Energy accumulation boiling water boiler

A boiling water boiler and boiling technology, which is applied in the field of electric boiling water boilers, can solve problems such as inability to continuously supply boiling water, hidden dangers, and inability to achieve complete sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

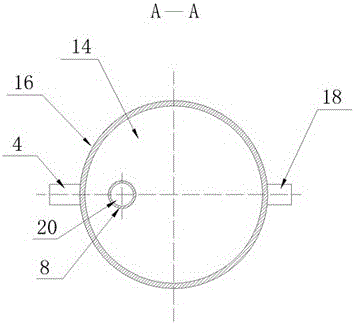

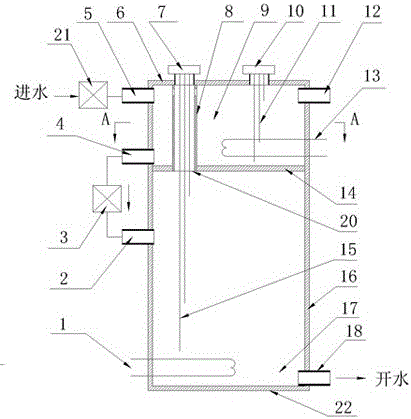

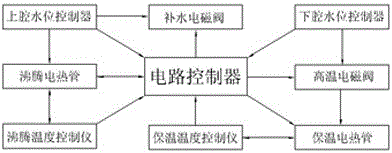

[0022] As shown in the attached figure, an energy storage boiling water boiler includes a circuit controller, a thermal insulation electric heating tube 1, a lower chamber water inlet pipe 2, a high temperature solenoid valve 3, an upper chamber water outlet pipe 4, an upper chamber water inlet pipe 5, and a body cover Plate 6, lower chamber electrode head 7, electrode sleeve 8, upper chamber 9, upper chamber electrode head 10, upper chamber water level electrode 11, overflow pipe 12, boiling electric heating tube 13, separator 14, lower chamber water level electrode 15, Main body 16, lower chamber 17, boiling water outlet pipe 18, replenishment solenoid valve 21, bottom plate 22.

[0023] The bottom plate 22 of the energy-storage boiling water boiler, the body 16 and the body cover 6 form a closed container, and a partition 14 is arranged on the top of the body 16, and the partition 14 divides the body 16 into two parts, the lower chamber 17 and the upper chamber 9. The space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com