Multi-layer fermentation device for livestock manure

A fermentation device and manure technology, which is applied in the field of multi-layer fermentation devices for livestock manure, can solve the problems of great difference in quality, unfavorable aerobic fermentation, and inability to effectively disperse, etc., and achieve the improvement effect, shorten the fermentation period, and share the effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

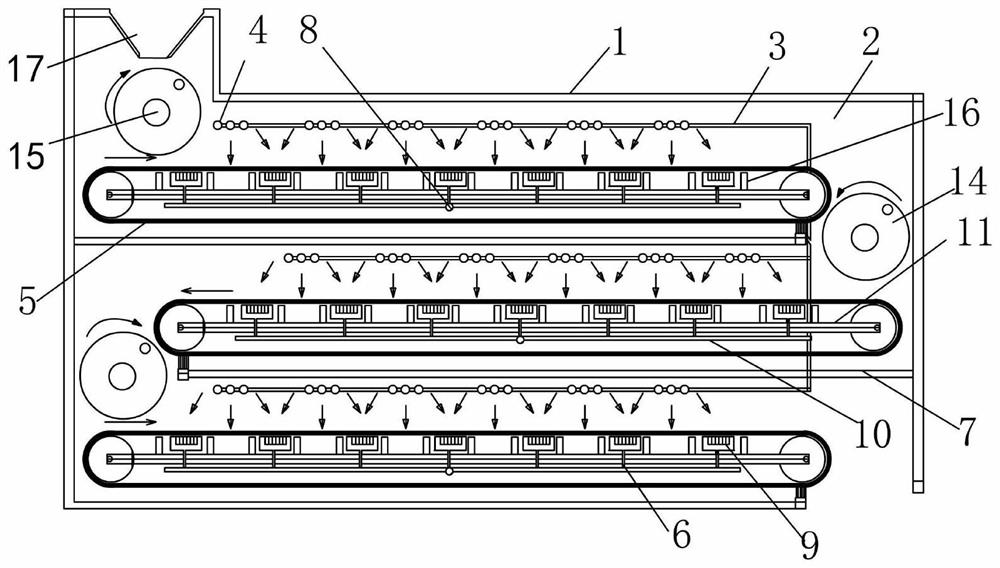

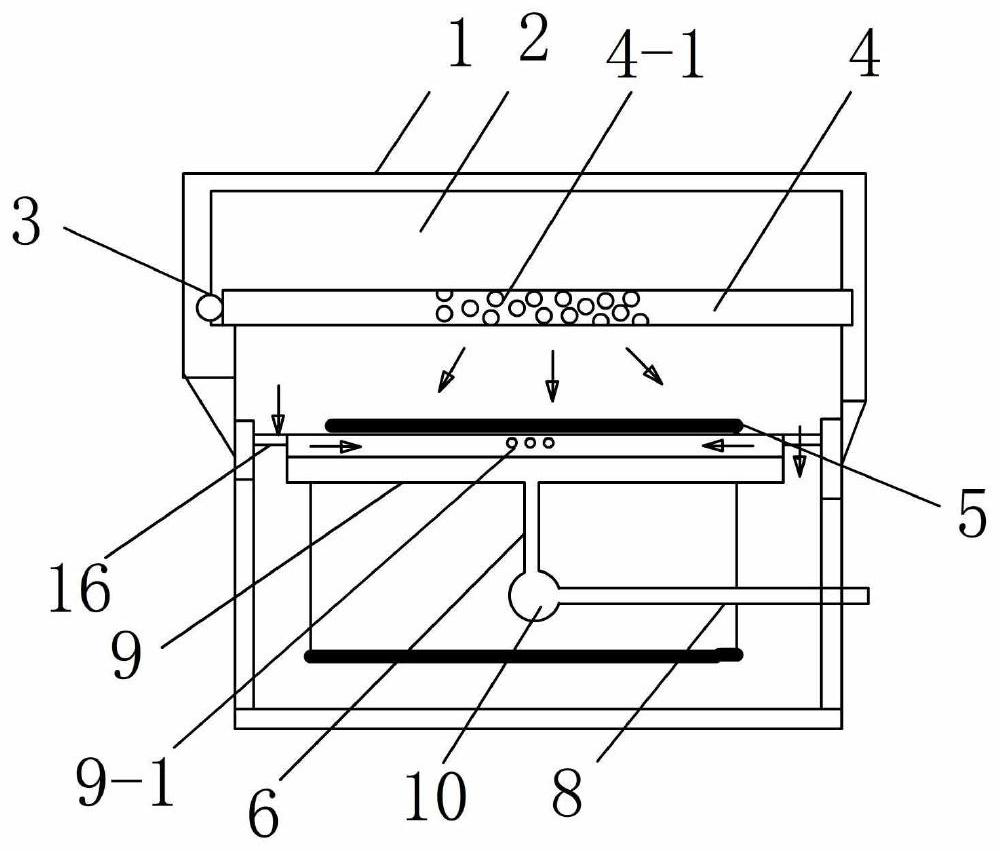

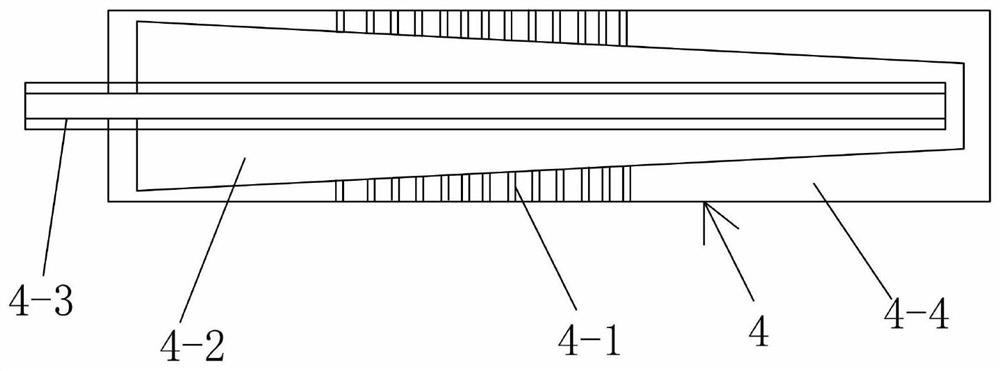

[0029] Such as Figure 1-9 As shown, a multi-layer fermentation device for poultry and livestock manure includes a thermal insulation cover 1; several layers of dehydration conveyor belts are distributed in the thermal insulation cover 1, and each layer of the dehydration conveyor belts includes a conveyor belt assembly, and the conveyor belt assembly includes air outflow Trachea 4 and conveyer belt 5, described thermal insulation outer cover 1 is fixed on the conveyer belt support 11 and conveyer belt is all covered, only leaves the material inlet and outlet gap size that is enough to get final product, also be provided with bottom plate cover 7 certainly There are some air outflow trachea 4 distributed in the heat preservation outer cover 1, and the two ends of the air outflow trachea 4 are fixed on the side wall of the heat preservation outer cover 1, and one end thereof communicates with the air intake main pipe 3; the air outflow trachea The middle part of the pipe wall o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com