Device for hydrogen sulfide high-pressure corrosion resistance test

A hydrogen sulfide and corrosion-resistant technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of high labor intensity, hidden safety hazards, stress corrosion cracking, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

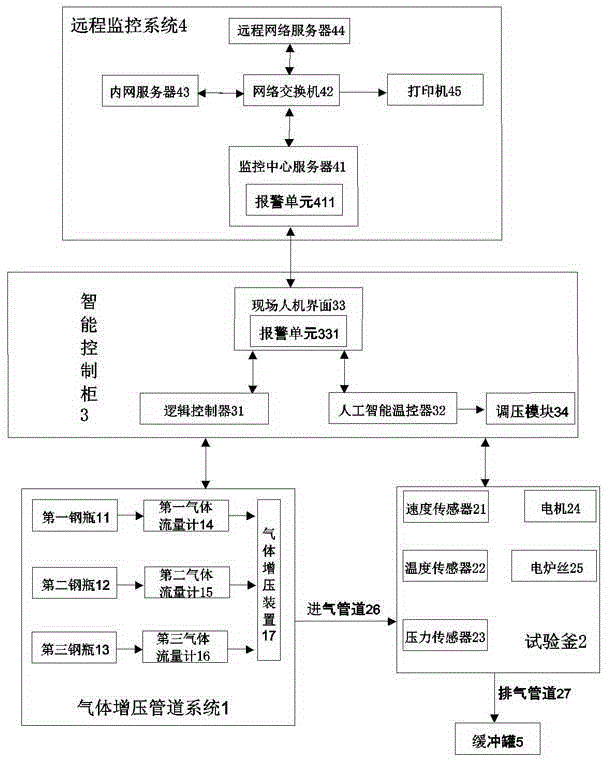

[0012] Such as figure 1 As shown, the device for the hydrogen sulfide high-pressure corrosion resistance test involved in the present invention includes a gas pressurized pipeline system 1, a test kettle 2 and an intelligent control cabinet 3; The intelligent control cabinet 3 is connected with the gas pressurization pipeline system 1 and the test kettle 2 respectively.

[0013] The gas pressurization pipeline system 1 includes a first steel cylinder 11, a second steel cylinder 12, a third steel cylinder 13, a first gas flowmeter 14, a second gas flowmeter 15, a third gas flowmeter 16 and a gas booster device 17 wherein nitrogen is housed in the first steel cylinder 11, carbon dioxide is housed in the second steel cylinder 12, hydrogen sulfide gas is housed in the third steel cylinder 13, and described first steel cylinder 11 is through fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com