Cooling system bracket for construction machinery

A technology for a cooling system and construction machinery, applied in the field of cooling system equipment, can solve the problems of poor cooling effect, unsatisfactory cooling effect of the rear heat exchanger, and insufficient adjustment of the air volume of the heat exchanger, and achieves light weight and is beneficial to The effect of heat exchange and avoiding cyclic mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Referring to the accompanying drawings, the present invention will be described in detail below.

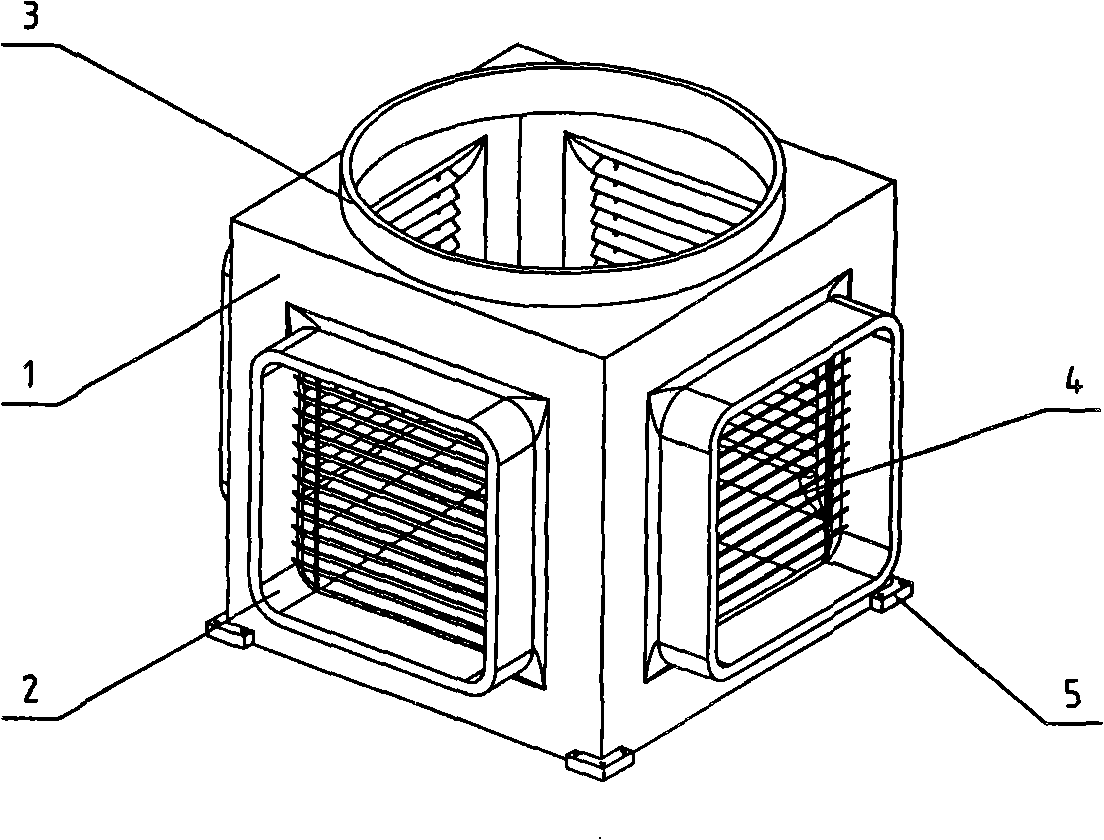

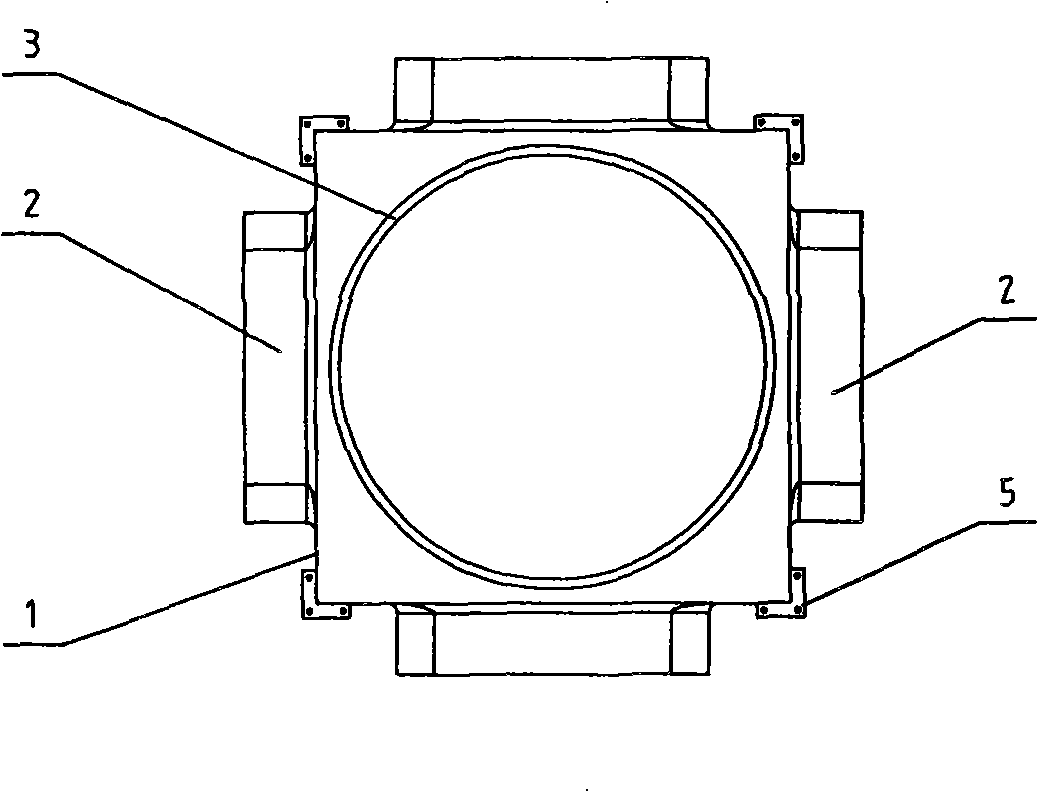

[0018] The engineering machinery cooling system bracket in the present invention includes a hexahedron-shaped main frame 1, four heat exchanger mounting brackets 2 are located on the side of the main frame 1, and fan mounting brackets 3 are located on the top surface of the main frame 1. The heat exchanger mounting opening provided on the heat exchanger mounting bracket 2 is also provided with a louver structure 4, and the fan mounting bracket 3 is provided with a fan cover.

[0019] The main frame 1 is fixed on the installation plane through the installation bottom plate 5, and can also be directly fixed on the installation plane. A seal is used to seal the connection gap between the components of the cooling system bracket.

[0020] It should be understood that: the above embodiments are only descriptions of the present invention, rather than limitations of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com