Embedded negative pressure solenoid valve for milk metering device and working method of embedded negative pressure solenoid valve

A metering device and embedded technology, applied in the direction of valve device, valve operation/release device, valve lift, etc., can solve the problems of inability to work for a long time, large working current, small flow capacity, etc., and achieve simple structure and fast response Fast, acting air-stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

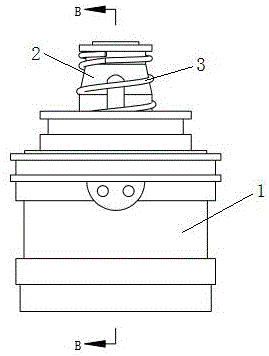

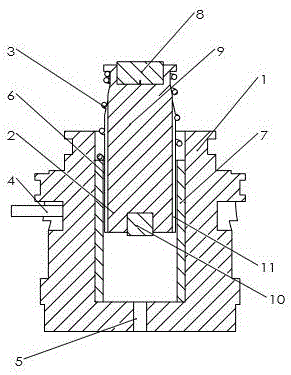

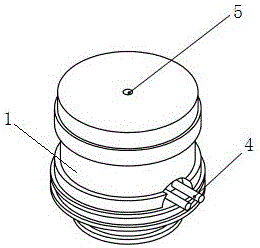

[0024] Such as figure 1 , figure 2 , image 3 As shown, an embedded negative pressure solenoid valve for a milk metering device includes a valve body 1, a valve core 2 and a spring 3 that match it, and a cylindrical track is opened inside the valve body 1, and a matching The spool 2 is provided with a mounting hole, and the spring 3 is installed on the spool 2 through the mounting hole and is concentric with the spool 2.

[0025] The valve body 1 includes a power lead wire 4, an invisible air inlet 5, and a coil 7. The power lead wire 4 is arranged on the side of the valve body 1, the invisible air inlet 5 is arranged at the bottom of the valve body 1, and the coil 7 is arranged between the valve body 1 and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com