A preparation method of cr5 type forged steel work roll for rolling extremely thin material

A work roll and forged steel technology, applied in the field of Cr5 forged steel work roll and its preparation, can solve the problems of reducing the toughness of the roll, achieve the effects of promoting movement, uniform distribution of nitrogen gas, and improving cryogenic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

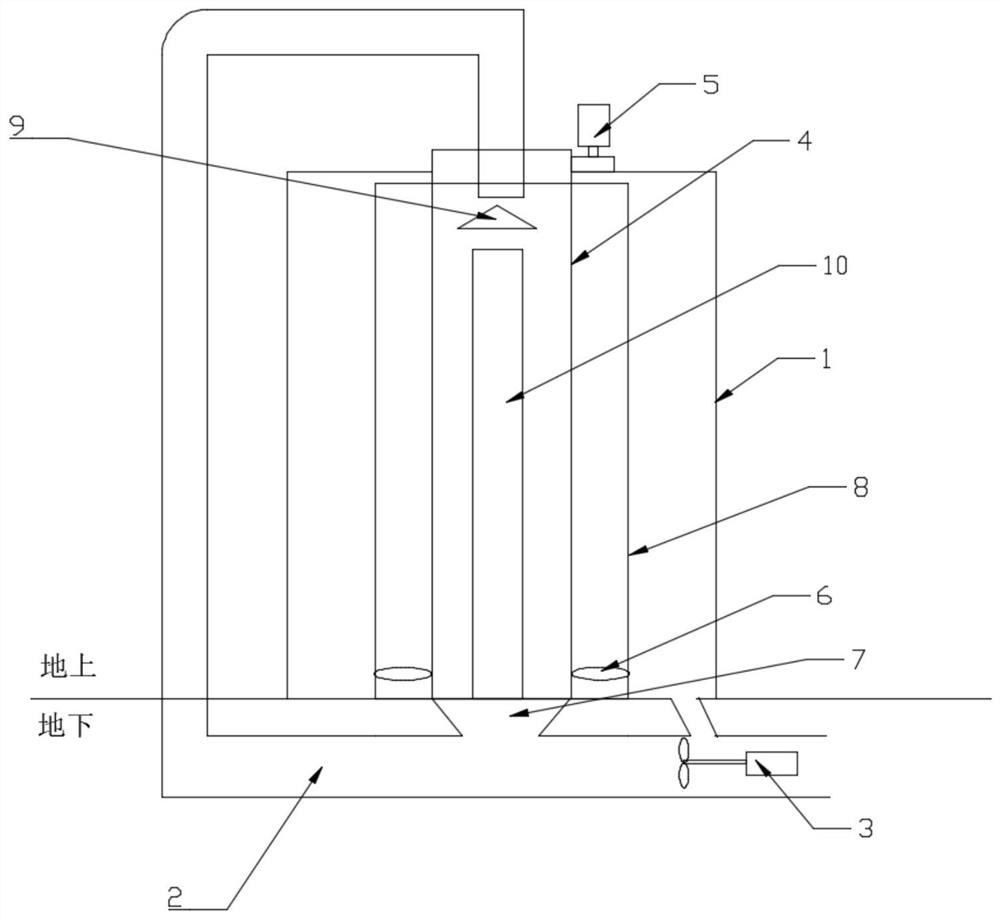

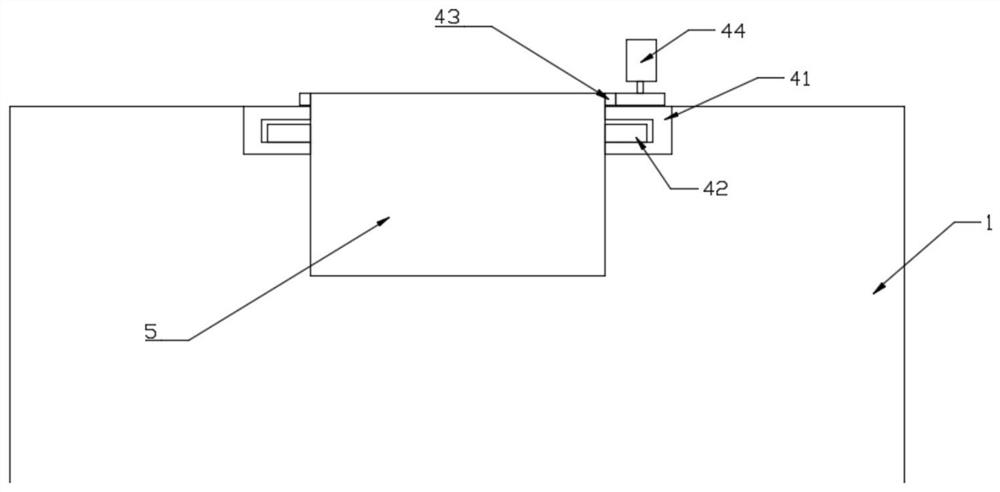

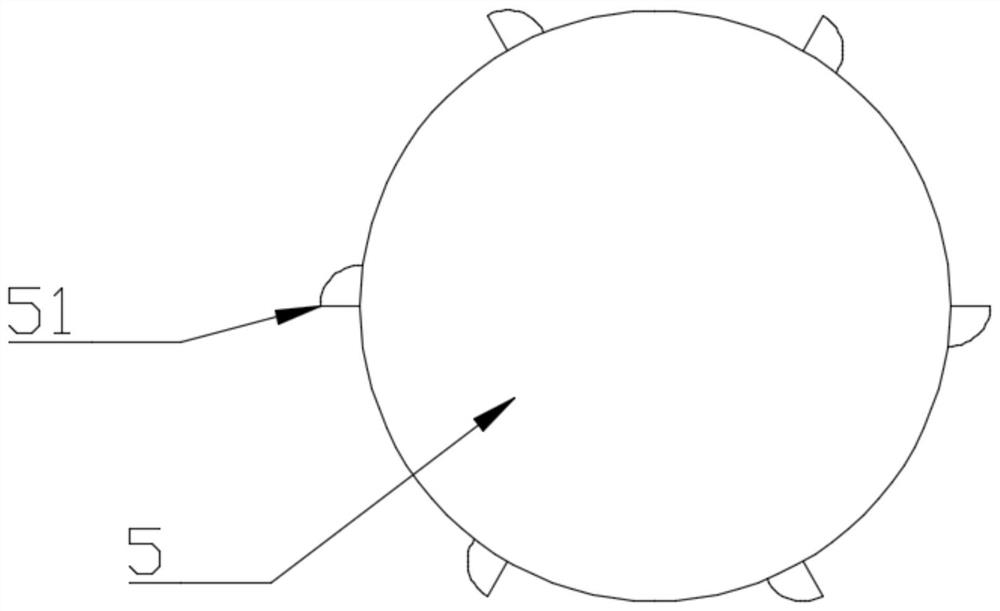

Method used

Image

Examples

Embodiment 1

[0040] According to the weight ratio, carbon: 0.6wt%, silicon: 1.2wt%, manganese: 0.2wt%, phosphorus: 0.03wt%, sulfur: 0.02wt%, chromium: 5.5wt%, molybdenum: 0.3wt%, vanadium: 0.05wt% %, the balance is iron and other impurities, the residual copper content is not more than 0.2%, and other impurities such as lead, tin, arsenic, bismuth, etc. are not more than 0.02%, ready for casting materials.

[0041] Melting the alloy solution: according to the above weight ratio, put each component into an intermediate frequency induction furnace for melting, the melting temperature is 1600°C, and the melting time is 30 minutes to make an alloy solution.

[0042] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0043] Casting cold billet: open the pour hole of the power frequency holding furnace, pour the alloy liquid into the metal mold, and remove the metal mold after it is completely cooled.

[0044] Washi...

Embodiment 2

[0055] According to weight ratio, carbon: 1wt%, silicon: 0.5wt%, manganese: 0.5wt%, phosphorus: 0.02wt%, sulfur: 0.015wt%, chromium: 6.5wt%, molybdenum: 0.7wt%, vanadium: 0.25wt% , the balance is iron and other impurities, the residual copper content is not more than 0.2%, and other impurities such as lead, tin, arsenic, bismuth, etc. are not more than 0.02%, ready for casting materials.

[0056] Melting the alloy solution: according to the above weight ratio, put each component into an intermediate frequency induction furnace for melting, the melting temperature is 1800°C, and the melting time is 40 minutes to make an alloy solution.

[0057] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0058] Casting cold billet: open the pour hole of the power frequency holding furnace, pour the alloy liquid into the metal mold, and remove the metal mold after it is completely cooled.

[0059] Washing and...

Embodiment 3

[0069] According to the weight ratio, carbon: 0.8wt%, silicon: 1.05wt%, manganese: 0.25wt%, phosphorus: 0.03wt%, sulfur: 0.02wt%, chromium: 5.7wt%, molybdenum: 0.4wt%, vanadium: 0.1wt% %, the balance is iron and other impurities, the residual copper content is not more than 0.2%, and other impurities such as lead, tin, arsenic, bismuth, etc. are not more than 0.02%, ready for casting materials.

[0070] Melting the alloy solution: according to the above weight ratio, put each component into an intermediate frequency induction furnace for melting, the melting temperature is 1800°C, and the melting time is 40 minutes to make an alloy solution.

[0071] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0072] Casting cold billet: open the pour hole of the power frequency holding furnace, pour the alloy liquid into the metal mold, and remove the metal mold after it is completely cooled.

[0073] Wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com