UAV (unmanned aerial vehicle) built-in exhaust pipe

An exhaust pipe and unmanned aerial vehicle technology, applied in the field of exhaust pipes, can solve the problems of inconvenient transportation and moving operators, unclean wiping, etc., and achieve the effect of preventing direct ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

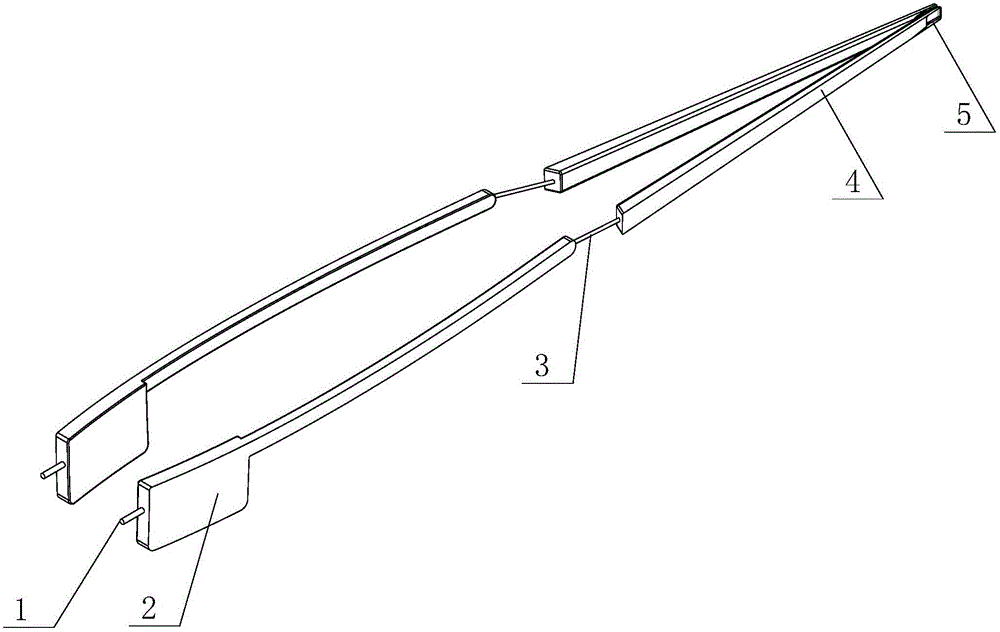

[0016] as attached figure 1 As shown, a built-in exhaust pipe for a UAV includes an air intake pipe 1 connected to the exhaust port of the UAV engine. The pipe rear pipe 4, the exhaust pipe front pipe 2 and the exhaust pipe rear pipe 4 are fixed on both sides inside the drone fuselage, and the end of the exhaust pipe rear pipe 4 stretches out of the drone fuselage tail.

[0017] The front portion of the exhaust pipe front pipe 2 in this embodiment is flat.

[0018] In order to cater to the internal shape of the fuselage, the front pipe 2 of the exhaust pipe is designed as an arc.

[0019] The end of the exhaust pipe rear pipe 3 is provided with an oil retaining fence 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com