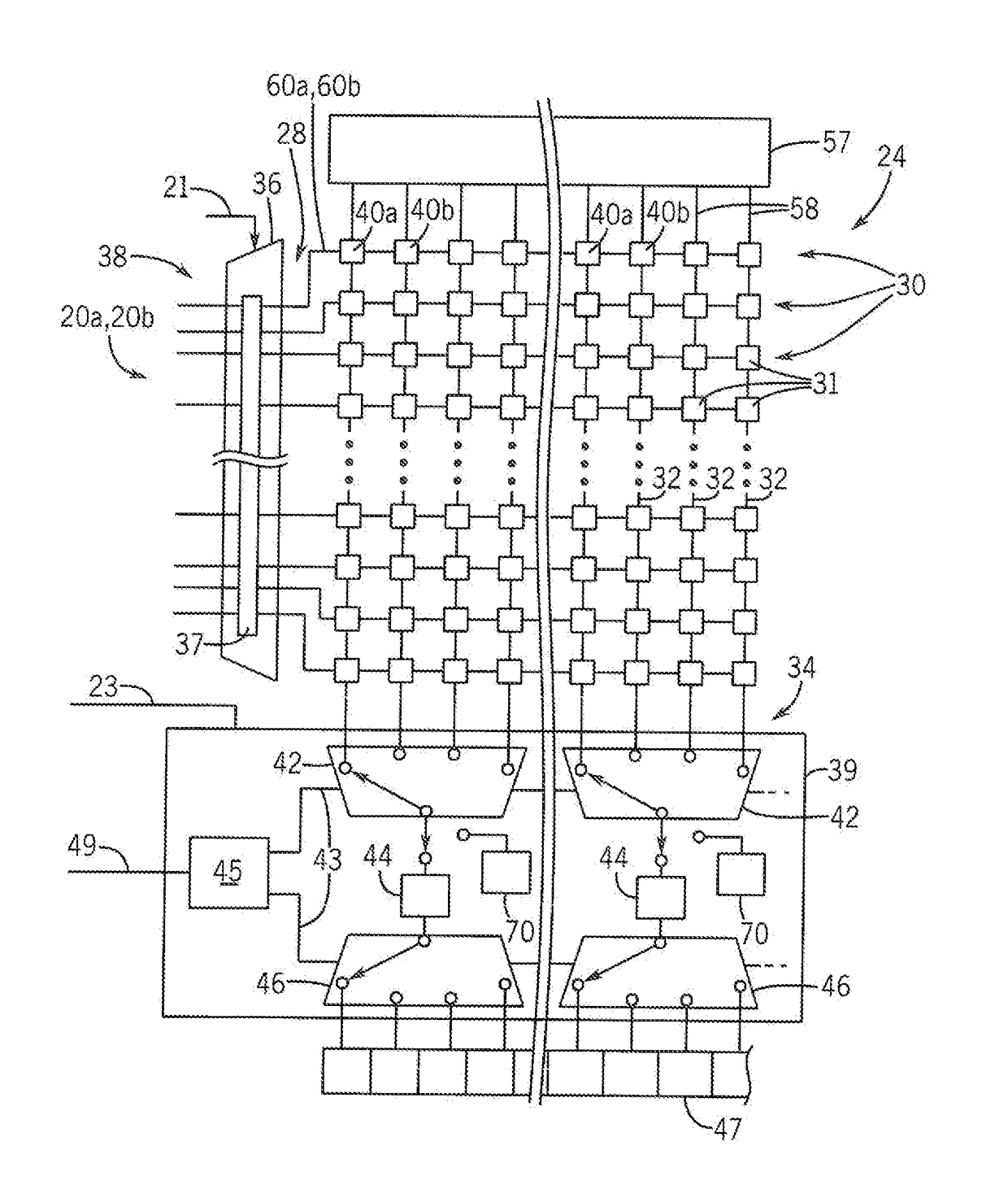

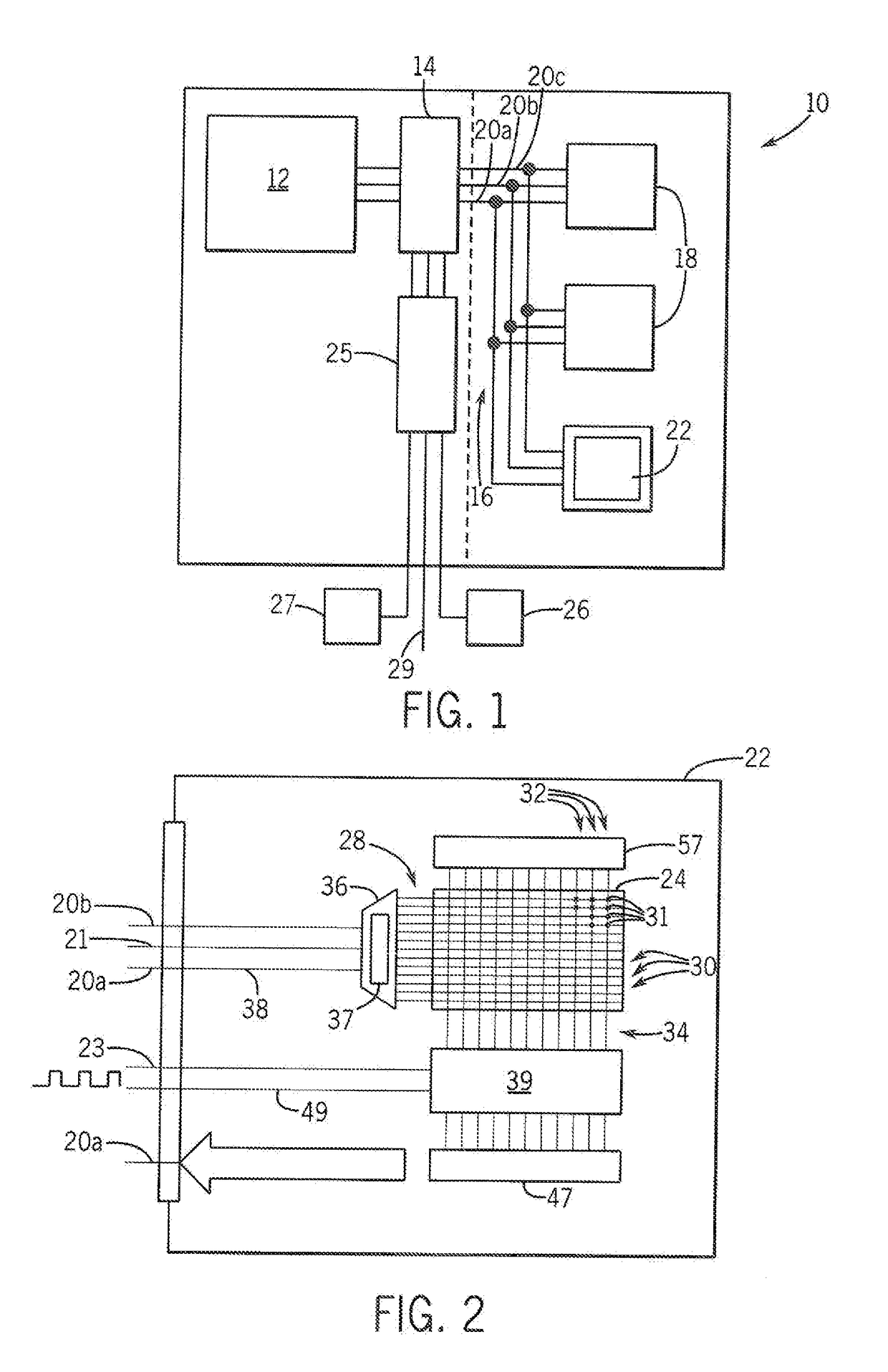

High Density Content Addressable Memory

ActiveUS20170163534A1Eliminate delaysReduce in quantityDigital storageData switching networksMultiplexingAudio power amplifier

An associative memory that can be integrated with standard computer memory flexibly reduces its parallelism to match the memory bus speed thereby providing substantial increases in memory density possible by a multiplexing of sense amplifiers that otherwise dominate the memory structure. Apparent parallel operation is provided by an accumulator that reassembles the multiplex data. Higher memory density makes dual use of the associative memory as a content addressable memory and random-access memory possible.

Owner:WISCONSIN ALUMNI RES FOUND

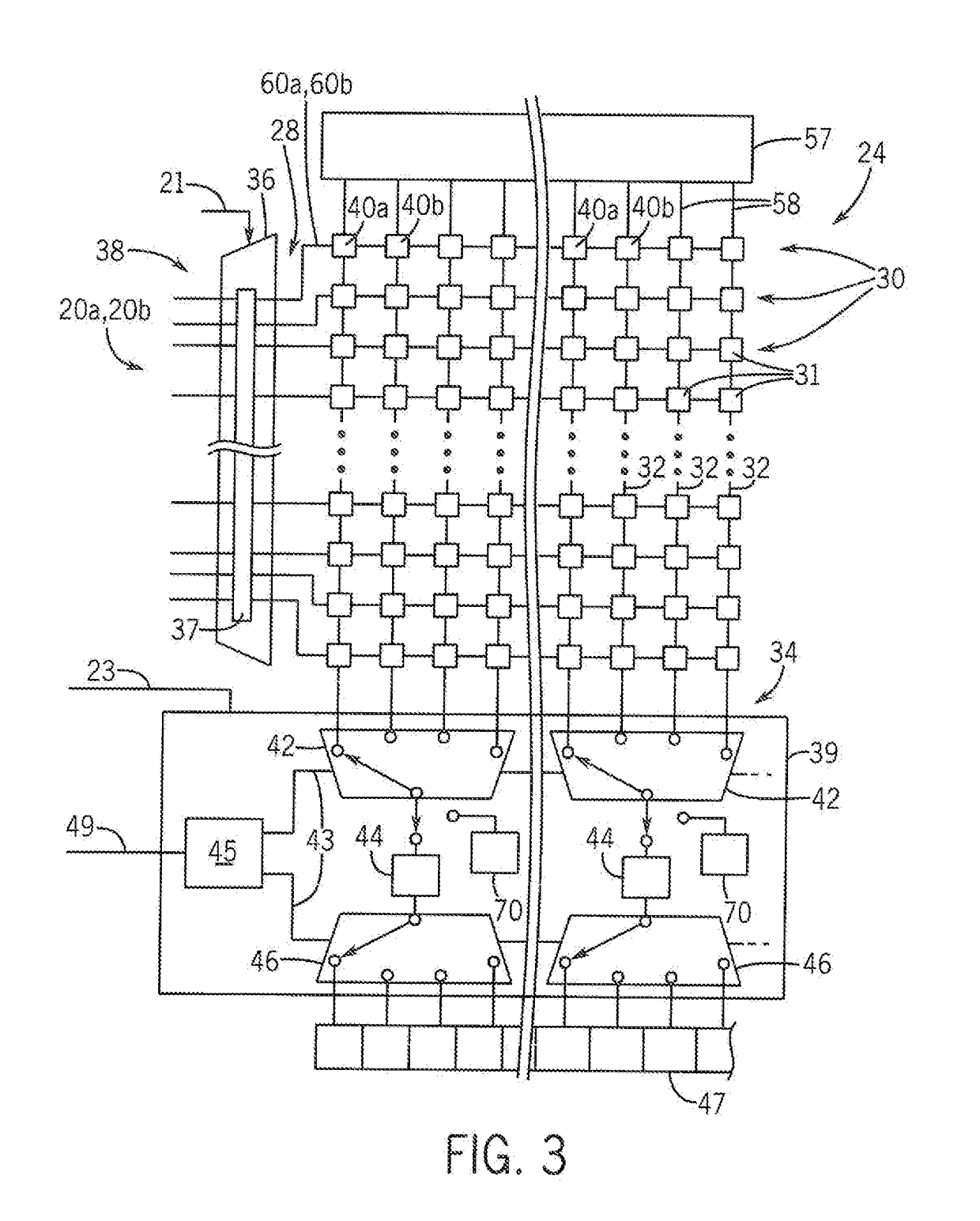

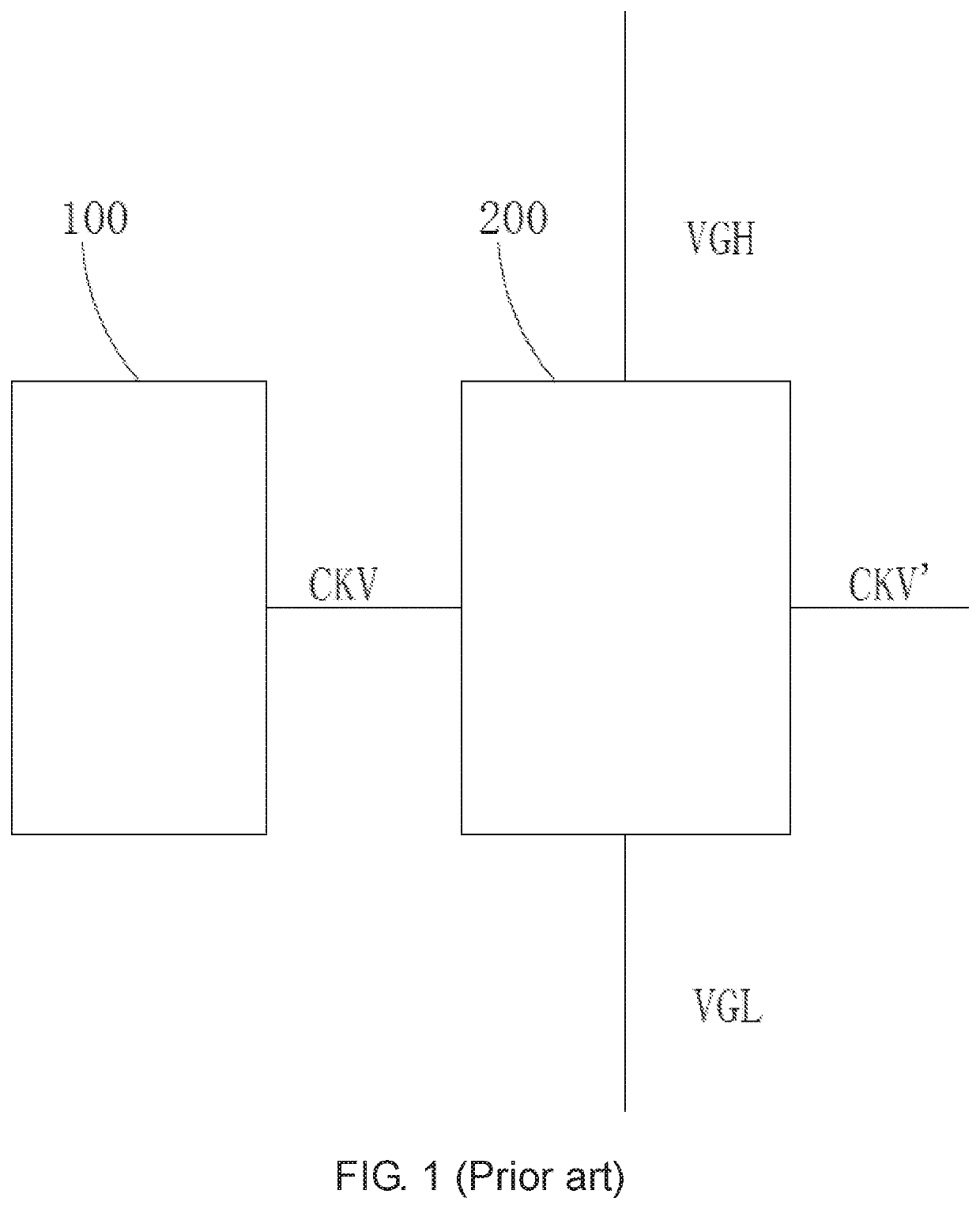

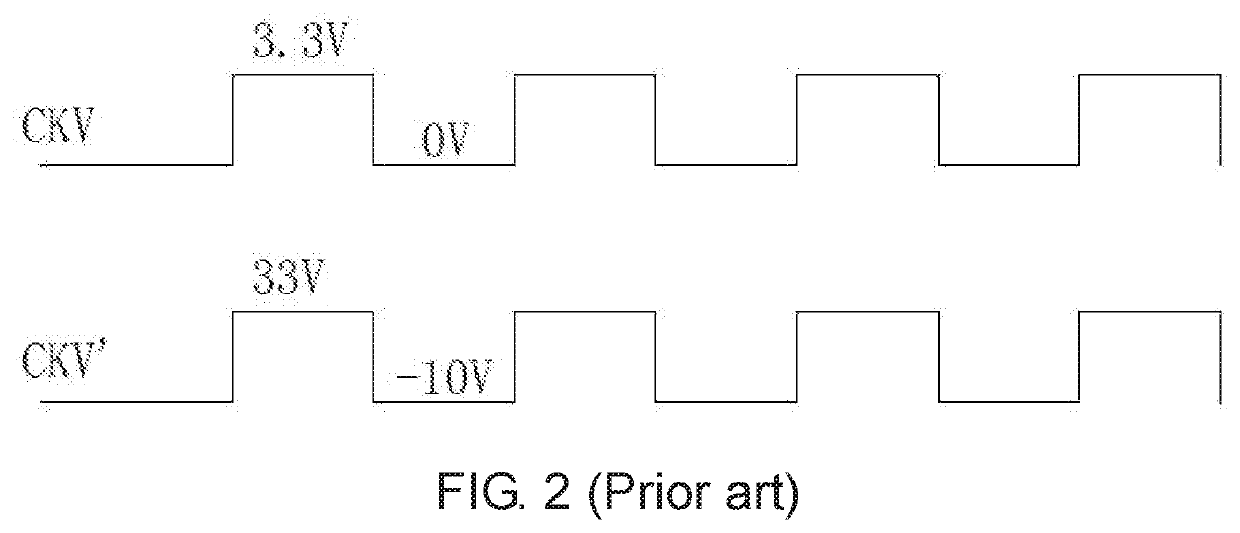

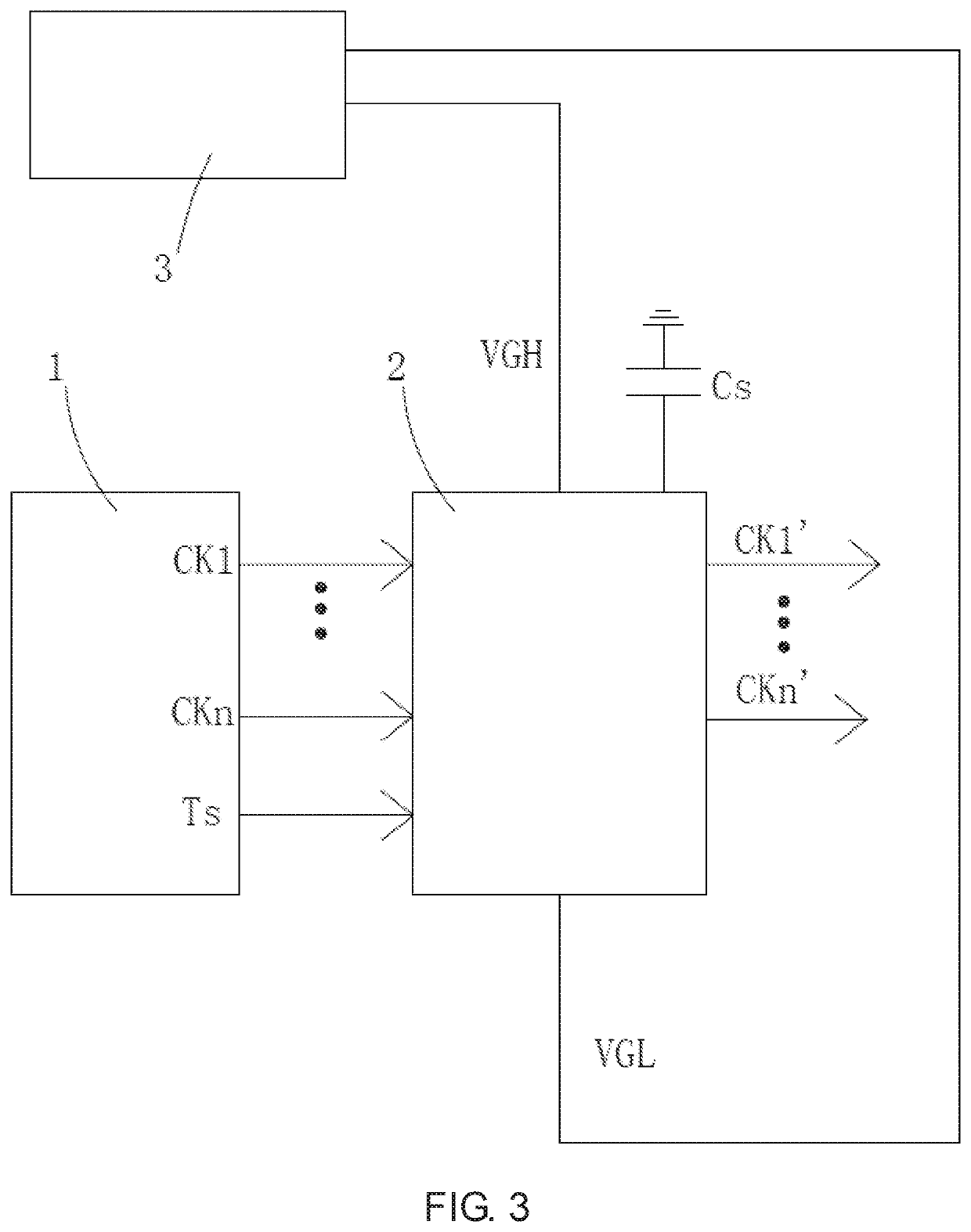

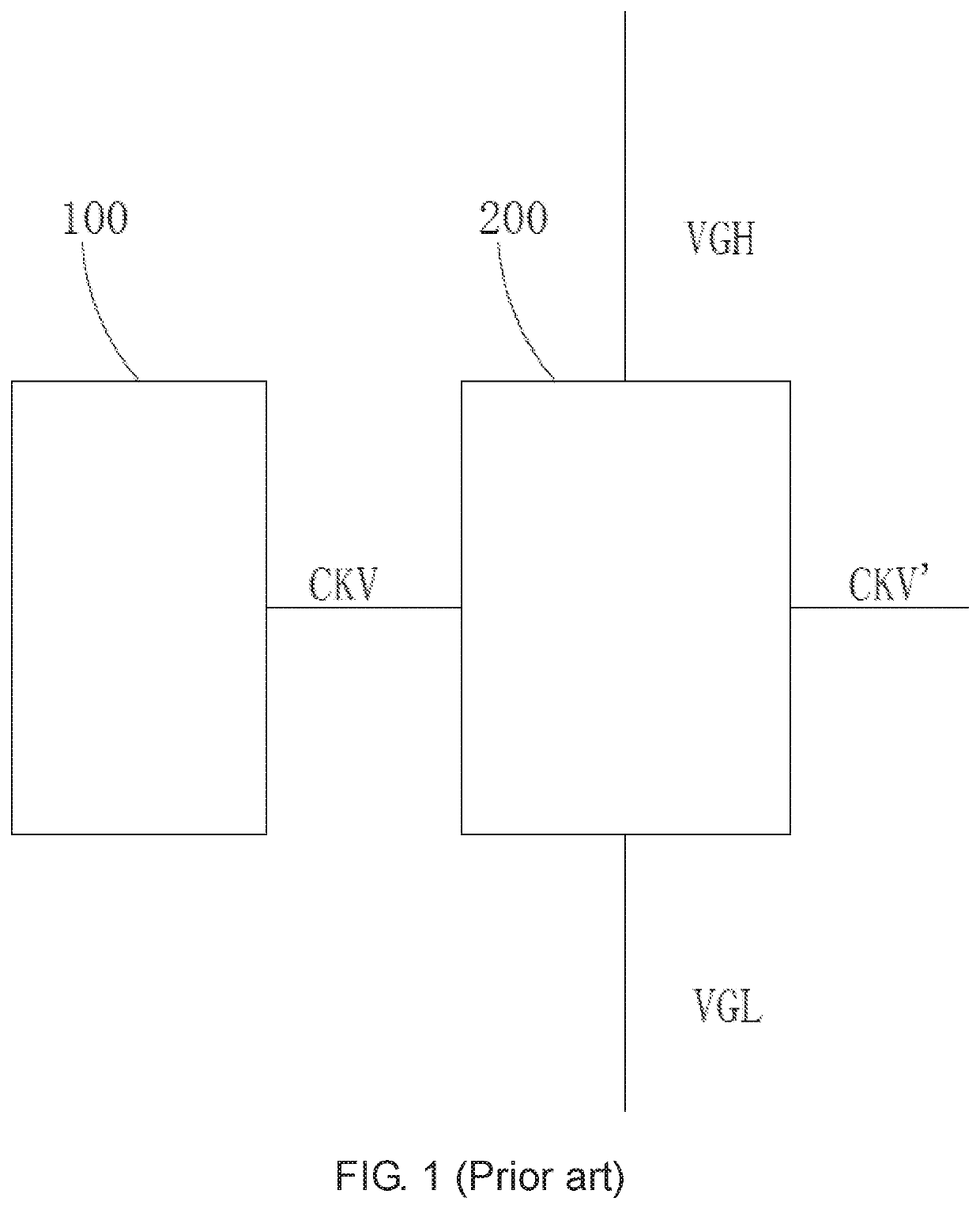

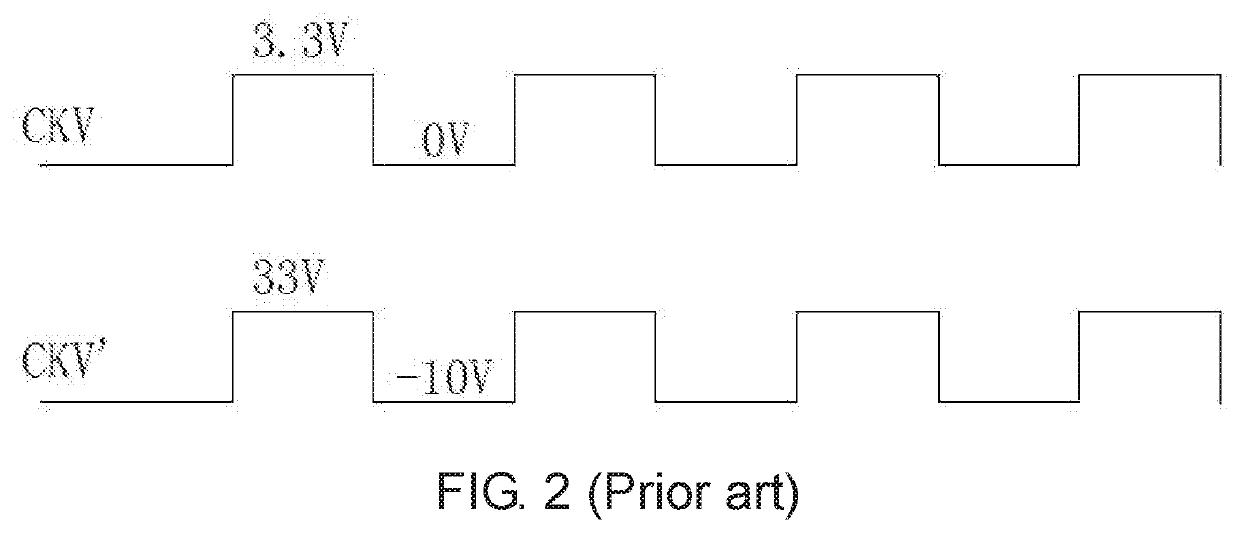

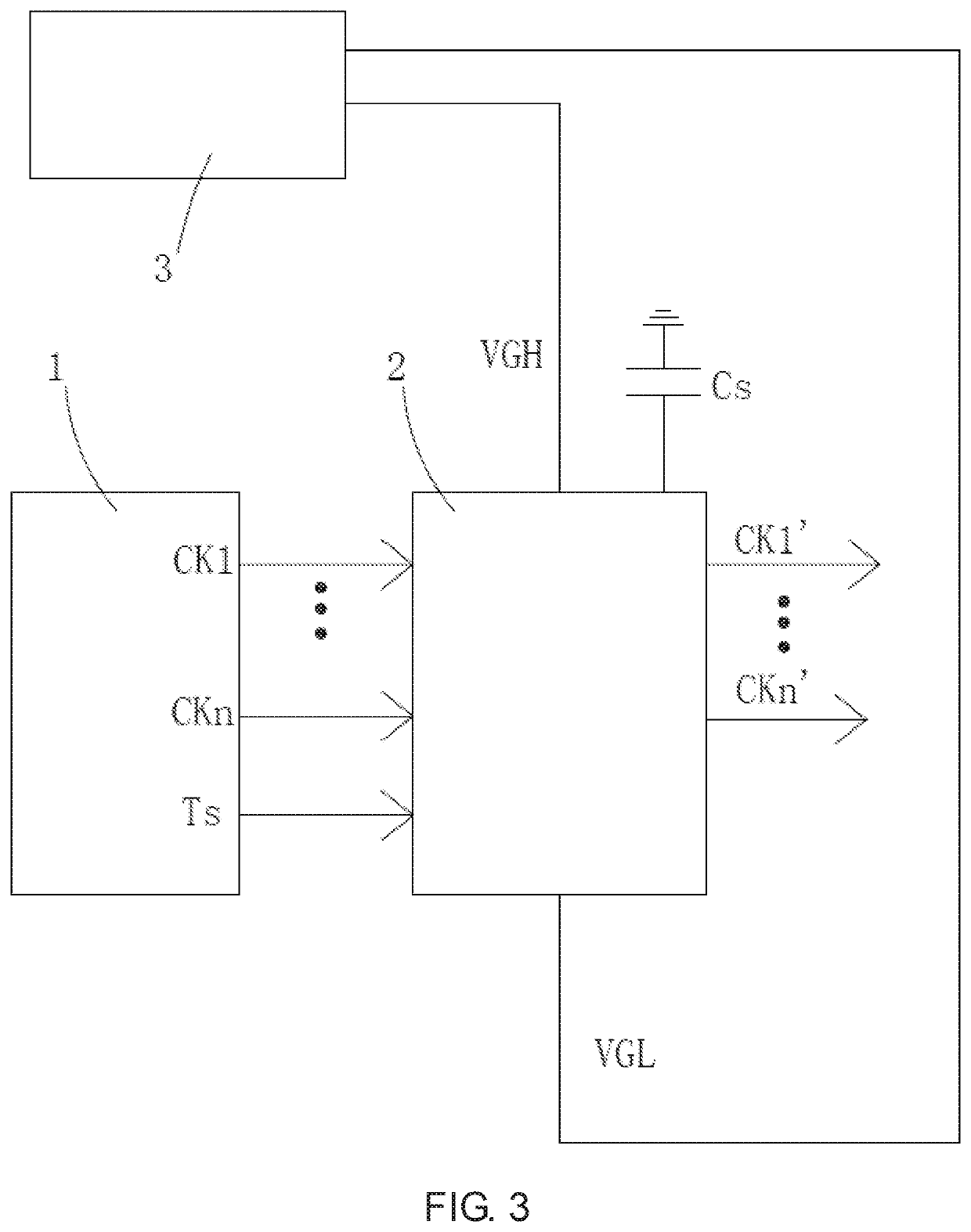

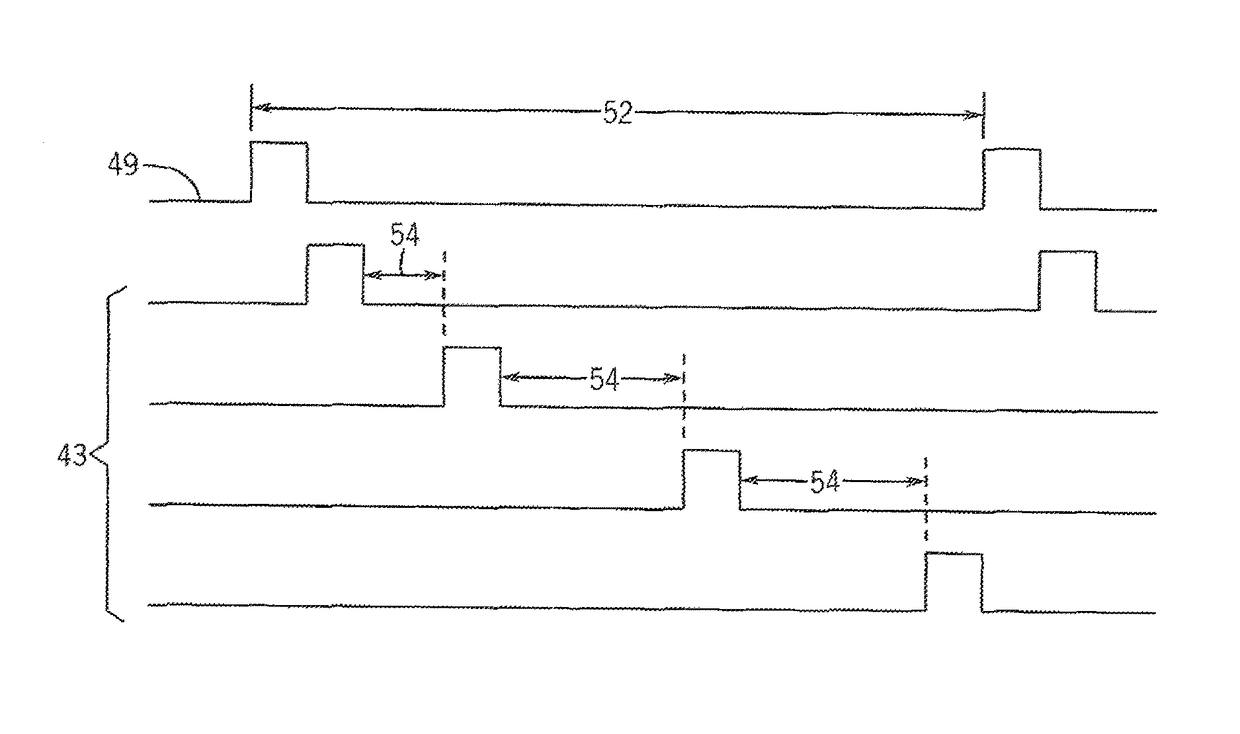

Goa circuit driving method and driving device

ActiveUS20210125574A1Maximize reductionMaximizing reduction of power consumption and feedthrough effectStatic indicating devicesCapacitanceLow voltage

The present invention teaches a GOA circuit driving method and a GOA circuit driving device. Through the configuration of a buffer capacitor electrically connected to the level shift IC, the level shift IC connects to the buffer capacitor and switches to the transition level during shifting the target clock signals from high to low level or from low to high level. Through the buffer capacitor, the present invention is able to keep the transition level always equal to one half of the sum of the low voltage and the high voltage, thereby maximizing reduction of power consumption and feedthrough effect of the GOA circuit.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

GOA circuit driving method and driving device

ActiveUS11011128B1Maximizing reduction of power consumption and feedthrough effectMaximize reductionStatic indicating devicesLevel shiftingCapacitance

The present invention teaches a GOA circuit driving method and a GOA circuit driving device. Through the configuration of a buffer capacitor electrically connected to the level shift IC, the level shift IC connects to the buffer capacitor and switches to the transition level during shifting the target clock signals from high to low level or from low to high level. Through the buffer capacitor, the present invention is able to keep the transition level always equal to one half of the sum of the low voltage and the high voltage, thereby maximizing reduction of power consumption and feedthrough effect of the GOA circuit.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Topical Pharmaceutical Composition for Treating Multiple Wounds of Skin and the Preparation Methods Thereof

ActiveUS20190125815A1Rapidly and effectively seal woundRemove wound swellingAntibacterial agentsHydroxy compound active ingredientsMedicineMoisture absorption

The invention generally relates to a liquid topical pharmaceutical composition used in treating various skin wounds. The composition is characterized by strong moisture absorption and retention capabilities and being able to quickly seal the wound. The composition can resist oxidation, effectively inhibit bacteria and sterilization, protect germinal cells from further damage, eliminate wound swelling and promote wound healing. The pharmaceutical composition can be widely used in the treatment of burn, skin abrasion, laceration, infectious skin ulcer and wound exposure, save dressing and be used in a convenient and highly effective way.

Owner:FU YUANQIAO

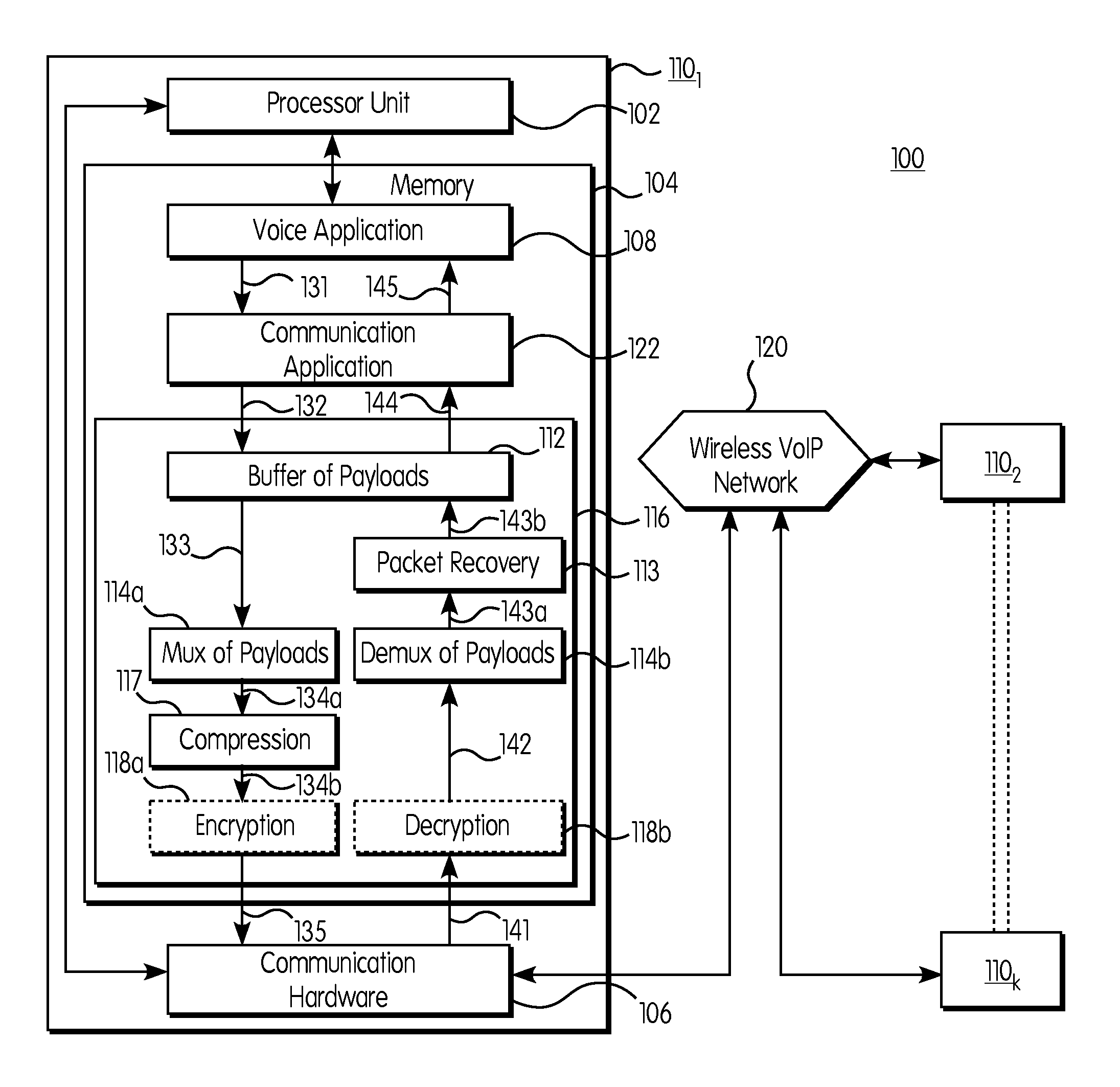

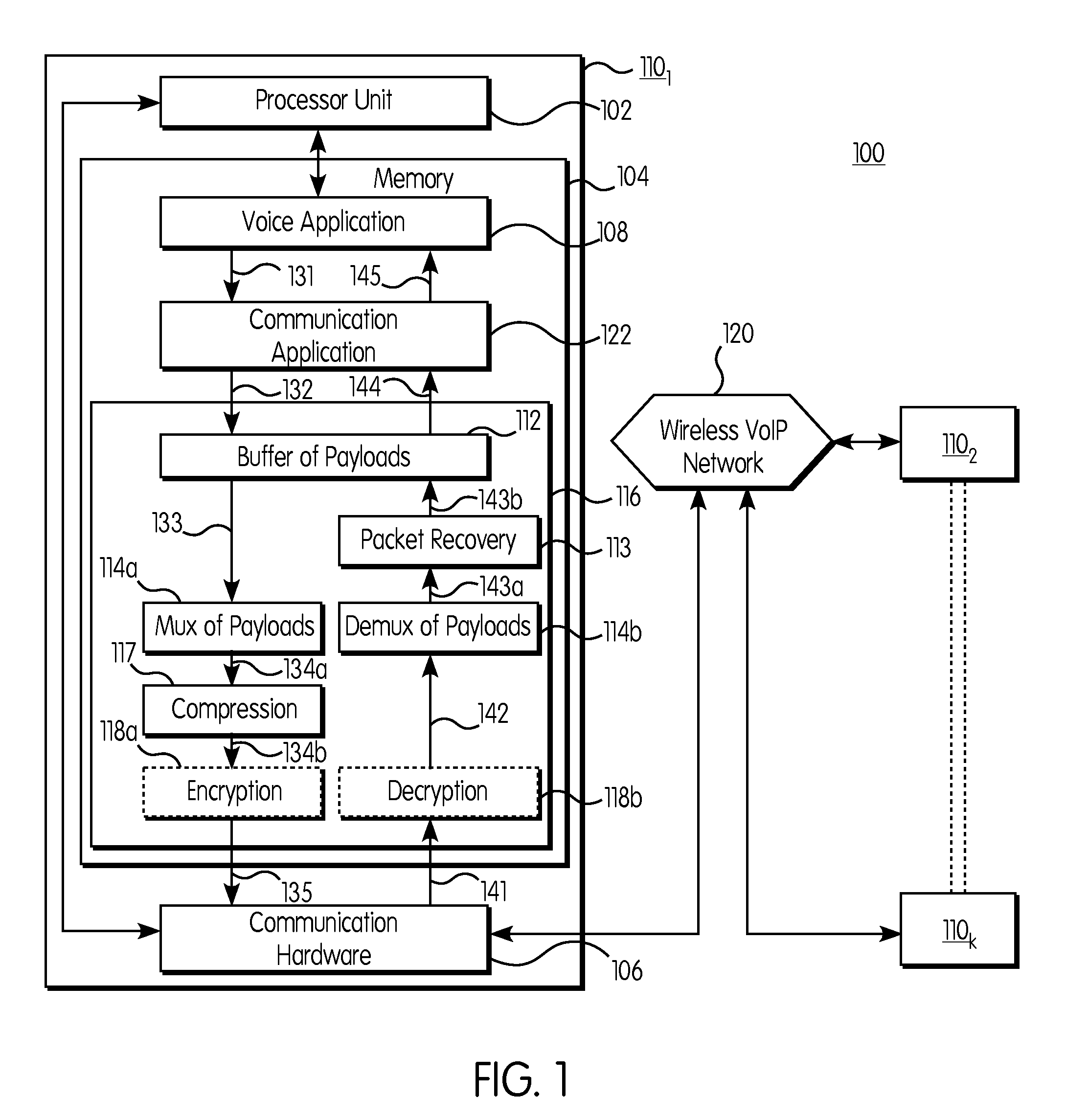

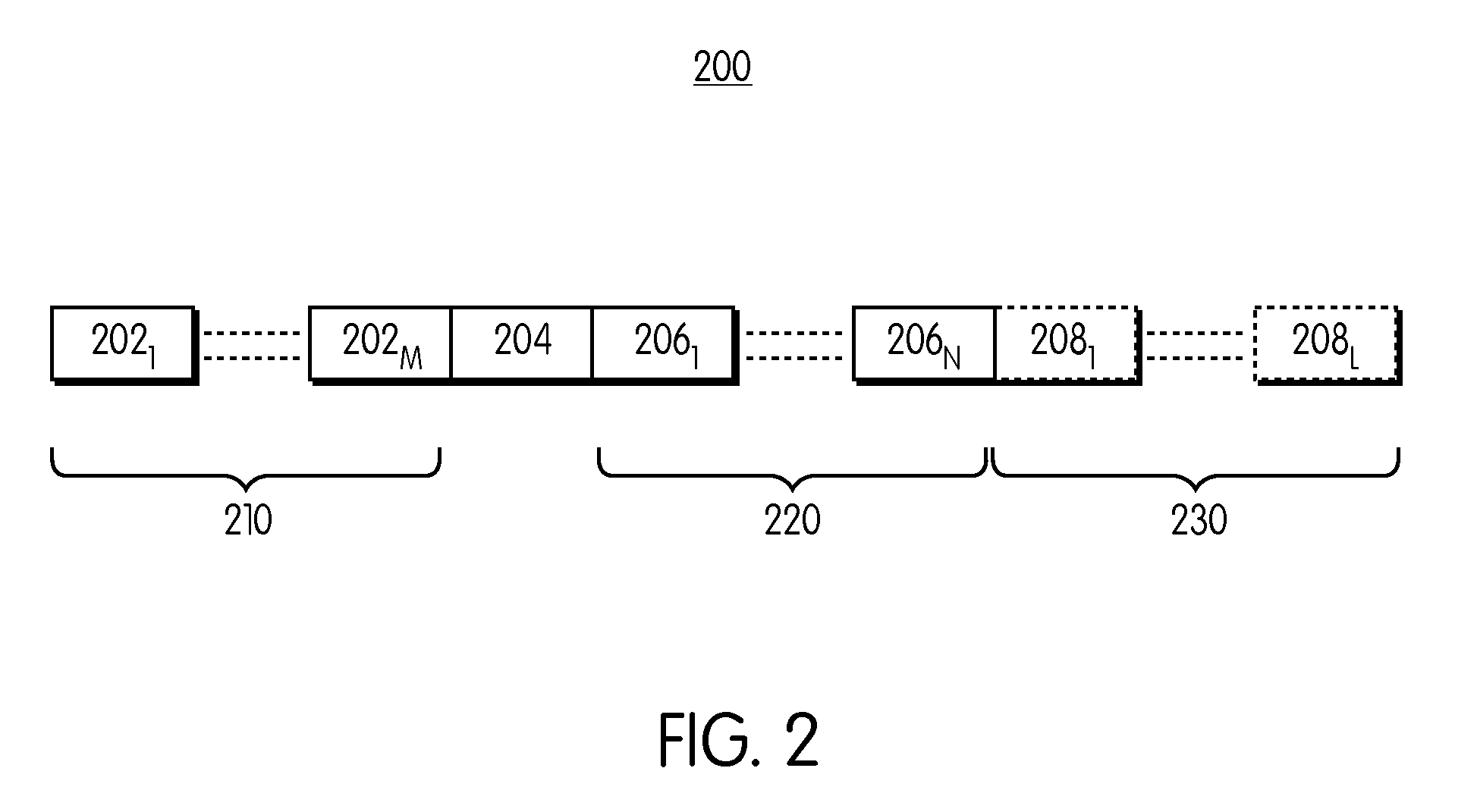

Method and system for wireless VoIP communications

InactiveUS8594075B2Reduce in quantityIncrease overheadFrequency-division multiplex detailsPicture reproducers using cathode ray tubesMultiplexingPacket loss

Methods, an apparatus, and a system for communications using multiplexed packets including payloads of the current and at least one preceding packet are disclosed. The invention is able to implement both robustness and a degree of compression while still being able to operate in environments of limited bandwidth having high rates of packet loss, such as in wireless VoIP networks.

Owner:D& S CONSULTANTS

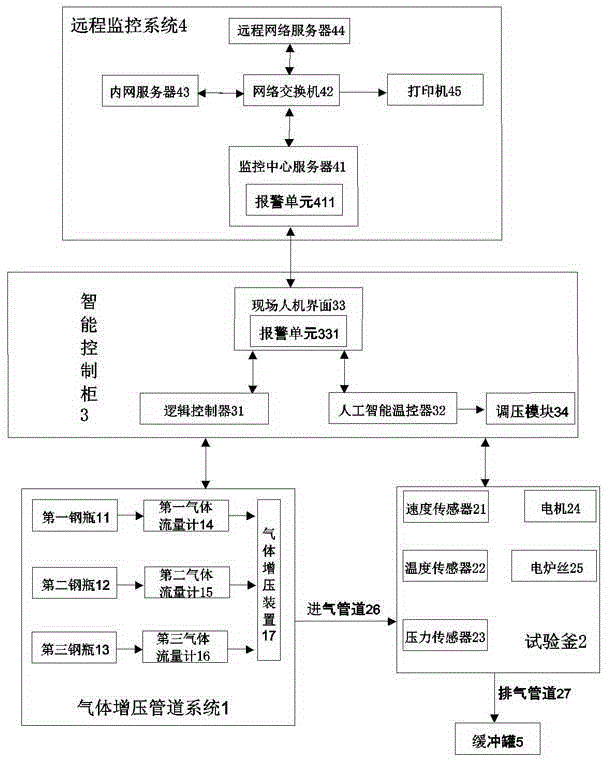

Device for hydrogen sulfide high-pressure corrosion resistance test

InactiveCN105424584AHigh degree of automationMaximize reductionWeather/light/corrosion resistanceHuman–machine interfaceHigh pressure

The invention provides a device for a hydrogen sulfide high-pressure corrosion resistance test. The device comprises a gas pressurizing pipeline system, a test kettle and an intelligent control cabinet, wherein the test kettle and the intelligent control cabinet are connected with the gas pressurizing pipeline system, and the intelligent control cabinet is further connected with the test kettle. The gas pressurizing pipeline system comprises three steel cylinders which are connected to the test kettle through a first gas flow meter, a second gas flow meter, a third gas flow meter and a gas pressurizing device. The test kettle is provided with a speed sensor, a temperature sensor, a pressure sensor, a motor, an electric furnace heating wire, a gas inlet pipeline and an exhaust pipeline, wherein the other end of the gas inlet pipeline is connected to the gas pressurizing device, and the other end of the exhaust pipeline is connected to a buffering tank. The intelligent control cabinet comprises a logic controller and an artificial intelligent temperature controller, wherein the logic controller and the artificial intelligent temperature controller are connected with an on-site man-machine interface, the artificial intelligent temperature controller is further connected with a pressure regulating module, and the on-site man-machine interface comprises an alarming unit. The device is high in automation degree and capable of displaying various parameter values in the test kettle and regulating the parameter values as needed.

Owner:WEIHAI XINLONGDE ELECTRICAL CO LTD

Medical skin wrinkle reduction device using rrss laser irradiation method and wrinkle reduction method of using same

ActiveUS20210060352A1Avoid confusionMaximization of the efficiency of skin shrinkageMechanical/radiation/invasive therapiesInstrument handpiecesEngineeringTouchscreen

A medical skin wrinkle reduction device using an RRSS laser irradiation method is proposed to reduce skin wrinkles and minimize tissue damage. The device includes: a main body having a mounting groove provided in an upper portion thereof, a tablet computer being attached to and detached from the mounting groove, and comprising signal transmission and reception parts exchanging signals with the tablet computer, and a microcomputer controlling an output of a laser beam; a handpiece comprising: a laser oscillation part generating the laser beam; an optical part emitting the laser beam as parallel light; a laser scanner controlling an irradiation position of the laser beam transmitted from the optical part; a laser pattern part having movement coordinate values set therein such that moving direction of the laser beam has a regular pattern; a tablet computer having functions of inputting data in a touch screen method and displaying a screen.

Owner:KIM YOUIN

Water separator having a gutter

ActiveUS8945285B2Reduce air contentReduce moistureCombination devicesAuxillary pretreatmentWater contentWaste management

A water separator reduces a water content of an air stream, which is used in an HVAC unit for a vehicle. The water separator includes a diverter wall and an adjacent wall spaced from the diverter wall to define an air passage. The diverter wall has a terminal end extending into the air passage for changing a direction of the air stream flowing through the air passage to separate water droplets from the air stream to reduce the water content of the air stream. A gutter is coupled to the terminal end of the diverter wall and extends into the air passage. The gutter defines a drainage channel configured to receive the water droplets that form on the diverter wall for preventing the water droplets from reentering the air stream flowing through the air stream passage.

Owner:VALEO CLIMATE CONTROL

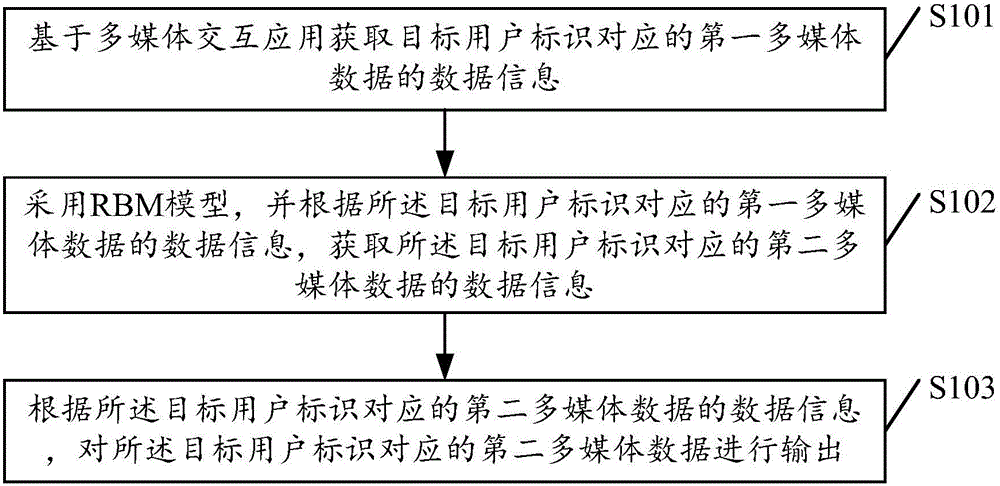

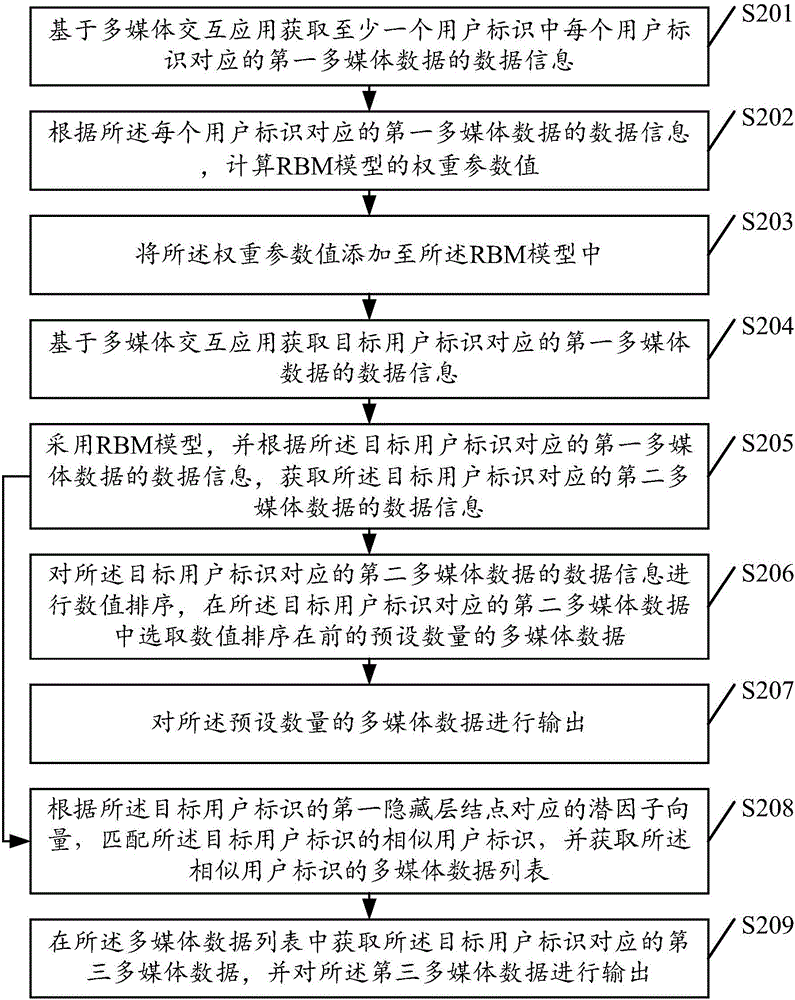

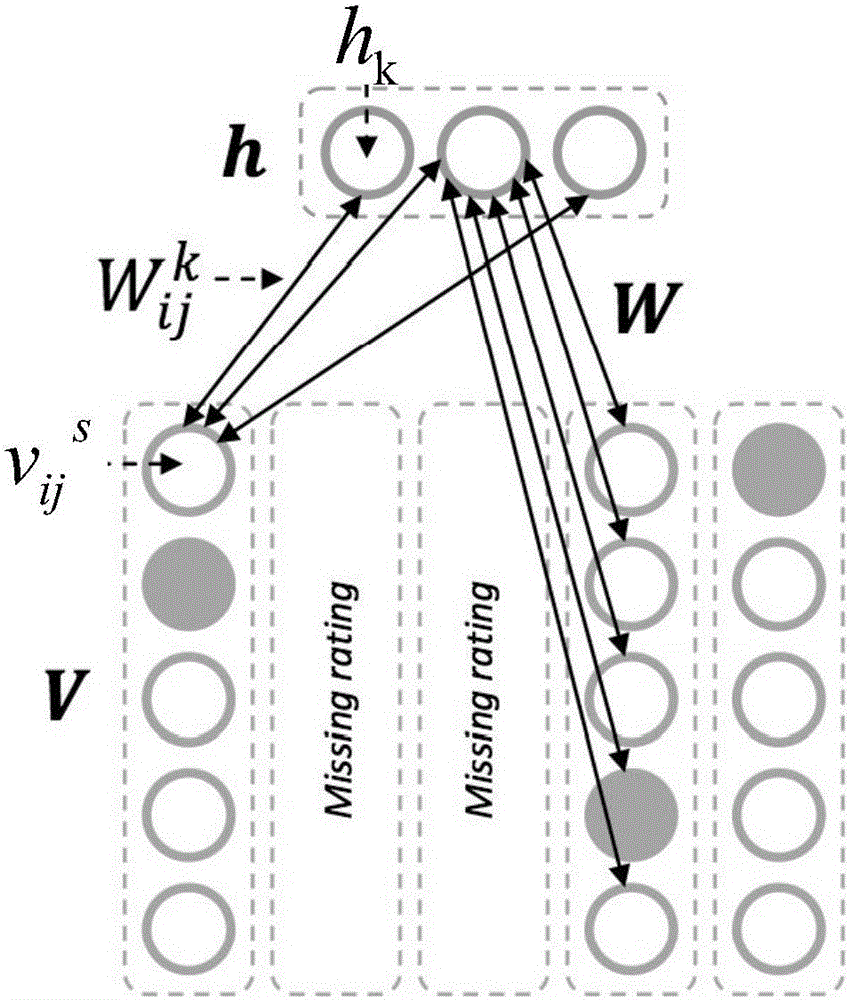

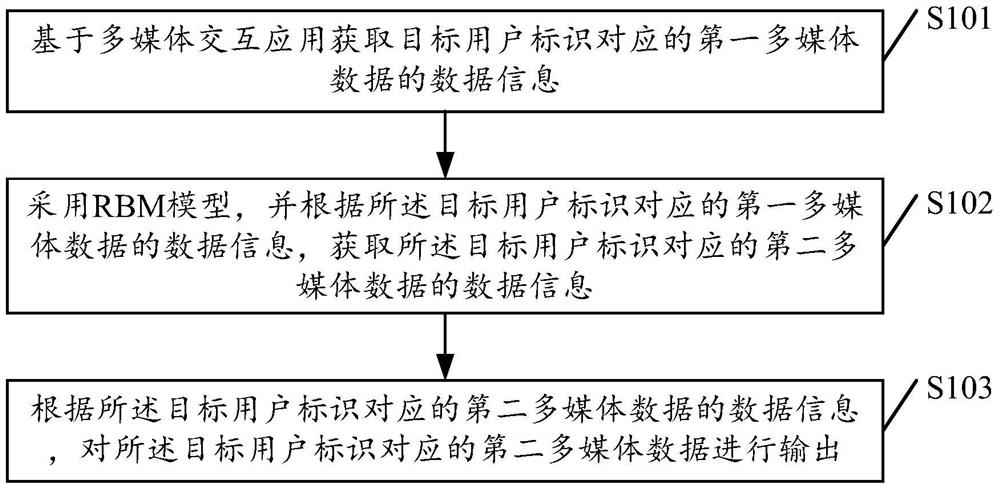

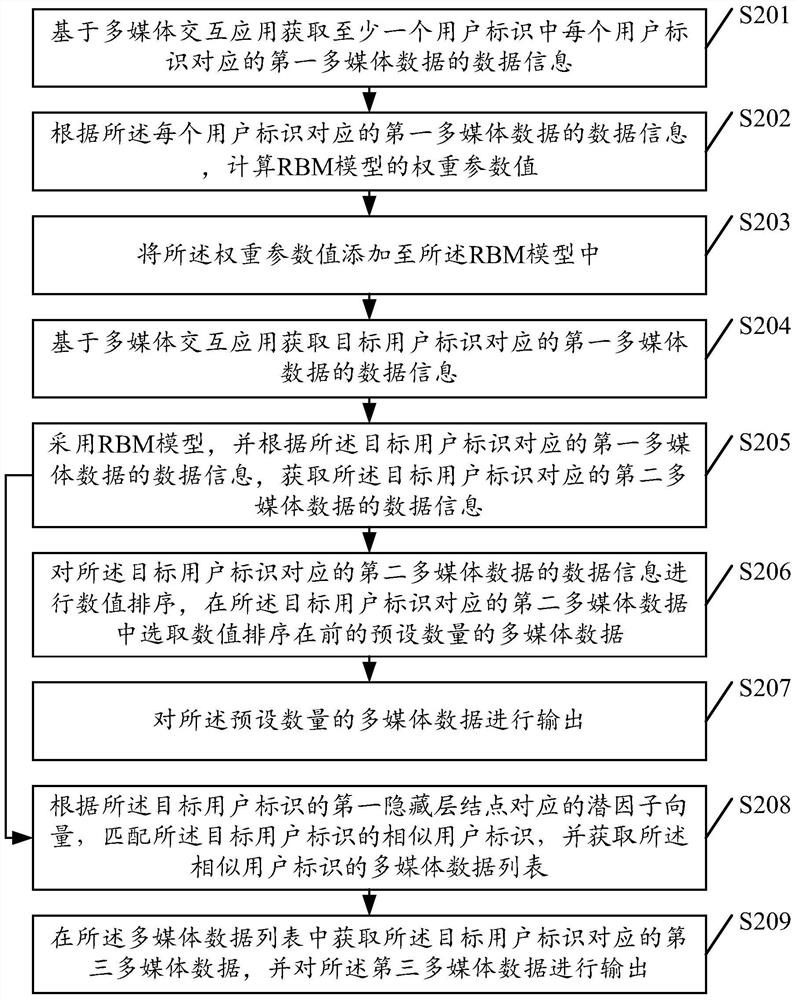

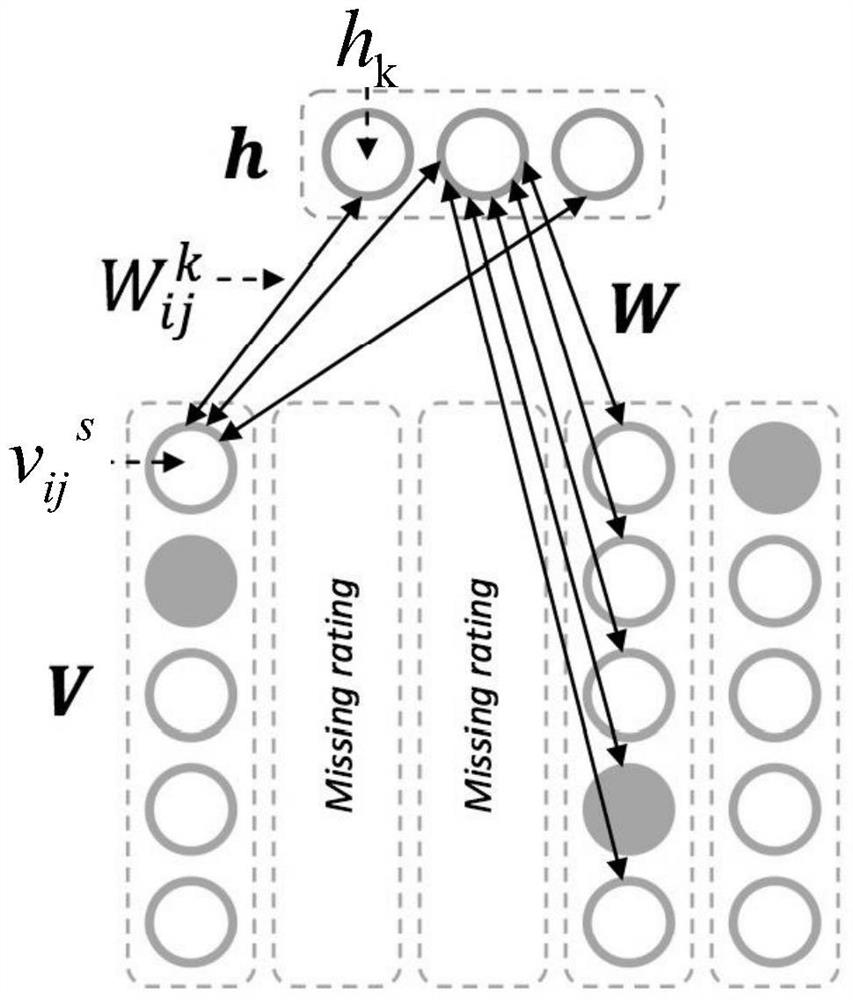

Multimedia data processing method and device

ActiveCN106021314AMaximize reductionAvoid local optimaBiological neural network modelsSpecial data processing applicationsComputer networkData information

The embodiment of the invention discloses a multimedia data processing method and device. The multimedia data processing method includes the following steps: acquiring data information of first multimedia data corresponding to a target use identification based on a multimedia interaction application; adopting an RBM model, and acquiring data information of second multimedia data corresponding to the target user identification according to the data information of the first multimedia data corresponding to the target user identification; and outputting the second multimedia data corresponding to the target user identification according to the data information of the second multimedia data corresponding to the target user identification, wherein the first multimedia data is operated multimedia data, and the second multimedia data is not operated. The multimedia data processing method and device can restore original input data to the greatest extent, and can improve the stability of a solution result.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Pharmaceutical composition for treating skin wounds and a method of treating skin wounds using thereof

ActiveUS10864240B2Maximize reductionWound quicklyAntibacterial agentsPowder deliverySkin abrasionsPharmaceutical drug

The invention generally relates to a liquid topical pharmaceutical composition used in treating various skin wounds. The composition is characterized by strong moisture absorption and retention capabilities and being able to quickly seal the wound. The composition can resist oxidation, effectively inhibit bacteria and sterilization, protect germinal cells from further damage, eliminate wound swelling and promote wound healing. The pharmaceutical composition can be widely used in the treatment of burn, skin abrasion, laceration, infectious skin ulcer and wound exposure, save dressing and be used in a convenient and highly effective way.

Owner:FU YUANQIAO

Golf putter

InactiveUS20090069110A1Encourage rollingMinimizing rotational forceGolf clubsRacket sportsMoment of inertiaEngineering

A golf putter providing a center mount of the hosel to the club head and a shaft engagement to the hosel at the heel end of the club head. The center mount provides the sole engagement of the hosel to the head as a gap is formed by a pathway formed through the body of the head which is larger than the circumference of the hosel in its communication therethrough. The centered engagement provides better touch to the user and feedback on striking a ball while concurrently removing the shaft from the user's line of sight to the ball and club face and reduces the twist or torque at impact with a golf ball, thereby increasing the moment of inertia.

Owner:SCHMIDT JACOB H

High density content addressable memory

ActiveUS9979649B2Eliminate delaysReduce in quantityDigital storageData switching networksMultiplexingHigh density

Owner:WISCONSIN ALUMNI RES FOUND

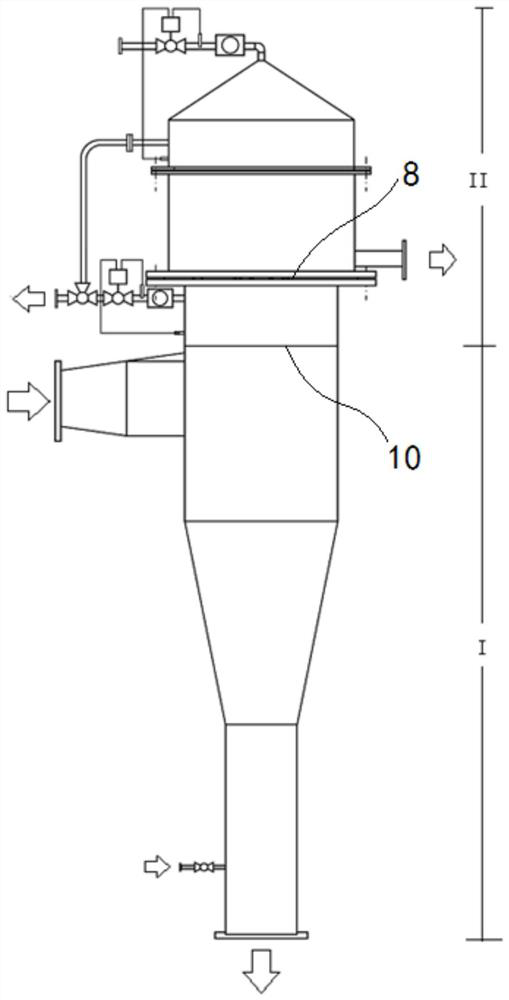

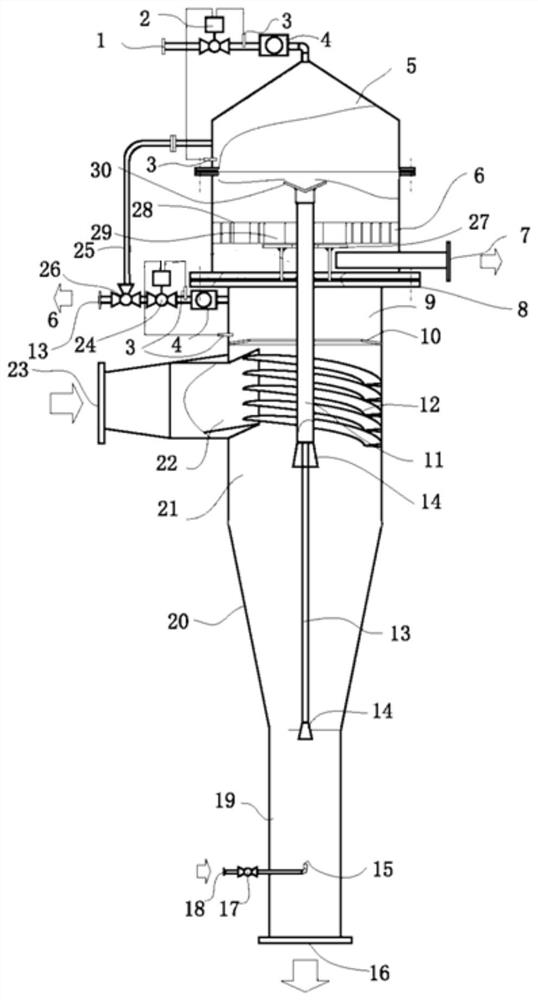

An industrial circulating water online oil monitoring and degreasing device

ActiveCN106006840BMaximize reductionGuaranteed functionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSewageBottle

Owner:SHANGHAI SOARUP ENERGY TECH

A kind of multimedia data processing method and its equipment

ActiveCN106021314BMaximize reductionAvoid local optimaDigital data information retrievalBiological neural network modelsData scienceMultimedia

The embodiment of the present invention discloses a multimedia data processing method and a device thereof, wherein the method includes the following steps: obtaining data information of first multimedia data corresponding to a target user identifier based on a multimedia interactive application; The data information of the first multimedia data corresponding to the user identifier is obtained, and the data information of the second multimedia data corresponding to the target user identifier is obtained; according to the data information of the second multimedia data corresponding to the target user identifier, Outputting second multimedia data corresponding to the target user identifier; wherein, the first multimedia data is operated multimedia data, and the second multimedia data is unoperated multimedia data. By adopting the invention, the original input data can be restored to the maximum extent, and the stability of the solution result can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

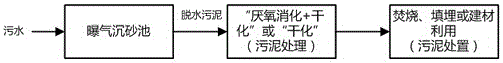

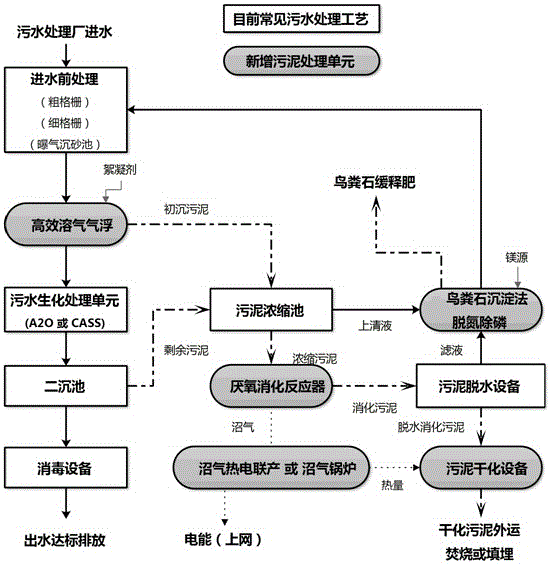

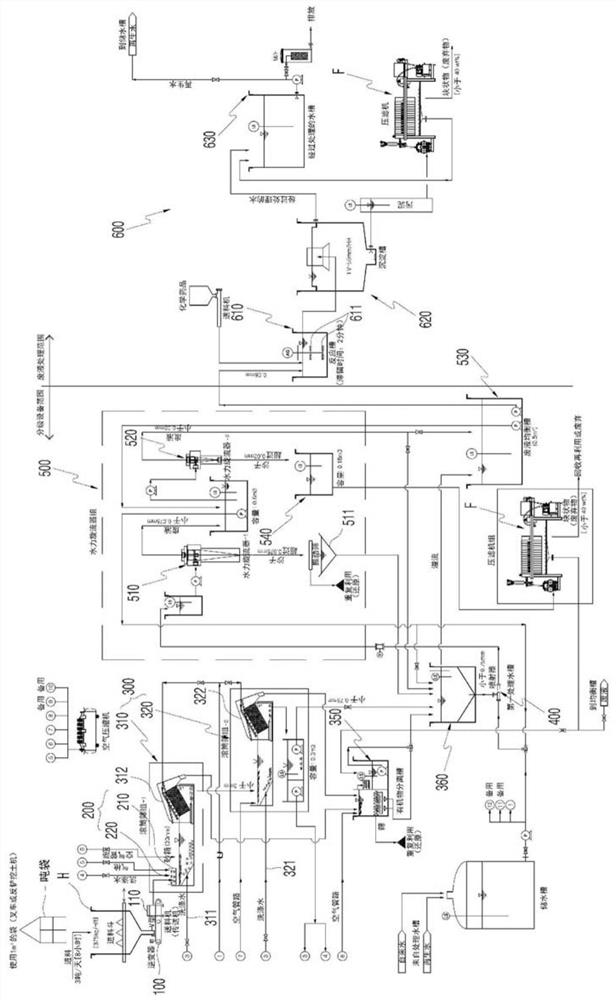

A sewage treatment plant sludge reduction and recycling process

ActiveCN104803546BEfficient removalIncrease productionSludge treatmentMultistage water/sewage treatmentInduced gas flotationNitrogen

A technology for reducing and recycling treatment of sludge of a sewage treatment plant comprises steps as follows: sewage is treated with an air-floatation method, pretreated sewage and primary sludge are produced, the pretreated sewage is drained after biochemical treatment, treatment by a secondary sedimentation tank and disinfection treatment, excess sludge is separated in the secondary sedimentation tank, the primary sludge and the excess sludge are concentrated, and concentrated sludge and a supernate are separated out; the concentrated sludge has an anaerobic digestion reaction, digested sludge is subjected to incineration or landfill treatment after dehydration and drying treatment, a filtrate is produced during dehydration of the digested sludge, and biogas is subjected to power generation and / or heat recovery treatment after dehydration and desulfurization treatment; the supernate and the filtrate are mixed for nitrogen and phosphorus removal. With the adoption of the technology, the primary sedimentation effect of the sewage is improved, the yield of the primary sludge is increased, the primary sludge is removed before biochemical treatment, the yield of the excess sludge is decreased from the source, the primary sludge and the excess sludge are subjected to anaerobic digestion treatment, the higher organic matter transformation rate and the higher biogas yield can be obtained, and the sludge can be reduced and recycled.

Owner:CHINA NAT ELECTRIC APP RES INST

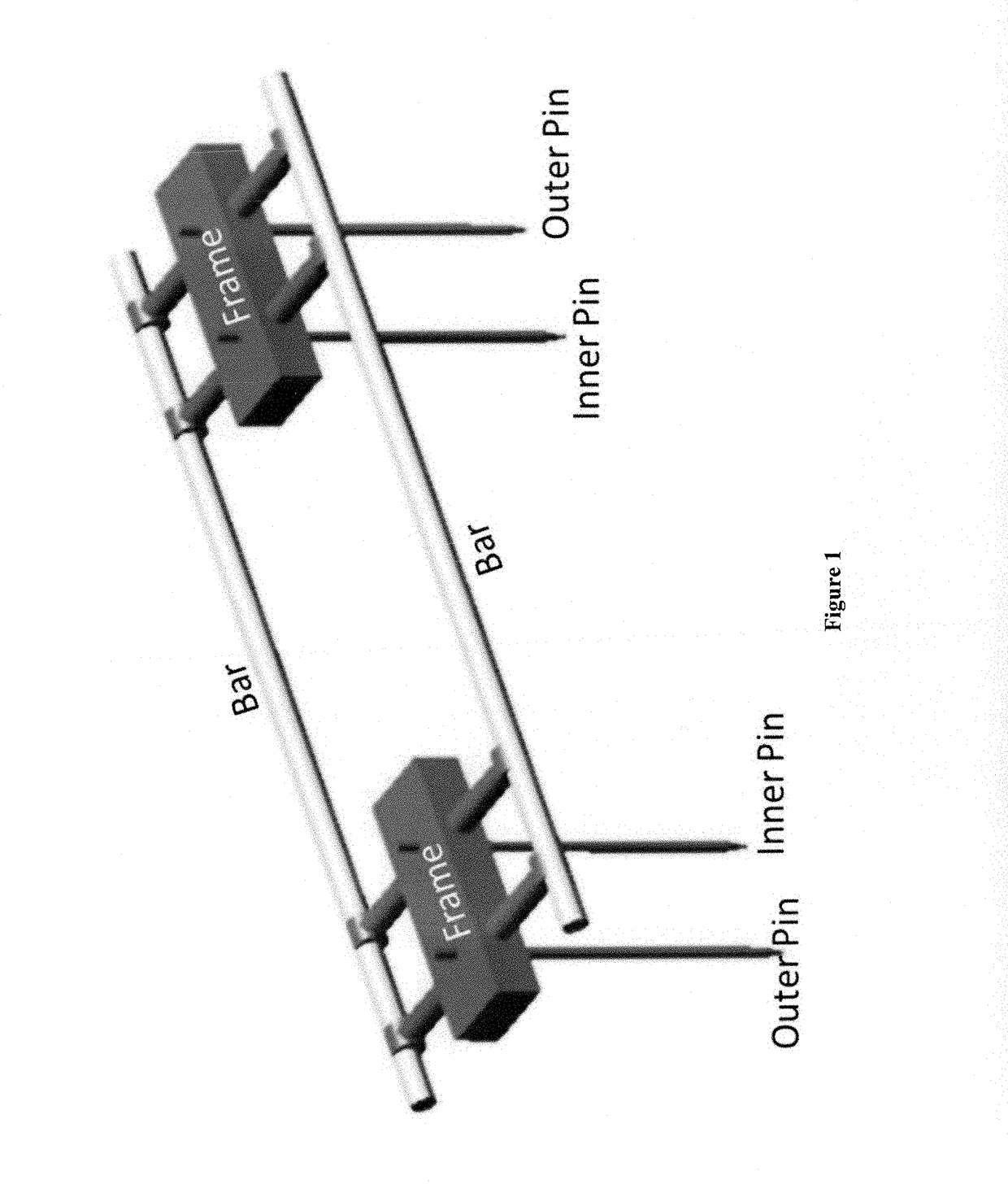

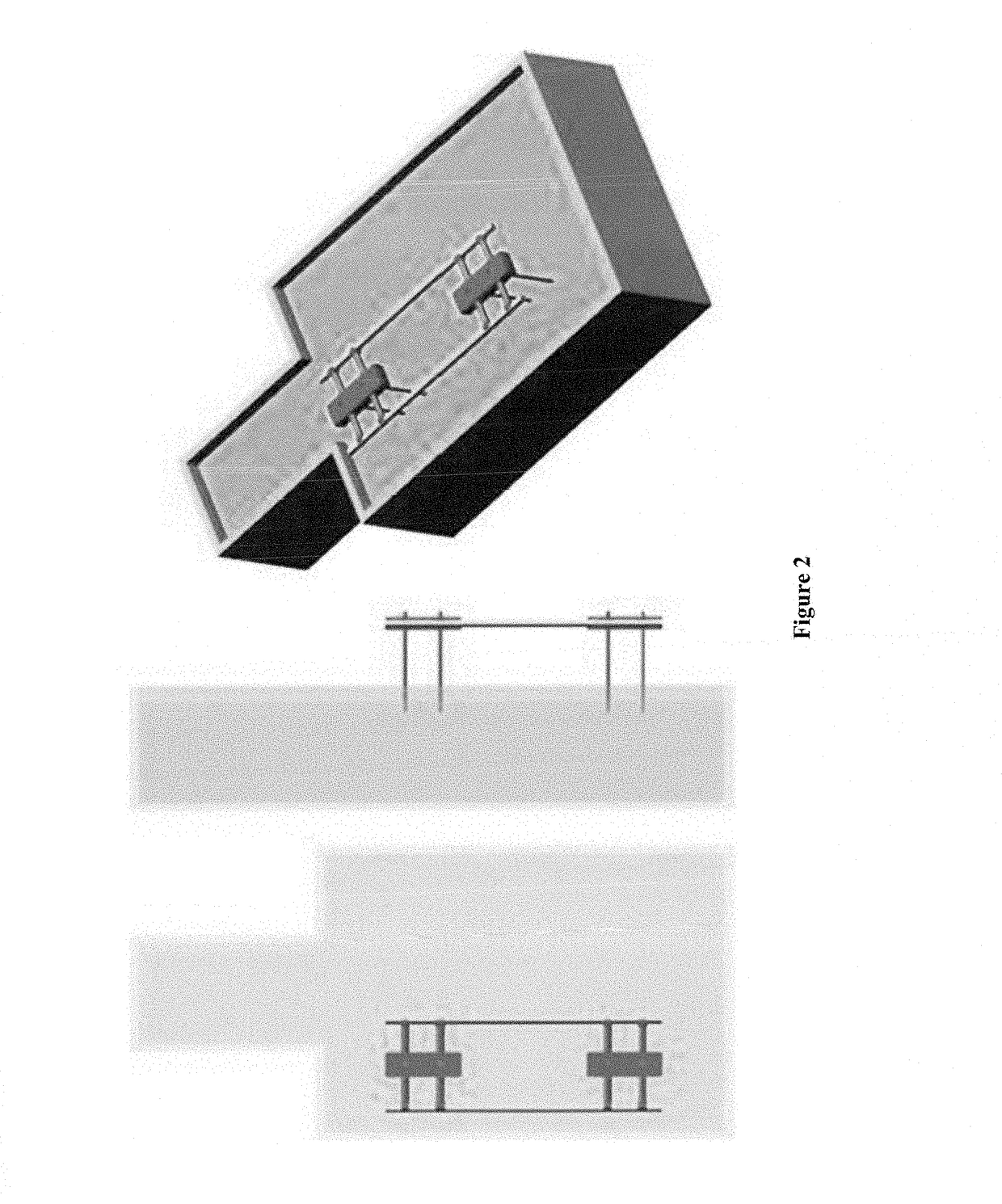

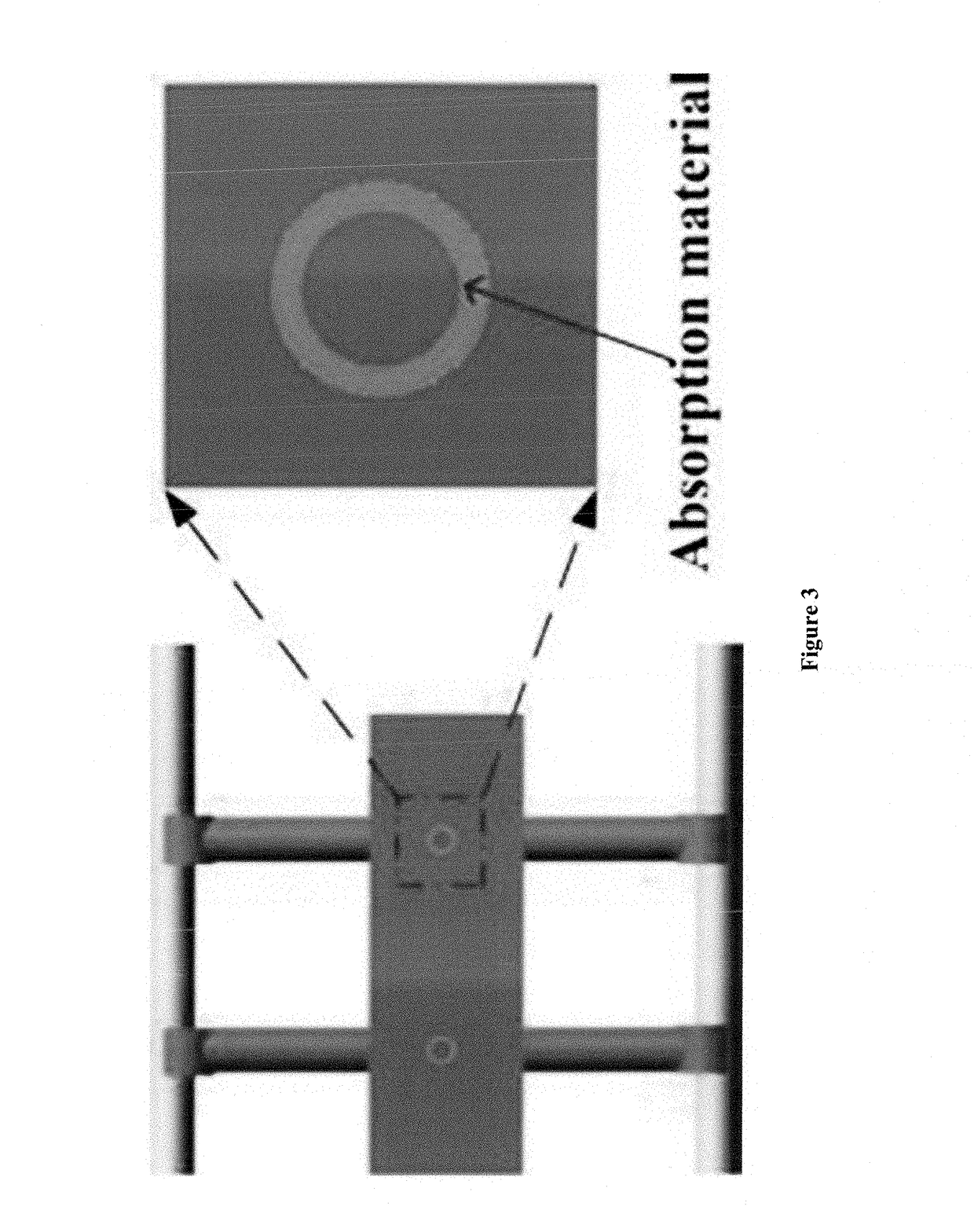

Use of absorption material to reduce radio frequency-induced heating in external fixation devices

ActiveUS10219834B2Reduce heatMaximize reductionDiagnostic recording/measuringSensorsRadio frequencyBiomedical engineering

The present invention in general provides methods for reducing RF-induced heating in an external fixation device including at least two bars, at least two clamps and at least two pins; and external fixation devices with significantly lower RF heating at the pins' tips when compared to other external fixation devices.

Owner:UNIV HOUSTON SYST

Radioactive Contaminated Soil Purification System

ActiveCN107262519BImprove the efficiency of purification operationsLow operating efficiencySievingScreeningPollution soilRadioactive contamination

The present invention relates to a radioactive contaminated soil purification system, which provides a system including a pre-treatment filter unit, a drum screen group, an ejector, a hydrocyclone group and a waste liquid treatment unit The radioactive contaminated soil purification system, in more detail, relates to a radioactive contamination that separates gravel and organic matter through a screen and a blower, and only separates fine soil with a high degree of radioactive contamination to improve the purification efficiency and the reduction rate of reusable soil Soil purification system.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com