Simple multi-layer vehicle storage carrying equipment based on comb-like transfer robot

A technology for handling robots and handling equipment, which is applied in the direction of building types, buildings where cars are parked, buildings, etc., can solve the problem that the height of the loaded vehicles cannot be greatly adjusted, and achieve an increase in the number of cars that can be parked, a low cost, and an increase in the number of cars that can be parked The effect of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope expressed in the embodiments.

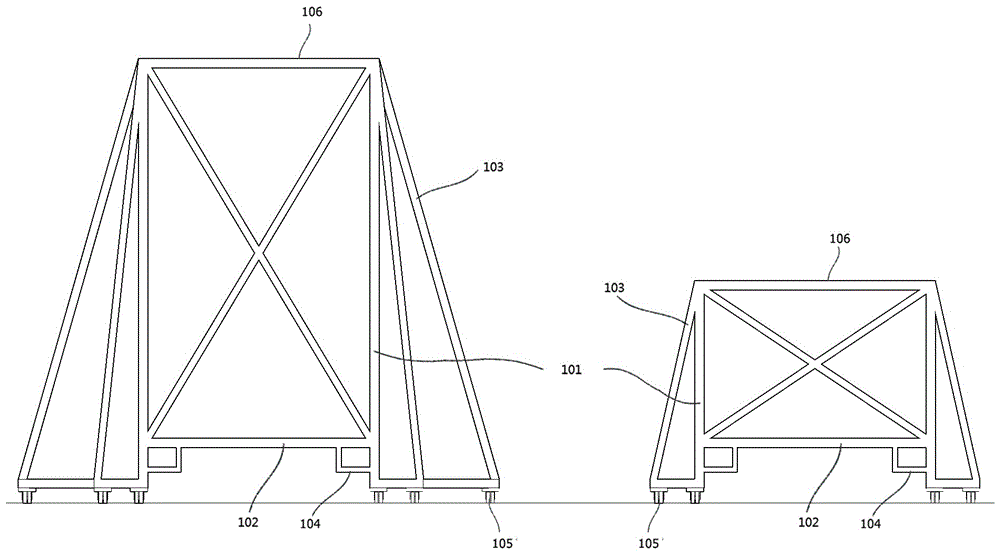

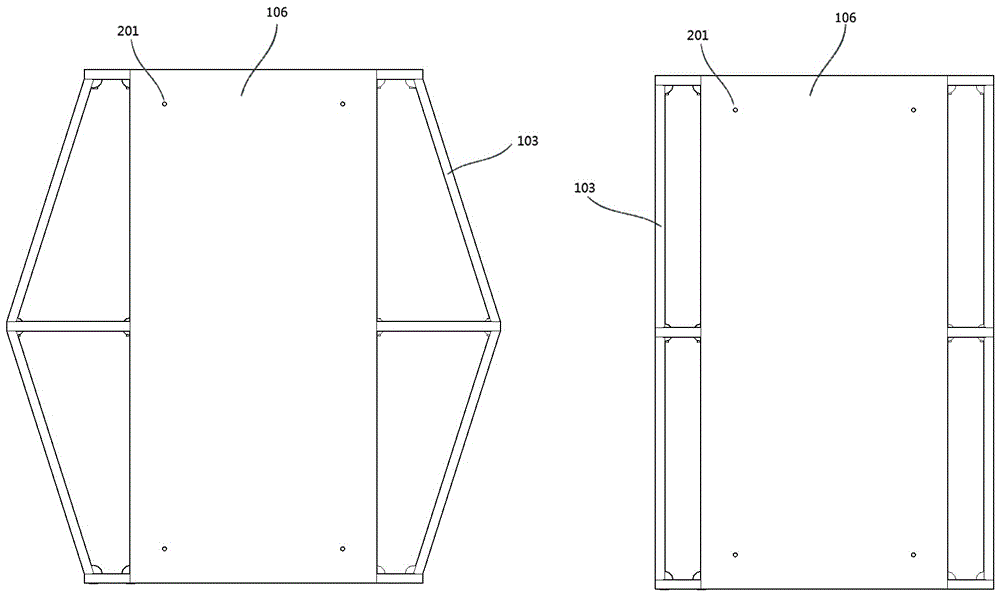

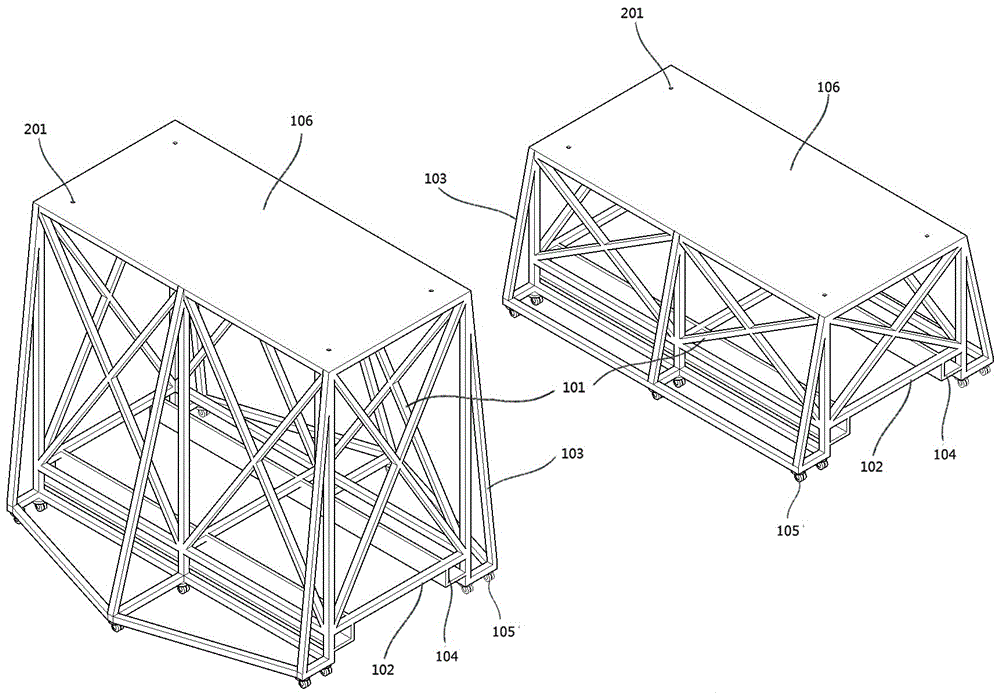

[0051] Such as figure 1 , 2 , 3, the handling elevated frame is composed of an increased frame 101, a robot accommodation frame 102 positioned below the increased frame 101, a side support frame 103 positioned at the side of the increased frame 101, two centering fixing plates 104 located in the robot accommodation frame 102, It is composed of passive walking wheels 105 installed under the robot accommodation frame 102 and the side support frame 103 , a vehicle-loading plate 106 at the top of the heightening frame 101 , and the like. Such as figure 2 As shown, there should be several retaining jacks 201 on the vehicle-loading plate 106, and correspondingly several controllable retractable retaining plugs should be installed on the comb-type handling robot.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com